ATC CNC Router Machine with Two 4x8 Workbenches

Double Workbench ATC CNC Wood Router Machine

[Function Description]

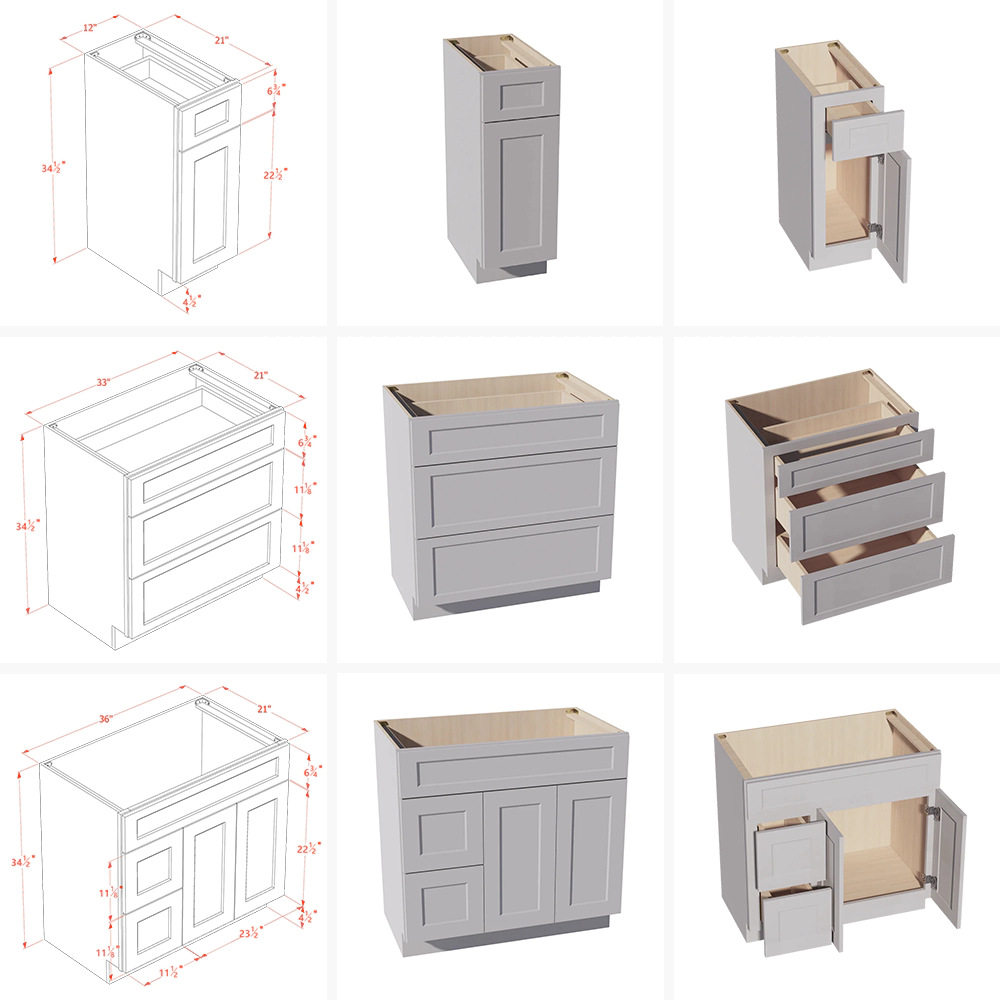

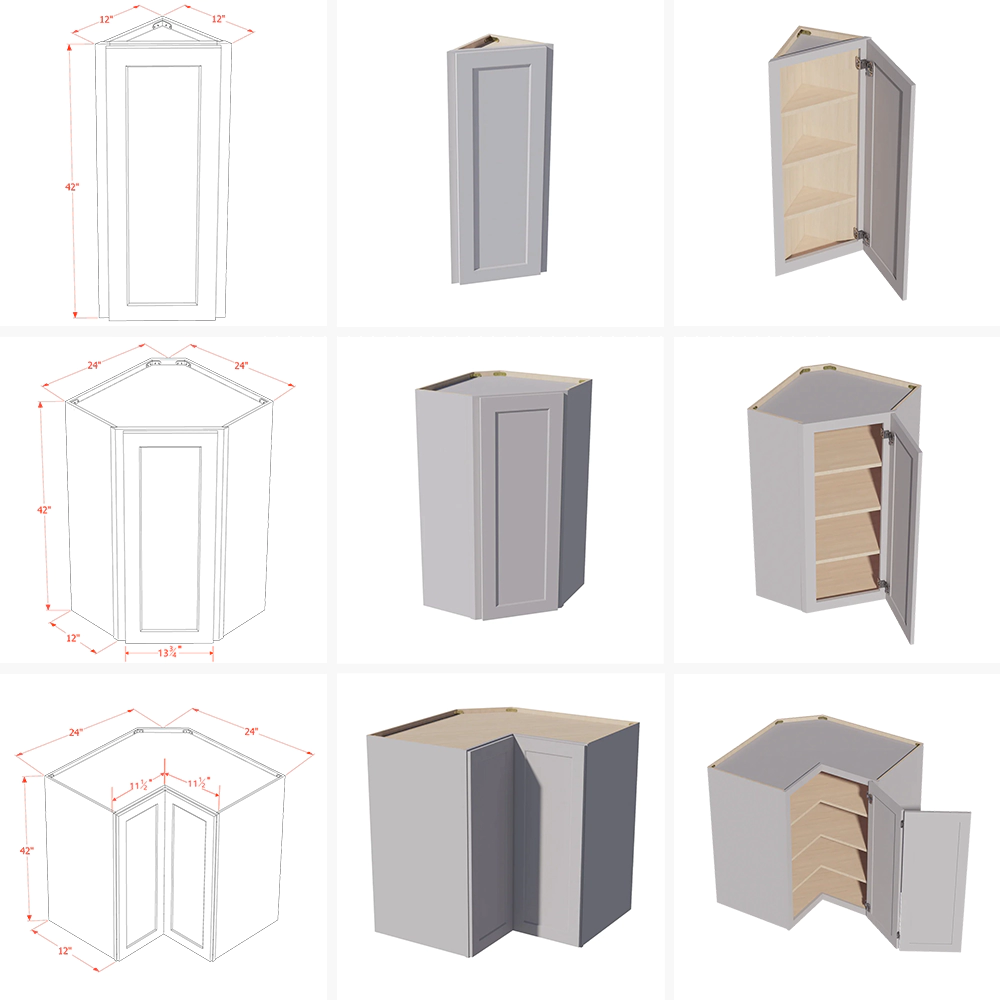

The double-workbench CNC router innovatively adds an additional 4*8 feet workbench to the traditional 1325 model CNC router, meaning it is equipped with two independent 4*8 feet worktables simultaneously. This design allows for the placement of two wooden boards at once, enabling alternating processing. For example, while one workbench is being processed, the operator can load or unload materials on the other workbench, thereby eliminating the idle time of the spindle caused by unloading, loading, board positioning, and fixing after the completion of board processing on a conventional 4*8 single-workbench CNC router, significantly improving production efficiency.

Moreover, double-workbench CNC router is also equipped with an automatic tool change kit, which can automatically switch the required tools during the processing according to work requirements without manual intervention. It can assemble 8/12/16 tools at once, and with the automatic tool setter, it automatically sets the tools for processing, avoiding the waste of time and potential errors caused by manual tool changes and calibration, thereby achieving higher processing accuracy while further enhancing processing efficiency.

Advantages of Double-Workbench CNC Routers Suitable for Furniture Production

- It has two 4x8ft workbenches, which can place two materials at a time. After processing the first material, it will automatically process the second material, saving time and improving efficiency.

- Automatic tool change kit, which can be equipped with 8/10/12/16 tools at a time. The machine automatically changes tools according to processing requirements or system settings without manual operation.

