The purpose of this metal nameplate marking project is to meet the demand for clear, durable, and permanent markings on industrial metal nameplates. The client requires an identification solution that maintains consistent quality during mass production while delivering high-contrast text and graphics.

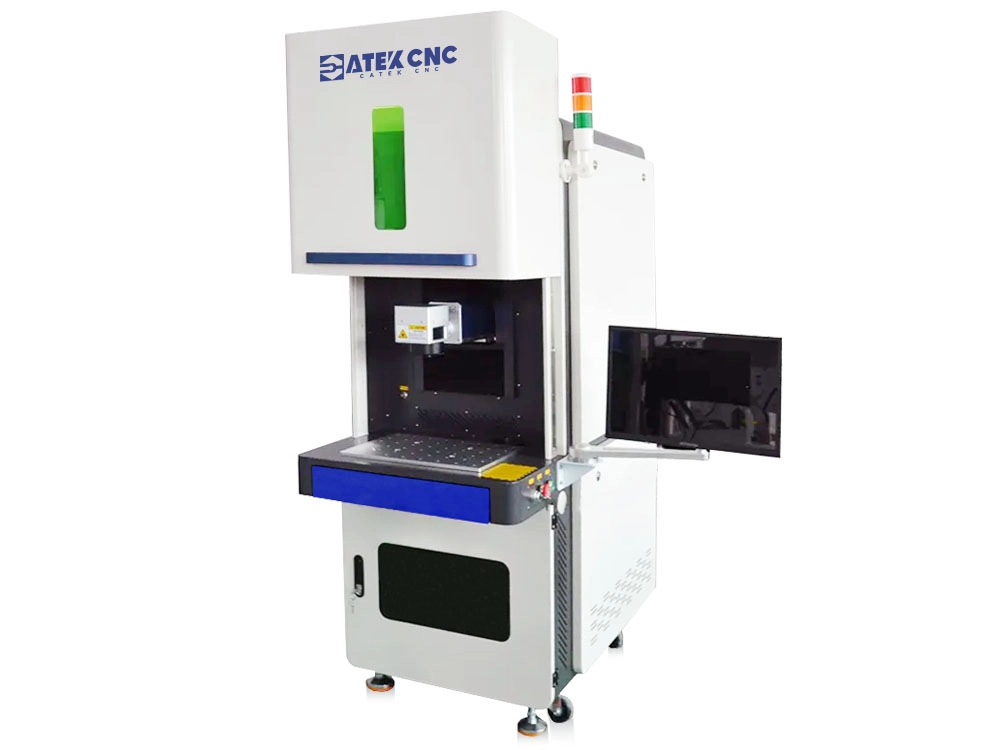

After evaluating multiple marking methods, the enclosed laser marking machine was selected as the optimal solution. Its high positioning accuracy, excellent stability, and superior safety features make it particularly well-suited for industrial environments with stringent requirements for product quality and operator safety.

I. Material and Nameplate Characteristics

This project involves marking on metal nameplates commonly used in industrial applications, including aluminum plates and stainless steel with varying surface treatments. Each material requires precise laser parameter control to ensure clear marking without damaging the surface.

Stainless steel nameplates are widely used due to their corrosion resistance and long service life, making them particularly suitable for harsh environments. Aluminum nameplates, meanwhile, offer lightweight and cost-effective solutions. Despite these material differences, both achieved outstanding processing results using the same metal fiber laser marking machine, fully demonstrating the system's flexibility.

II. Marking Requirements and Project Challenges

The customer requires metal nameplates to display detailed information such as logos, serial numbers, model numbers, and QR codes. These markings must remain clearly legible after prolonged use, chemical exposure, and frequent cleaning.

A key challenge in this metal nameplate marking project is maintaining consistent quality for small characters and fine lines during mass production. Traditional marking methods often result in uneven marking depth or fading over time. In contrast, fiber laser technology enables precise control over marking depth and contrast, ensuring uniform marking results across all nameplates.

