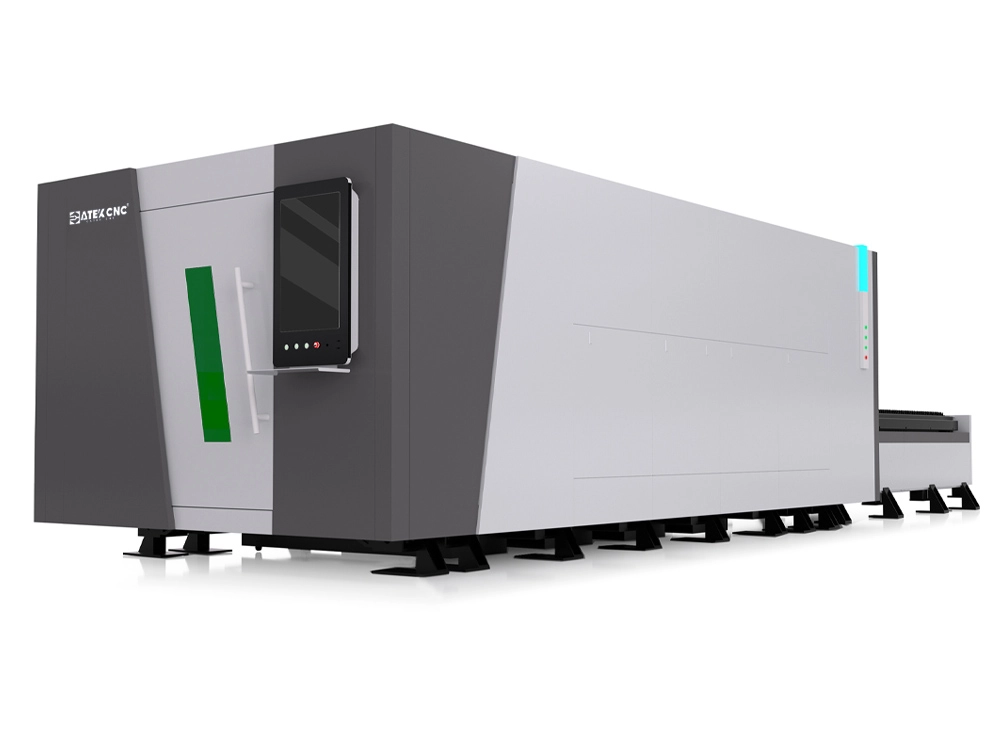

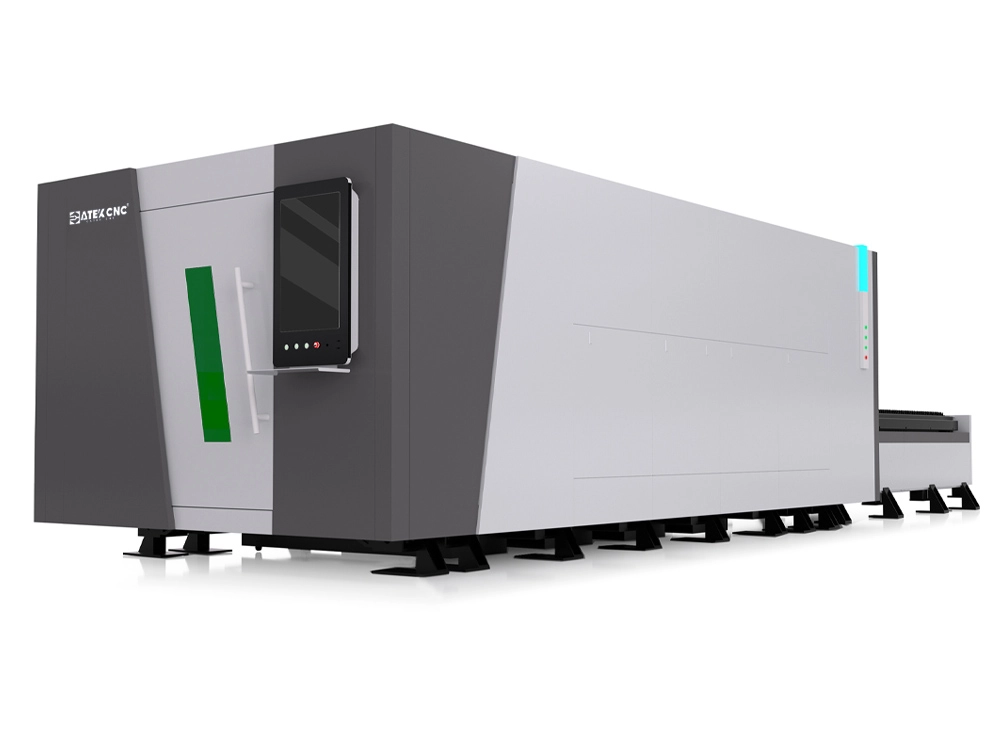

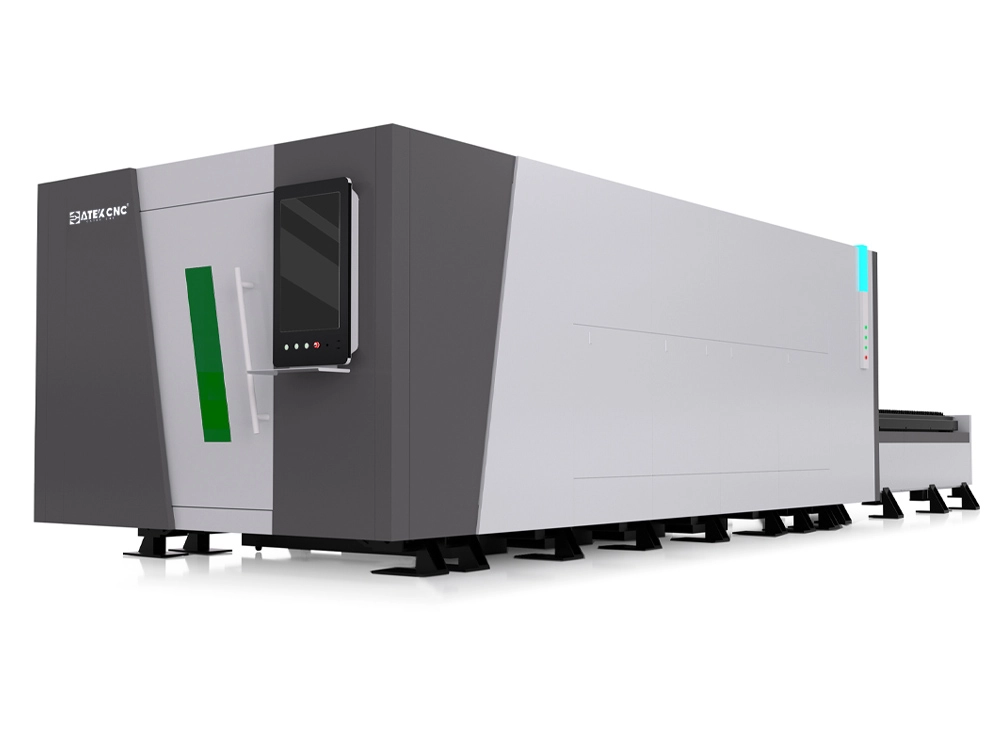

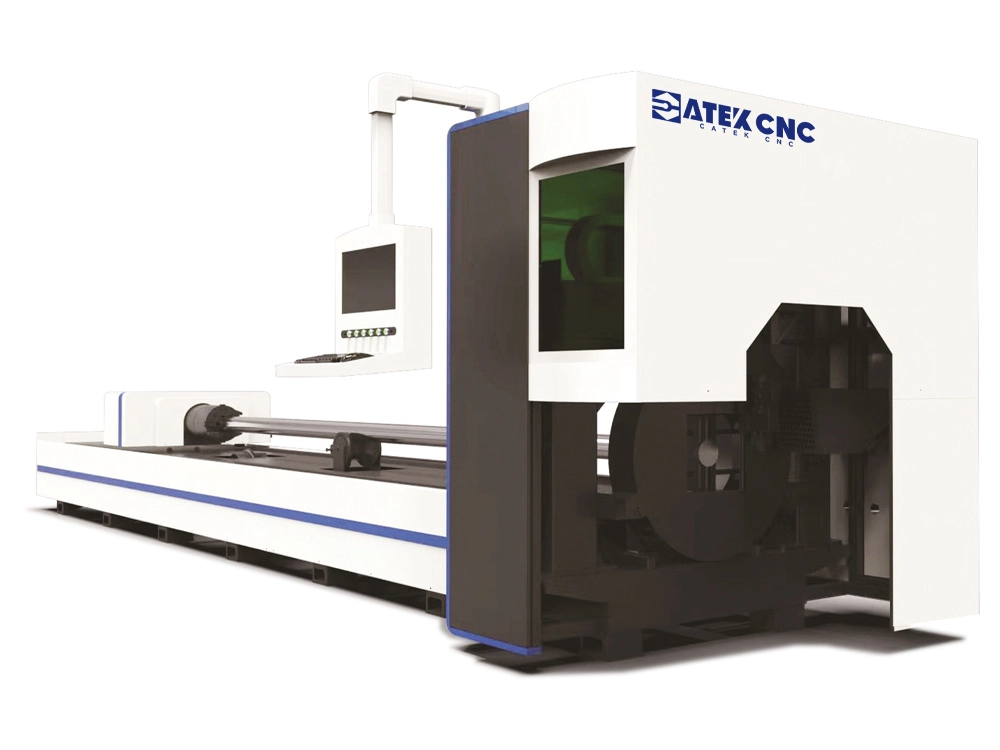

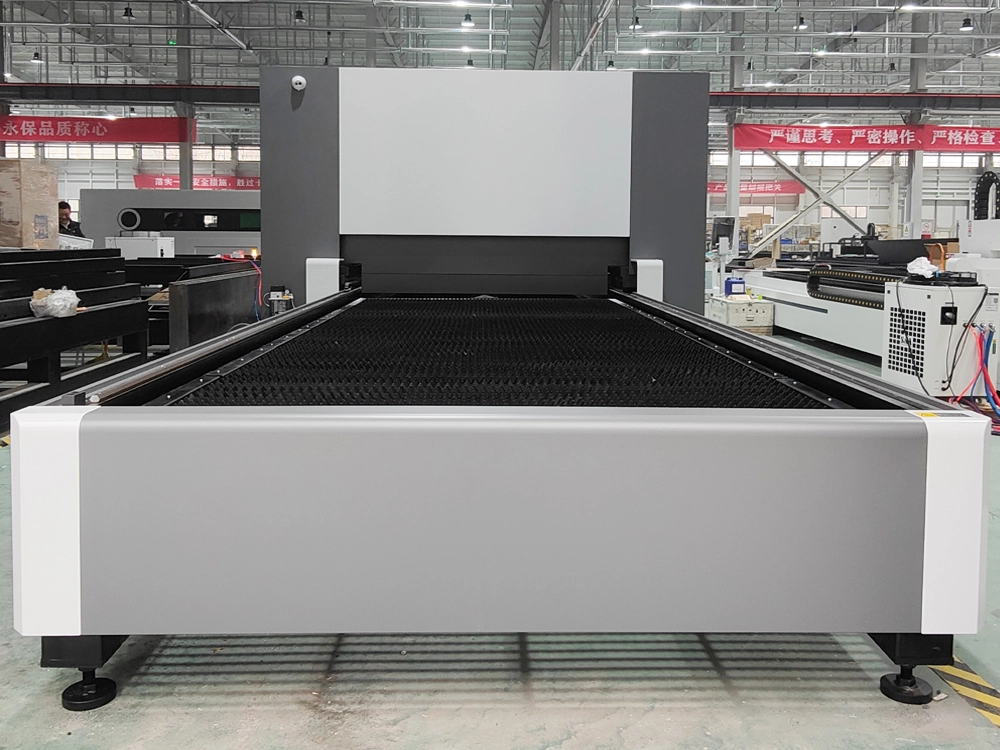

2040 Fiber Laser Cutting Machine With Fully Enclosure and Exchange Table

Top 2040 Enclosed Fiber Laser Cutting Machine With Dual-Shuttle Table

[Function Description]