- Both workbenches use vacuum adsorption platforms, which makes it easier to fix the plates and avoid material movement caused by plate fixation problems during processing.

- Using CNC nesting software and automatic nesting processing can maximize the utilization rate of the plate (can be increased by about 20%), save material costs and improve corporate benefits.

- The servo drive system and high-precision transmission system ensure high precision and high stability during the processing, effectively improve the fit of the product and save time for the subsequent assembly process.

- It has complete functions and supports a variety of processing methods, such as engraving, cutting, drilling, grooving, milling, etc. Complex products can be processed in one go.

- The processing speed is fast, the processing speed can reach 25000mm/min, and the idle speed can reach 60000mm/min. Compared with ordinary CNC routers, the processing efficiency can be increased by 200%.

- The bed structure is stable, welded with thickened and thickened steel pipes and treated with high temperature to ensure that it will not deform during long-term use.

Features of ATC CNC Router with Two Vacuum Adsorption Workbenches

- 9kw automatic tool changing spindle and large-capacity tool magazine make tool replacement easier.

- Two multi-partitioned vacuum adsorption workbenches, the adsorption function of each workbench can be independently controlled, making material fixation more convenient.

- Both tables are equipped with 4+2 positioning cylinders. 4*8ft plates can be positioned and loaded quickly and accurately by simply pressing against the positioning cylinders.

- The tool setting is done by using the automatic tool setting instrument, which is easy to use. Tools of different lengths can also be calibrated to zero point with one click.

- Taiwan LNC control system, modular control, just click to start processing easily, easy to use, greatly reducing the operating threshold.

- Friendly and easy-to-read operating instructions make it easy to operate even if you are a novice in CNC.

- Perfect after-sales service, CATEKCNC's engineers are online 7x24 to help you troubleshooting.

