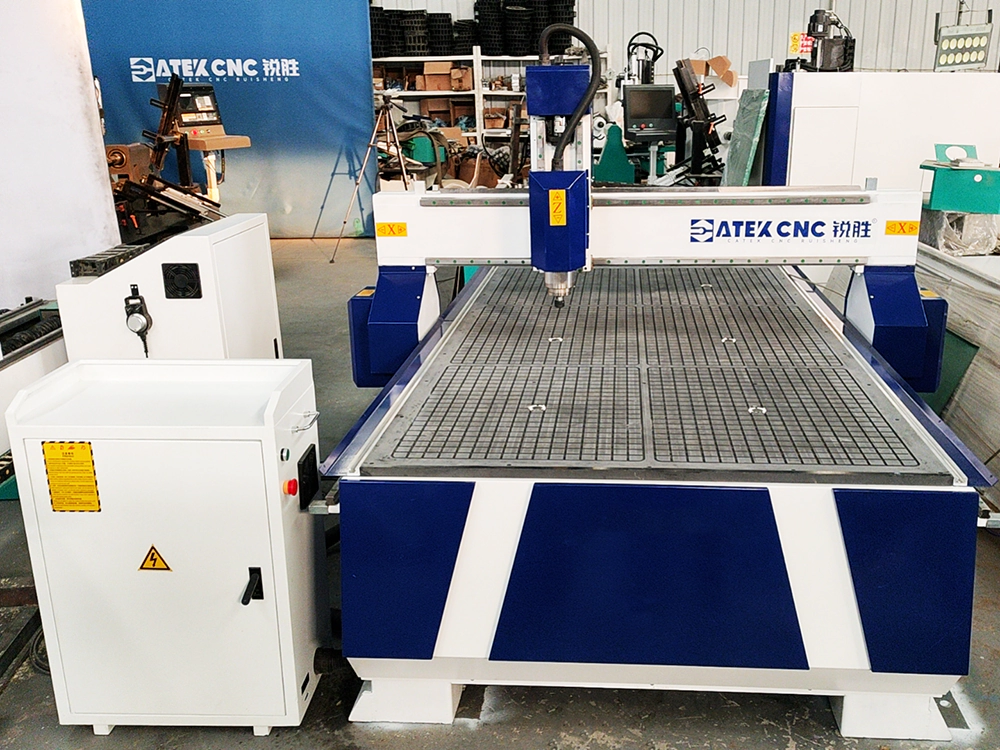

Low Price Entry-Level 4'x8' CNC Wood Router For Sale

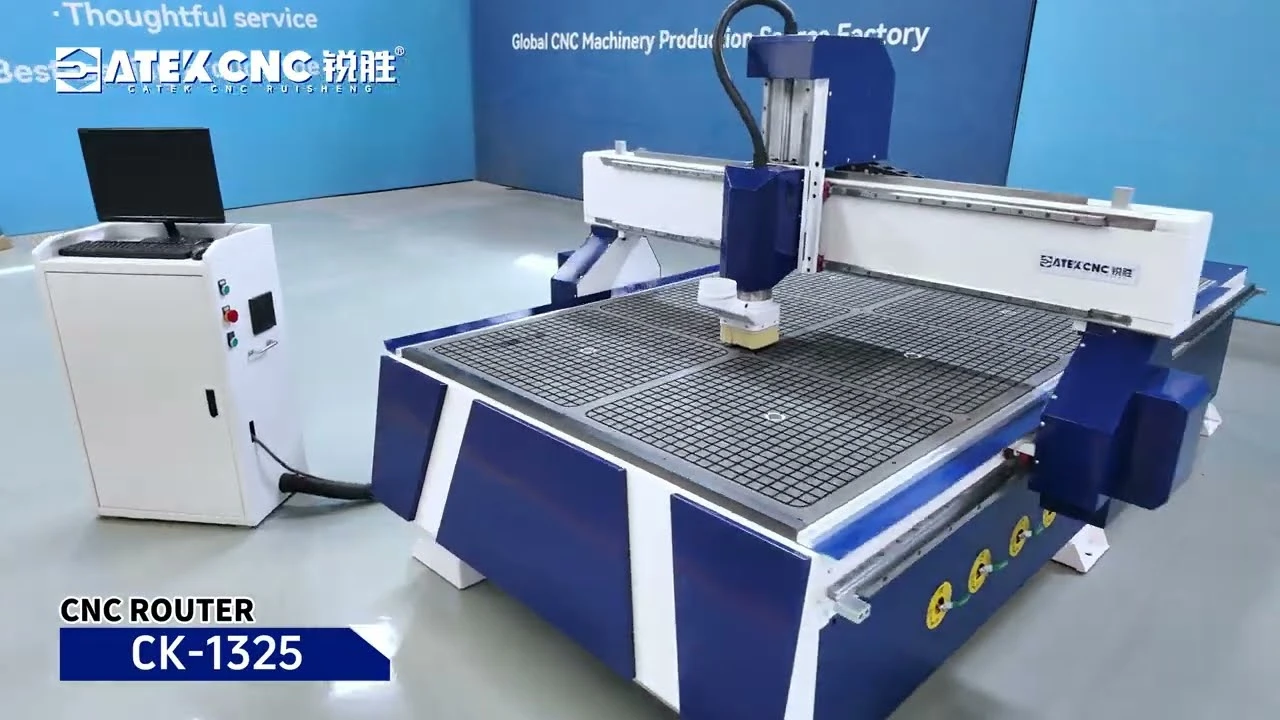

Entry-Level 4x8 feet 1325 CNC Wood Router Machine for Hobby

[Function Description]

Why Is the 4x8 CNC Router the Most Popular CNC Wood Router for Beginners?

- Wide range of applications: widely used in woodworking, advertising, furniture, handicrafts and other industries, and can also be used in stone and metal industries by selecting a sink.

- Large processing size: The standard workbench size is 1300*2500mm (4*8 feet), which means you can directly process various large plates without cutting the plates in advance.