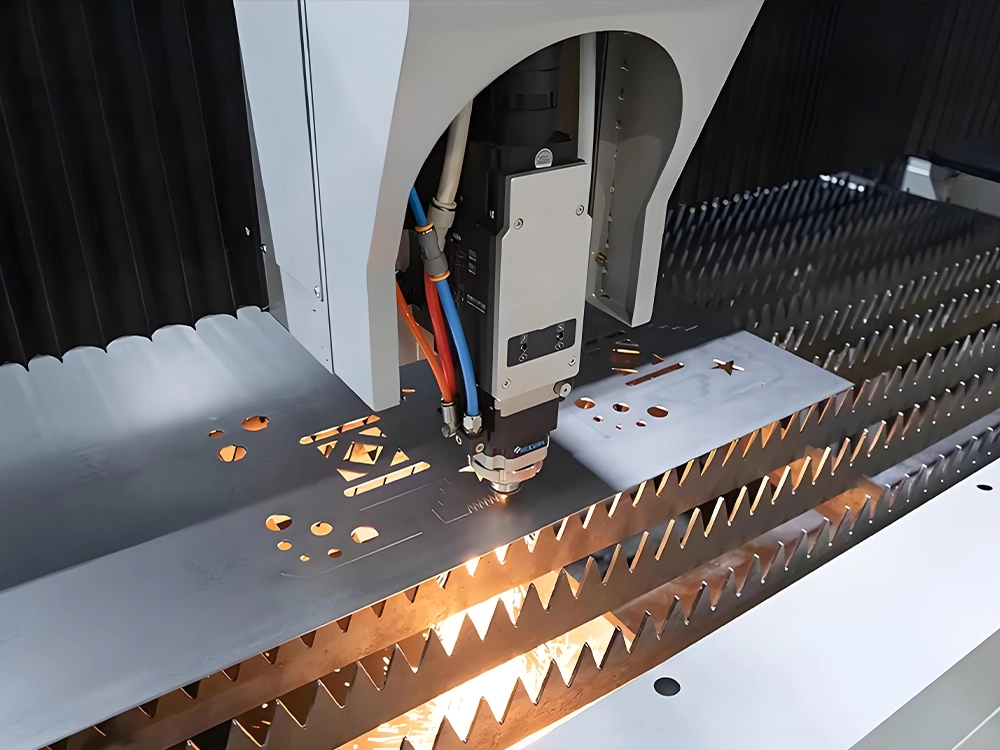

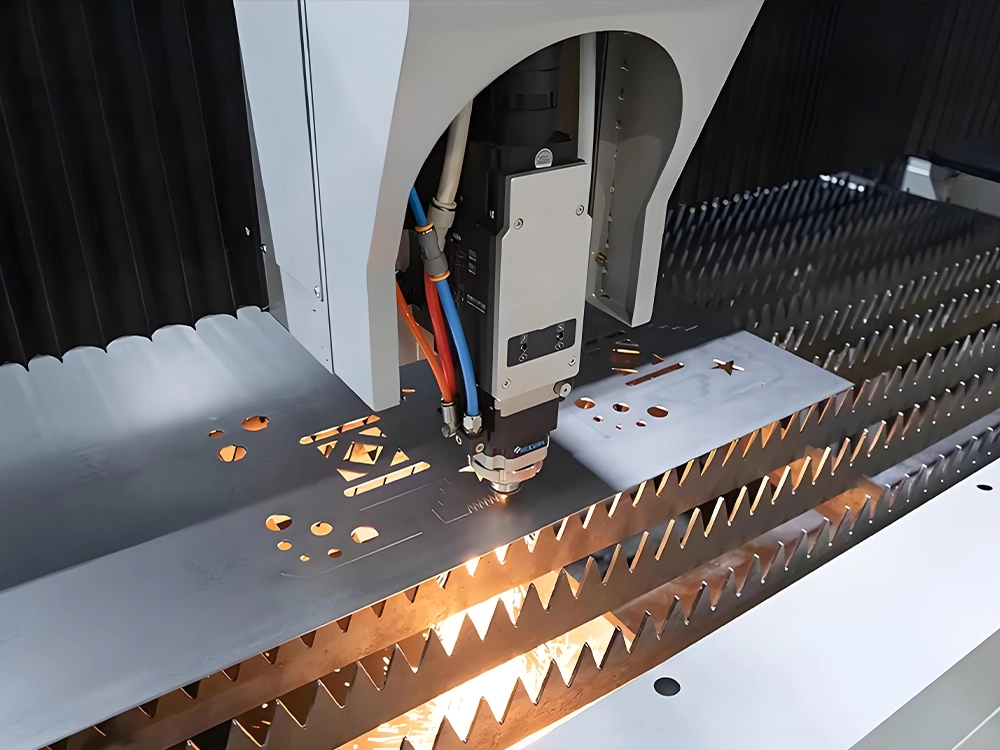

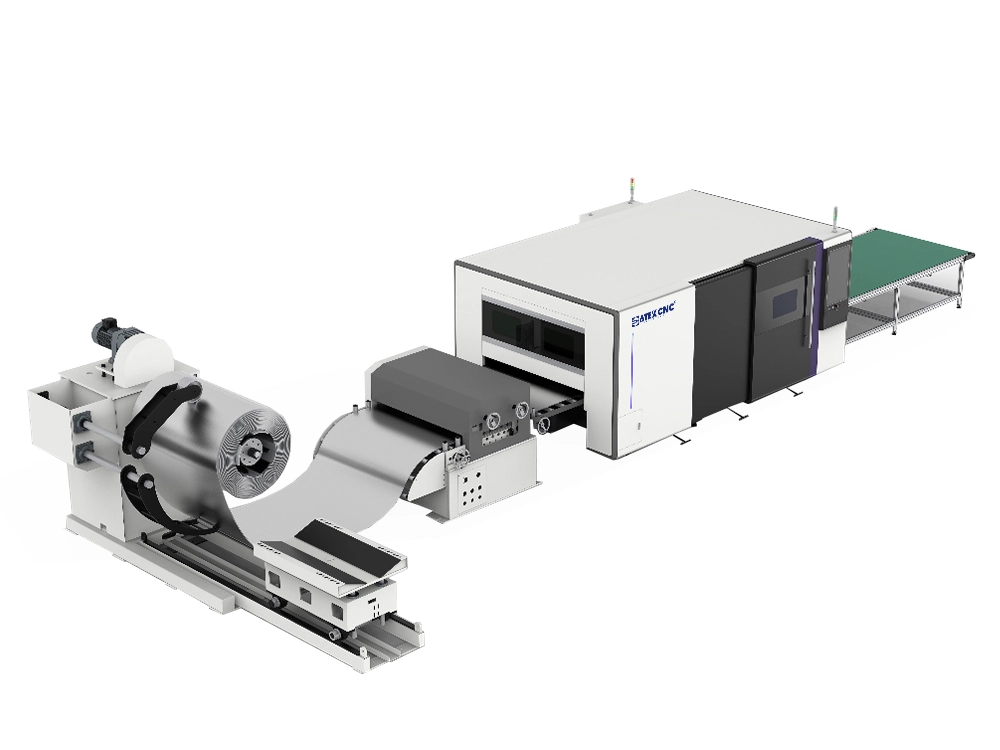

This 2040 model fiber laser cutting machine combines the safety and environmental benefits of a fully enclosed enclosure with the high-efficiency production capabilities of an exchange table, making it widely applicable in sheet metal processing, automotive manufacturing, machinery production, and other industries. During operation, the fiber laser emits a high-energy-density laser beam that is focused onto the workpiece surface, causing the irradiated area to instantly melt and vaporize. The movement of the laser cutting head is precisely controlled by the CNC system, enabling high-speed automatic cutting.

