4x8 CNC Woodworking Router with Linear Automatic Tool Changer for Woodworking on Sale

Most-Sold CNC Router with Linear Automatic Tool Changer for Sale

[Function Description]

Overview of 4x8 CNC Router with Linear Automatic Tool Changer

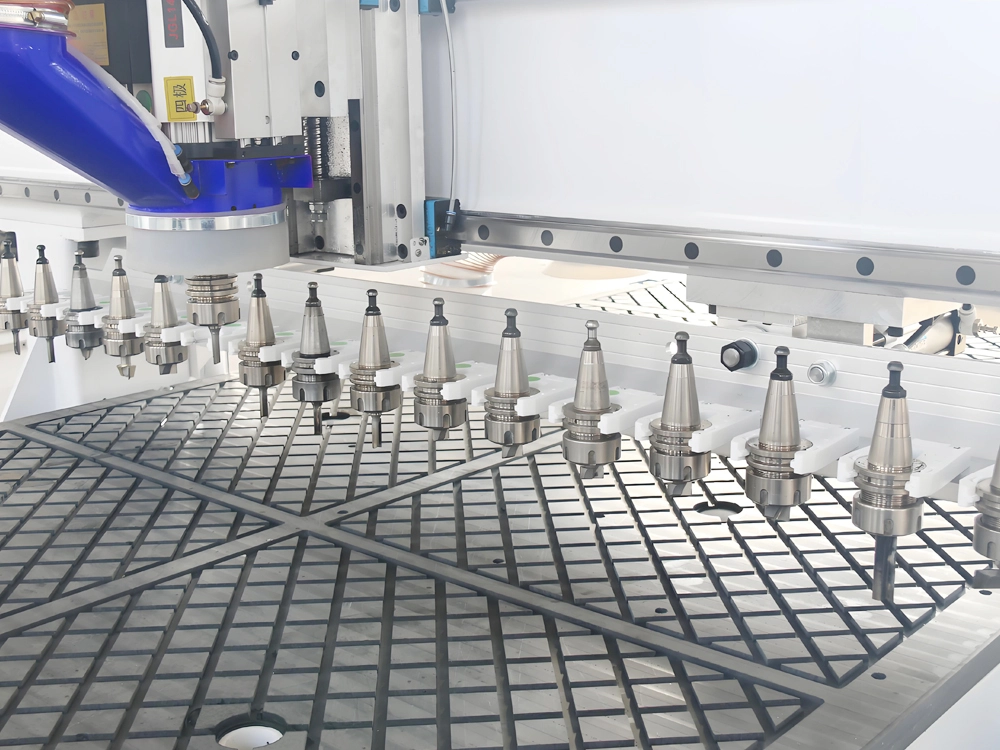

The CK-1325-T is a classic automated CNC router equipped with a linear automatic tool-changing system. Its automatic tool changer can accommodate up to 8/12/16 tools at once, and the tool magazine can hold various tools of different shapes and lengths, such as engraving tools, round-bottom tools, cutting tools, and milling tools. When processing products with complex shapes, the machine can recognize the processing drawings and automatically change tools according to the processing requirements without manual intervention. The machine's XYZ axes are all powered by 1.5KW high-power servo motors, which not only provide fast movement and high processing precision but also operate with lower noise. Equipped with a Japanese-made Shimpo reducer, the machine features high positioning accuracy, fast movement speed, and quick braking, significantly improving processing efficiency and reducing labor costs during operation.

The 4*8 automatic tool-changing CNC router has a processing size of 1300*2500mm and offers multiple functions, including engraving, cutting, drilling, milling, and 3D carving. It can complete multiple processes on a part in a single run, avoiding the time wasted by manual tool changes required by ordinary three-axis CNC routers after completing one process, thereby greatly shortening the processing interval. It adopts an intelligent CNC system with a user-friendly interface and intuitive functions, requiring only one operator. Additionally, the machine supports various nesting software, enabling one operator to manage multiple machines simultaneously.