- High processing accuracy: CNC engraving machines have extremely high processing accuracy, which ensures the consistency of processing the same products, which is very important for batch processing.

- High speed and efficiency: Fully automatic processing, fast moving speed, high processing speed effectively improves production efficiency and saves labor.

- Versatility: By installing different tools on the spindle, engraving, cutting, drilling, grooving, etc. can be performed.

- Easy to use: Using the English operating system and friendly interface, even novices who have never been exposed to CNC can easily get started.

- Low price: The price of a 4*8 CNC router starts at only US$2,000, which is cheap and affordable. The subsequent maintenance is also very simple and low-cost.

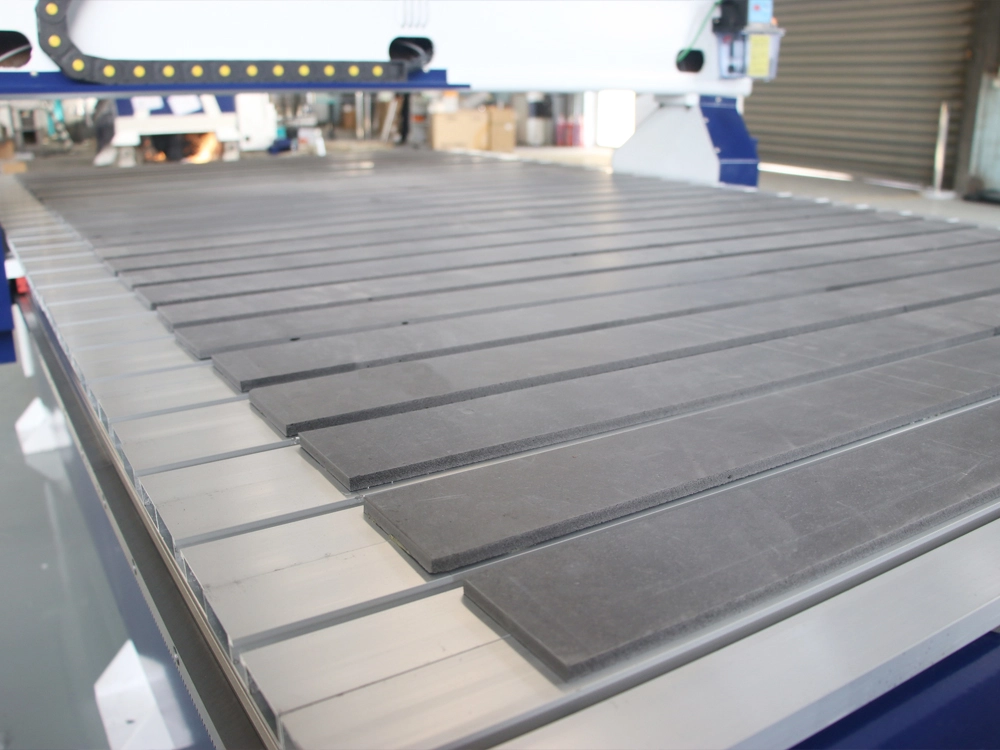

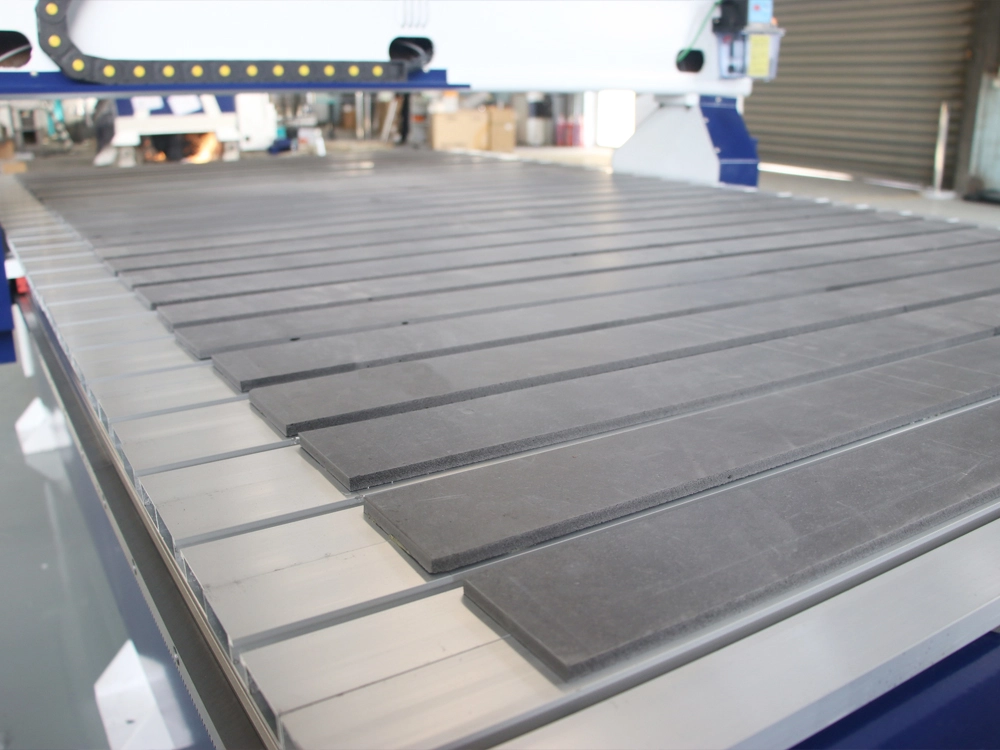

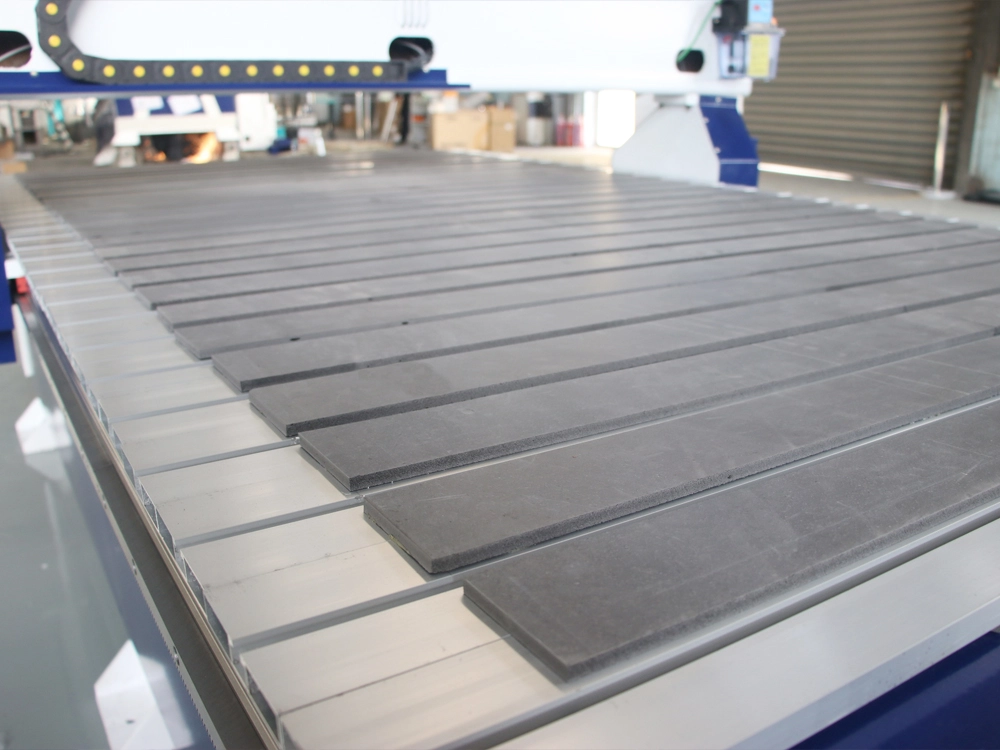

What Is a T-slot Workbench?

The 4x8 CNC router uses an aluminum alloy T-slot workbench to fix the workpiece. The workbench is made of high-strength aluminum alloy, and the surface is oxidized. It has the characteristics of corrosion resistance, wear resistance and high precision. The aluminum alloy material is light in weight, high in strength, and has a flat surface. It will not deform after long-term use. The surface of the workbench is processed with multiple T-shaped structural grooves. These grooves are used to fix the hold-down clamp. Use the clamp to press the wooden board on the table, and then tighten the screws of the clamp to firmly fix the workpiece on the workbench, ensuring the stability of the workpiece during processing and preventing it from moving during processing.

Advantages of 4*8 CNC Wood Engraving Machine

- We can provide you with fully customized diversified customization, including processing size, servo motor, automatic tool change spindle, work platform, control system, and even machine color.

- Simple operation, the CNC wood engraving machine runs through G code control, supports various cad, cam type software such as AUTOCAD, POWERMILL, ARTCAM, etc., just simple settings, import the drawings into the machine through the U disk to start processing.

- Optional dust collection system to reduce wood chips and dust pollution and improve the quality of the working environment.

- Use 3.5KW water-cooled spindle, supporting water circulation cooling system, lower running noise, can work continuously for 24 hours (optional air-cooled spindle).

- Reasonable structural design, easy maintenance and maintenance, low maintenance cost, provide free training and technical support services, reduce the cost of use.

- Use advanced CNC control system, support breakpoint resume engraving function, even if the machine stops due to an emergency, it can continue processing when it is turned on again.

- The designed bed base has good rigidity, is not easy to deform, has large load-bearing capacity, and has a service life of more than 10 years.

Details of 4x8 CNC Wood Engraving Machine

- Bed and gantry

-

The gantry bracket that has been treated with high temperature and the bed processed by five-sided gantry milling have high precision and can be used for more than 30 years without deformation.

