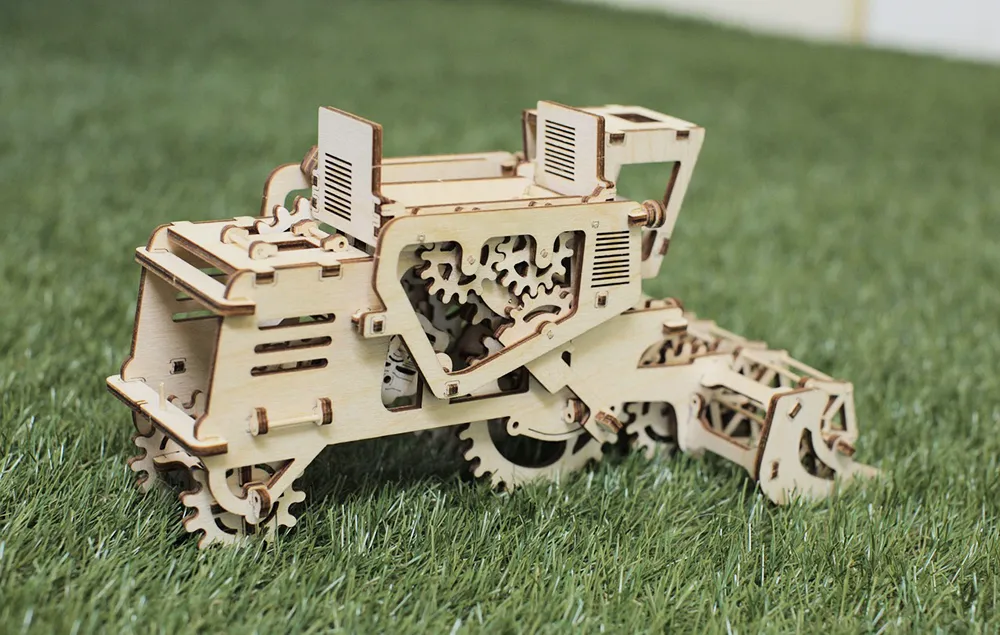

Creating wooden puzzles has become a popular craft and business activity. Using a CO2 laser cutting machine makes this process highly precise, efficient, and customizable. Whether you are a DIY enthusiast, a small business owner, or a woodworking professional, understanding how to use a CO2 laser engraving and cutting machine for wooden puzzles is essential for producing high-quality products.

This guide covers the project workflow, machine advantages, and step-by-step instructions for producing wooden puzzles, highlighting the benefits of laser-cutting technology in the woodworking industry.