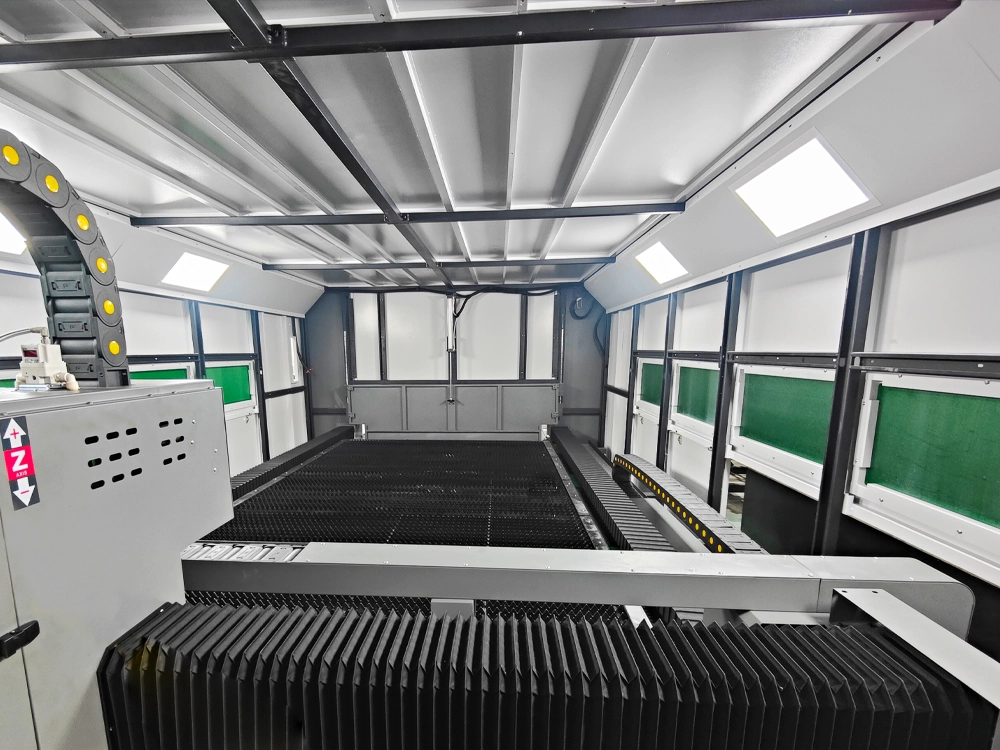

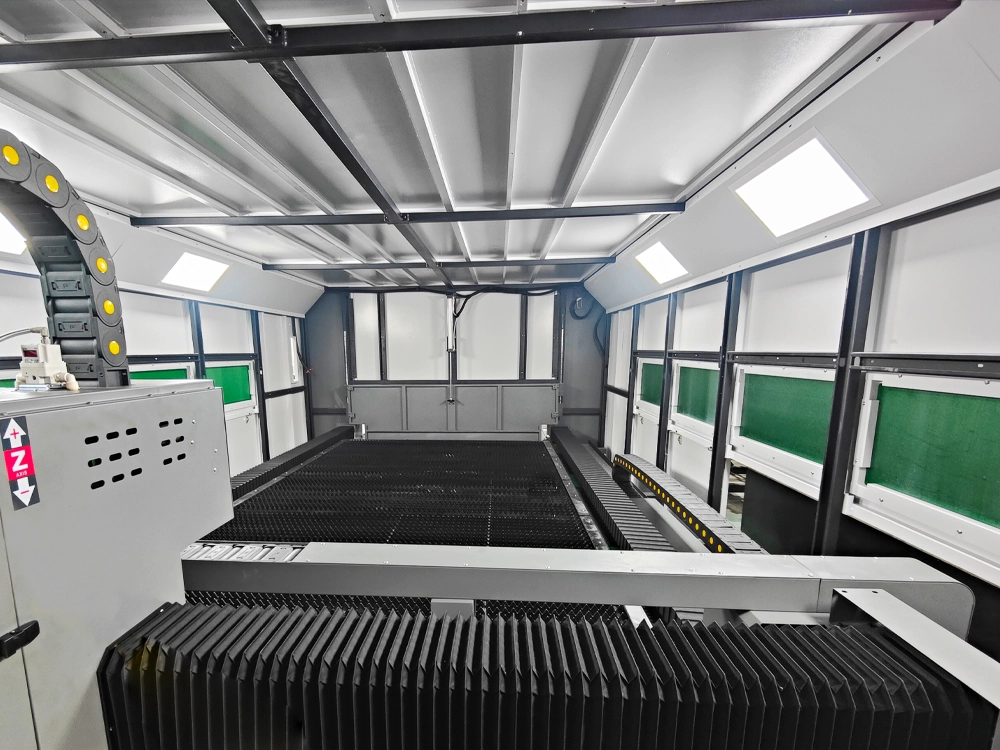

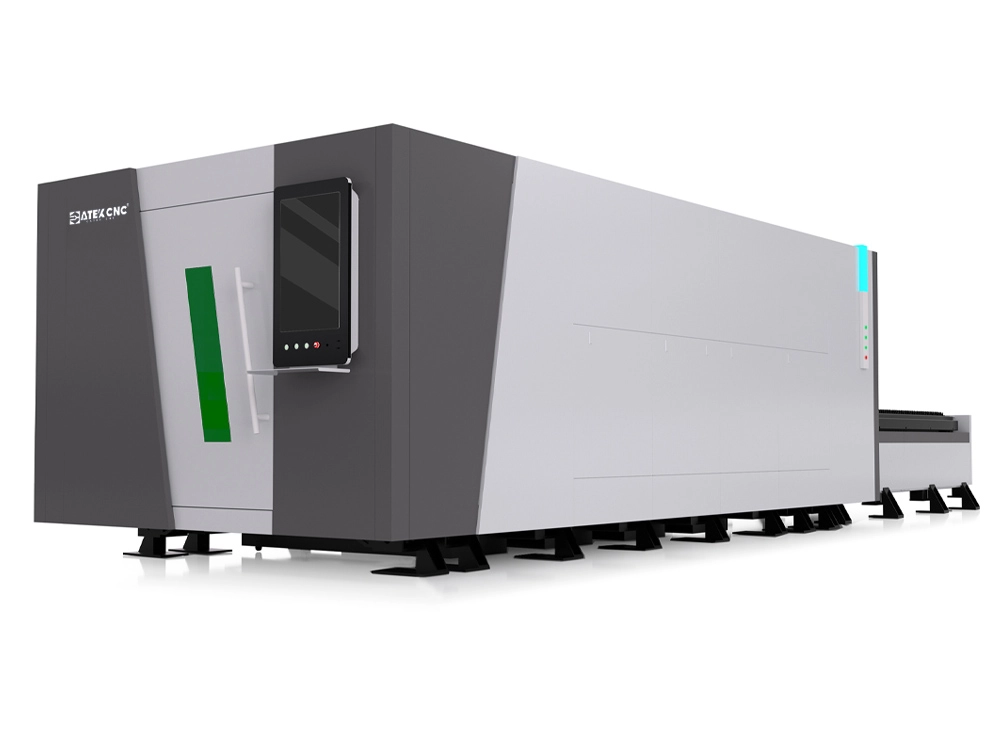

The fully enclosed protective cover of this laser cutting machine effectively isolates laser radiation, sparks, smoke, noise, and mechanical hazards generated during the cutting process, safeguarding the safety and health of operators and creating a cleaner, quieter working environment. It complies with EU CE/ROHS certifications. Additionally, high-definition monitoring cameras are installed at both the front and rear inside the enclosure. These, combined with an intelligent monitoring system, enable real-time intelligent supervision of the machining process, reducing the incidence of accidents and further enhancing operational safety.

The laser cutting machine is equipped with two 2000*4000mm laser cutting worktables. These tables automatically alternate to handle cutting and loading & unloading tasks: while one table is engaged in cutting, the operator can load or unload materials on the other table, ensuring seamless transition and continuity in the machining process. The use of this exchange table significantly reduces auxiliary loading and unloading time, with a switching time of only 15 seconds between the two tables, markedly improving the continuous processing efficiency of the machine.

