Carousel ATC CNC Router with Automatic Loading and Unloding Factory Direct Sales

Carousel ATC CNC Router with Automatic Loading And Unloading

[Function Description]

The carousel ATC CNC router with automatic loading and unloading platform integrates functions such as automatic loading, processing scheme optimization, cutting, slotting, drilling, and automatic material unloading, and each process is seamlessly connected. The entire processing flow of the machine is automated. During machine processing, workers only need to unload the finished products on the conveyor belt platform, which does not affect the continuity of router processing and can effectively increase production efficiency by more than 30%. Equipped with a central intelligent dust removal system, it effectively collects wood chips and dust generated during processing to ensure a clean working environment. The spindle adopts an advanced carousel tool changer, which can save more than 95% of tool change time compared with a manual tool changer. With the automatic loading and unloading platform, one device can save 2 to 3 manual labor. In addition, by optimizing typesetting through professional nesting software, the effective utilization rate of materials can be increased to more than 98%.

How Does the Loading and Unloading Platform of a CNC Nesting Machine Work?

The loading platform is equipped with a hydraulic lifting mechanism, which can automatically adjust the height according to the height of the stacked plates. The high-precision laser sensor ensures that the plates to be loaded are always in the best position, and the error is controlled at the millimeter level to avoid subsequent processing deviations. When the number of plates decreases, the platform automatically rises to maintain the effective working distance of the adsorption device. The suction cups on the crossbeam of the CNC router firmly grasp the plates from the loading platform. The plates are driven by the crossbeam and move along the Y axis of the machine to the vacuum adsorption workbench. No manual intervention is required throughout the process. After placing the material on the vacuum adsorption workbench, the positioning cylinder starts to run, and the cylinder automatically pushes the plate against the fixed processing position, and the machine starts automatic processing. After the processing is completed, the pneumatic pushing system on the crossbeam pushes the processed plates from the processing table to the conveyor belt unloading platform, and completes the secondary dust collection of the workbench during the pushing process. After processing a plate, the unloading structure starts immediately, and the loading platform will also prepare the next plate to be processed in advance, realizing the loading-processing-unloading-loading cycle, which shortens the unloading time by more than 60% and can be produced continuously for 24 hours.

Advantages of Carousel ATC Automatic Loading and Unloading CNC Router Suitable for Cabinet and Wardrobe Production

- High processing efficiency, labor-saving, and capable of operating 24 hours a day.

- Rotary tool-changing device, equipped with over 12 tools at once, saving time with automatic tool changes.

- 9KW automatic tool-changing spindle with a maximum speed of 24,000 rpm, enabling rapid material processing.