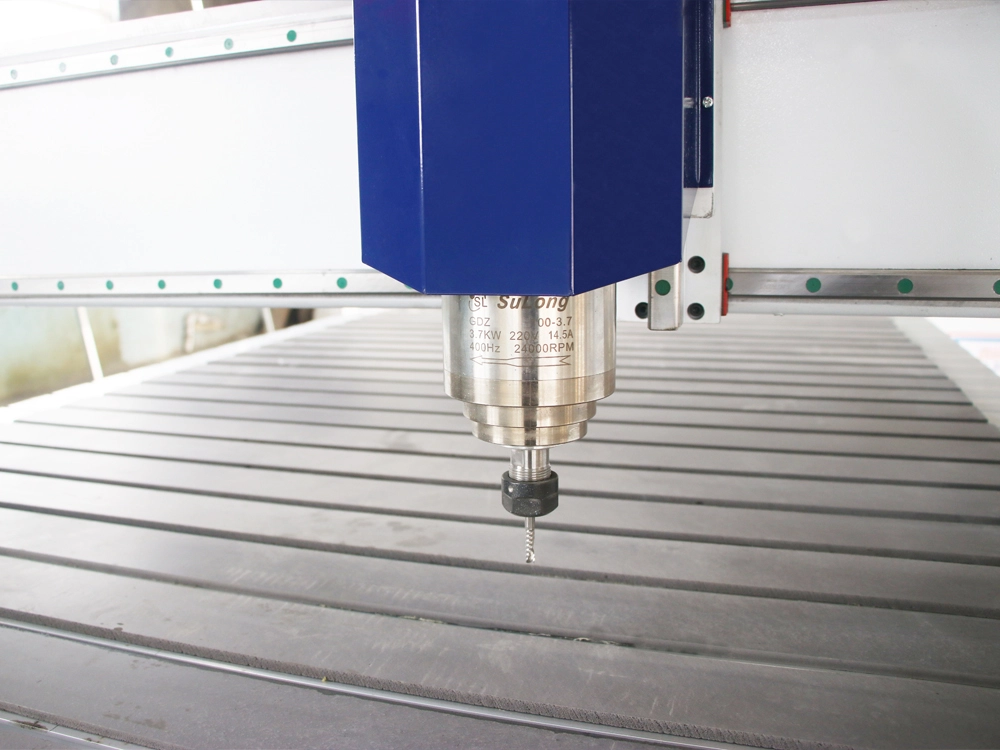

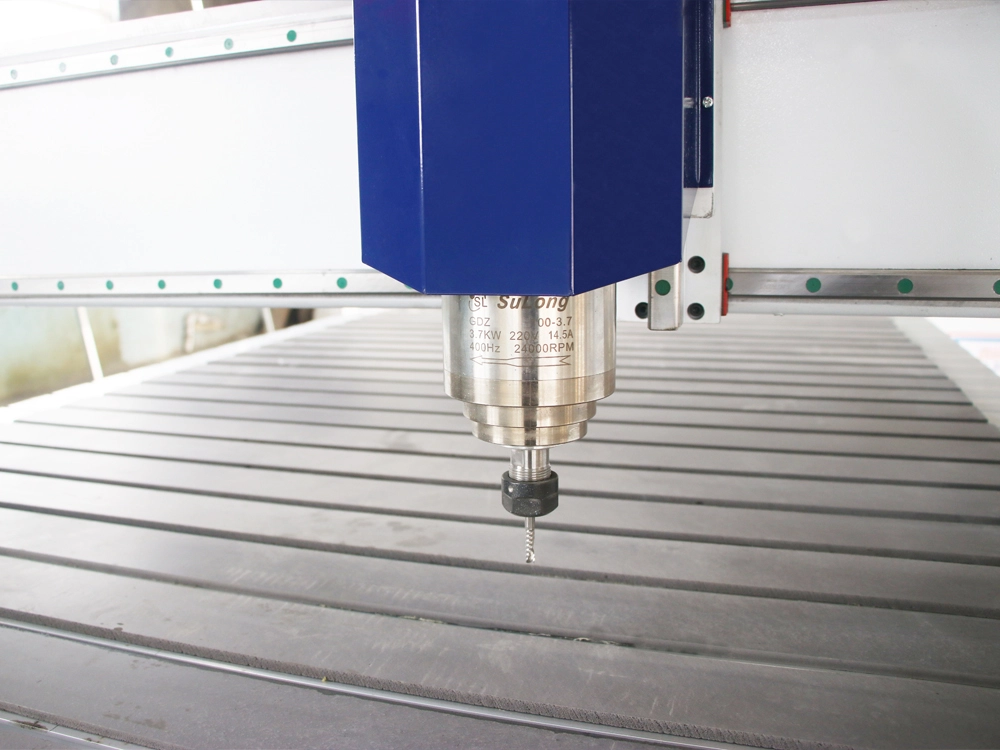

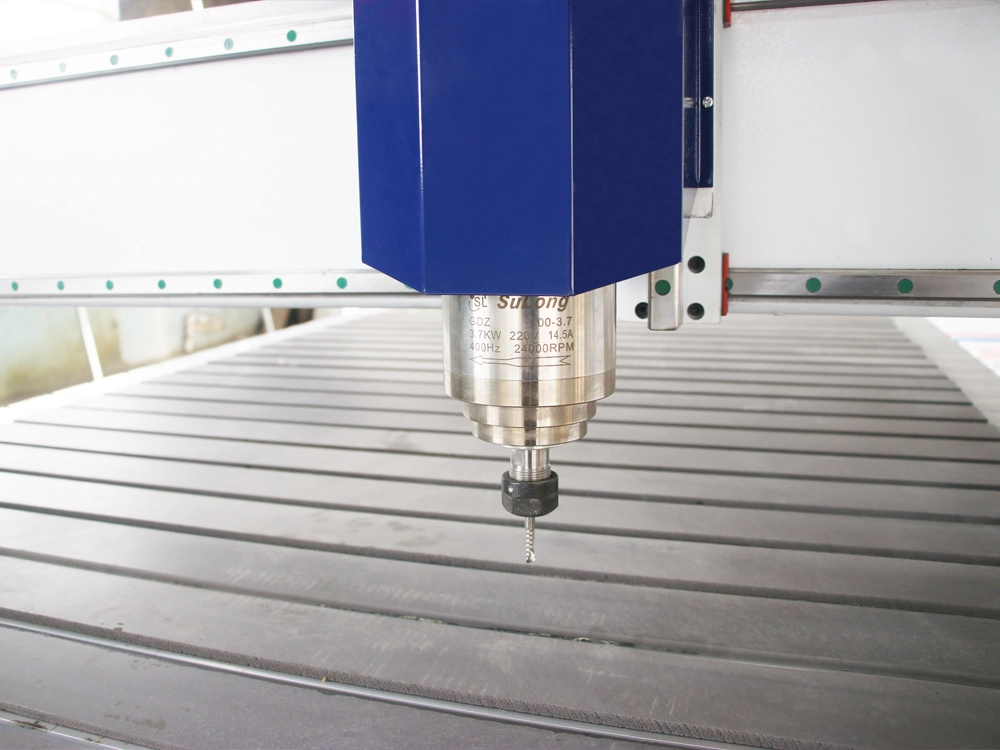

- Water-cooled spindle

-

3.5KW high-power water-cooled spindle, better heat dissipation performance, lower noise, and maximum speed of 24000rpm.

- Aluminum alloy T-slot workbench

-

The high-strength aluminum alloy T-slot platform is covered with a hard PVC plate to prevent damage to the tabletop. The workpiece can be fixed arbitrarily regardless of its shape by using a hold-down clamp.