Features of 2040 Enclosed Fiber Laser Cutting Machine With Dual-Shuttle Table

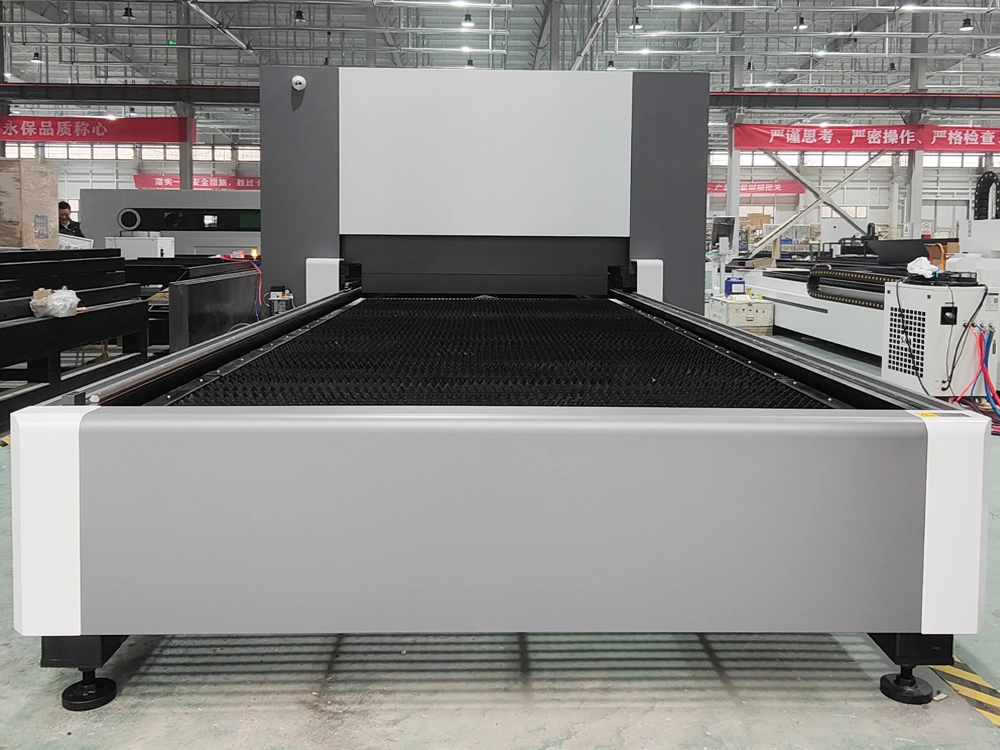

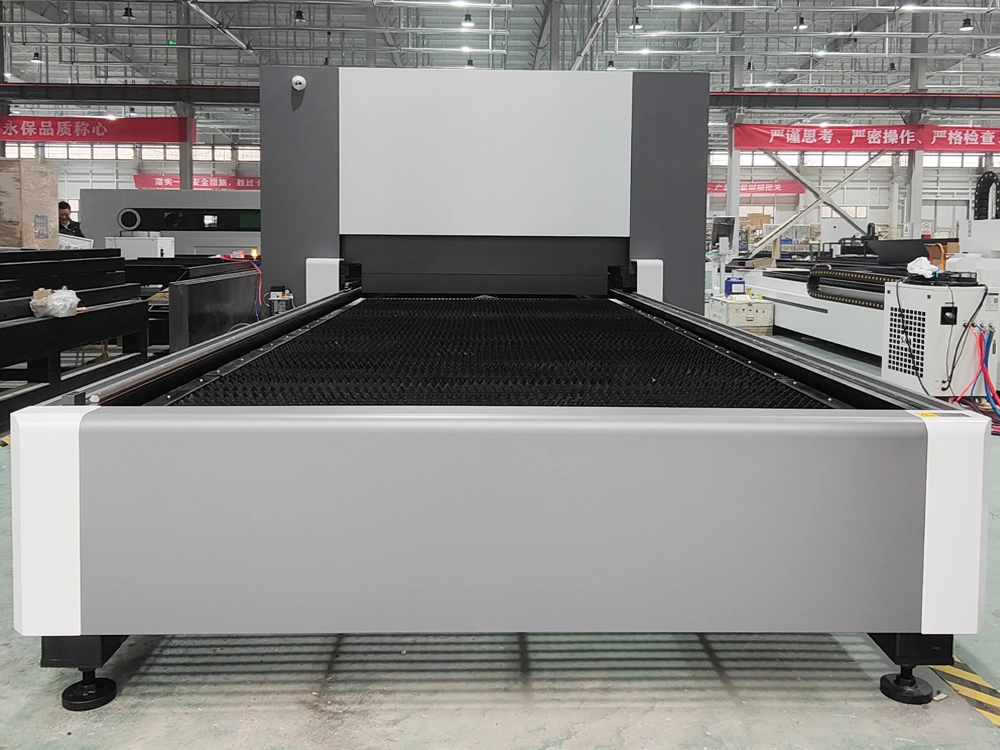

1. Heavy-Duty Bed Frame, Superior Operational Accuracy and Stability

The machine utilizes a heavy-duty bed constructed from thickened steel tubes with reinforced supports at key load-bearing points, ensuring it withstands impacts from the exchange table, workpieces, and cutting processes while preventing accuracy loss due to deformation. The entire bed undergoes high-temperature annealing and vibration stress relief treatments to eliminate welding and structural stresses, enhancing overall strength. Large CNC gantry milling machines precision-mill mounting surfaces for guide rails and table supports, ensuring flatness and long-term stability.

2. Aerospace-Grade Aluminum Alloy Integrated Lightweight Gantry

The aerospace-grade aluminum alloy beam, designed for lightweight performance, is formed through high-pressure die-casting and undergoes heat treatment and multiple machining processes. It supports higher speeds and acceleration while maintaining smooth operation. The lightweight beam offers reduced weight, high rigidity, excellent dynamic performance, and lower inertia during high-speed motion, enabling rapid response and precise control for improved dynamic accuracy.

