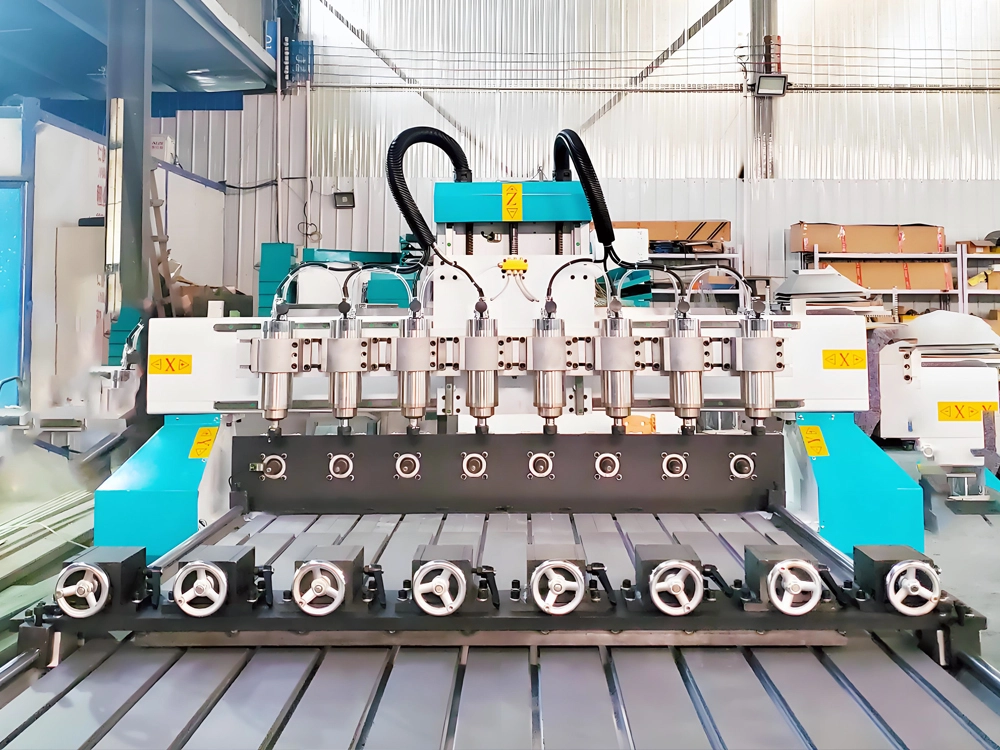

CNC 3D Wood Sculpting Machine with 10 Carving Spindles and Rotary Axis

Multi-Head CNC Wood Router for Batch 3D Carving

[Function Description]

What Is a Multi-Station Four-Axis 3D CNC Woodworking Router?

The 4-axis rotary CNC woodworking router is a CNC machine that uses a CNC system to control the machine for 3D carving and processing, mainly used for engraving the surface-of-revolution of parts. Its processing method is very similar to the four-axis CNC lathe, there is a spindle that can clamp the workpiece indexing rotation, perpendicular to the surface-of-revolution of the workpiece multifunctional spindle for carving, milling and other processing of the workpiece. Specific operation, the use of programming software to convert the 3D model into the machine can recognize and run the G code program, by the CNC system to control the X, Y, Z, A-axis linear movement or rotation, to achieve automated engraving and processing, with high precision, high efficiency and flexibility.

CNC Multi-station rotary carving router can be configured with multiple spindles, such as two, three, four, eight, ten or even more. This design allows the CNC carving machine to process multiple identical parts at the same time, which can significantly increase processing speed and productivity when batch processing the same part, while ensuring consistent and high quality parts. Moreover, the machine is flexible, all processing stations are independent of each other, all spindles can work at the same time, but also can designate a few of them to work, according to the number of products to be processed to designate the processing station to be run, such a design makes the use of the four-axis CNC router is more flexible, to avoid the waste of energy.

The processing size of multi-station CNC rotary carving router is generally 100mm, 150mm, 200mm, 300mm in diameter and 1000mm, 1500mm, 2000mm, 2500mm in length, which can be selected or customized by users according to the processing requirements. In addition, other customizations can be made according to the material of the processed products, such as processing stone or soft metal, high-power spindles and circulating cooling water tanks can be used.

The CNC rotary carving router can be equipped with the flat engraving function of the traditional 3-axis router with only a slight modification, which only requires the addition of a flat working platform. In this way, a machine can carry out both flat three-axis engraving and 3D four-axis engraving, which only requires the cost of investing in one machine and occupying the space of one machine, further enhancing the operation convenience and processing efficiency, and optimizing the operation cost of the factory.