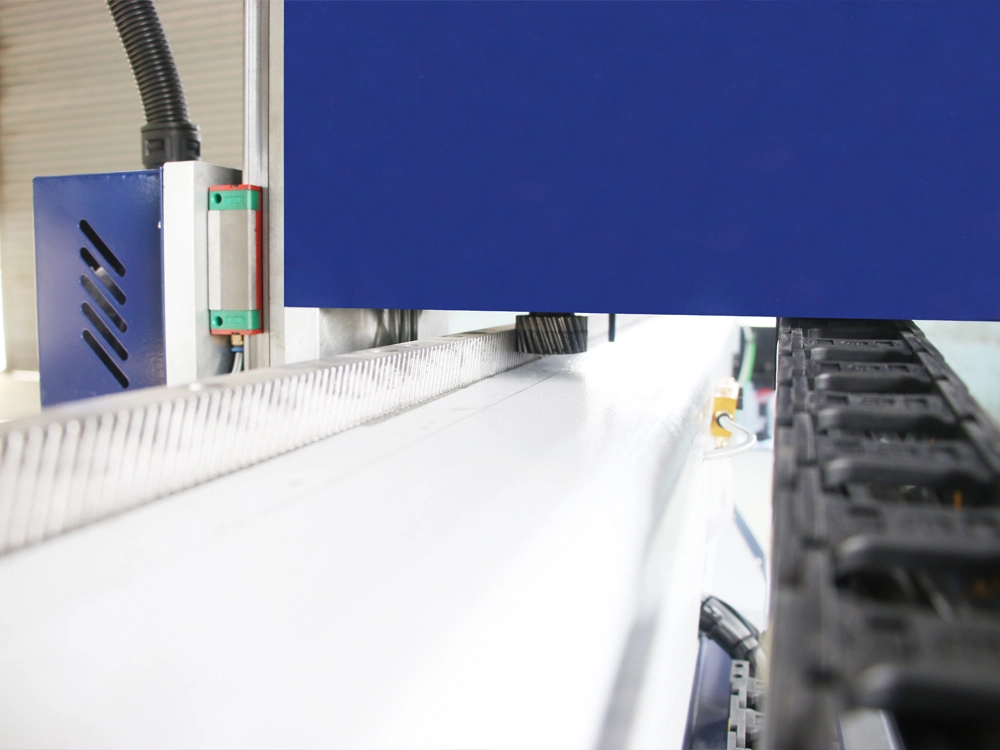

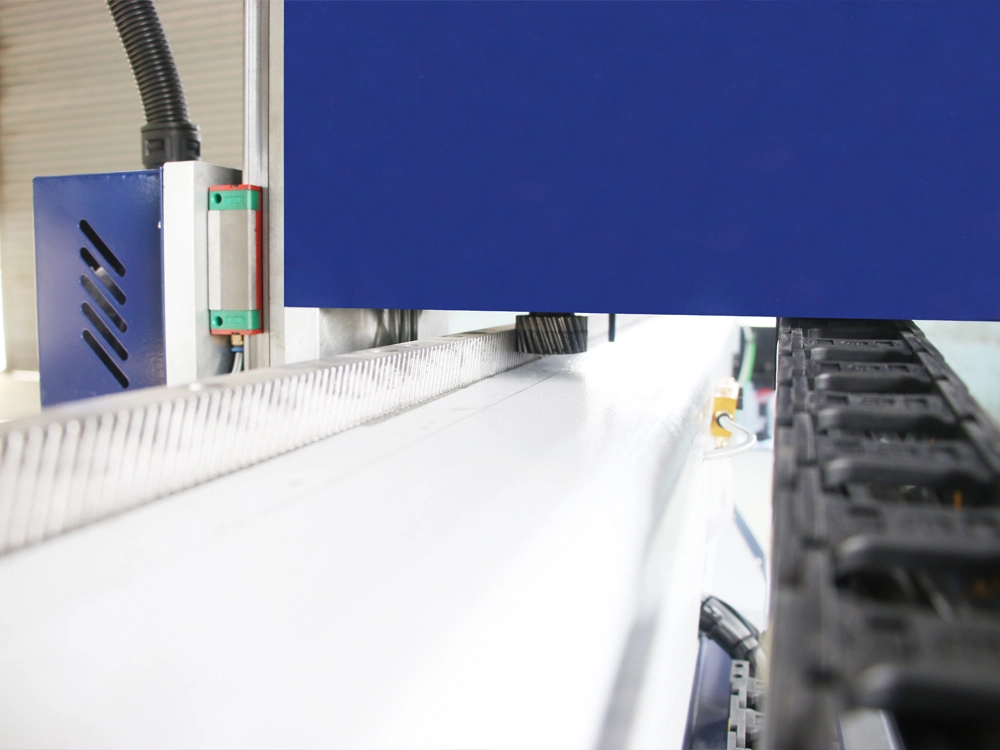

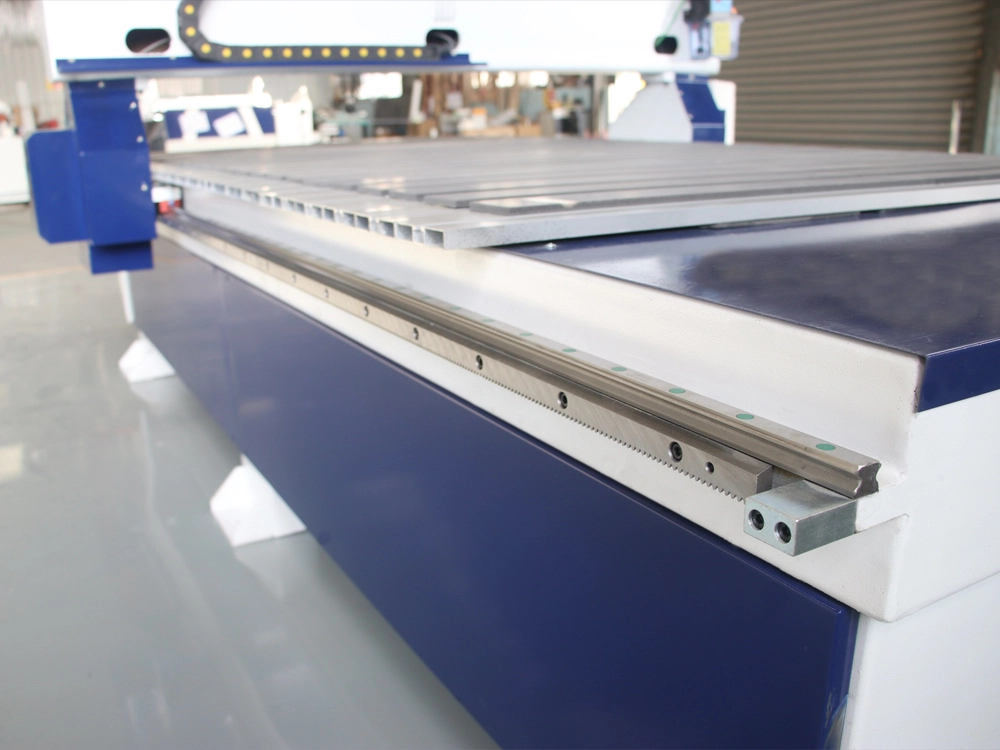

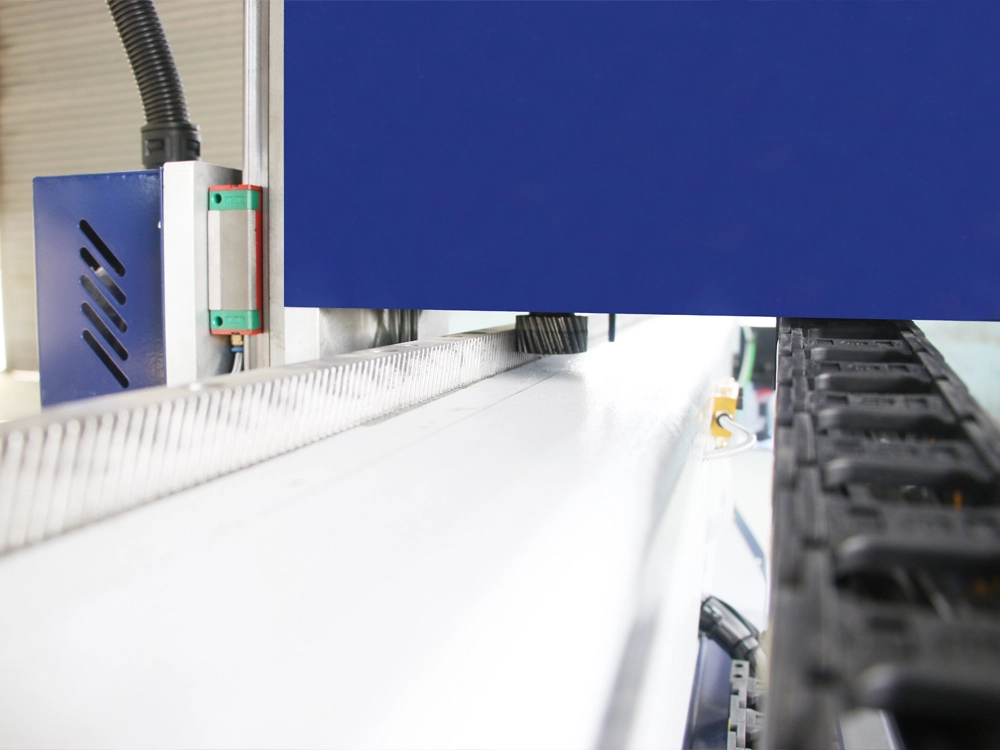

- Transmission system

-

Using Hiwin guide rails/sliders, high-precision helical racks on the XY axis, and high-precision TBI ball screw on the Z axis, the processing is fast and positioning.

- Lubrication system

-

Using a fully automatic electric lubricating oil pot, the lubrication time can be set according to actual conditions, which is simple and convenient.