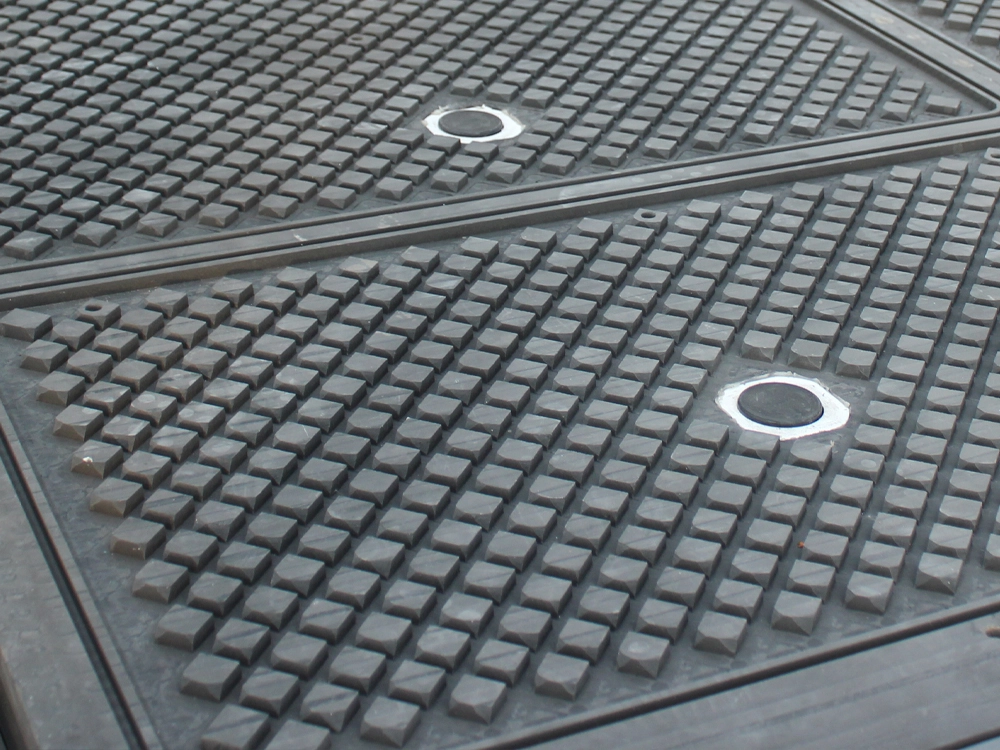

- Vacuum adsorption table with multiple zones and hole positions, each zone independently controllable for flexible use.

- 4+2 positioning cylinders, simplifying the placement and positioning of boards.

- Hydraulic lifting loading platform for automatic material loading.

- Conveyor belt style unloading platform, automatically unloading processed materials to save time.

- TBI ball screws + helical racks + gears, ensuring fast movement and higher positioning accuracy.

- ISO30 tool holder and ER32 collet, offering a wide range of tool compatibility.

- LNC CNC system, featuring highly intelligent and integrated control with simple operation.

- Central automatic lubrication system, providing timed lubrication and maintenance for the machine.

- Central dust collection system, automatically collecting waste and wood chips generated during processing.

Details of CNC Router with Carousel Tool Changer and Automatic Loading and Unloading

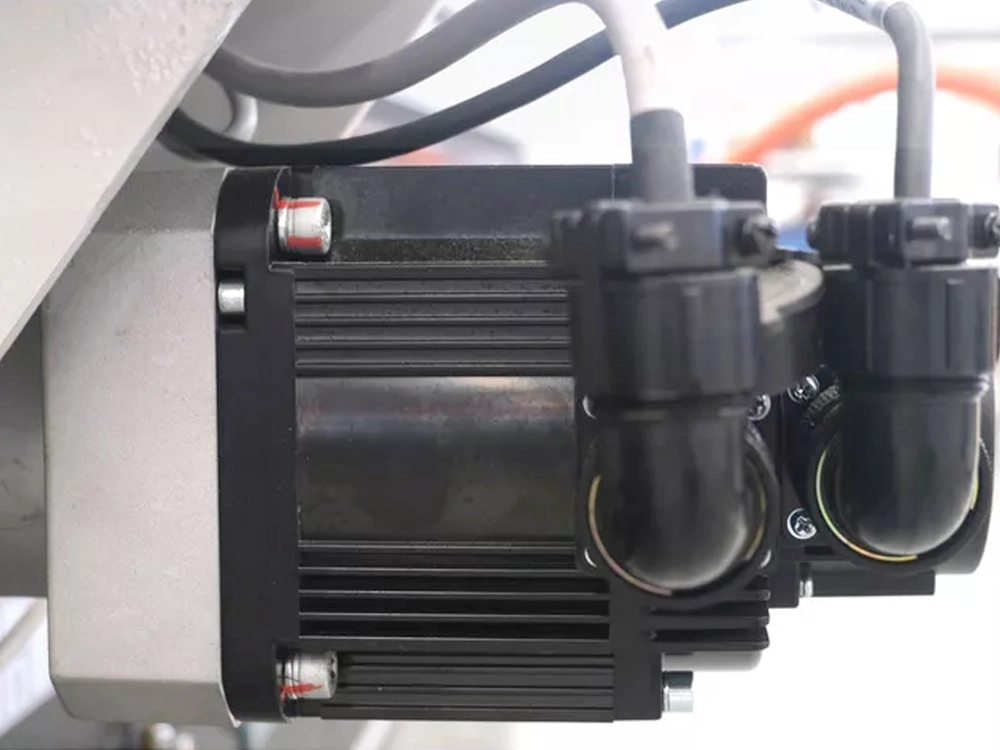

- Servo motor

High control accuracy, stable operation, fast dynamic response, strong overload capacity and wide speed range, superior performance.