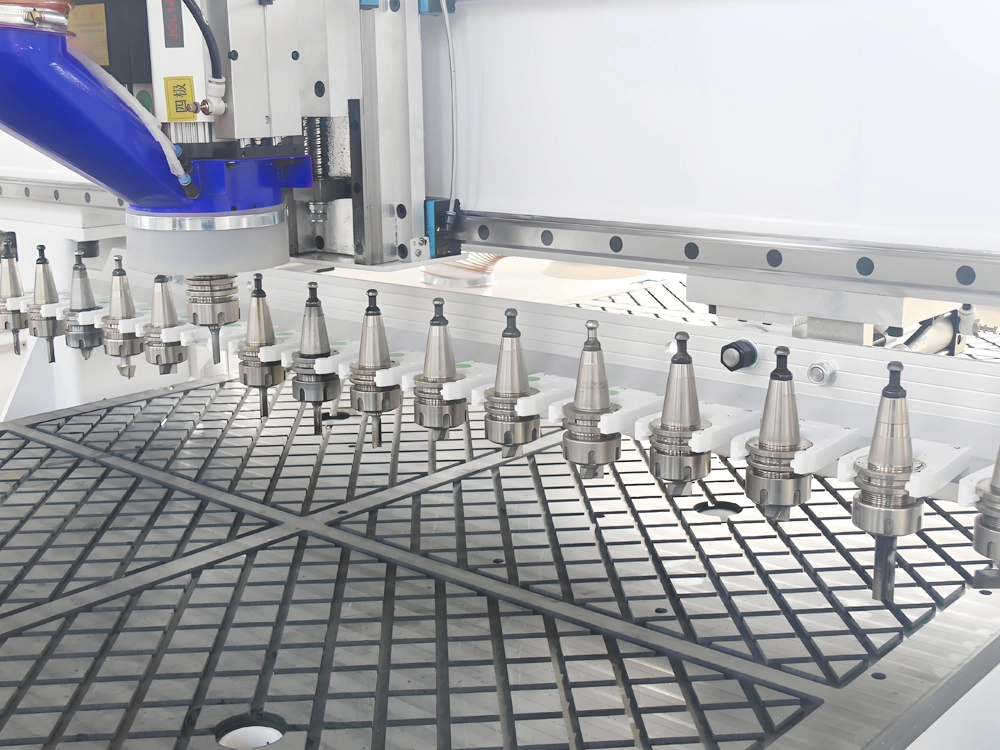

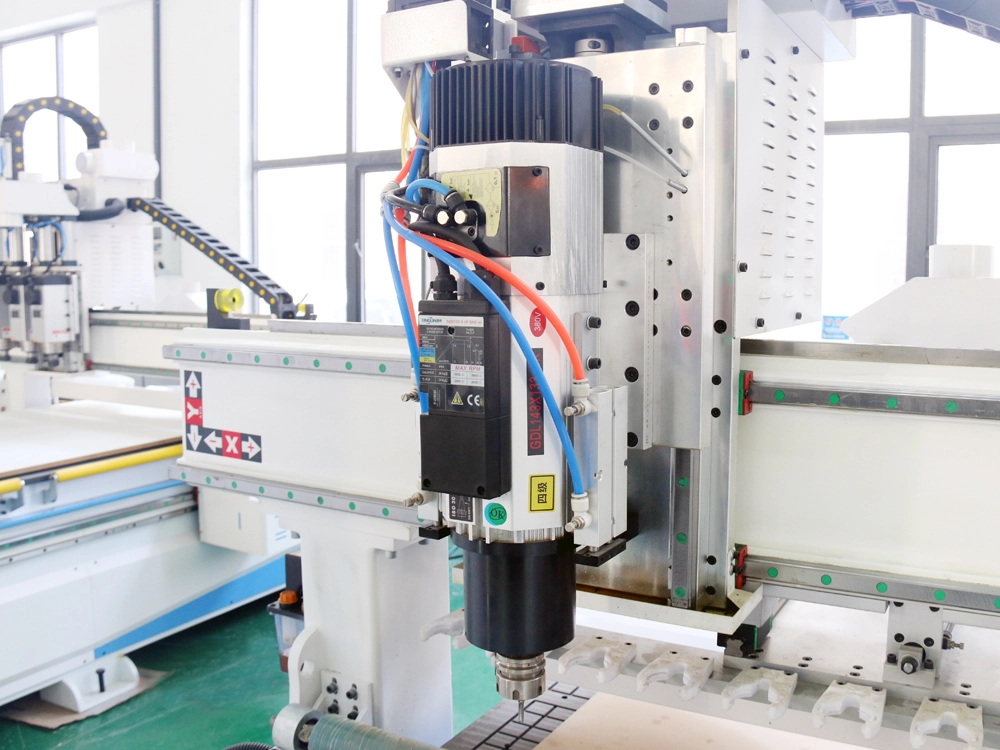

How Does the Linear Automatic Tool Changer Work?

