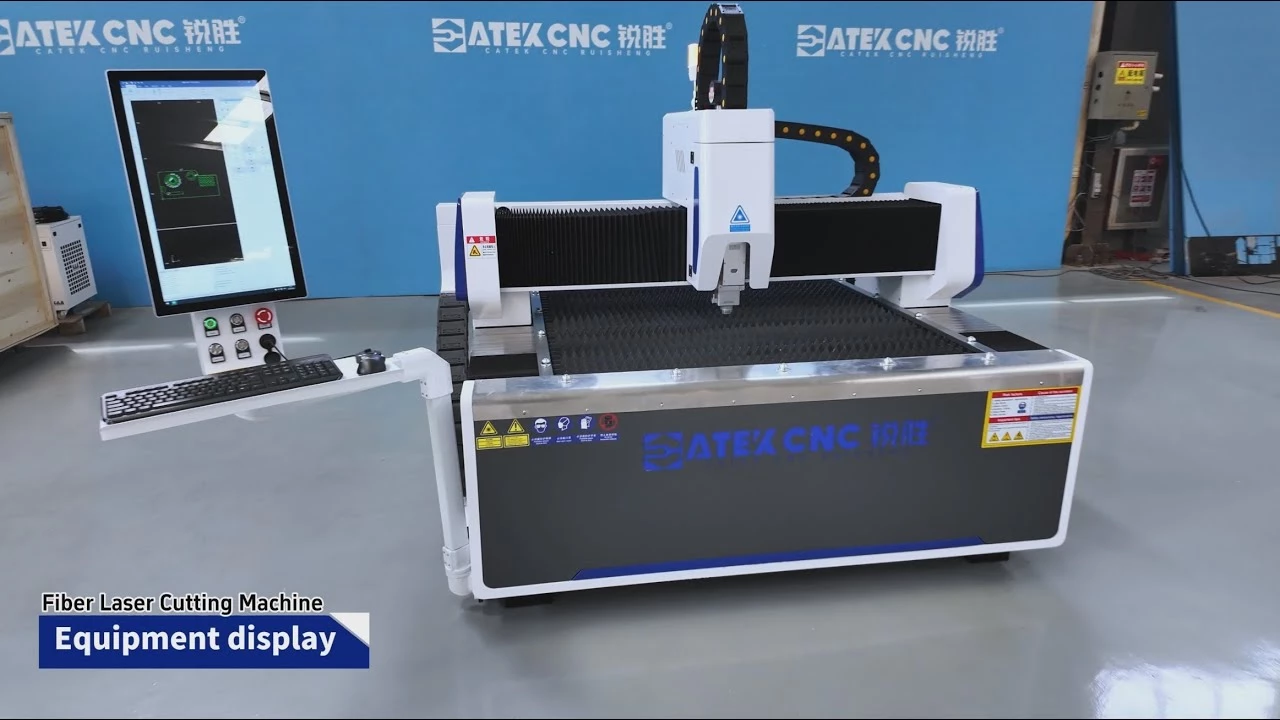

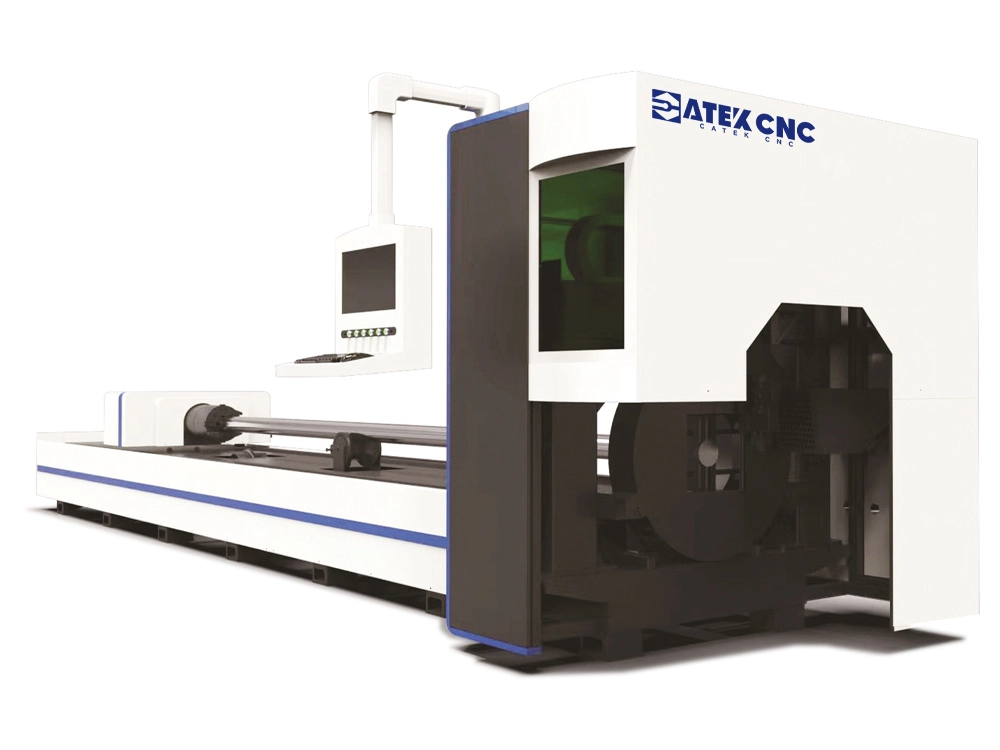

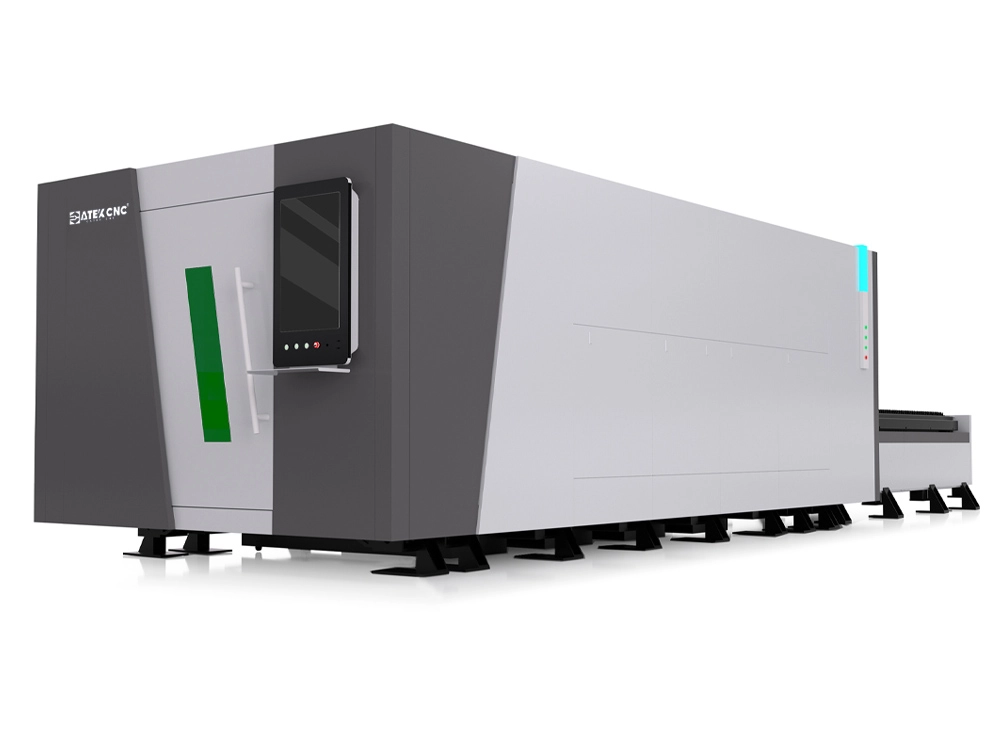

Fiber Laser Cutting Machine for Cutting Stainless Steel or Carbon Steel Plates

5x10 1500W/2000W/3000W Fiber Laser Cutter for Sale at Competitive Price

[Function Description]

