4x9ft Linear ATC CNC Wood Router With Pressure Rollers and Five-Axis Saw Blade

4x9ft Linear ATC CNC Wood Router for Plate Machining and Fast Cutting

[Function Description]

The CK-1328-TS CNC router is designed for efficient wood board cutting. A five-axis saw blade cutting device that can be used for efficient cutting of boards is additionally installed on the standard CNC router with automatic tool changer. The automatic tool changer is equipped with 12 tools at a time, which can be used for various cutting, engraving, milling, grooving and other work scenarios. The tool can be automatically changed during multiple process processing to improve production and processing efficiency, and the five-axis saw blade cutting device can be used for efficient cutting of various boards, whether it is the commonly used MDF board, plywood, multi-layer board, or gypsum board, aluminum-plastic board, it can easily cope with it. When cutting, due to the difference between the saw blade and the milling cutter, the saw blade can cut multiple layers of board at a time. Compared with cutting with a milling cutter, the saw blade cutting can cut various boards at a speed of more than two to three times, and the cutting speed can reach 30,000 mm/min, which is far superior to the traditional milling cutter cutting. It can cut multiple layers at a time with completely consistent cutting accuracy and extremely high cutting efficiency, which can greatly improve processing efficiency and save costs.

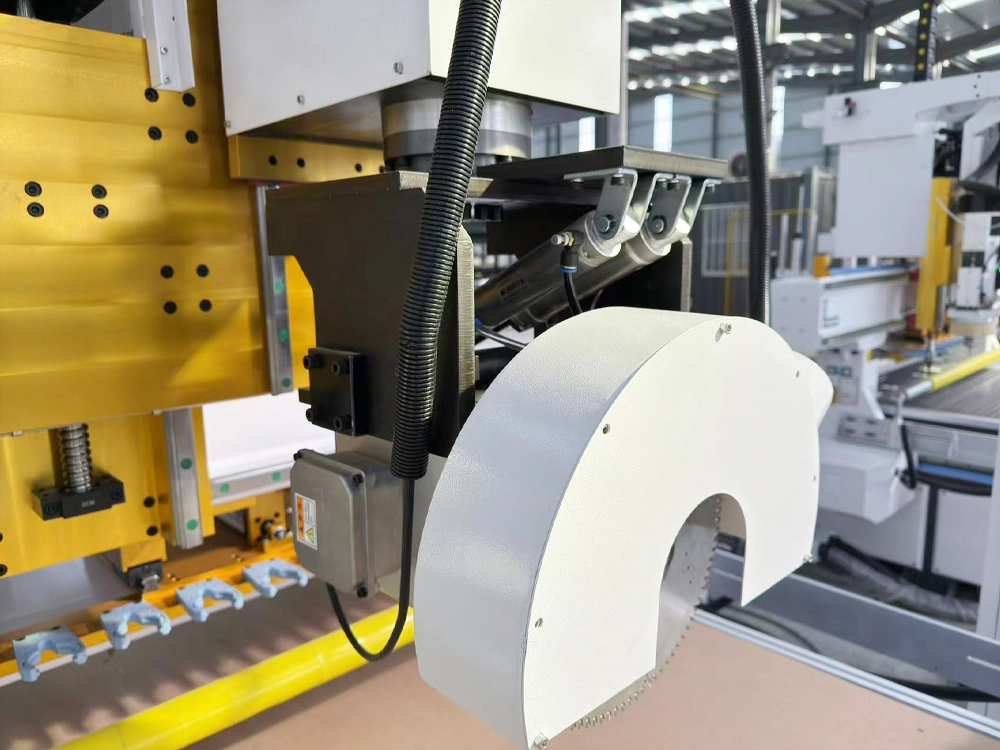

What Is a Five-Axis Saw Blade Cutting Device

The five-axis saw blade cutting device is specially designed for plate cutting. It can efficiently cut various plates, such as wood boards, mdf boards, gypsum boards, acrylic boards, etc. It uses a 300mm diameter alloy saw blade, a 5.5KW high-power high-speed motor drive, a speed of 18000r/min, and a maximum thickness of 130mm that can be cut at one time. The saw blade is controlled by a five-axis system. The A axis can rotate 360 degrees for cutting, and the C axis can rotate 45 degrees for cutting bevels. The saw blade's lifting, feed speed and angle adjustment are controlled by the CNC system to achieve precise cutting. It can cut 1-6 plates at a time. By working with the nesting software, it can greatly optimize the layout and reduce material waste. The material utilization rate can be increased by more than 8%, which greatly reduces production costs and improves processing efficiency. It is very suitable for the production of various cabinets, wardrobes, wooden doors, building templates and other products.