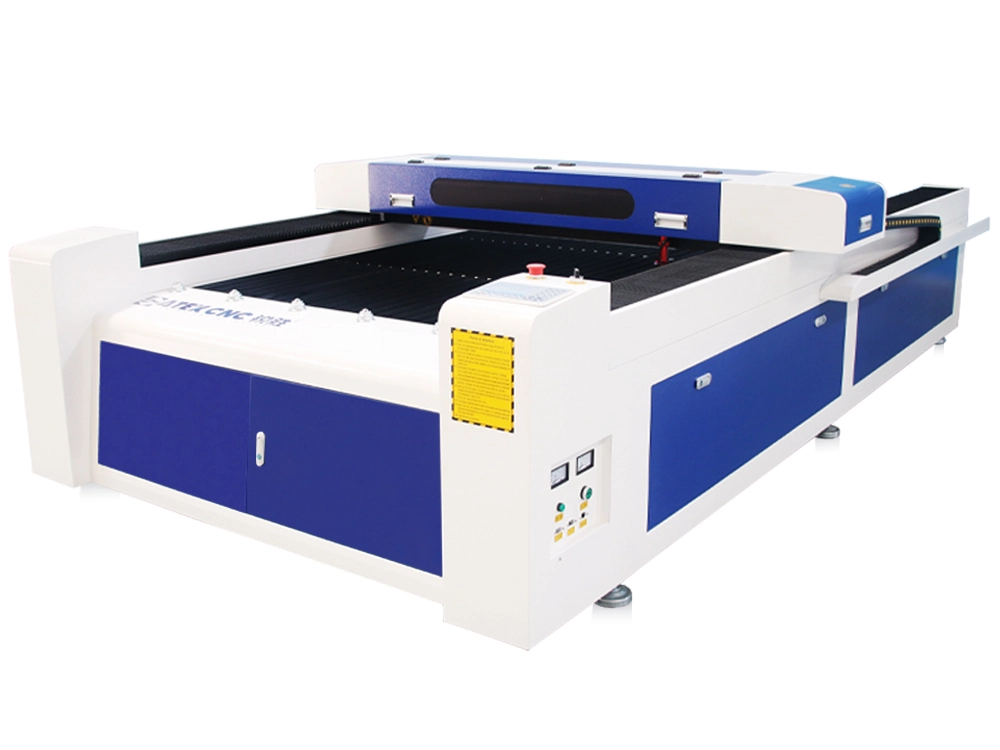

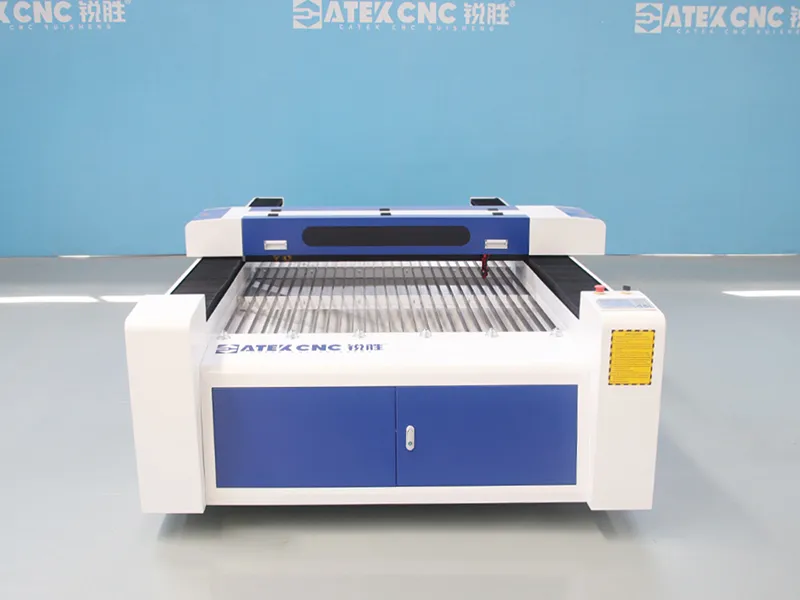

I. What is a CO2 Laser Cutting Machine?

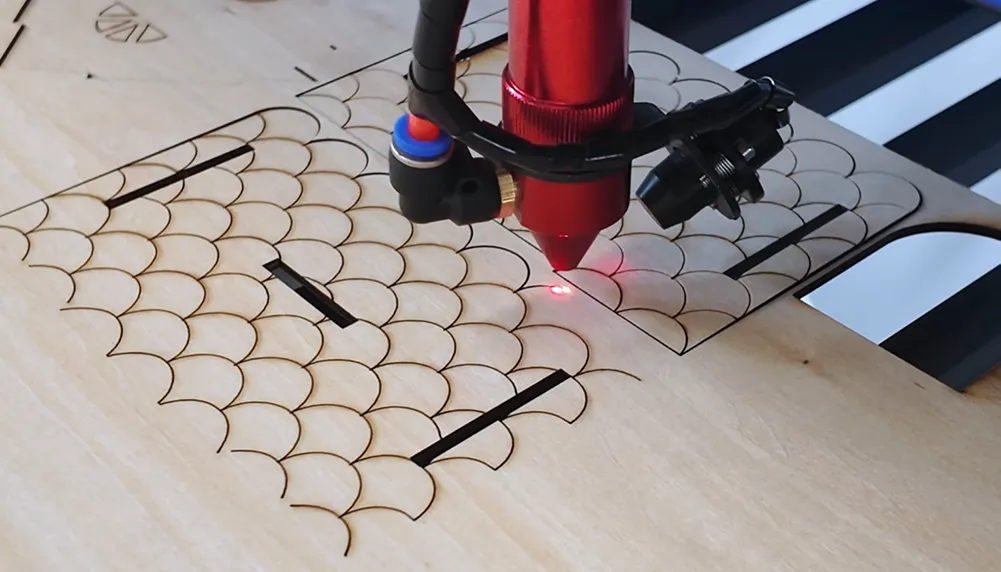

A CO2 laser cutting machine is a device that uses a high-energy laser beam to cut and engrave non-metallic materials. It is suitable for materials such as wood, acrylic, leather, and paper. Its working principle is to heat, melt, or vaporize the material surface using the laser beam, thereby achieving precise cutting and engraving.