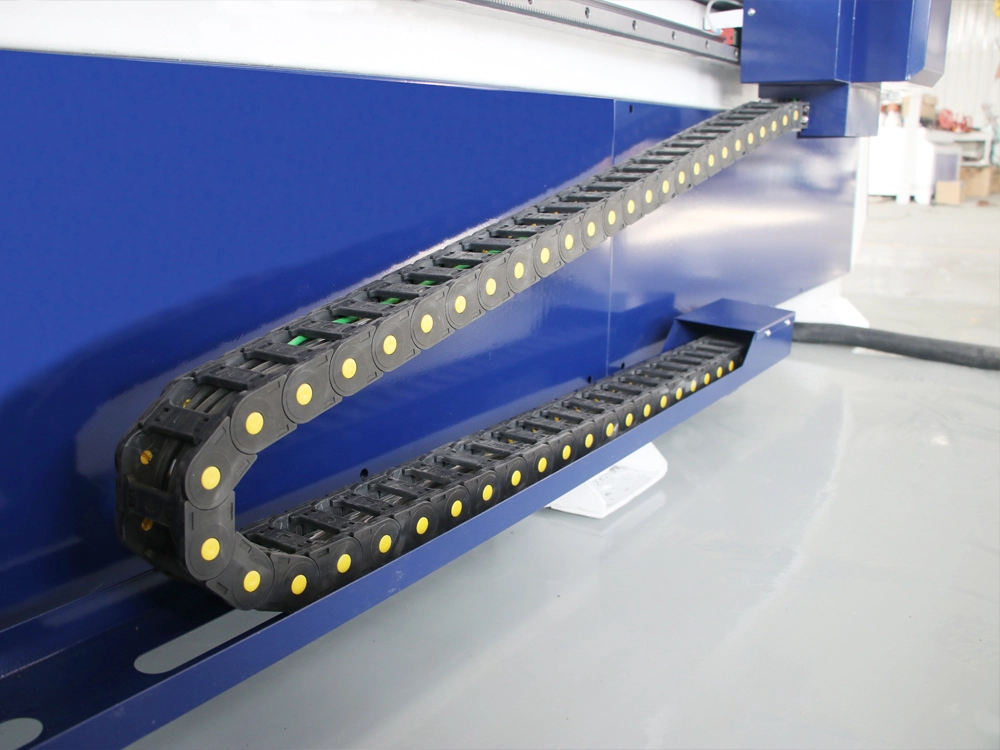

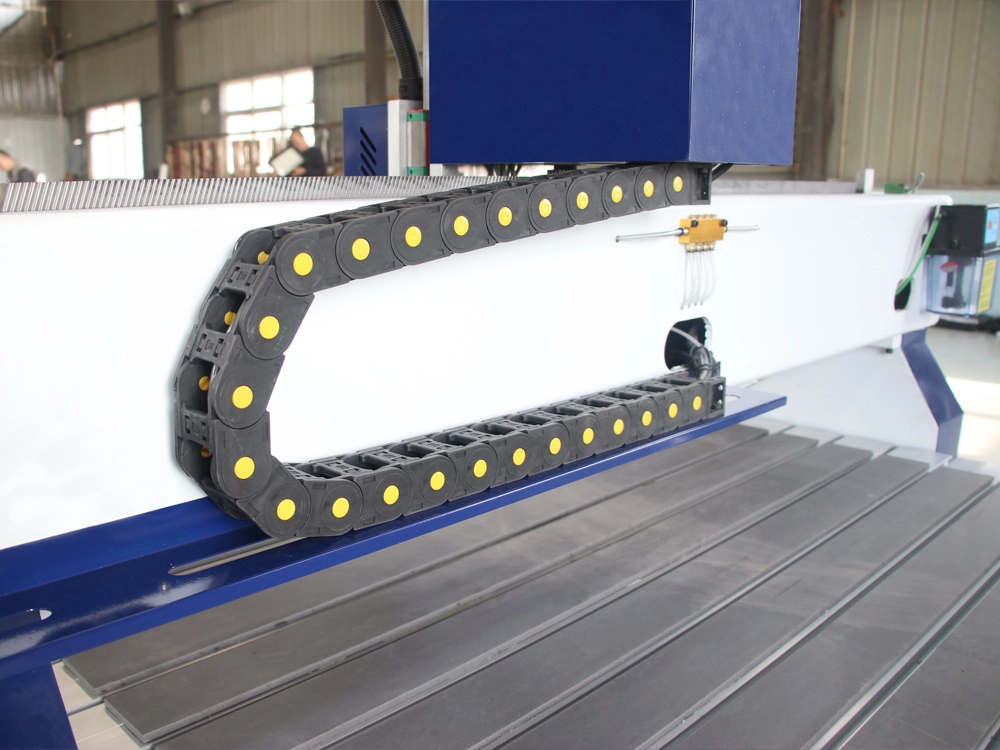

- Cable drag chains

-

Heat-resistant and flame-retardant cable drag chains can organize and fix cables and effectively protect them from damage.