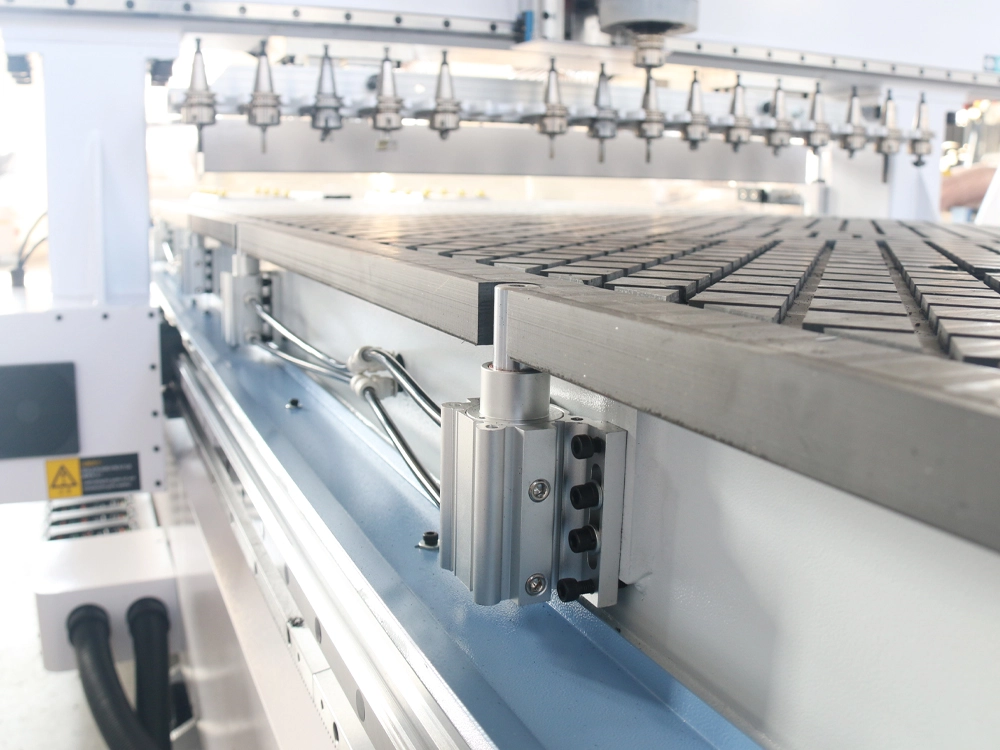

The CK-1325-T ATC CNC router is equipped with a linear tool magazine, with optional capacities of 8, 12, or 16 tools. There are two types of linear tool magazines: one is a fixed tool magazine mounted at the rear of the worktable, and the other is a follow-type tool magazine mounted on the machine's gantry frame. The tool-changing process for both types is essentially the same. When a tool change is required during processing, the control system issues a command. The spindle stops working and moves to the designated position in the tool magazine. The cylinder holding the spindle releases the current tool holder, and the tool magazine synchronously pushes in to place the used tool back into the magazine. The spindle then moves above the required tool, descends, and uses the cylinder to clamp the new tool holder. Finally, the tool magazine synchronously retracts, completing the entire tool-changing process. The entire tool-changing process takes only about 5 seconds and is automatically coordinated by the control system without the need for manual intervention.