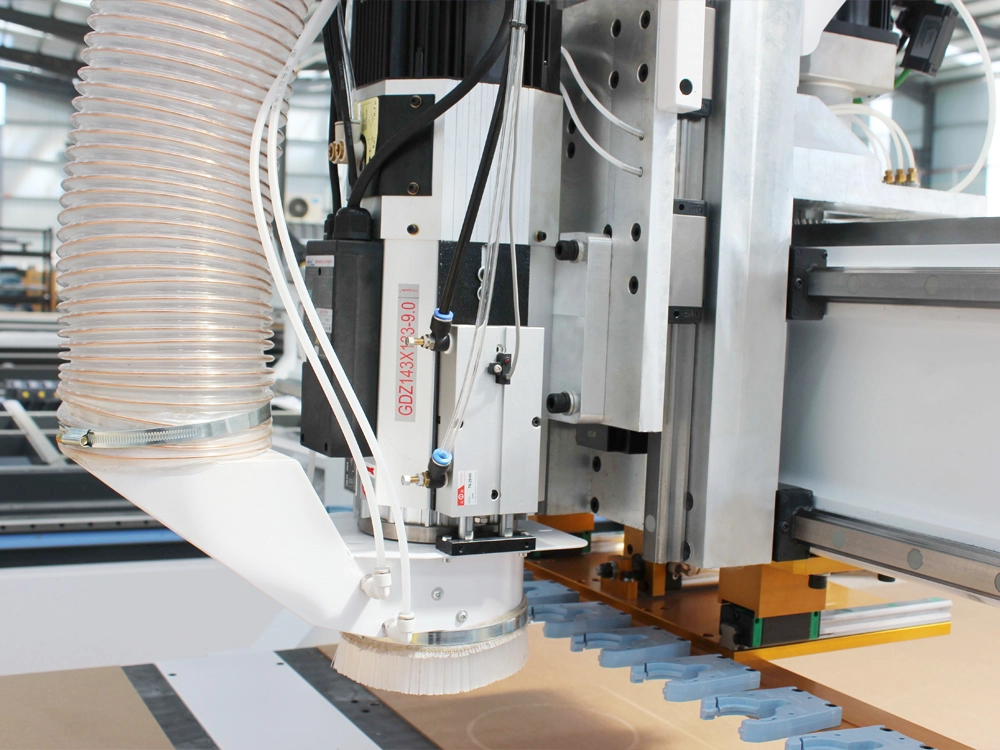

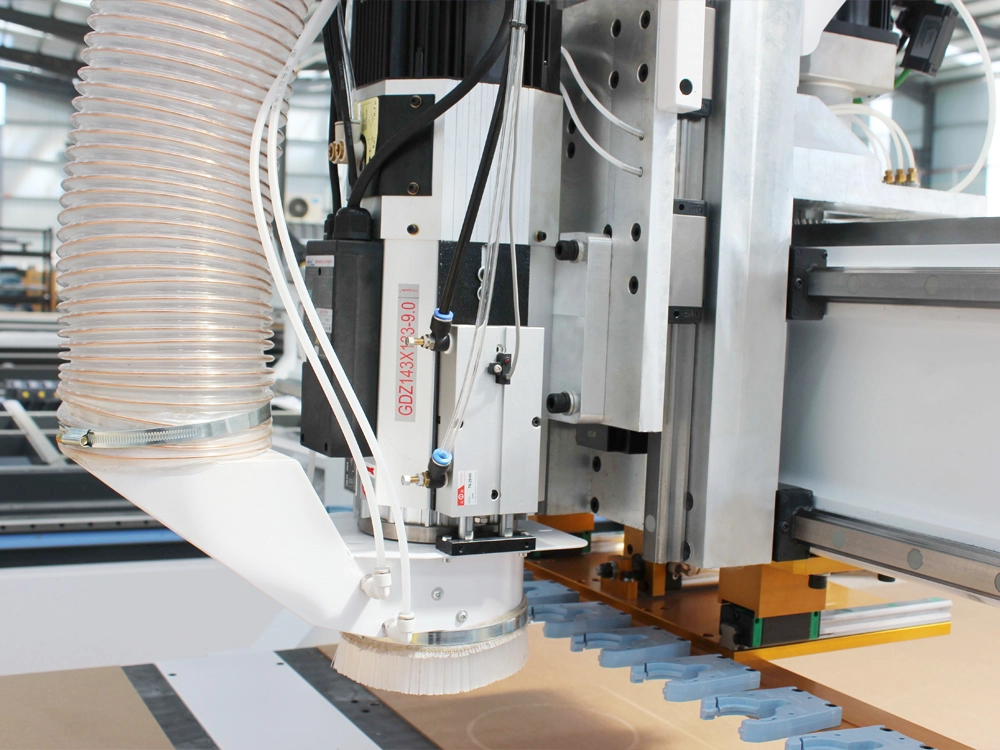

Details of CNC Router That Can Be Used for Furniture Manufacturing

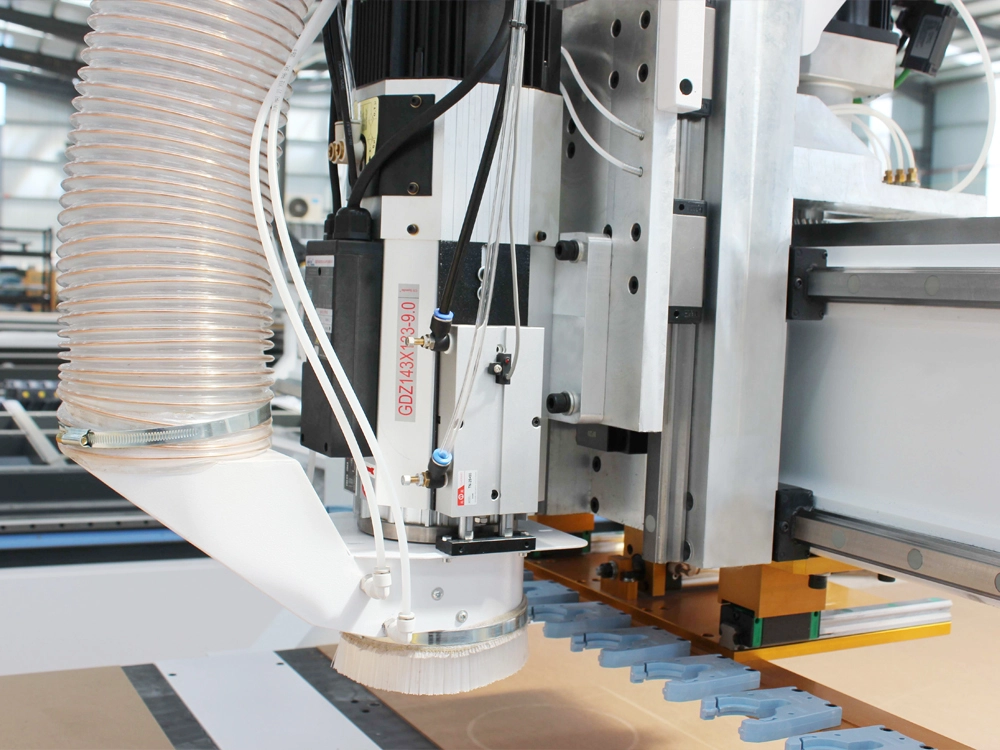

- 9kw automatic tool change spindle

High speed, high torque, fast processing speed, and support for automatic tool change.

- Linear tool changer

8/12/16 linear tool change magazine, moves with the gantry, fast tool change speed.