The Advantages of a ATC CNC Router With Five Axis Saw Blade

- Equipped with a 1300*2800mm (4*9 feet) vacuum adsorption workbench, using a 7.5KW water ring vacuum pump, with super suction force, it can adsorb multiple plates at a time, ensuring the fixation of the plates during processing, preventing the plates from shifting during processing, and easy to use.

- Use 9KW HQD high-power high-speed air-cooled automatic tool-changing spindle, the speed can reach 24000r/m, use ISO30 tool holder, ER32 tool holder, the maximum clamping diameter of the tool holder is 20mm.

- Standardly equipped with 12 linear automatic tool change magazines, 12 different tools can be installed at a time. During processing, the tools can be automatically changed according to the processing requirements of the drawing to improve processing efficiency.

- The saw blade uses a 300mm diameter alloy blade saw blade, driven by a 5.5KW high-speed motor with a rotation speed of 18000r/m. The angle rotation adjustment is controlled by a servo motor. It can rotate 360 °degrees horizontally and tilt 45 degrees. It can be used for 90-degree vertical cutting and 45-degree bevel cutting.

- The drive motor uses a Leadshine 1500W servo motor, the Z-axis uses a servo motor with a brake, and is equipped with a Japanese Shinpo planetary gear reducer. The machine's idling speed can reach 100,000 mm/min, and the fastest processing speed can reach 30,000 mm/min, which is far higher than ordinary CNC routers, and the processing efficiency is increased by more than 3 times.

- Since the Z-axis needs to carry a 9KW automatic tool change spindle and a 5.5KW saw blade motor at the same time, the load is larger than that of ordinary engraving machines. We specially thickened the Z-axis hanging plate to 75mm and used the whole anodized aluminum alloy material, which is lighter and effectively ensures that the machine can be used for a long time and prevents the hanging plate from deformation.

- The control system uses Taiwan LNC numerical control system, which can support various nesting software and is also compatible with various CAD/CAM type software. It is simple to use and very easy to get started.

- 11KW Fuling inverter has stable speed control, fast starting speed, minimal speed fluctuation, can adapt to various working environments, and can work continuously for 24 hours.

- The motion system of the XYZ axis uses 30mm Taiwan Hiwin linear guides and 30mm linear bearings. The transmission system XY axis uses YYC 2M helical racks and gears imported from Taiwan. The Z axis uses Taiwan TBI 3210 ball screw. The positioning accuracy can reach ±0.02mm. The processing accuracy is extremely high and can meet various high-precision processing tasks.

- Equipped with 5.5KW high-power dust collector, which automatically collects dust during processing to prevent dust from spreading and polluting the working environment.

- The bed is made of 8MM thick steel plate and heavy-duty thickened bed after quenching and sandblasting to ensure the stability of the machine when running at high speed, and to ensure the service life and processing accuracy of the machine.

- Aluminum alloy T-slot strips and positioning cylinders can be used as positioning cylinders, or the T-slot can be used alone to fix materials. It is multifunctional and more flexible.