III. Enclosed Fiber Laser Marking Machine Solution

To meet quality and safety requirements, we employ fully enclosed cabinet-style fiber laser marking machines. This enclosed structure not only effectively shields operators from laser exposure but also helps control smoke and dust generated during the marking process.

At the core of the enclosed laser marking machine lies a high-performance fiber laser, featuring an integrated structural design that ensures compact dimensions, high stability, and minimal energy loss. Electrical power supplied by the laser power system is converted into high-energy infrared laser light at a wavelength of 1064 nm. The laser output possesses sufficient power density to achieve precise and permanent marking on stainless steel and aluminum nameplates.

The laser beam is controlled by a high-speed galvanometer scanning system, featuring precision motor-driven mirrors on both the X and Y axes. These mirrors rapidly adjust the laser reflection path according to CNC instructions, enabling swift and precise laser movement across metal surfaces. This ensures sharp text edges, fine details, and consistent marking quality—even for complex graphics or small characters.

To achieve precise focusing and uniform marking results, the system incorporates an f-θ field lens. This lens focuses the parallel laser beam onto a precise focal point on the workpiece surface. By selecting different focal lengths to match varying marking area sizes, this enclosed fiber laser marking machine easily adapts to metal nameplates of different dimensions while maintaining clarity and uniformity.

The entire marking process is coordinated by an intelligent control system. Combining a hardware control card with dedicated software, the fiber laser marking machine system enables operators to edit text, logos, serial numbers, and QR codes, adjust laser parameters, and precisely control the galvo scanner movement. This level of control ensures stable and repeatable results during mass production.

Multiple auxiliary systems further enhance reliability and usability, including:

- A red light positioning system providing a visible preview of the marking area for precise alignment.

- A stable aluminum alloy workbench offering excellent heat dissipation and deformation resistance.

- An air-cooled system that efficiently dissipates heat without requiring water cooling, thereby reducing maintenance complexity and operating costs.

This enclosed fiber laser marking system, benefiting from its highly integrated design, is well-suited for industrial metal nameplate marking projects demanding high performance and safety standards.

IV. Metal Nameplate Marking Process

The metal nameplate marking process utilizing an enclosed fiber laser marking machine is designed for simplicity and efficiency, making it suitable for continuous industrial production. Prior to marking, the metal nameplate is positioned on the workbench or fixture, with visual alignment and software ensuring precise placement. Subsequently, the marking content is imported into the control system, where laser parameters—such as power, speed, and frequency—are precisely adjusted according to the specific metal material. Once configured, the marking process commences immediately, with the system automatically and accurately executing the preset marking path.

This non-contact laser marking process completely eliminates mechanical stress on the metal sheet. Unlike traditional engraving or stamping methods, it involves no physical contact, thereby avoiding risks of tool wear and deformation. This helps maintain the integrity of the material surface, ensuring consistent marking quality with no degradation in precision or clarity, even during prolonged production runs.

V. Marking Results and Finished Product Quality

The finished nameplates clearly demonstrate the advantages of permanent laser marking. Text and graphics appear sharp and crisp, creating a striking contrast against the metal surface. Even when scaled down to small dimensions, QR codes and barcodes remain perfectly legible.

Laser-marked content exhibits outstanding abrasion resistance, corrosion resistance, and environmental adaptability. This durability is particularly well-suited for industrial metal nameplates, ensuring long-term clarity and readability.

VI. Advantages of the Enclosed Design

Fiber laser technology inherently offers high precision, while the enclosed cabinet structure further enhances safety and creates a cleaner working environment—a critical factor in modern production.

First, improved safety. The enclosed structure effectively isolates laser radiation, preventing direct or reflected laser exposure that could potentially harm operators, ensuring safe and reliable equipment operation during daily production.

Second, improved workshop cleanliness. During metal marking, lasers generate smoke and fine particulate matter. The enclosed cabinet of fiber laser marking machines confines these emissions internally, where they are processed by integrated extraction systems. This minimizes pollutant dispersion into workshop air, enhancing overall working conditions and reducing cleaning costs.