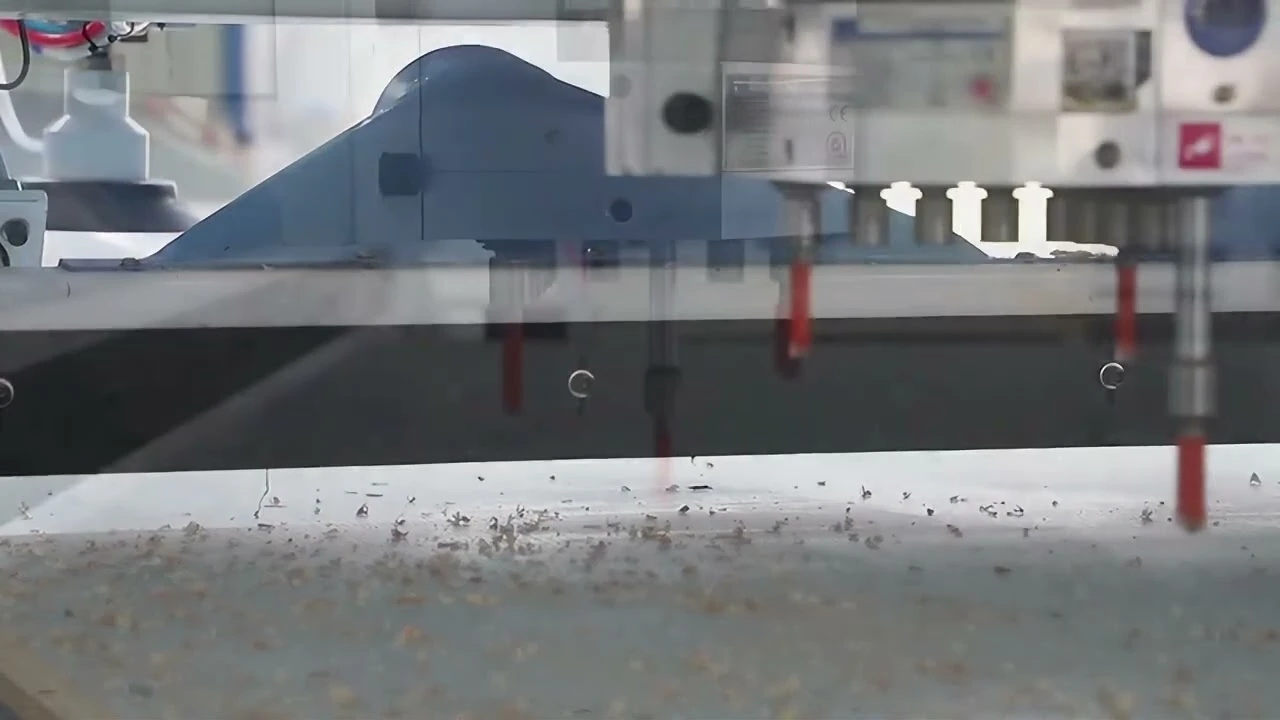

- Carousel tool changer

Fast tool change speed, compact structure, does not affect the maximum processing height.

- Vacuum adsorption workbench

The wood board to be processed is automatically fixed on the workbench, easy to use.