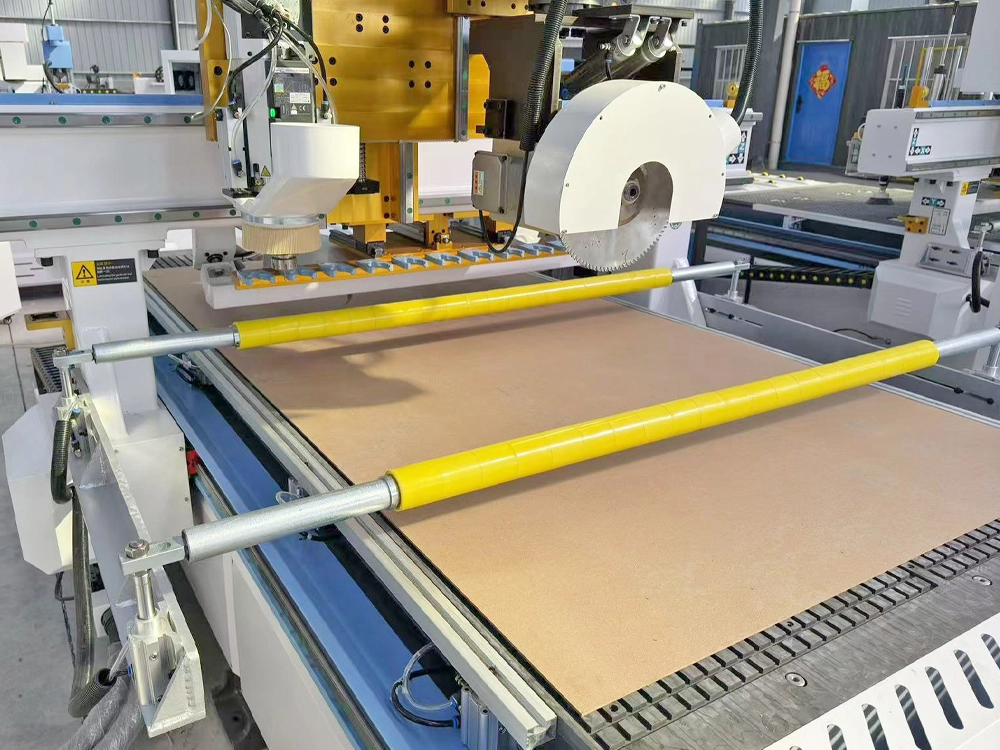

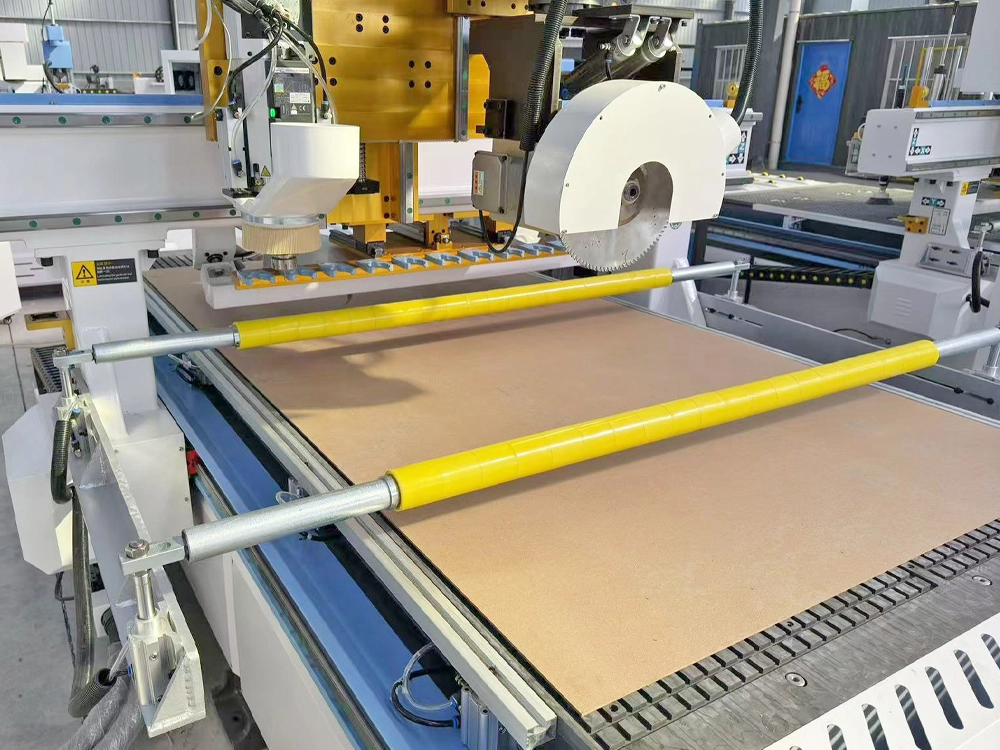

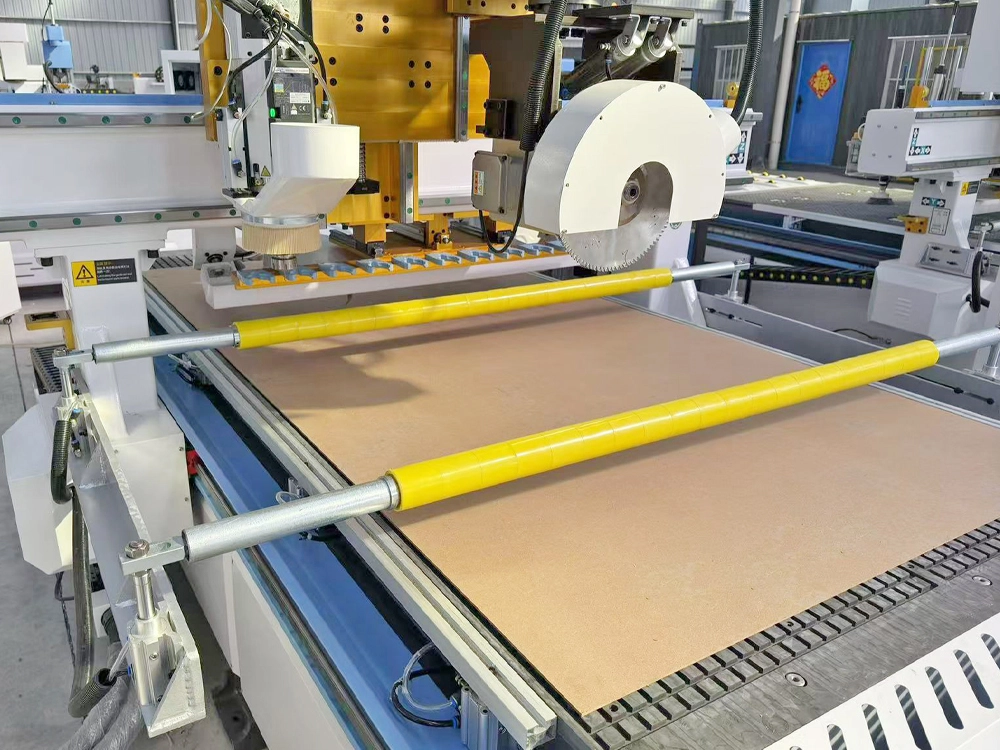

- A double-rod pneumatic pressure roller is installed at the same time, which can be used in conjunction with the vacuum adsorption workbench, or the pressure roller can be used alone to fix the material, which is more convenient for fixing the material.

- Fully automatic electric lubricating oil pot automatically lubricates the transmission parts of the machine during use, without manual maintenance, extending the service life of the machine.

- The spindle can use an automatic tool setter. Since the lengths of the tools installed in the linear tool magazine are not uniform, the spindle can automatically use the tool setter to calibrate the Z-axis height after automatic tool change, which is more convenient to use.

- The machine has complete functions. It can process the installation grooves required for invisible parts in various furniture. It can also be used to process the installation holes of various two-in-one and three-in-one connectors, Lock and Lock invisible parts, etc. It can quickly drill, groove, cut, chamfer, mill, engrave, etc. to meet the processing needs of various products.

Details of CNC Router with Automatic Tool Changer and Saw Blade

- Automatic tool changing spindle

-

9KW automatic tool changing air cooling spindle, speed 24000r/m, can automatically change different tools to process various materials.

- Linear tool change magazine

-

Can hold 12 tools at a time, automatically changing different tools according to different processes during processing, without manual tool change.

- Five-axis saw blade cutting device

-

Driven by a 5.5kw motor, can rotate 360° degrees horizontally and tilt 45 degrees, can cut a variety of different materials, and cut multiple layers at a time.

- Double-rod pneumatic pressure roller

-

The cylinder controls the automatic lifting and lowering, which can press multiple layers of materials at one time and is easy to use.