Additionally, production stability is enhanced. The enclosed structure of fiber laser marking machines effectively minimizes interference from external light, airflow, and dust on the laser path, ensuring a more stable marking process. For high-volume production, this guarantees consistent marking results within the same batch.

Key advantages include:

- Enhanced laser safety protection for operators, reducing workplace injury risks.

- Effective control of smoke/fume and odor dispersion, maintaining workshop cleanliness.

- Minimized external environmental interference, improving marking consistency and stability.

- Greater compliance with industrial safety and production standards, facilitating corporate regulatory management.

These comprehensive benefits make enclosed fiber laser marking machines the optimal choice for manufacturers seeking high-quality, reliable solutions that meet safety standards.

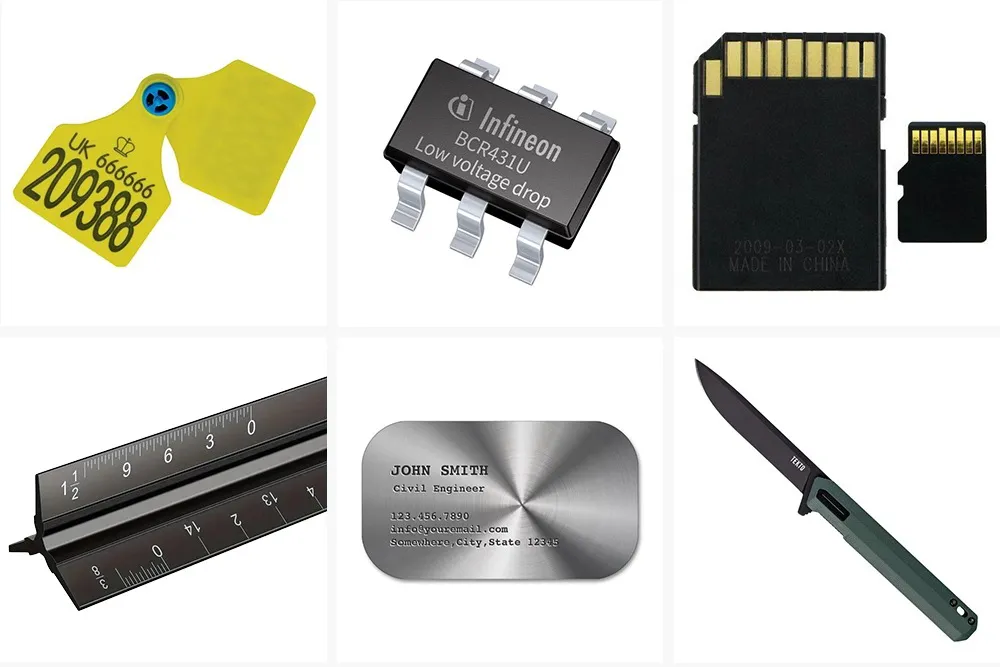

VII. Application Scenarios

The laser marking solution for metal nameplates adopted in this project offers versatile applications, suitable for various industrial uses requiring permanent, high-contrast identification. This fiber laser marking machine processes most metal materials—such as stainless steel, aluminum, copper, titanium, and alloy steel—as well as certain opaque non-metallic materials, making it the optimal choice for applications demanding both precision and surface quality.

In industrial machinery, laser-marked nameplates display model numbers, technical specifications, safety instructions, and brand identifiers. For electrical cabinets and control panels, it ensures permanent marking of wiring diagrams, warning symbols, and serial numbers. Automated equipment and production lines achieve efficient traceability and maintenance tracking through laser-marked QR codes and barcodes. This solution is also widely adopted in asset management, providing permanent, tamper-proof identification for tools, machinery, and infrastructure.

The fiber laser marking system offers flexibility, allowing manufacturers to adapt to different materials, sizes, and marking content without complex adjustments.

VIII. Conclusion

This metal nameplate marking project utilizing an enclosed fiber laser marking machine fully demonstrates the capabilities of fiber laser technology in achieving precise, durable, and safe metal marking. Combining high-quality laser performance with an enclosed safety design, this machine delivers stable and reliable marking results that meet the demands of harsh industrial environments.