Fiber laser cutting machines utilize a fiber laser generator as the laser source, transmitting the laser beam through optical fibers with a wavelength of 1064 nm. During cutting, the high-power laser beam is transmitted via flexible optical fibers to the cutting head, where it is focused on the material surface, causing localized instant melting. The CNC system controls the movement of the laser beam, enabling automated cutting. Fiber laser cutting produces extremely narrow kerfs, a small heat-affected zone, and very smooth cuts with excellent verticality, eliminating the need for secondary processing.

Fiber lasers have a photoelectric conversion efficiency of 25%-35%, resulting in lower energy consumption. The machine's structure is simple, as it does not require complex optical lens systems; instead, it directly transmits the laser through optical fibers, ensuring stronger optical path stability. Fiber lasers have a long service life and, when paired with a water-cooling system, offer excellent cooling and heat dissipation performance, meeting the demands of continuous 24-hour industrial processing.

Features of High-Power 5x10 Fiber Laser Cutting Machine

- The machine structure is initially welded with thickened square steel, undergoes annealing to relieve internal stress, and is then rough-machined. After secondary artificial thermal aging treatment, it is precision-machined to eliminate stress from welding and machining, enhancing the machine's stability.

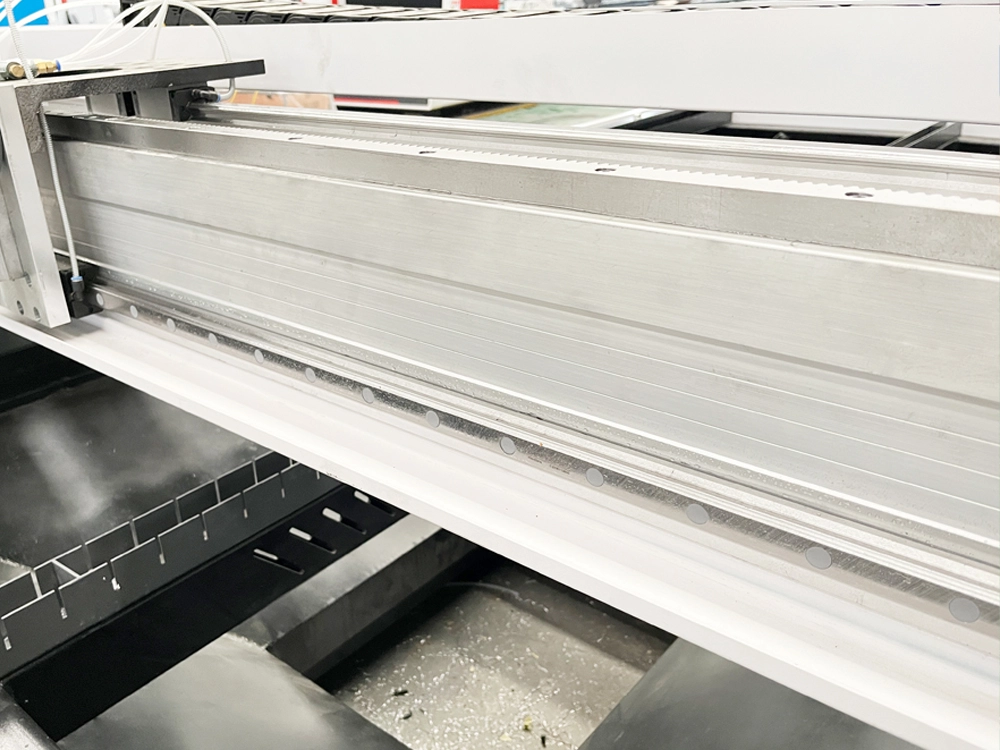

- The XYZ axes are equipped with dust-proof covers, effectively preventing dust ingress during processing, ensuring machine accuracy, and extending its service life.