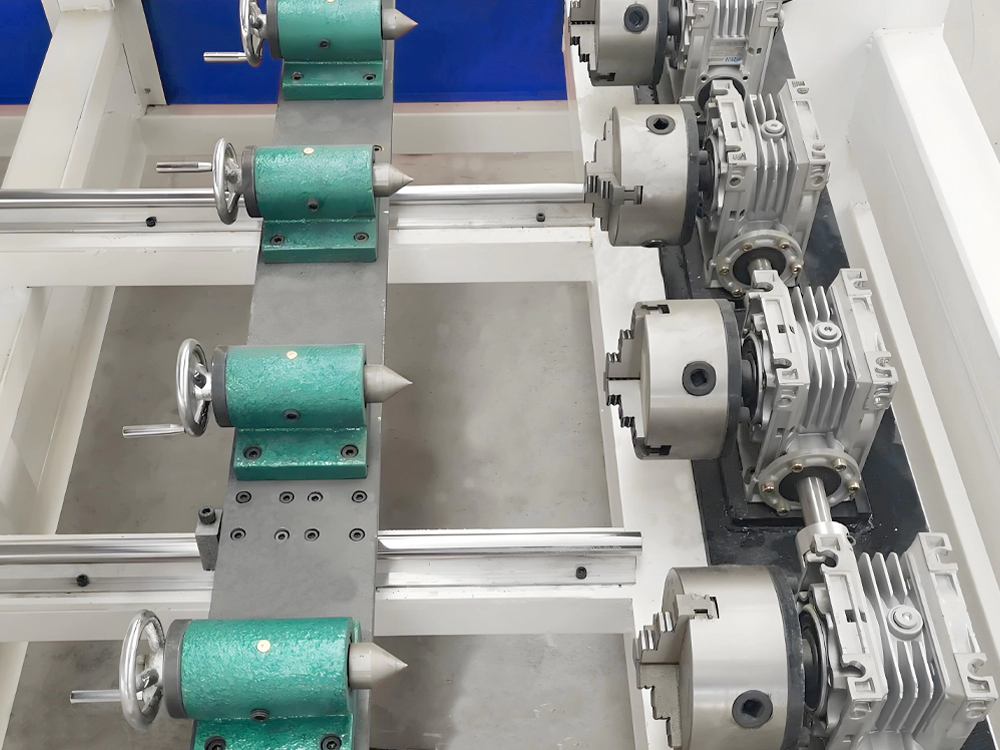

What Is the Rotary Axis of a CNC Router?

There are many types of rotary axes for CNC routers. Specifically, on this multi-head 3D four-axis rotary carving router, we refer to it as the fourth axis or A-axis. It is a lathe center capable of indexing rotation, primarily designed to clamp parts and rotate them around the central axis of the rotary axis. This exposes different sections of the workpiece's revolving surface according to processing needs, enabling continuous cutting, engraving, and milling of cylindrical or irregularly shaped parts. The rotary axis is installed on the worktable of the CNC engraving machine and driven by a servo motor combined with a reducer, allowing the workpiece to be indexed or paused at various angles. This processing method not only improves efficiency but also eliminates the hassle of manually flipping and re-clamping the workpiece, simplifying the production process. Since the XYZA four axes operate synchronously in this machine, this processing is also known as four-axis four-linkage machining. It can accomplish many tasks that ordinary three-axis CNC routers cannot, such as 3D carving of furniture components, decorative accessories, and sculptural artworks.

Similar to four-axis linkage lathes, this machine's rotary axis also comes in two types: one is the chuck-type rotary axis, which can be used for single-end clamping or paired with a tailstock for two-end clamping of the workpiece. The second is the center rotary axis, which can only be used for two-end clamping.

Advantages of Multi-Head CNC Router with Rotary Axis

- Equipped with 10 identical processing stations, each station is equipped with an independent spindle and rotary axis. These stations can work individually or simultaneously, which can greatly shorten the time required for batch processing and improve processing efficiency.

- High-strength structure, seamless steel pipe welded bed, guide rail installation platform and working platform processed by metal gantry milling machine, higher precision, ensuring the consistency of each processed workpiece.

- High-speed water-cooled spindle, using water circulation cooling, four silent ceramic bearing structures, more suitable for long-term continuous work.

- Taiwan TBI ball screw, using ball internal circulation design, more suitable for high-speed processing applications.

- dsp four-axis linkage system, select processing files through U disk, easy to get started and simple to operate.

- Fully automatic electric lubricating oil pump, automatic timing lubrication of the precision transmission parts of the machine.

- Optional aluminum alloy T-slot table, flat engraving and 3D carving integrated, more complete functions.

- High-performance servo motor and driver, low noise, high torque.

- The control system has the function of power-off resume carving and breakpoint resume carving to cope with the problem of engraving interruption caused by unexpected situations.

Details of Multi-Head 3D CNC Wood Carving Router

- 10 station

With ten processing stations, ten identical products can be processed at one time.

- Taper rotary axis

Taper rotary axis: The taper at one end drives the material to rotate, and the taper at the other end is used to clamping the material.

- Chuck rotary axis

Chuck rotary axis: Can use only the chuck at one end to fix the material for processing, or the workpiece can be supported at both ends by the chuck and taper.