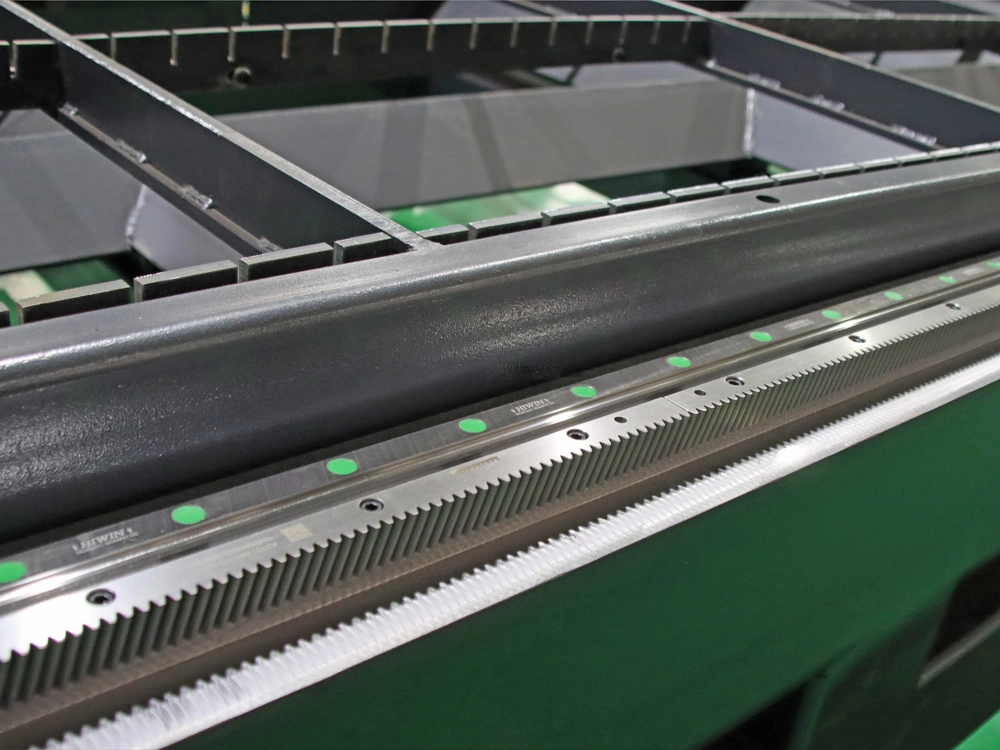

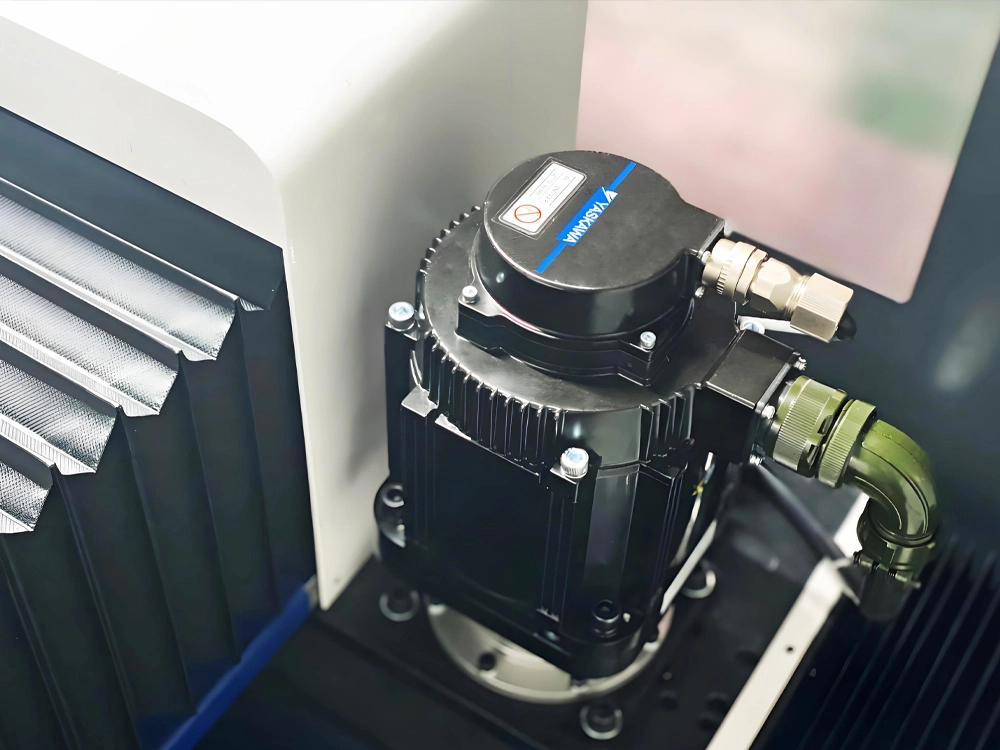

3. High-Precision Motion System, Enables Accurate Control

Drive Motors: XYZ axes employ high-precision Japan Yaskawa bus-type absolute servo motors for superior dynamic response and precise positioning. The Y-axis utilizes dual-side drive, with servo motors, racks/gears, and reducers symmetrically installed on both sides of the beam. This dual-drive design ensures balanced force distribution, preventing uneven loading and enhancing accuracy and stability.

Transmission System: Features Taiwan HIWIN square guide rails with high surface precision and wear resistance, paired with YYC ground helical gears/racks. Carburizing, quenching, and grinding processes provide extreme tooth surface hardness and minimal backlash, reducing transmission errors.

Reducer: Equipped with Motoreducer planetary gear reducers to adjust servo motor speed and torque, optimize power transmission efficiency, and mitigate high-frequency motor fluctuations for smoother cutting edges.

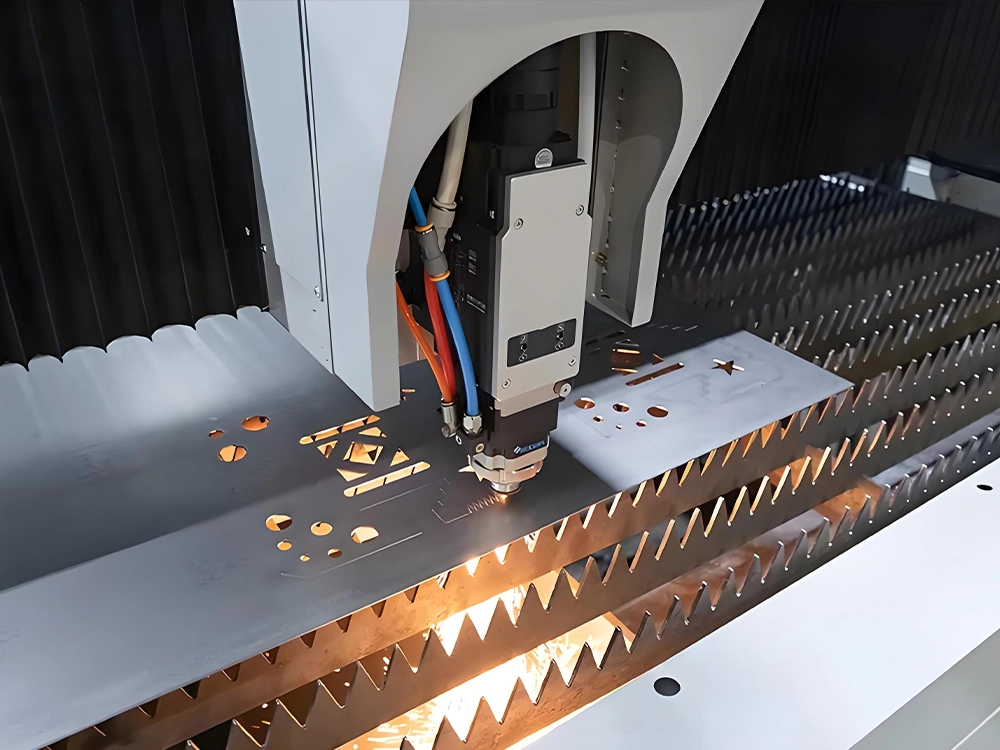

4. Fiber Laser Cutting Core, High-Energy Laser Generator

Equipped with a Raycus CE edition 12,000W laser generator, offering high electro-optical conversion efficiency and superior beam quality with a smaller focused spot for higher cutting line precision. Its modular semiconductor design supports 24/7 continuous operation with stable output and zero maintenance needs, complying with EU CE safety standards. The 12,000W power enables cutting of carbon steel up to 45mm thick, and it also features multiple anti-high-reflection capabilities, which can effectively prevent damage to the laser caused by reflected light when processing high-reflection materials. Additionally, it is equipped with a signal monitoring function that can real-time monitor the working status of the laser, ensuring the stability and safety of the machine's operation.

Alternative laser brands such as JPT, MAX, BWT, and IPG are also available.

5. Multi-Functional Laser Cutting Head

Equipped a BOCI intelligent laser cutting head with auto-focus, intelligent piercing, process monitoring, protective lens detection, and air pressure detection. An anti-collision design with protective screws and set screws buffers impact forces, safeguarding internal components, reducing maintenance frequency, and improving machine return on investment.

6. Dedicated Multi-Functional Laser Cutting Control System

Utilizes the BOCHU FSCUT8000C control system based on EtherCAT bus technology for high-speed communication and stable data transmission, ensuring precise and stable laser operation. The system includes multiple piercing solutions adaptable to different metal thicknesses, along with slag removal during piercing and vibration suppression. The FSCUT8000C control system also supports intelligent cutting and high-speed edge-finding functions. During the processing, it can intelligently start and stop laser output as required, achieving gap-free and residue-free cutting. This system has wide support for various file formats and can directly use files in formats such as DXF and NRP. It provides users with a simpler and more efficient operation method, assisting in the rapid completion of production tasks.