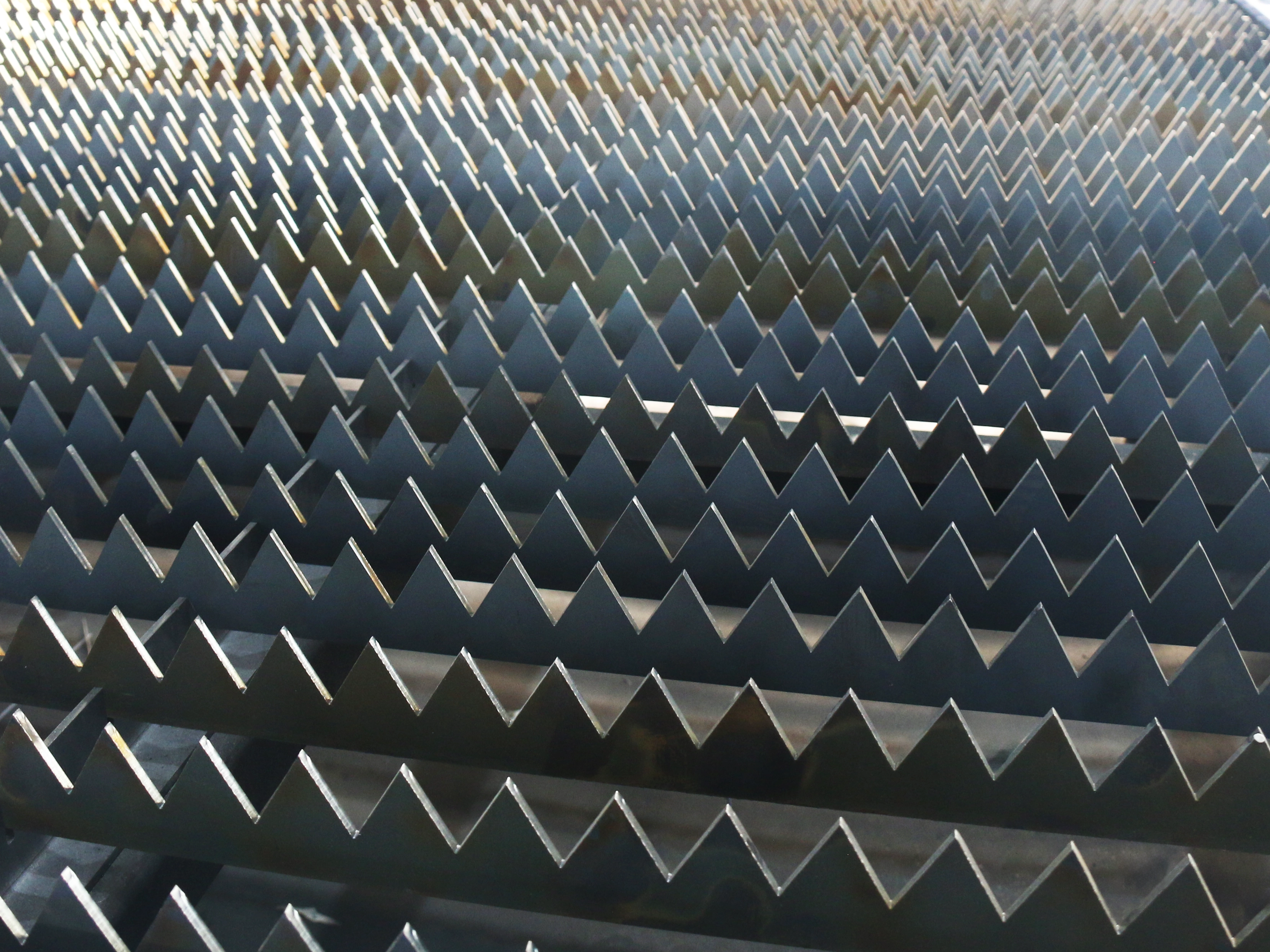

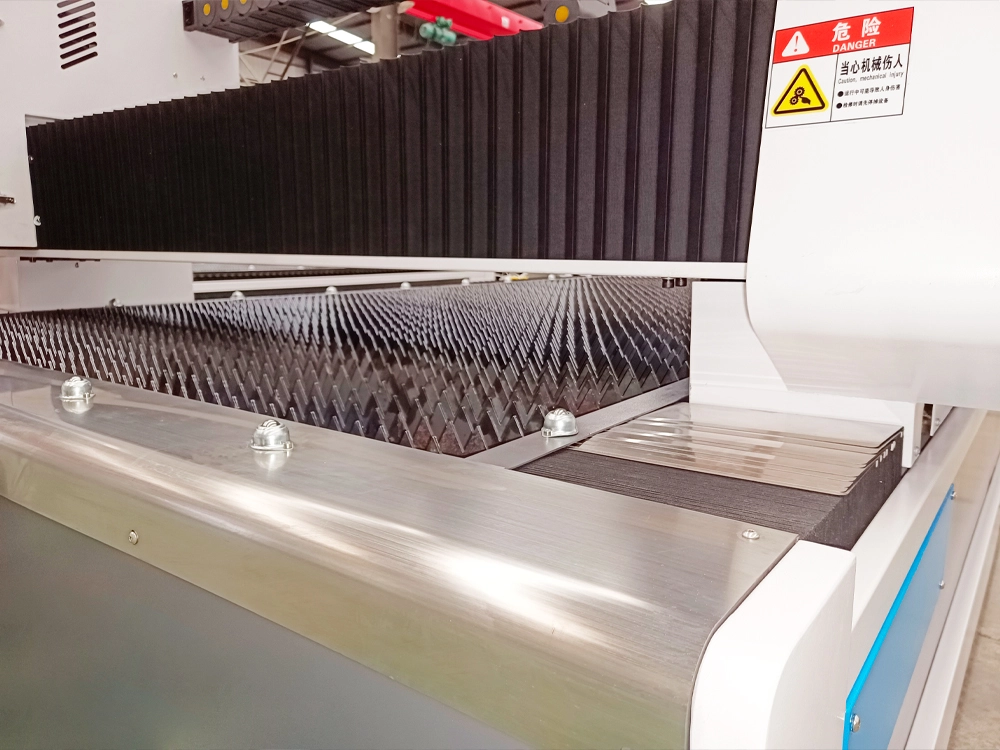

- A tooth-type slats workbench is used to reduce the contact area between the material and the platform, effectively ensuring cutting quality.

- The aerospace-grade aluminum alloy beam structure, made through cast aluminum technology, offers corrosion resistance, oxidation resistance, and excellent toughness and ductility. It significantly increases processing speed while maintaining precision.

- Professional laser cutting nesting software improves material utilization by over 10%, featuring graphic nesting and sharp corner smoothing functions, enabling high-speed piercing and rapid cutting.

- Equipped with an auto-focusing laser head, it automatically calibrates the focus based on material thickness, using multiple focal modes to reduce piercing time and improve piercing quality.

- High electro-optical conversion efficiency, exceeding 30%, ensures low energy consumption. The laser requires only electricity to operate, and with auxiliary gas blowing, it achieves smooth cutting surfaces.

- Imported high-precision ground helical racks and gears make the machine faster, quieter, and more durable.

- High-quality laser sources (optional) with a lifespan of over 100,000 hours enable 24-hour continuous operation.

- A water-cooling system maintains a constant temperature, ensuring the laser generator operates at the optimal temperature and preventing overheating.