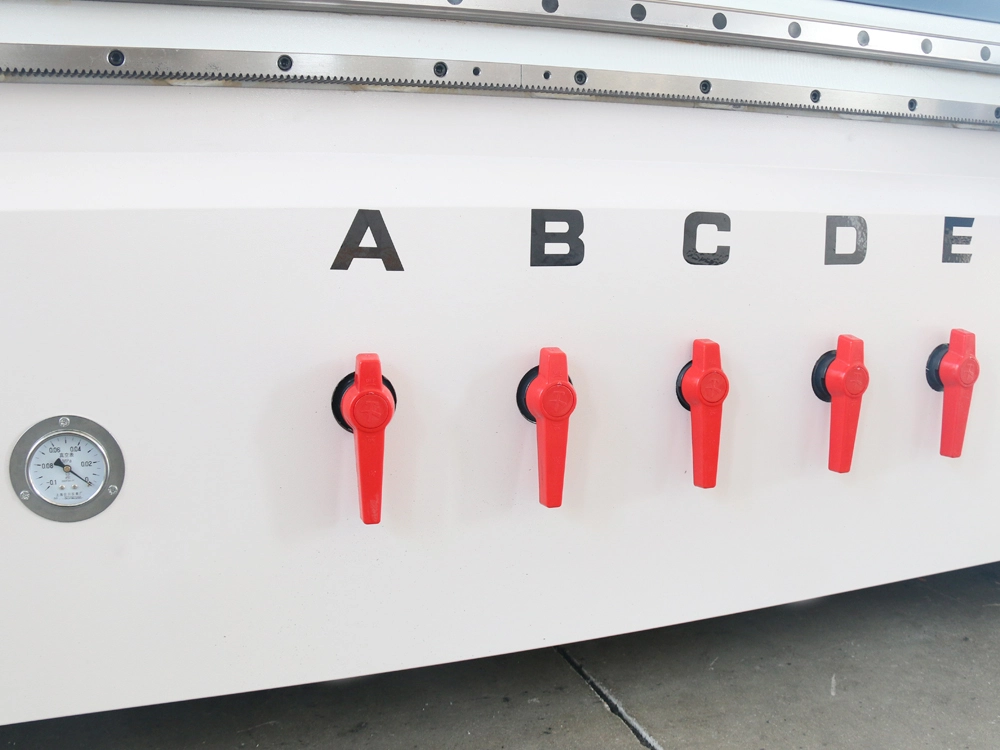

- Vacuum adsorption zone control valve

This valve group can control the opening and closing of each air hole on the vacuum adsorption workbench.

- Clamping device for separating the tool and the holder

When separating the blade from the knife holder, this device can be used to clamp the knife holder to facilitate removal of the blade.

- Automatic lubrication oil pot

The lubrication interval and lubrication duration can be set, and the oil pot will automatically lubricate the transmission parts according to the settings.

- 4+2 positioning cylinder

Accurately position and fix the full-size board.