7. Efficient Cooling Core, Dedicated Laser Chiller

Incorporates a S&A 12,000W laser chiller with precise temperature control (±1°C accuracy). It offers both constant temperature and intelligent temperature modes—the former maintaining a fixed water temperature as needed, and the latter adjusting relative to ambient conditions to prevent condensation. Dual temperature control systems independently manage the fiber laser and cutting head temperatures, ensuring optimal performance during intensive operation.

8. Comprehensive Safety Protection, Fully Enclosed Enclosure

A metal frame with thickened steel panels fully encloses the working area, containing laser radiation, sparks, and dust. Integrated high-definition cameras allow real-time internal monitoring without the need for manual inspection, significantly reducing accident risks and ensuring safe production.

9. Core of Efficient Production, Dual-Shuttle/Exchange Table

Two tooth-type slats worktables are switched via reducers and chains, separating the working and loading/unloading areas. When one table completes processing, the other automatically alternates, drastically reducing idle time and boosting production efficiency.

Details of 2040 Enclosed Fiber Laser Cutting Machine With Dual-Shuttle Table

- Heavy-duty bed frame

The machine utilizes a heavy-duty bed constructed from thickened steel tubes, with reinforced supports added at key load-bearing points. Large CNC gantry milling machines are employed to precision-machine mounting surfaces for guide rails, table support areas, and other transmission system components.

- Lightweight aluminum alloy gantry beam

The lightweight beam is integrally formed from aerospace-grade aluminum alloy through die-casting, offering excellent rigidity and long-term resistance to deformation. With low motion inertia, it enables high-speed movement and rapid acceleration/deceleration response.

- Transmission system

Equipped with HIWIN guideways (Taiwan) and YYC ground helical gears/racks, the system ensures machining accuracy and long-term operational stability.

- Yaskawa servo motors

Both X,Y and Z axes employ high-precision, bus-type absolute Yaskawa servo systems imported from Japan, delivering superior dynamic response speeds and precise positioning.

- Fully enclosure

The full-perimeter sheet metal structure, equipped with sliding protective doors, effectively isolates dust, noise, debris, sparks, high temperatures, and laser radiation generated during metal cutting. This prevents harm to operators and the surrounding environment while maintaining a clean workspace.

- Dual-shuttle/exchange table

This machine has two 2000×4000mm worktables. While one table is used for processing, the other handles loading and unloading. Controlled by the CNC system, they switch automatically to enable continuous operation.

- Raycus laser source

Equipped with a Raycus 12,000W high-power laser generator, featuring a laser wavelength of 1064nm and output power fluctuation within ±1%. With an electro-optical conversion efficiency exceeding 40%, it significantly reduces energy consumption and operating costs.

- BOCI laser cutting head

Features the BOCI BLT series laser cutting head, which includes auto-focus, anti-collision protection, and automatic piercing functions. It automatically adjusts the focal length for materials of varying thicknesses, ensuring cutting precision while improving processing efficiency.

- BOCHU FSCUT8000C laser control system

The FSCUT8000C control system is a high-end intelligent bus system designed for fiber laser cutting machines over 8000W. It offers stable and reliable operation, simple and convenient debugging, and a wide range of functions. It supports intelligent piercing, mark-free micro-joining, automatic re-cutting, and is ideal for cutting large metal sheets.

- S&A 12,000W chiller

Includes a S&A (Teyu) 12,000W chiller with dual temperature control systems, allowing precise temperature management for both the laser generator and the cutting head. It also provides multiple protective functions such as compressor delay protection, water flow alarms, and temperature alarms, ensuring stable and safe machine operation.

- Cooling air conditioner for control cabinet

A dedicated cooling air conditioner for the control cabinet uses a unique circulation design that completely isolates external air from the internal cabinet environment, preventing dust ingress. It dissipates heat from the control cabinet through air circulation, effectively extending the service life of electrical components.

- High-definition camera

A built-in HD camera inside the enclosure allows real-time monitoring via an external display during processing, enabling operators to observe machine operation and further enhance safety.

Technical Parameters of 2040 Enclosed Fiber Laser Cutting Machine With Dual-Shuttle Table

| Model | CK-2040-2FC |

|---|---|

| Sheet Cutting Size | 2000mm * 4000mm * 2 (Processing dimensions customizable) |

| Bed Frame / Gantry | High-strength heavy-duty bed frame, aerospace-grade aluminum alloy gantry |

| Laser Wavelength | 1064nm |

| Laser Generator | Raycus / Max / IPG / Reci / BWT, etc. |

| Laser Head | BOCI BLT Series |

| Fiber Laser Power | 12000W (Power customizable) |

| Cooling Method | S&A 12000W dedicated fiber laser chiller |

| Drive System | Yaskawa bus-type absolute servo motor * 4 |

| Guideways | Taiwan HIWIN high-precision square linear guide rails, HIWIN sliders |