Key features of CO2 laser cutting machines:

- High Precision: Capable of cutting intricate shapes and designs

- Smooth Edges: Minimal post-processing required

- Custom Engraving: Add text, logos, or decorative patterns

- Fast Production: High-speed cutting for batch production

- Versatile Material Handling: Works with plywood, MDF, hardwood, and craft materials

- User-Friendly Operation: Easy to learn and operate, suitable for small businesses and DIY projects

II. Why Choose a CO2 Laser Cutting Machine for Wooden Puzzles?

Using a CO2 laser cutting machine to cut wooden puzzle pieces has several advantages:

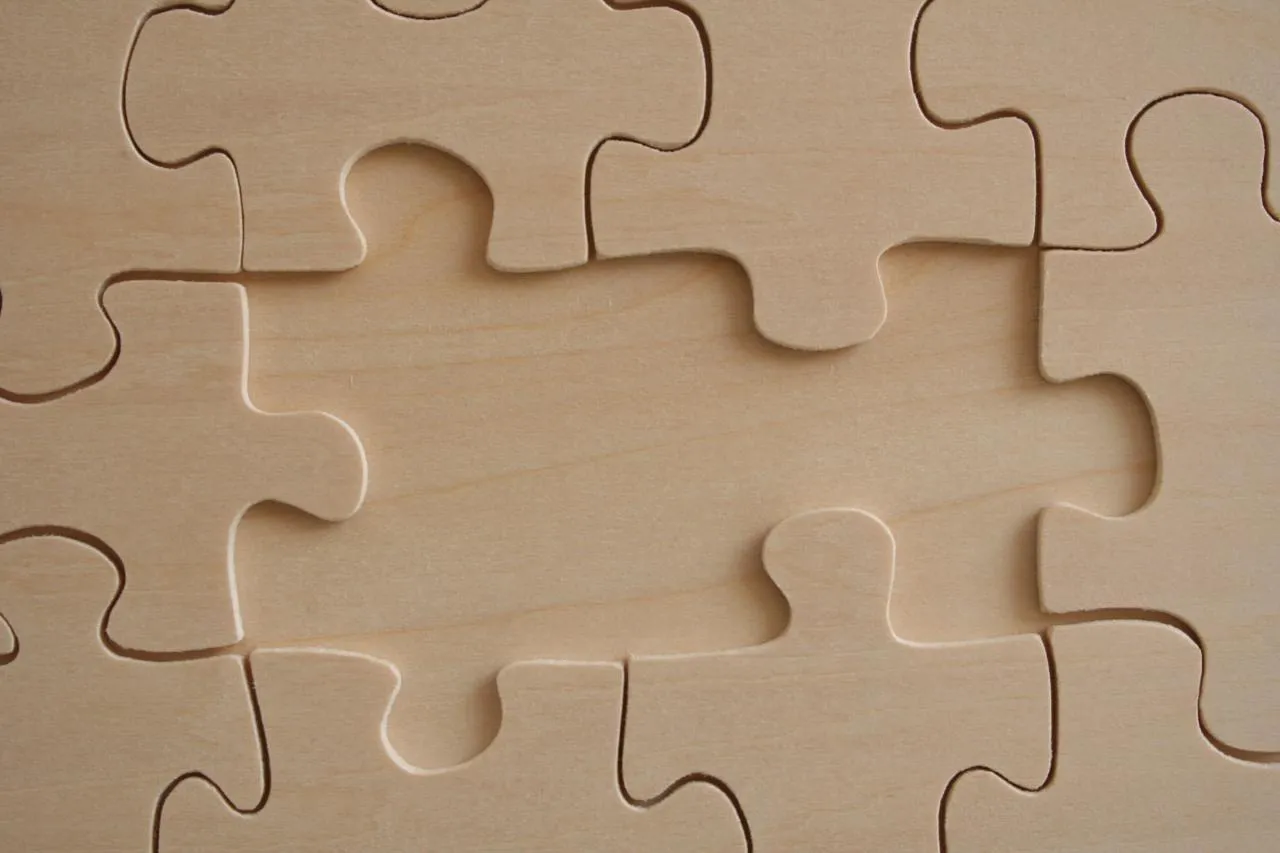

1. Precision and Consistency

CO2 laser cutting machine delivers high-precision cutting, ensuring each puzzle piece fits perfectly. A custom 100-piece puzzle with intricate designs can be cut repeatedly, with every piece aligning exactly to the design without manual adjustments. Even the most complex and detailed designs can be accurately replicated, eliminating human error. This high precision guarantees consistent quality across multiple production batches, which is crucial for large-scale commercial orders.