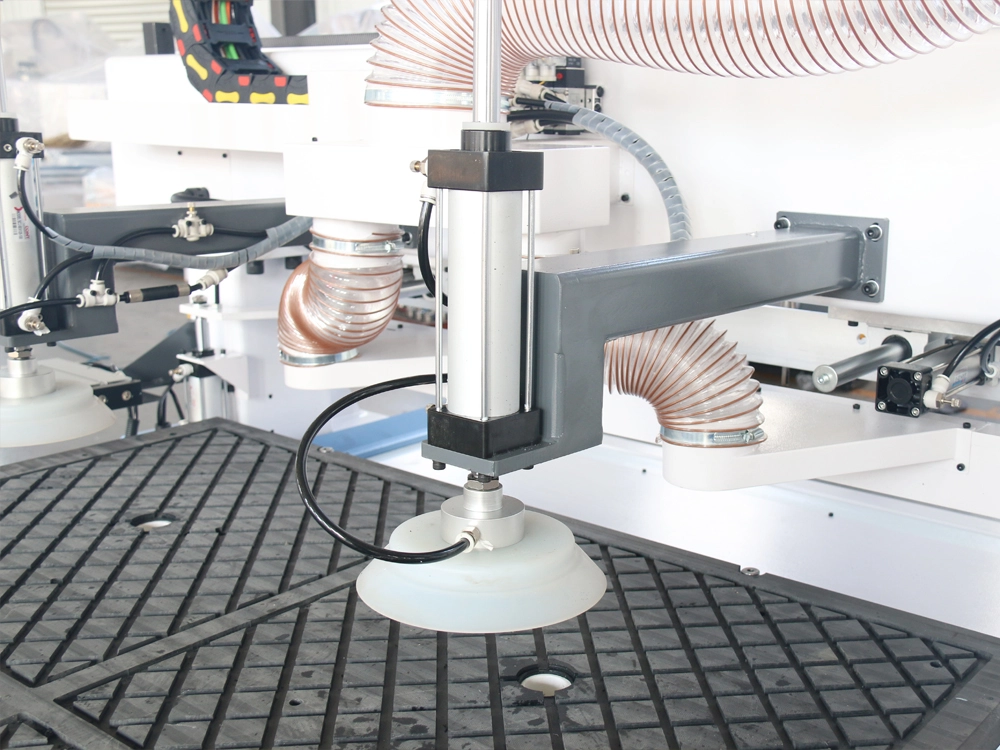

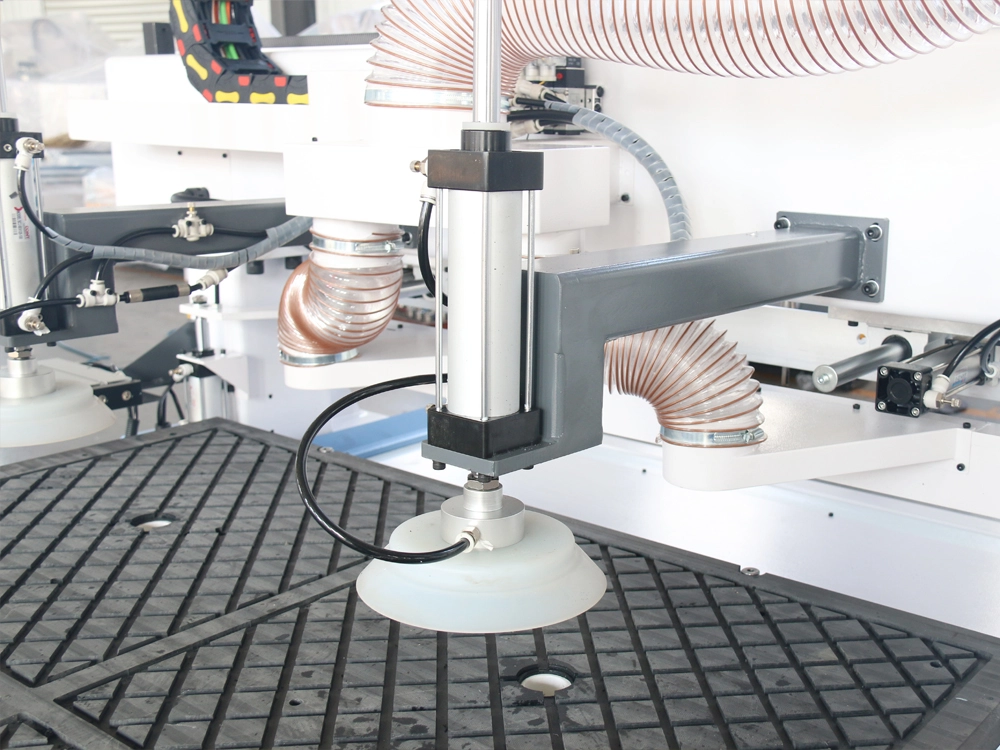

- Transport suction cup

The double suction cups can firmly absorb the plate through the loading platform and place the plate at the designated position on the workbench.