Advantages of Linear ATC CNC Router with Vacuum Adsorption Table

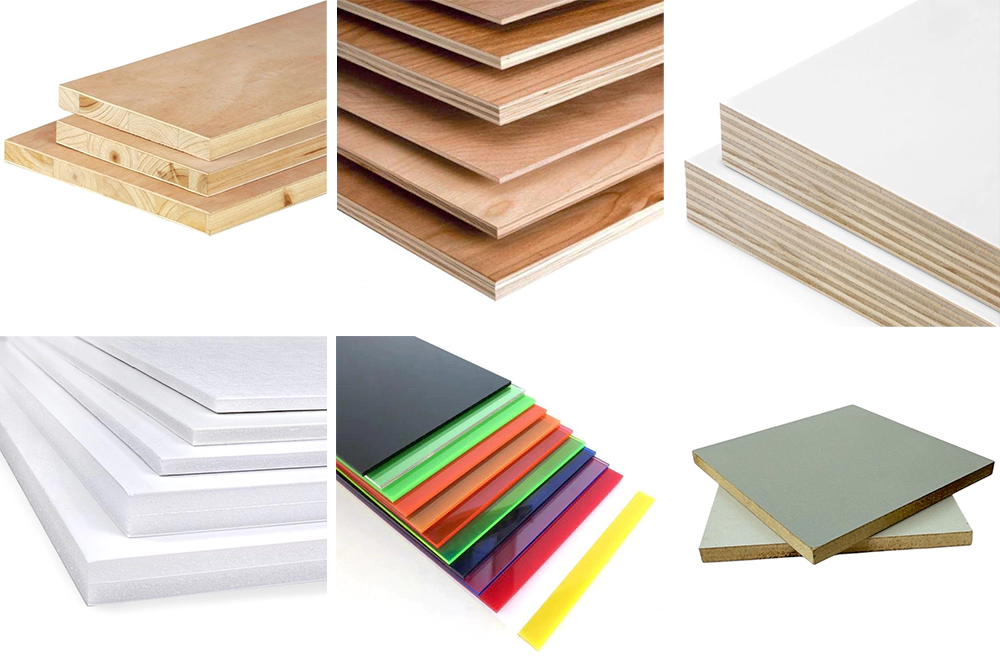

- The 9KW HQD automatic tool-changing air-cooled spindle, with a maximum speed of 24,000 rpm, can quickly process various types of boards, offering large cutting depths and high cutting speeds.

- Equipped with a linear tool magazine with a capacity of 8/12/16 tools, it enables automatic tool changes for different processing needs, allowing for the automatic machining of complex parts.

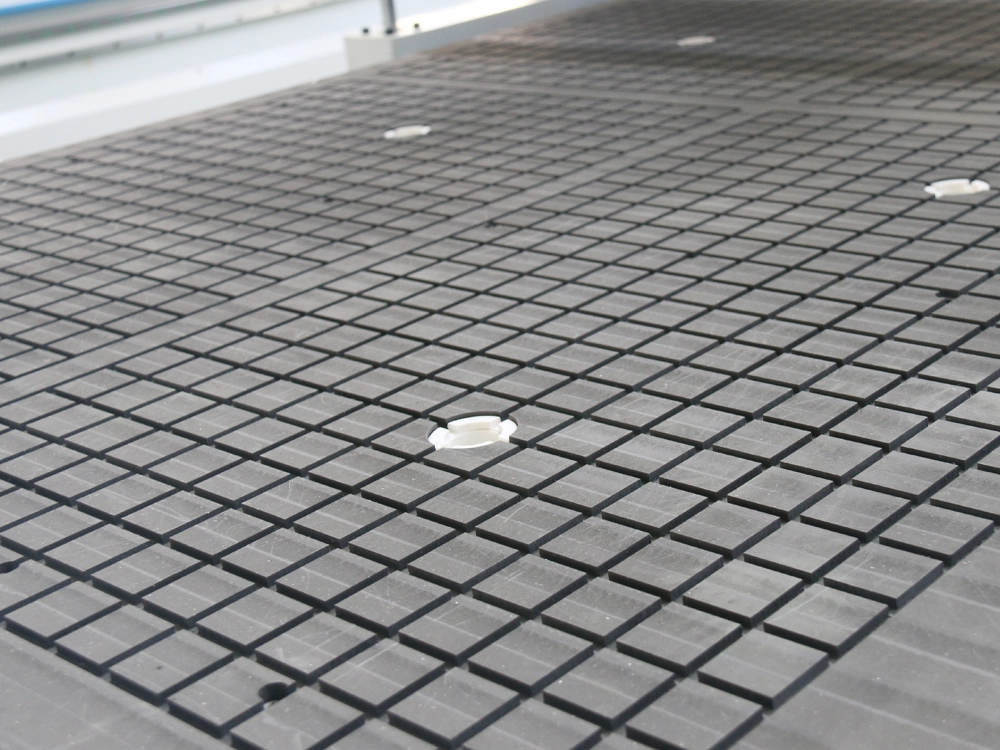

- The machine uses an 11KW water-ring vacuum pump paired with a 6-zone, 24-hole vacuum adsorption table. Each zone can be controlled individually via switches, ensuring one-click fixation for parts of any size.