2. Enhanced Efficiency

CO2 laser cutting machine reduces manual labor as machines automatically follow pre-programmed cutting paths. This technology accelerates production speeds, making it suitable for both prototyping and high-volume orders. Hobbyists can craft intricate puzzles within hours.

3. Reduce Material Waste

Laser cutters precisely follow vector paths defined in design files, minimizing scrap compared to traditional manual or mechanical cutting methods. Optimizing nesting layouts within the software further maximizes material utilization, and efficient material usage lowers overall production costs.

4. Customizable Designs

CO2 laser cutting machine enable personalized engraving, allowing designers to add text, logos, intricate patterns, and even photographs to puzzle surfaces. Utilizing CO2 laser engraving machine for wood carving empowers small businesses to offer unique, high-value products that stand out in the marketplace.

5. Versatile Applications

CO2 laser cutting machine can process a wide range of wood materials, including plywood, medium-density fiberboard, hardwoods, and even specialty craft boards. They can handle varying wood thicknesses, enabling manufacturers to produce everything from lightweight DIY puzzle kits to high-end wooden puzzles. Adjusting laser power and cutting speed according to material type and thickness ensures clean, precise cuts while preventing scorched or charred edges.

III. Application of Laser Cutting Machines in Wooden Puzzles

Due to its high precision, flexibility, and production efficiency, the CO2 laser cutting machine has found extensive application in the wooden puzzle industry. It enables manufacturers, processing plants, and creative studios to produce diverse puzzle products catering to varying market demands and customer preferences.

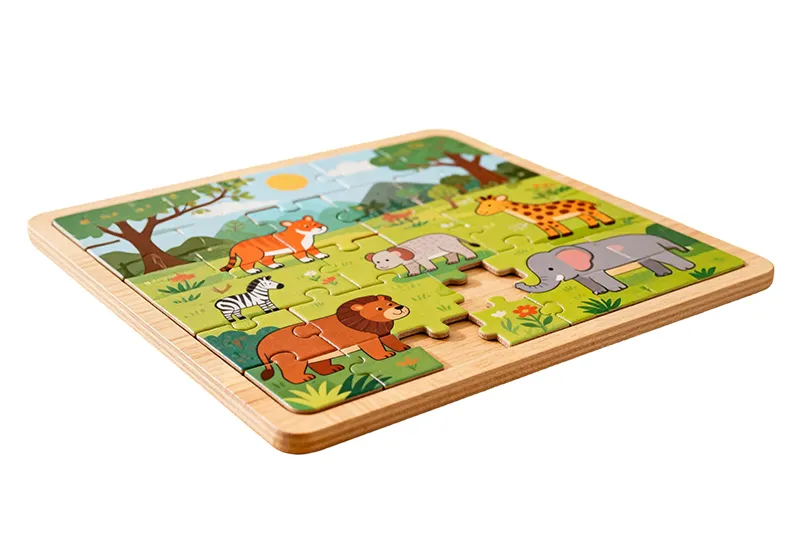

1. Customized Gift Puzzles

Using CO2 laser engraving machines to etch directly onto wood surfaces allows names, dates, messages, and logos to be permanently inscribed on puzzle pieces. This high level of customization significantly enhances both the emotional and commercial value of the product, making laser-cut wooden puzzles highly popular in the market.

2. Educational Wooden Puzzles

The high-precision cutting of CO2 laser machines ensures puzzle pieces are safe with smooth edges, facilitating easy assembly for children. Additionally, engraved symbols and text remain clear and durable even after repeated use, making them ideal for classroom settings.

3. Decorative and Artistic Puzzle Designs

Since lasers can precisely follow digital design files, designers can transform intricate concepts into physical products without compromising on detail or quality. This makes CO2 laser cutting machines powerful tools for the artistic and decorative woodworking industries.

4. DIY Wooden Puzzle Kits

CO2 laser cutters are also widely used to produce DIY wooden puzzle kits supplied to retail stores and online platforms. These kits are popular among hobbyists and families who enjoy hands-on creation.

Key advantages of DIY puzzle production include:

- Uniform part dimensions for easy assembly

- Clean, precise cuts reducing sanding requirements

- Efficient batch production for large orders

With CO2 laser engraving and cutting machines, manufacturers can maintain consistent quality across multiple batches, ensuring customer satisfaction and reducing return rates.

5. Suitable for Commercial Production

One of the most significant advantages of using CO2 laser cutting machine for wood engraving is their ability to produce highly repeatable engraving results. Once design files and cutting parameters are set, the machine can replicate hundreds or thousands of identical puzzle patterns with minimal deviation.