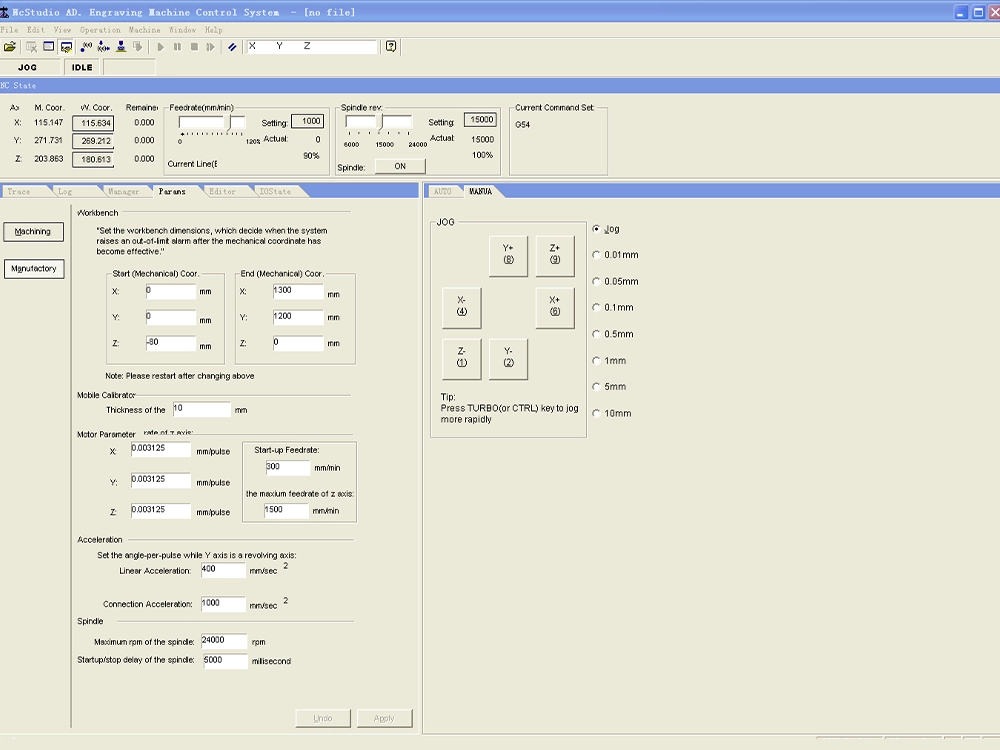

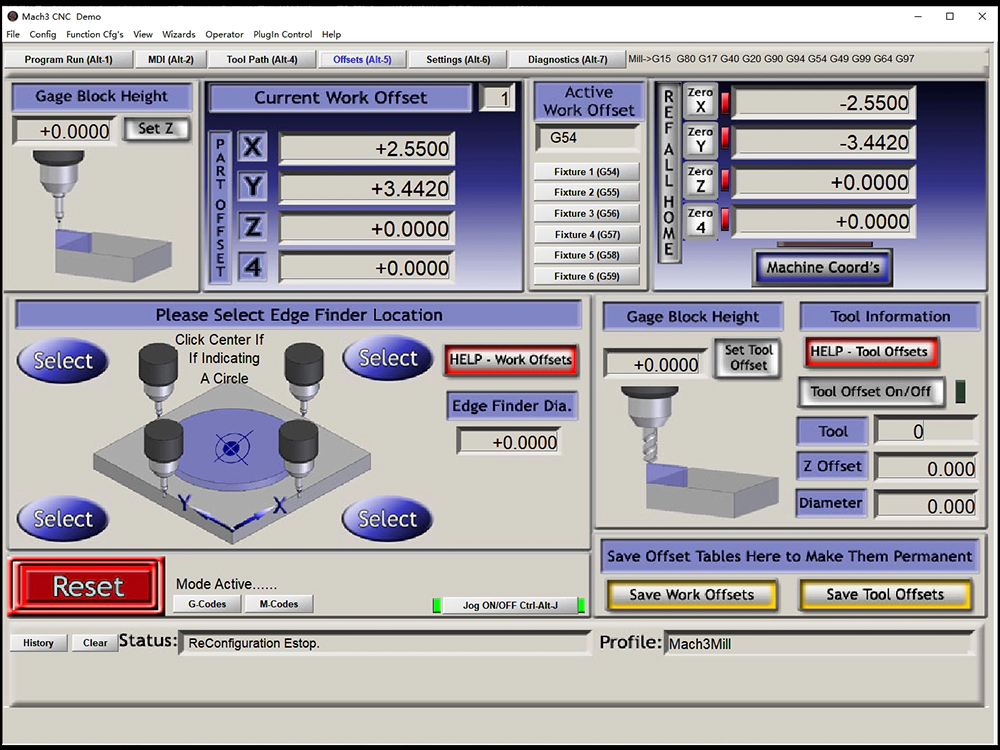

- CNC system

-

Richauto DSP A11/NK105/NCStudio V5.4.49/Mach3

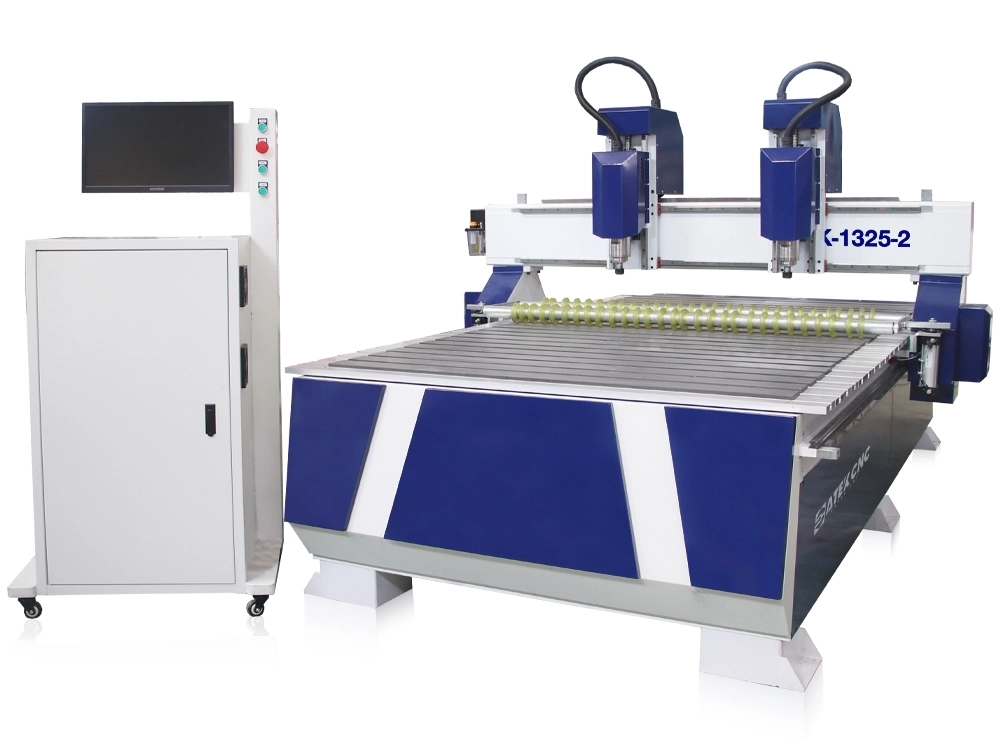

- CNC wood router with pneumatic pressure roller

- CNC wood router with vacuum adsorption workbench

- CNC wood router with saw blade kit for cutting wood

Technical Parameters of 1325 CNC Wood Router with T-slot-Worktable

| Model | CK-1325 |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Yako/Leadshine motor driver |

| Frequency Converter | BEST/Hpmont inverter |

| Table | Aluminum alloy T-slot table (optional: vacuum adsorption platform) |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) / Richauto DSP A11 / Mach3 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V/50/60HZ |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Processing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1260kg |

| Dimensions | 3100*2100*1750mm |

Application Scope of CK-1325 CNC Wood Router

Applicable Materials:

Suitable for wood board, density board, gypsum board, multilayer board, PVC board, acrylic, PCB, plastic, acrylic, foam, honeycomb board, aluminum-plastic board, copper, aluminum, etc.

Applicable Industries:

- Furniture industry: cabinets, furniture, wooden doors, cabinets, office furniture, solid wood furniture cutting, 3D carving, antique carving, cabinet door panels, wood carvings, etc.

- Construction industry: building accessories, siding, wall decorations, wood decorations, etc.

- Advertising industry: logo cutting, advertising word cutting, crystal word cutting, acrylic cutting, packaging engraving, cutting, acrylic light box, signage, billboards, badges, etc.

- Crafts industry: crafts engraving, small ornaments, pendant engraving, sand table model manufacturing, architectural models, aircraft models, car models, souvenirs, etc.

- Electronic industry: insulation parts, plastic chemical parts, pcb board, bakelite board, etc.

Application Case of 4x8ft CNC Wood Router

| Model | CK-1325 |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Yako/Leadshine motor driver |

| Frequency Converter | BEST/Hpmont inverter |

| Table | Aluminum alloy T-slot table (optional: vacuum adsorption platform) |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) / Richauto DSP A11 / Mach3 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1260kg |

| Dimensions | 3100*2100*1750mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.