- It features the Taiwan LNC CNC cutting machine system, which offers expanded functionality, user-friendly design, and simple operation.

- The XY axes are driven by 1.5KW high-power servo motors, paired with high-precision planetary gear reducers, while the Z axis uses a motor with a braking device for precise control.

- High-quality Schneider/DELIXI electrical components are used, with independent filters installed at each signal output point, providing stronger anti-interference capabilities and more stable operation.

- A 3KW dual-barrel independent dust collector is included, which automatically collects dust during processing and performs overall dust suction after completion, ensuring a dust-free working environment.

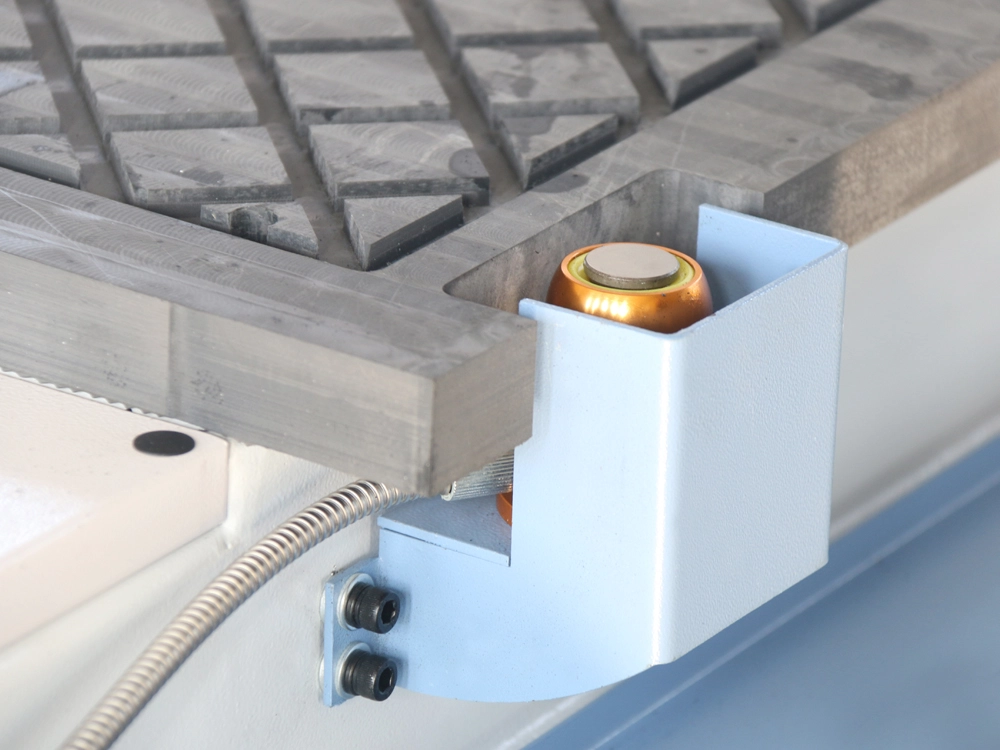

- The automatic tool setting device allows for one-click tool calibration, regardless of tool size or length differences, eliminating the hassle of recalibrating after each tool change for greater convenience.

- The machine features a heavy-duty, double-layer bed made of thickened square steel, processed with a five-face gantry milling machine and treated at high temperatures for enhanced stability and higher processing precision.

- An automatic lubrication system is included to lubricate all transmission parts of the machine, extending its service life.

- The intelligent system features a user-friendly interface, making it easy even for beginners to operate. Each function is controlled by independent buttons for more intuitive use.

- It uses 30mm linear guides, linear bearings, and TBI ball screws for precise positioning and fast movement speeds.