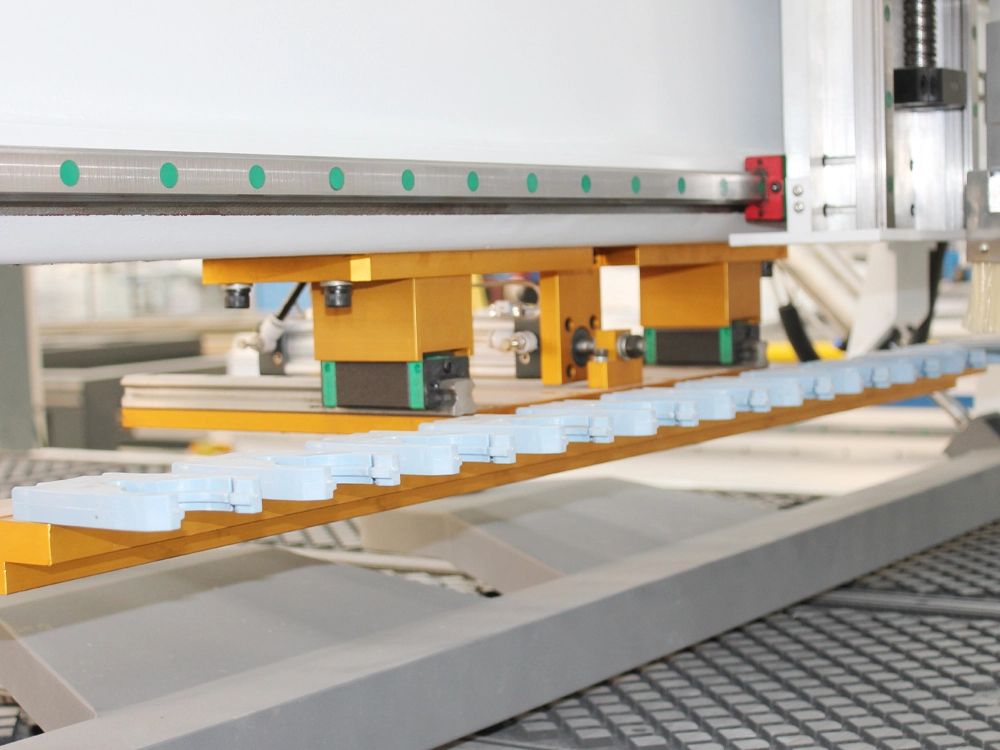

- Vacuum adsorption worktable

-

Equipped with 7.5KW water ring vacuum pump, 6 zones, 24 holes design, can adsorb workpieces of various sizes.

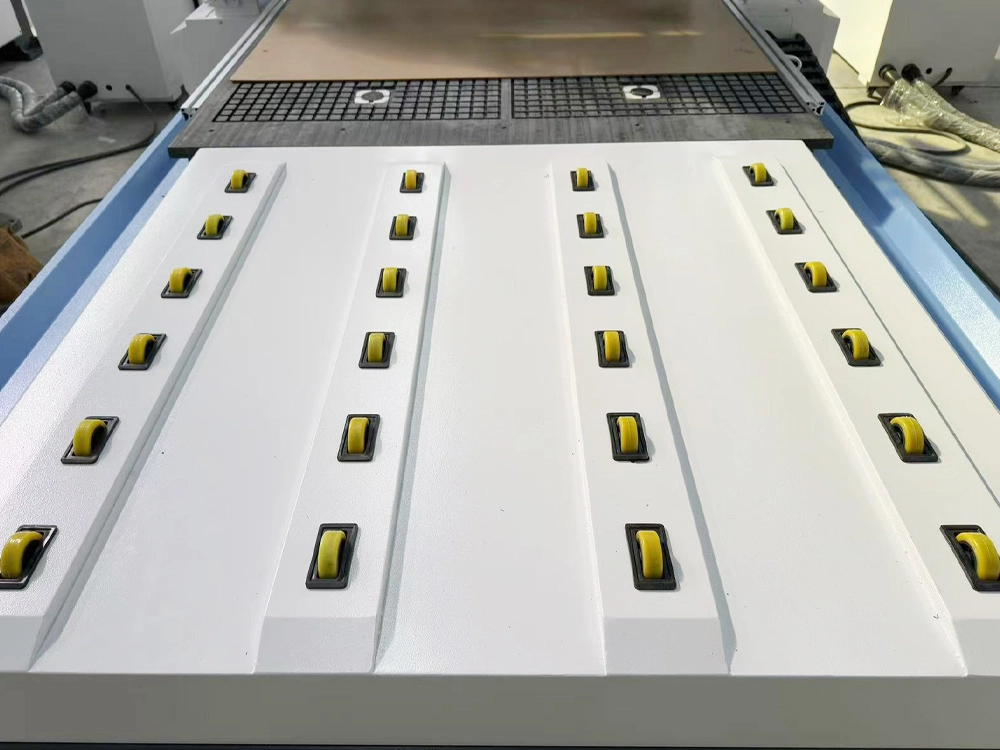

- Loading pulley

-

Four rows of loading pulleys are provided at the tail of the machine, making loading more labor-saving.

- High-precision helical rack/gear

-

Fast running speed, higher processing efficiency and more accurate positioning, equipped with rack protection cover to extend service life.

- Vacuum adsorption zone switch

-

Each zone of the vacuum adsorption workbench can be opened and closed independently, and can be freely controlled according to the size of the raw materials, which is flexible to use.

- Warranty: All machines enjoy a 3-year free warranty, and damaged parts will be repaired or replaced with new parts free of charge within three years.

- Out of warranty: After the machine is used for three years and out of warranty, we will provide you with new machine parts at cost price.

- Usage teaching: After you purchase the product, we will send you the user manual, operation video, installation video, maintenance video and software of the machine.