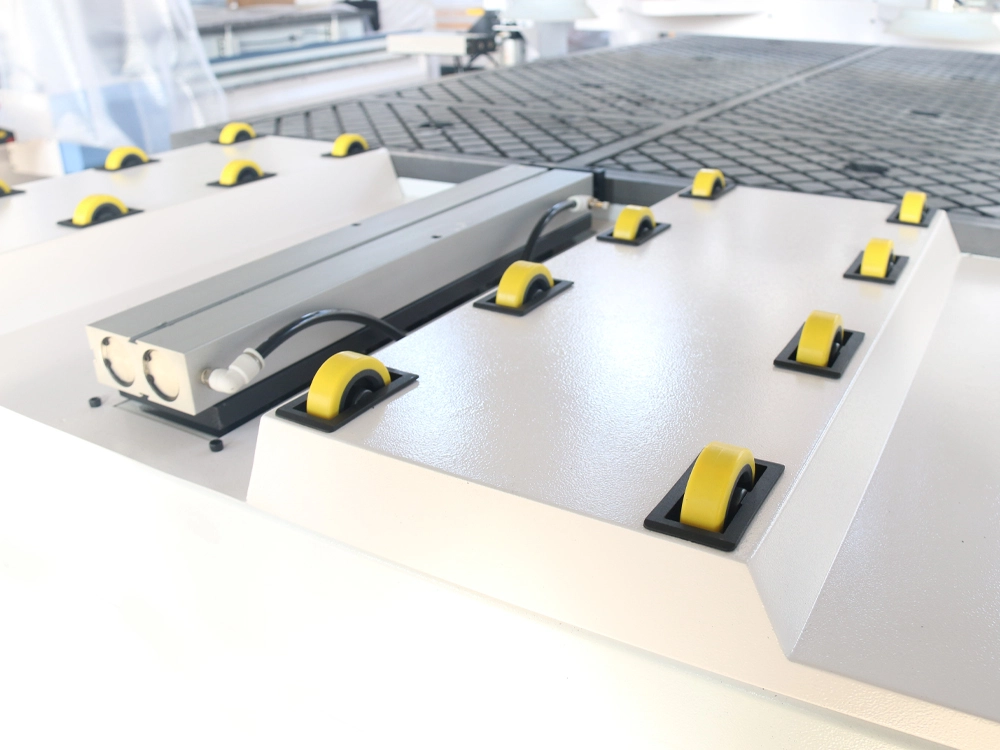

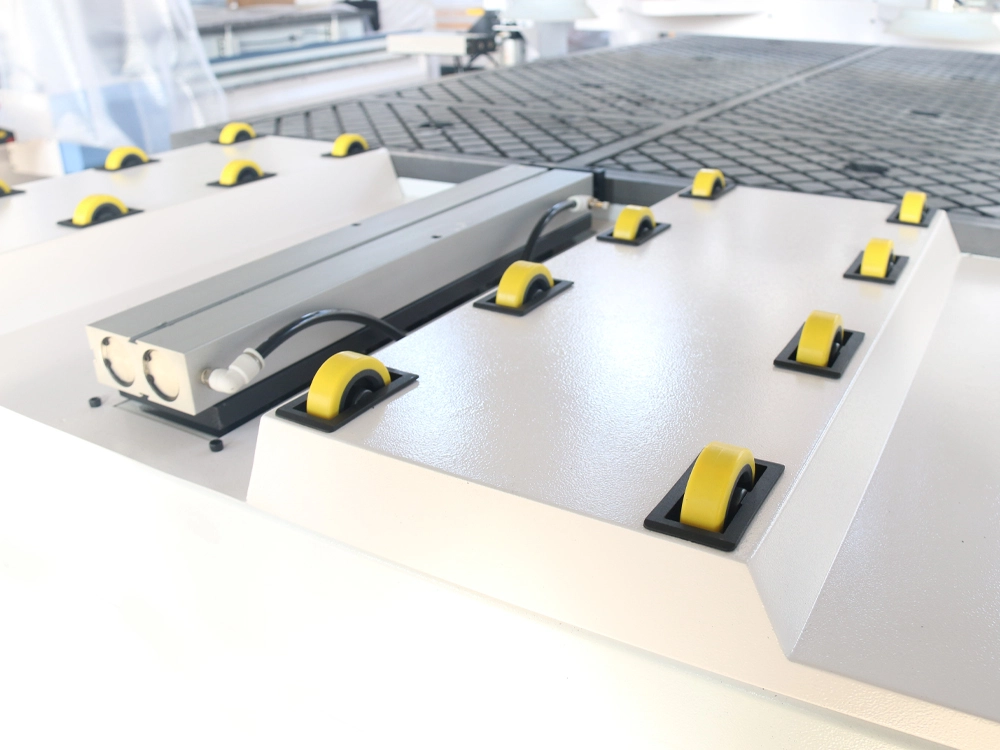

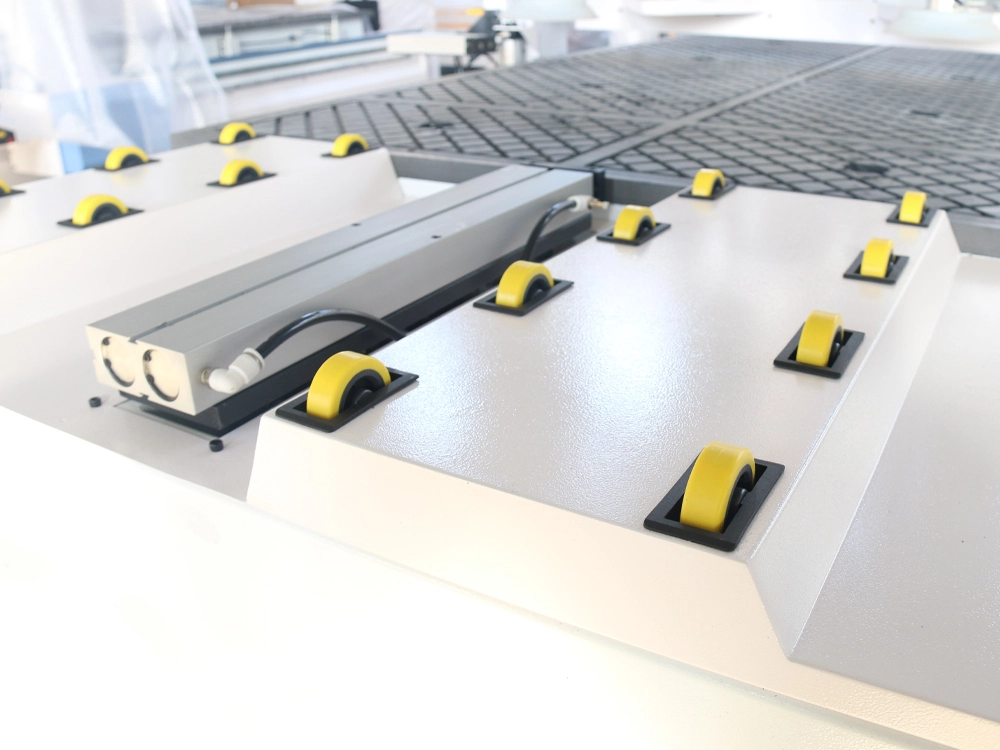

- Feeding roller

Reduce the static friction between the board and the tabletop, make loading easier, and avoid board wear.

- Automatic loading platform

Automatically load wooden boards and automatically raise and lower the height with infrared sensors.

- Automatic unloading platform

A conveyor belt unloading platform that can automatically transfer the processed workpieces.

Carousel ATC CNC Router With Automatic Loading & Unloading Technical Parameters

| Model | CK-1325-AT |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Bed | Independent anti-interference control cabinet for machining center bed (heavy duty bed) |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 6/8/10/12 carousel tool magazine |

| Table | Vacuum table 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4600kg |

| Dimensions | 9850*2150*2200mm |

Optional Accessories for ATC CNC Router With Automatic Loading & Unloading Technical

| Spindle | Italian HSD spindle/Italian HITECO spindle |

| Control System | Syntec/NCStudio/Mach3 etc. |

| Saw Blades | The saw knife can be rotated to cut the board |

| 5+4 Pneumatic Drilling Kit | HQD 5+4 Pneumatic Drilling Kit/CNC side milling angle head |

| Pressure Roller | Double rod independent pneumatic pressure rollers can be individually controlled to fix the plate |

| Labeling Machine | Fully automatic printing, typesetting and labeling machine |

| Tool Changing Method | Linear tool changer (8/12/16) |

Application Scope of Carousel ATC CNC Router With Automatic Loading & Unloading