Detailed Introduction of 4x8 Linear ATC CNC Router

- ATC spindle

9KW automatic tool change spindle, four ceramic bearings, air cooling.

- Linear Automatic tool changer

Linear tool magazine with large tool capacity and easy to use.

- Servo motor

High power servo motor, large output torque and fast moving speed.

- 4+2 positioning cylinder

Accurately position and fix the full-size board.

- Taiwan LNC control system interface

The LNC control system for CNC routers is mature, stable, and user-friendly.

- Pulse handwheel

Wired pulse handwheel

Wireless pulse handwheel

- Control cabinet

Independent control cabinet effectively protects electrical components and facilitates circuit inspection.

- Automatic tool setting instrument

Automatic tool setting, which can automatically calibrate tools even if they have different lengths and diameters.

- Vacuum adsorption table

The multi-zoned vacuum adsorption platform can quickly and automatically fix the panels.

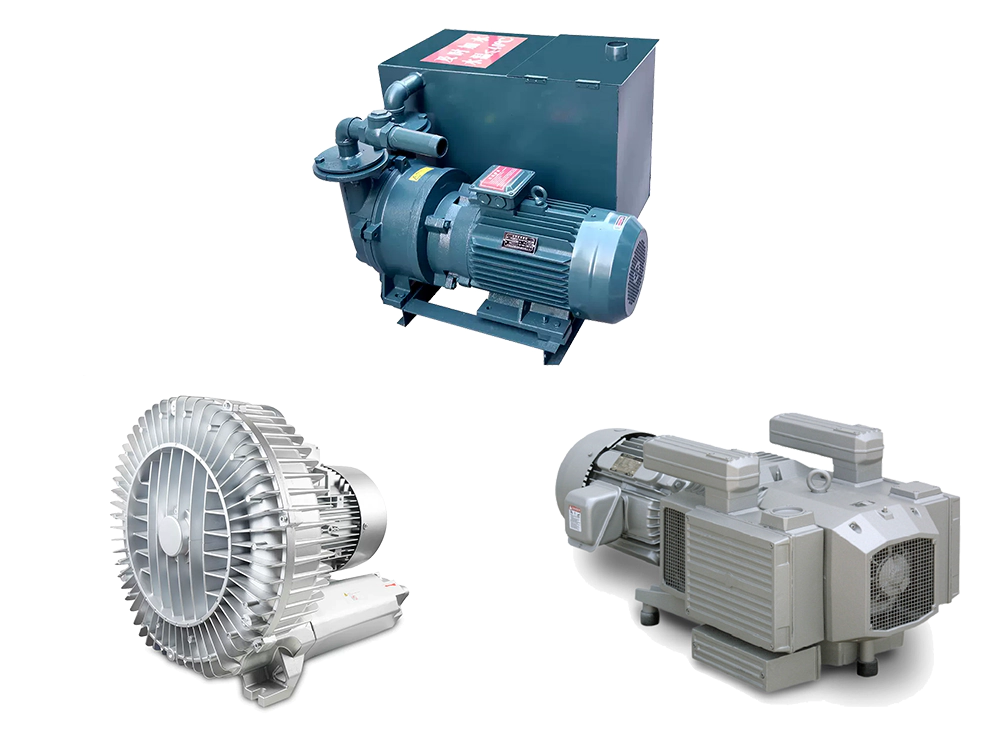

- Vacuum pump

A variety of vacuum pumps are available.

- Automatic lubrication oil pot

Automatically lubricate the transmission parts of the machine.

- Optional saw blade spindle

For fast cutting of wood panels.