| Rack | Taiwan YYC high-precision ground helical rack and gear |

| Reducer | Motoreducer planetary gear reducer |

| Equipment Cables | Pure copper highly flexible anti-bending cables |

| Proportional Valve | SMC |

| Electrical Components | Schneider Electric components |

| Control System | FSCUT 8000C laser system |

| Lubrication System | Electric lubrication and oil maintenance system |

| Compatible Software | ArtCAM, Type3, CAD drawing, CDR, AI, etc. |

| Maximum Acceleration | 1.2G |

| Operating Voltage | AC380V |

| Repeated Positioning Accuracy | ±0.02mm/1000mm |

| Maximum Moving Speed | 150,000mm/min |

| Machine Weight | 5500kg |

| Machine Dimensions | 10600 * 3300 * 2400mm |

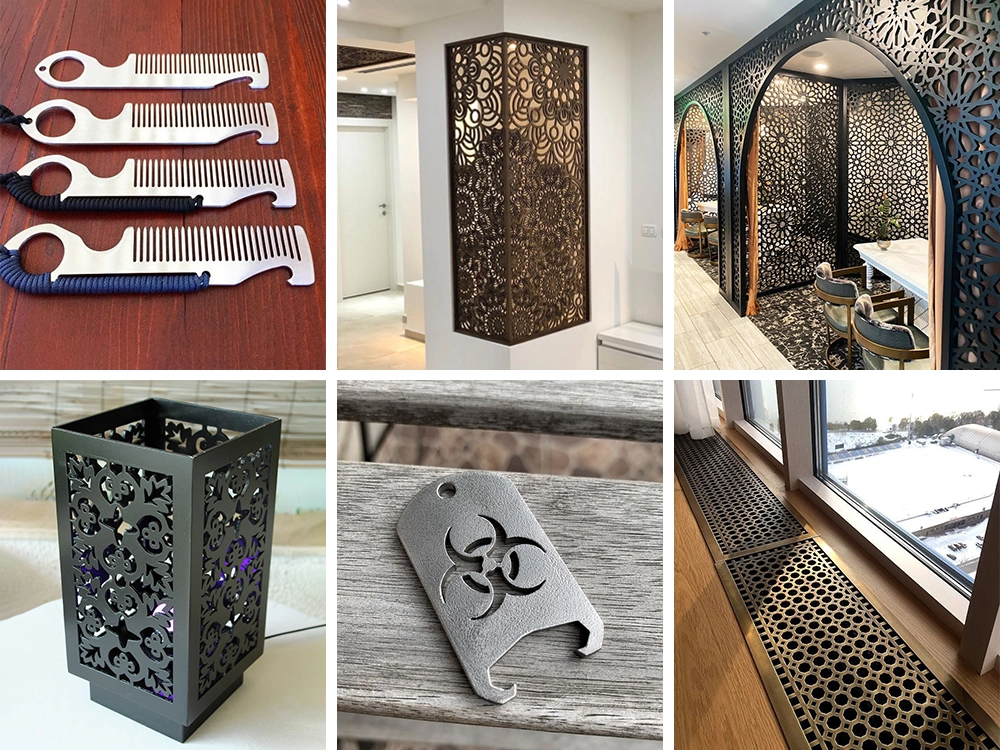

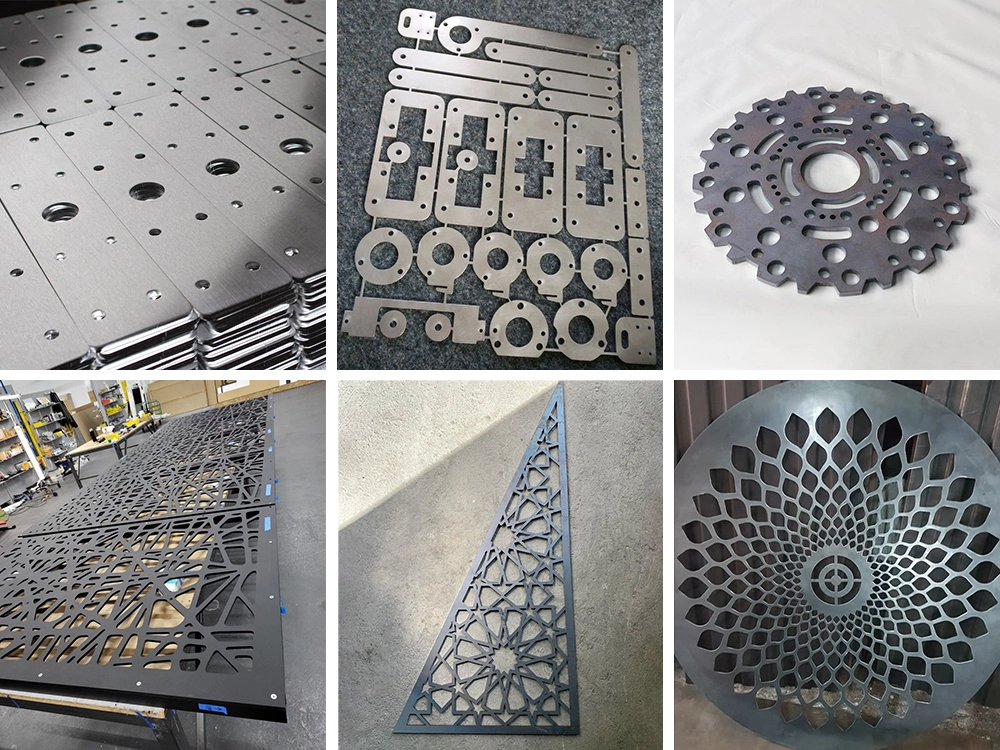

Application Scope of 2040 Enclosed Fiber Laser Cutting Machine With Dual-Shuttle Table

Carbon Steel: Low and medium carbon steels of various thicknesses, including Q235, 45# steel, tool steel, and spring steel. Capable of cutting carbon steel materials up to 45mm thick, suitable for machinery manufacturing, structural construction, and related industries.

Stainless Steel: Common stainless steel series such as 304/316, widely used in kitchenware, chemical equipment, machinery, medical devices, and other sectors.

Aluminum Alloy: Grades including 1060, 5052, 6061, as well as pure aluminum, extensively applied in aerospace, automotive components, electronic device housings, and more.

Copper: Materials such as brass, red copper, bronze, and copper alloys, used in furniture, home appliances, hardware, building materials, and various other industries.

Other Metals: Including titanium alloys, manganese steel, nickel-based alloys, zinc alloys, magnesium alloys, and similar materials.

What is an Dual-Shuttle/Exchange Table and How Does It Work?

The dual-shuttle table in a fiber laser cutting machine is an automated worktable system consisting of two identical cutting tables. Through its mechanical structure and automated control system, it enables simultaneous cutting and loading/unloading operations. A fiber laser cutting machine equipped with an dual-shuttle table completely eliminates machine downtime caused by waiting for loading and unloading, allowing the machine to perform cutting tasks continuously. Compared to conventional single-table fiber laser cutting machines, efficiency can be increased by over 30%. Moreover, since loading and unloading operations are conducted outside the machining area and are fully separated from it, the risk of operators coming into contact with moving parts, lasers, or sparks is significantly reduced, greatly enhancing safety.

The dual-shuttle table primarily consists of the worktables for carrying sheet materials, the drive system, and the positioning and locking mechanisms.

- Worktables: Divided into two identical tables, A and B, welded from thickened square steel and surfaced with tooth-type slats, capable of supporting sheet materials weighing several tons.

- Drive System: Composed of motors, reducers, gears, chains, etc., responsible for driving the worktables to move quickly and accurately between the cutting position and the loading/unloading position.

- Positioning and Locking Mechanism: When a worktable moves into the cutting area, it is secured by cylinders and positioning pins to ensure no displacement occurs during the cutting process.

Working Principle:

Initial Cutting Operation

After the machine starts, Worktable A moves into the cutting area, and the laser head automatically cuts the workpiece on it.

Simultaneous Loading

While Worktable A is cutting, the operator loads the next sheet onto Worktable B, which is in the standby position, without waiting for the cutting process to complete.

Table Exchange

Once cutting on Worktable A is finished, the control system automatically moves it out of the cutting area and simultaneously shifts Worktable B, now fully loaded, into the cutting area to begin the next cycle.

Cyclic Operation

Worktables A and B alternate continuously, achieving a seamless and uninterrupted production mode for cutting.

| Model | CK-2040-2FC |

|---|---|

| Sheet Cutting Size | 2000mm * 4000mm * 2 (Processing dimensions customizable) |

| Bed Frame / Gantry | High-strength heavy-duty bed frame, aerospace-grade aluminum alloy gantry |

| Laser Wavelength | 1064nm |

| Laser Generator | Raycus / Max / IPG / Reci / BWT, etc. |

| Laser Head | BOCI BLT Series |

| Fiber Laser Power | 12000W (Power customizable) |

| Cooling Method | S&A 12000W dedicated fiber laser chiller |

| Drive System | Yaskawa bus-type absolute servo motor * 4 |

| Guideways | Taiwan HIWIN high-precision square linear guide rails, HIWIN sliders |

| Rack | Taiwan YYC high-precision ground helical rack and gear |

| Reducer | Motoreducer planetary gear reducer |

| Equipment Cables | Pure copper highly flexible anti-bending cables |

| Proportional Valve | SMC |

| Electrical Components | Schneider Electric components |

| Control System | FSCUT 8000C laser system |

| Lubrication System | Electric lubrication and oil maintenance system |

| Compatible Software | ArtCAM, Type3, CAD drawing, CDR, AI, etc. |

| Maximum Acceleration | 1.2G |

| Operating Voltage | AC380V |

| Repeated Positioning Accuracy | ±0.02mm/1000mm |

| Maximum Moving Speed | 150,000mm/min |

| Machine Weight | 5500kg |

| Machine Dimensions | 10600 × 3300 × 2400mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.