- We provide 7*24 hours of engineer online service, supporting communication methods such as email, telephone, video call, etc.

- If you need, we can provide you with engineer on-site installation teaching.

- We welcome you to come to the factory to study, and we can provide you with free course training.

Technical Parameters of ATC CNC Router with Five Axis Saw Blade Cutting Device

| Model | CK-1328-TS |

|---|---|

| Working Size | 1300*2800*200mm (processing size can be customized) |

| Spindle | 9KW HQD high speed air-cooled automatic tool change spindle |

| Spindle Speed | 0-24000r/min |

| Saw Blade Angle | Horizontal 360° rotation / 45° tilt |

| Saw Blade Motor | 5.5KW high speed rotating motor |

| Saw Blade Speed | 0-18000r/min |

| Spindle Hanging Plate | 75mm thick overall oxidation treated aluminum alloy hanging plate |

| Tool Magazine | 12 tool change linear tool magazine (support 8-16 tool customization) |

| Servo Motor | Leadshine 1500W servo motor / servo driver |

| Control System | Taiwan LNC control system |

| Frequency Converter | Fuling 11KW high torque inverter |

| Guideway | 30mm Taiwan Hiwin linear guide / linear bearing |

| Rack | Taiwan YYC 2M rack |

| Z-Axis Screw | Taiwan TBI 3210 ball screw |

| Positioning | 3+2 positioning cylinder |

| Pushing Function | Double cylinder automatic push |

| Bed Structure | 8MM thickened steel plate quenching and sandblasting heavy bed |

| Vacuum Pump | 7.5KW water ring vacuum pump |

| Dust Collection Device | 5.5KW high power dust collector |

| Tool Setting Method | Automatic tool setter |

| Max. Rapid Traverse Speed | 100000mm/min |

| Max. Working Speed | 30000mm/min |

| Control Cabinet | Independent anti-interference control cabinet |

| Electrical Components | Chint electric |

| Machine Voltage | 380V/3PH 220V/3PH |

| Dimensions | 3800*2200*2150mm |

| Weight | 2800kg |

What Can a ATC CNC Wood Router with Saw Blade Process?

Suitable Materials Include:

Density board, particle board, oriented strand board (OSB), multi-layer board, plywood, solid wood, gypsum board, PVC board, PCB board, aluminum composite panel, melamine board, foam board, and rubber board.

Applied Products:

MDF, wardrobes, cabinets, office furniture, computer desks, tatami, TV cabinets, bedside tables, wine cabinets, bookcases, floors, wall panels, wooden boxes, wooden pallets, bathroom cabinets, furniture, ceilings, wooden doors, door panels, door frames and other products.

Service and Support for ATC CNC Router with Saw Blade

| Model | CK-1328-TS |

|---|---|

| Working Size | 1300*2800*200mm (processing size can be customized) |

| Spindle | 9KW HQD high speed air-cooled automatic tool change spindle |

| Spindle Speed | 0-24000r/min |

| Saw Blade Angle | Horizontal 360° rotation / 45° tilt |

| Saw Blade Motor | 5.5KW high speed rotating motor |

| Saw Blade Speed | 0-18000r/min |

| Spindle Hanging Plate | 75mm thick overall oxidation treated aluminum alloy hanging plate |

| Tool Magazine | 12 tool change linear tool magazine (support 8-16 tool customization) |

| Servo Motor | Leadshine 1500W servo motor / servo driver |

| Control System | Taiwan LNC control system |

| Frequency Converter | Fuling 11KW high torque inverter |

| Guideway | 30mm Taiwan Hiwin linear guide / linear bearing |

| Rack | Taiwan YYC 2M rack |

| Z-Axis Screw | Taiwan TBI 3210 ball screw |

| Positioning | 3+2 positioning cylinder |

| Pushing Function | Double cylinder automatic push |

| Bed Structure | 8MM thickened steel plate quenching and sandblasting heavy bed |

| Vacuum Pump | 7.5KW water ring vacuum pump |

| Dust Collection Device | 5.5KW high power dust collector |

| Tool Setting Method | Automatic tool setter |

| Max. Rapid Traverse Speed | 100000mm/min |

| Max. Working Speed | 30000mm/min |

| Control Cabinet | Independent anti-interference control cabinet |

| Electrical Components | Chint electric |

| Machine Voltage | 380V/3PH 220V/3PH |

| Dimensions | 3800*2200*2150mm |

| Weight | 2800kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.