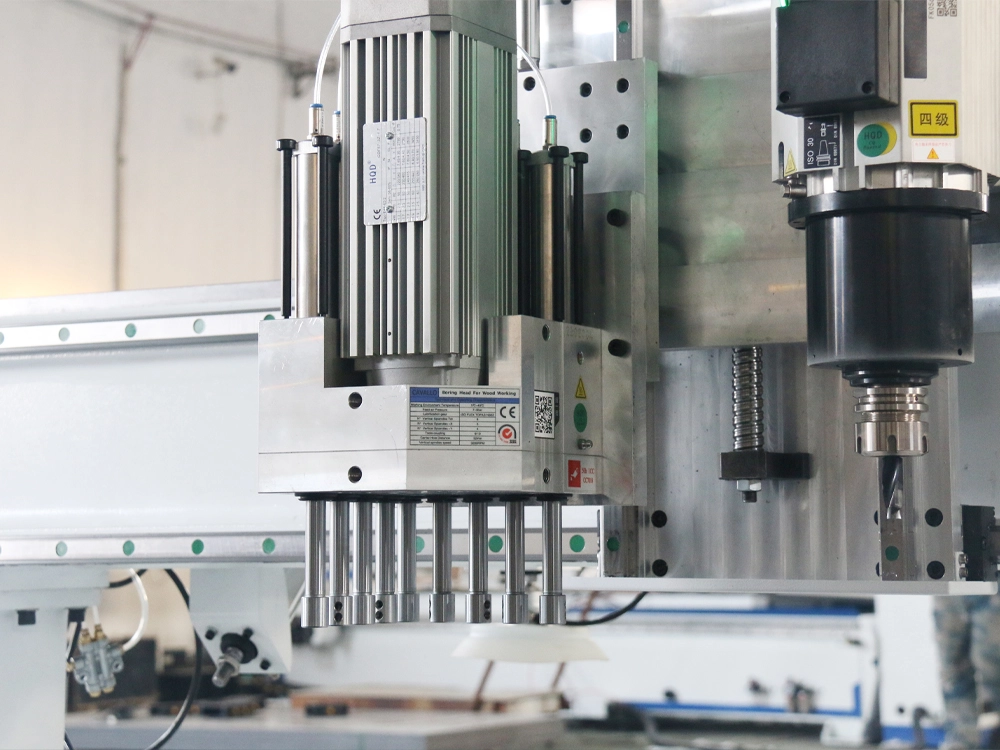

- Optional drilling kit

For drilling holes in wood.

- Optional automatic loading and unloading platform

For automated processing.

Technical Parameters of Linear ATC CNC Router

| Model | CK-1325-T |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW double-barrel bag vacuum cleaner |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Processing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2900kg |

| Dimensions | 3900*2100*2100mm |

Optional Accessories for Linear ATC CNC Router

| Spindle | Italian HSD spindle/Italian HITECO spindle |

| Servo Motor | Yaskawa servo motor/Delta servo motor |

| Control System | Syntec/NCStudio/Mach3 etc. |

| Vacuum Pump | Vortex air pump/rotary vane vacuum pump/variable frequency vacuum pump |

| Saw Blades | 6KW/7.5KW saw blade spindle |

| Pressure Roller | Double rod independent pneumatic pressure rollers can be individually controlled to fix the plate |

| Tool Changing Method | Carousel tool changer (6/8/10/12) |

| Pneumatic Drill Bits | 5+4 drill bit magazine/CNC side milling angle head |

| Automatic Feeding | Automatic lifting loading platform |

| Automatic Unloading | Rolling automatic unloading platform |

| Rotation Axis | 3D carving fourth axis rotation axis |

| Oscillating Knife | Oscillating knife for cutting paper/leather/foam/cloth etc |