Cabinets, wardrobes, tables, chairs, bookshelves, beds, bedside tables, office furniture, display cabinets, antique furniture, rosewood furniture, classical furniture, European-style furniture, bathroom cabinets, solid wood doors, paint-free doors, craft wooden doors, screens, craft windows, computer desks, conference tables, file cabinets, sewing machine tables, game console cabinets, bowling lanes, train interior panels, mattresses, protective packaging materials, 3D wave boards, artistic reliefs, openwork screens, mural carvings, relief ornaments, openwork pendants, wooden models, gift packaging boxes, wooden/acrylic signs, illuminated signs, advertising display boards, PVC cut letters, guitar panels, piano casings, speaker cabinets, composite doors, cabinet doors, partition grilles, electrical cabinet panels, instrument casings, hardware parts, carbon fiber composites, antique shelves, mini illuminated signs, acrylic high-gloss engraving, and batch production of signs.

The Following Are the Processable Products of Carousel ATC CNC Router With Automatic Loading & Unloading

| Model | CK-1325-AT |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Bed | Independent anti-interference control cabinet for machining center bed (heavy duty bed) |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 6/8/10/12 carousel tool magazine |

| Table | Vacuum table 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Syntec / NCStudio / Mach3 |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4600kg |

| Dimensions | 9850*2150*2200mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.