- Automatic tool setting instrument

Before initial machining or after each tool change, this device automatically measures the tool length, determines the position of the tool tip, and instructs the system to compensate accordingly.

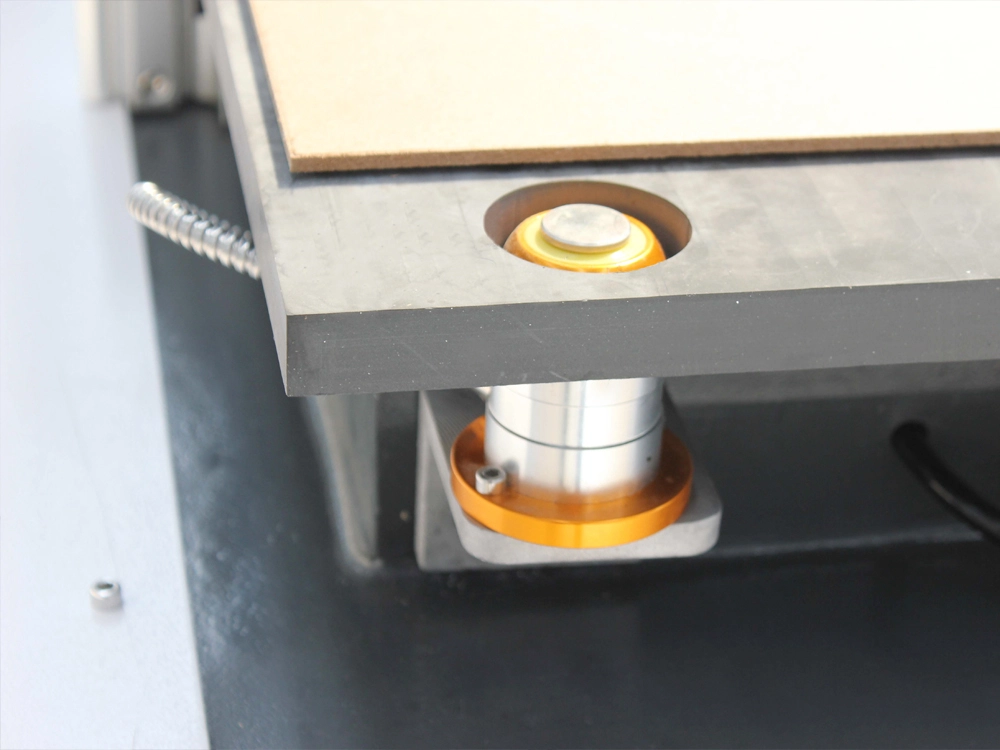

- 8+4 positioning cylinder

The positioning cylinder can quickly position full-size plates.