| Camera | CCD camera for scanning, printing and cutting |

Application Scope of 4x8 CNC Router with Automatic Tool Changing Kit

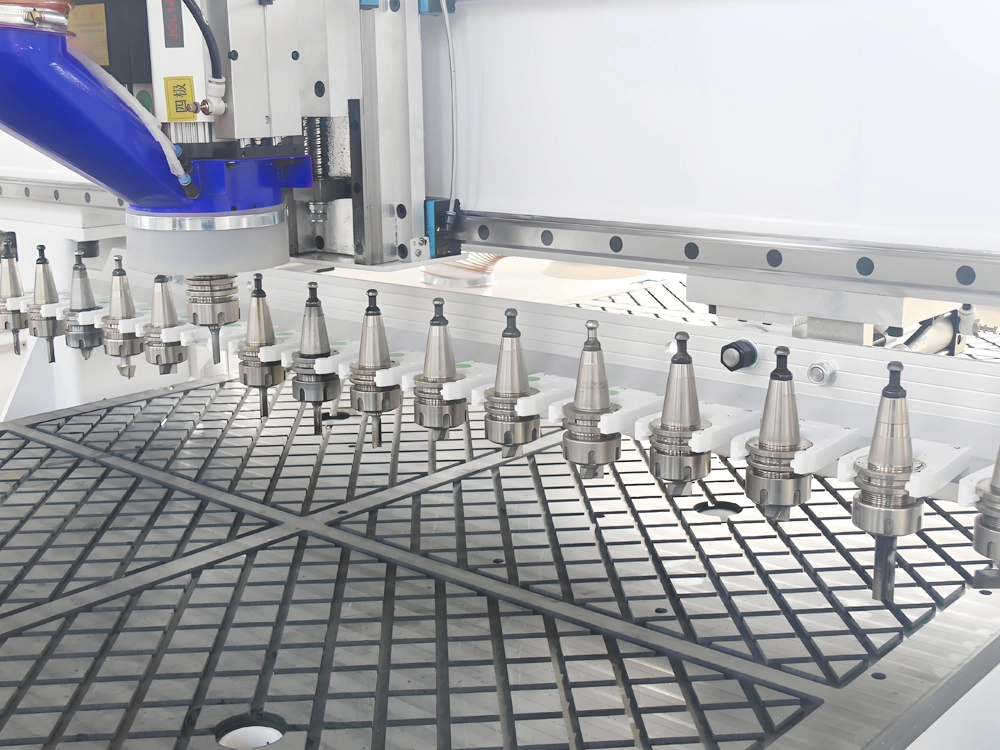

Applicable Materials:

Wood board, density board, MDF board, artificial board, particle board, gypsum board, multilayer board, plastic, PVC, PCB, acrylic, Chevron board, PTFE board, aluminum-plastic board, aluminum, copper, ABS, PP, PE, epoxy resin, carbon fiber mixture, artificial stone, plexiglass, PVC, KT board, etc.

Applicable Industries:

- Furniture industry: wooden furniture, panel furniture, mahogany furniture, cabinets, wardrobes, shoe cabinets, office furniture, custom furniture, wooden doors, tables and chairs, doors and windows, antique furniture, etc.

- Architectural decoration: stairs, architectural models, sand table models, decorative buckle lines, artistic reliefs, wall panels, decorative surfaces, etc.

- Advertising production: billboards, logos, three-dimensional characters, acrylic signs, work badges, medals, crystal characters, acrylic light boxes, etc.

- Mold manufacturing: wooden molds, plastic molds, foam molds, copper molds, aviation wooden molds, motorboat molds, etc.

- Musical instrument parts: audio shells, guitar shells, violins, cellos, piano parts, etc.

The Following Are the Processable Products of Linear ATC CNC Router for Your Reference

How to Buy a Better 4*8ft ATC CNC Router?

- Automatic Tool Changer: The automatic tool-changing system offers two options: linear tool changer and carousel-type tool changer. The linear tool changer is cost-effective, fast, and easy to operate. The carousel-type tool changer, which includes an additional rotation axis, is more expensive. However, it features a compact design, user-friendly operation, and does not affect the router's maximum processing thickness.

- Drive System: While ordinary CNC routers use stepper motors, our standard automatic tool-changing CNC routers are equipped with servo drive systems. For higher precision or quality requirements, you can opt for Japanese Yaskawa servos or Taiwanese Delta servos.

- CNC System: The standard configuration includes the LNC CNC system. If you are proficient with other systems, you can choose according to your preferences, such as the Syntec system, Mach3, DSP, etc.

- Additional Features: For more efficient cutting tasks, you can consider adding a saw blade spindle. If you have extensive drilling needs, such as side holes for cabinet or wardrobe connectors, you can opt for a drilling package or a side milling device. Additionally, the machine offers many other optional accessories. If you are unsure whether your product can be processed using a CNC router, please contact our sales specialist for a detailed introduction.

- Sample Confirmation: Before making a formal purchase, you can contact our sales specialist to arrange a trial processing using our existing machines. We will record processing videos and take photos for you to confirm the actual processing performance of the machine.

We Also Have Other Models of CNC Milling Machines to Recommend to You

| Model | CK-1325-T |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Syntec / NCStudio / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2900kg |

| Dimensions | 3900*2100*2100mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.