This proves invaluable for businesses engaged in:

- Repeat orders

- Wholesale or private-label production

- Branded products requiring consistent quality

By ensuring stable engraving depth and cutting precision, CO2 laser cutting machine helps companies establish a reputation for reliability and expertise in the wooden puzzle market.

IV. Step-by-Step Guide to Creating Wooden Puzzles

1. Design

- Select a puzzle theme—maps, cartoons, portraits, or other patterns.

- Create digital artwork—using vector software such as CorelDRAW, Adobe Illustrator, or AutoCAD.

- Design puzzle pieces—define interlocking shapes and the total number of pieces.

- Add engraving elements—text, logos, or patterns.

- Export files—save in laser-cutting compatible formats, primarily DXF or AI.

Tip: Allow slight tolerances between puzzle pieces in the design to ensure smooth final assembly.

2. Material Selection and Preparation

- Common materials: 3-5mm plywood, MDF, or hardwood. Different woods create distinct puzzle styles.

- Inspect material quality: Ensure surfaces are flat and smooth, free of knots or defects.

- Cut dimensions to match machine bed size: Verify sheet size fits the CO2 laser cutter's working area.

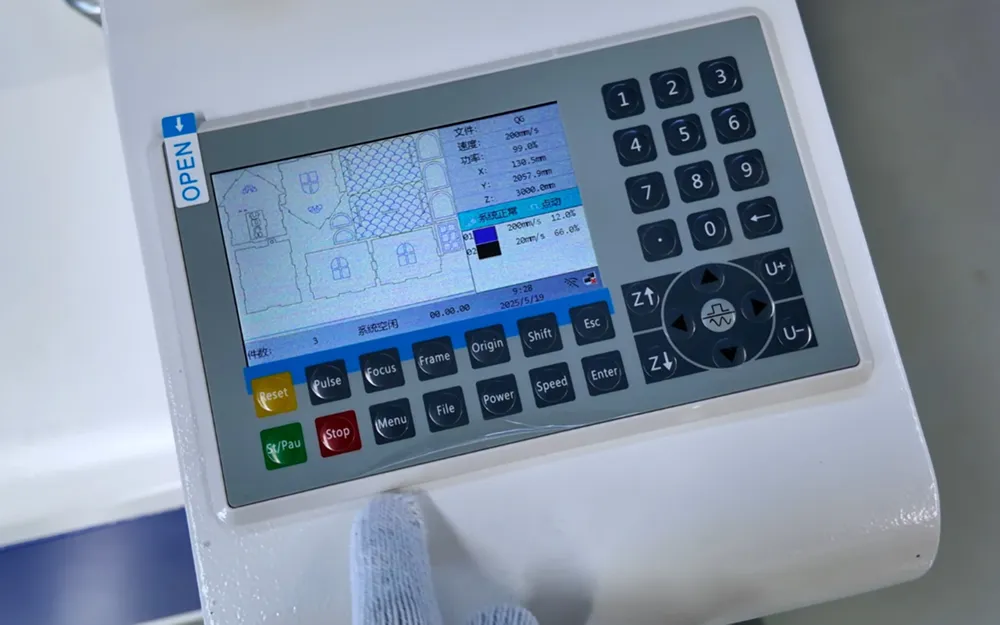

3. Laser Engraving

- Place wood on the machine bed

- Import design files into laser cutting software

- Set laser parameters—power, speed, and frequency—based on material properties

- Begin engraving puzzle surfaces

Note: Maintain engraving depth at 0.5–1 mm to avoid cutting through while preserving clarity.

4. Laser Cutting

- Switch to cutting mode in software

- Cut each puzzle piece along the vector path

- Monitor the cutting process to ensure smooth edges and precise cuts

- Repeat the above steps for batch production

5. Post-Processing and Quality Inspection

- Assemble a sample puzzle first to ensure pieces fit together.

- Lightly sand if necessary to remove minor burrs

- Stain, paint, or varnish as required

V. Conclusion

CO2 laser cutting machines offer an efficient and precise solution for wooden puzzle production, delivering clean cuts, consistent quality, and flexible customization. From small workshops to commercial manufacturing, CO2 laser technology enhances production efficiency while minimizing material waste.

As an experienced CO2 laser cutting machine manufacturer, we design and supply reliable equipment tailored specifically for woodworking applications. With stable performance, high precision, and professional technical support, our solutions empower customers to produce high-quality wooden puzzles, supporting manufacturers in achieving steady growth.