- Feeding roller

Reduce the static friction between the board and the tabletop, make loading easier, and avoid board wear.

- High precision helical rack

Grinded helical rack for higher precision.

Technical Parameters of Industrial-Grade Double-Workbench CNC Router

| Model | CK-1325-2WT |

|---|---|

| Processing Size | 1300*2500*200mm (two workbenches) |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Bed | Independent anti-interference control cabinet for machining center bed (heavy bed) |

| Spindle | 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Tool Setting Method | Automatic tool setting instrument |

| Tool Handle Specifications | ISO30/ER30/φ20 |

| Driving Mode | 1.5KW high-power servo motor drive (Z-axis uses brake motor) |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Reducer | Japan Shimpo planetary reducer |

| Table | Vacuum table 12 zones, 48 wells |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW double-drum dust collector |

| Vacuum Pump | 11KW water ring vacuum pump |

| Control System | Taiwan LNC MW2200 control system / Mach3 |

| Operating Voltage | AC380V/50/60Hz |

| Engraving Instructions | Standard G code |

| Positioning | 8+4 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 25000mm/min |

| Maximum No-Load Running Speed | 60000mm/min |

| Weight | 4600kg |

| Dimensions | 6550*2150*2240mm |

What Products Can a Double-Workbench CNC Router Be Used to Process?

- Furniture manufacturing: cabinet doors, wooden doors, wardrobes, classical furniture, doors and windows, office furniture, woodcarving screens, bookshelves, desks, etc.

- Advertising production: crystal characters, advertising characters, PVC or acrylic cutting, billboards, sign making, etc.

- Crafts production: musical instruments, speakers, decorative boxes, wooden boxes, wooden boxes, wooden crafts, wood patterns, etc.

- Other applications: wooden molds, foam molds, foam, artificial stone, bamboo, etc.

Delivery Time

We will start producing the machine immediately after receiving your deposit. For standard models, it takes 5-10 days to prepare, and customized models take 10-20 days.

Machine Transportation

Sea, land, air. For small machines, air transportation can be used for transportation. Air transportation has the highest price and the fastest speed; large CNC milling machines need to be transported by sea or land. Sea transportation is cheap, slow, and takes longer. Land transportation is more expensive and has average speed. You can choose the appropriate transportation method according to your needs.

After-Sales Service And Support

All CATEKCNC machines are provided with a free 3-year/36-month warranty service, and lifetime free maintenance and software upgrades. Engineers and technicians are online 24/7 and can provide technical support by phone, whatsapp, google meet, email, etc. You can come to the CATEKCNC factory for on-site training, and we will provide you with comprehensive machine operation, software operation and maintenance training for free. Free machine operation video, operation manual, drawing software.

| Model | CK-1325-2WT |

|---|---|

| Processing Size | 1300*2500*200mm (two workbenches) |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Bed | Independent anti-interference control cabinet for machining center bed (heavy bed) |

| Spindle | 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Tool Setting Method | Automatic tool setting instrument |

| Tool Handle Specifications | ISO30/ER30/φ20 |

| Driving Mode | 1.5KW high-power servo motor drive (Z-axis uses brake motor) |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Reducer | Japan Shimpo planetary reducer |

| Table | Vacuum table 12 zones, 48 wells |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW double-drum dust collector |

| Vacuum Pump | 11KW water ring vacuum pump |

| Control System | Taiwan LNC MW2200 control system / Mach3 |

| Operating Voltage | AC380V/50/60Hz |

| Engraving Instruction | Standard G code |

| Positioning | 8+4 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 25000mm/min |

| Maximum No-Load Running Speed | 60000mm/min |

| Weight | 4600kg |

| Dimensions | 6550*2150*2240mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.