- 3.5KW high speed water-cooled spindle

The heat generated by the spindle rotation is taken away by water circulation, which effectively reduces the spindle temperature and is suitable for long-term continuous work.

- 3D CNC router with T-slot work workbench

In addition to carving columnar wood, it can also process panels.

- DSP handle

DSP four-axis control handle supports four-axis linkage processing. It is easy to operate. Just insert the U disk and select the drawing to start processing.

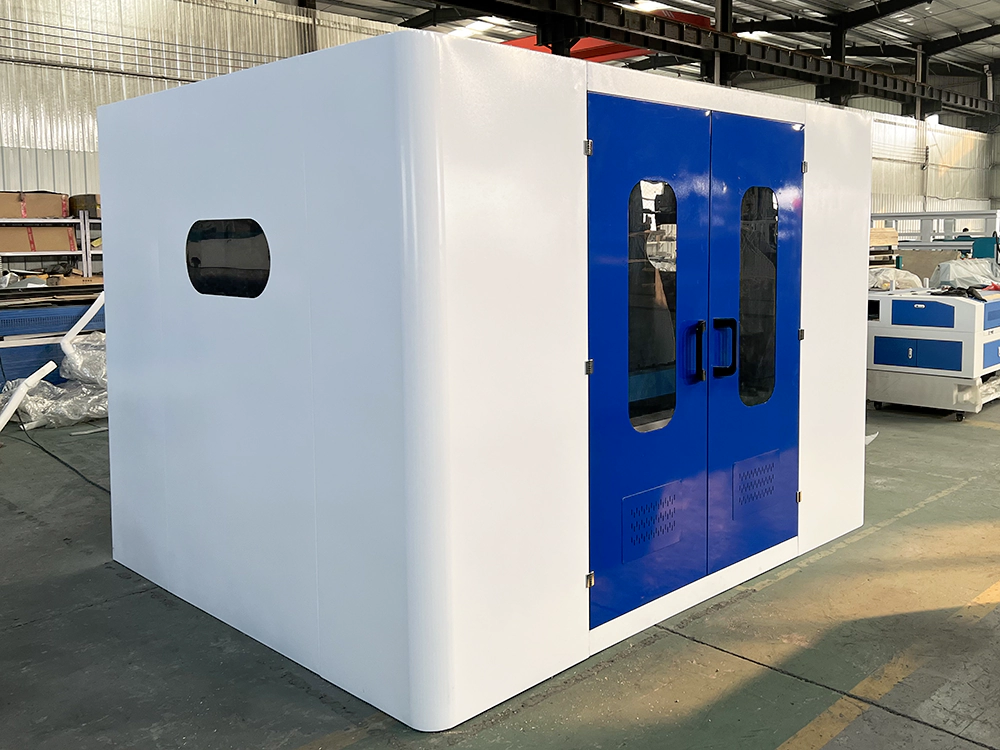

- Multi-station 3D CNC Router with full safety enclosure

Technical Parameters of 10-Station 3D CNC Router

| Model | CK-1020-10S |

| Processing Dimensions | 1000*200*200mm (processing size and quantity can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | CATEKCNC dedicated 3.5KW high-speed water-cooled spindle * 10 (the number of spindles can be customized) |

| Spindle Speed | 6000-24000r/min |

| Table | Aluminum Alloy T-Slot Table Top |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm,4mm,6mm,12.7mm etc. |

| Control System | RichAuto four-axis DSP handle / Mach3 |

| Lubrication System | Fully automatic oil filling and maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1800kg |

| Dimensions | 2600*1900*1650mm |

What Can a Multi-Spindle Four-Axis 3D CNC Router Be Used to Process?

Four-axis CNC routers can perform cutting,2D engraving, 2.5D engraving, 3D carving, hollowing, milling, etc. They are widely used in many industries. Here are some common industries and cases for your reference:

- Woodworking industry: Buddha statues, ornaments, furniture legs, Roman columns, wooden doors, stair railings, chair legs, sofa legs, screens, axe handles, hammer handles, etc.

- Advertising industry: advertising word cutting, crystal words, acrylic, signboards, trophies and other advertising decorations.

- Model mold making: foam models, wooden models, aviation models, wooden boat models, copper or aluminum molds, sand table models, etc.

- Musical instrument industry: guitars, violins, cellos, pianos and other musical instrument accessories.

- Crafts making: decorative ornaments, vases, gourds, decorative bases, wooden toys, etc.

| Model | CK-1020-10S |

|---|---|

| Processing Dimensions | 1000*200*200mm (processing size and quantity can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | CATEKCNC dedicated 3.5KW high-speed water-cooled spindle * 10 (the number of spindles can be customized) |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | DORNA 1.5KW servo motor drive (Z-axis brake motor) |

| Table | Aluminum Alloy T-Slot Table Top |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm,4mm,6mm,12.7mm etc. |

| Control System | RichAuto four-axis DSP handle / Mach3 |

| Lubrication System | Fully automatic oil filling and maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1800kg |

| Dimensions | 2600*1900*1650mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.