- A central automatic lubrication system lubricates all transmission parts, effectively extending the machine's service life.

- High-torque servo motors paired with planetary gear reducers ensure fast, smooth, and precise operation with low noise, improving processing efficiency.

- The user-friendly interface includes built-in processing parameters, allowing quick switching of drawings via software. Cutting of different parts can be completed within 3 minutes, offering flexible operation.

Details of Metal Fiber Laser Cutter with 5x10ft Table

- Fiber laser cutting head

Capable of rapid piercing and cutting of metal materials. The auto-focusing laser cutting head enables quick piercing of thick plates and can cut sheets of different thicknesses and materials through automatic focus adjustment.

- High Dust Resistance: IP65 dust-proof rating, fully enclosed optical path, minimizing the risk of lens contamination.

- Dynamic Zero Focus: Flexible scale adjustment ensures unified zero focus position, eliminating the hassle of adjusting process parameters.

- Heat Dissipation Optimization: Efficient water-cooled focusing lens and collimating nozzle with built-in cooling functions to address cutting heat issues.

- Structural Design Optimization: Integrated body design with an improved QBH fiber interface to prevent rust and other issues.

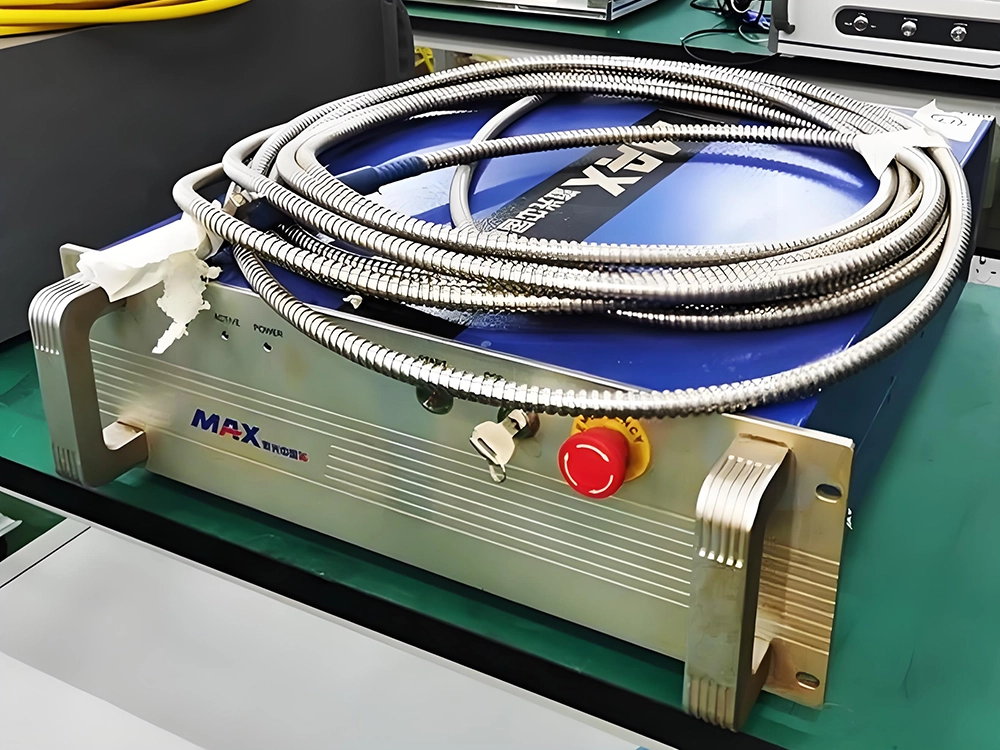

- Laser generator

There are many brands of lasers available. High electro-optical conversion efficiency, single-module continuous fiber laser, capable of sustained high-power output. Compact in size, combining high power, lightweight, and excellent beam quality. Modular design for easier maintenance and maintenance-free operation. Wide modulation frequency range and high anti-reflective capability.

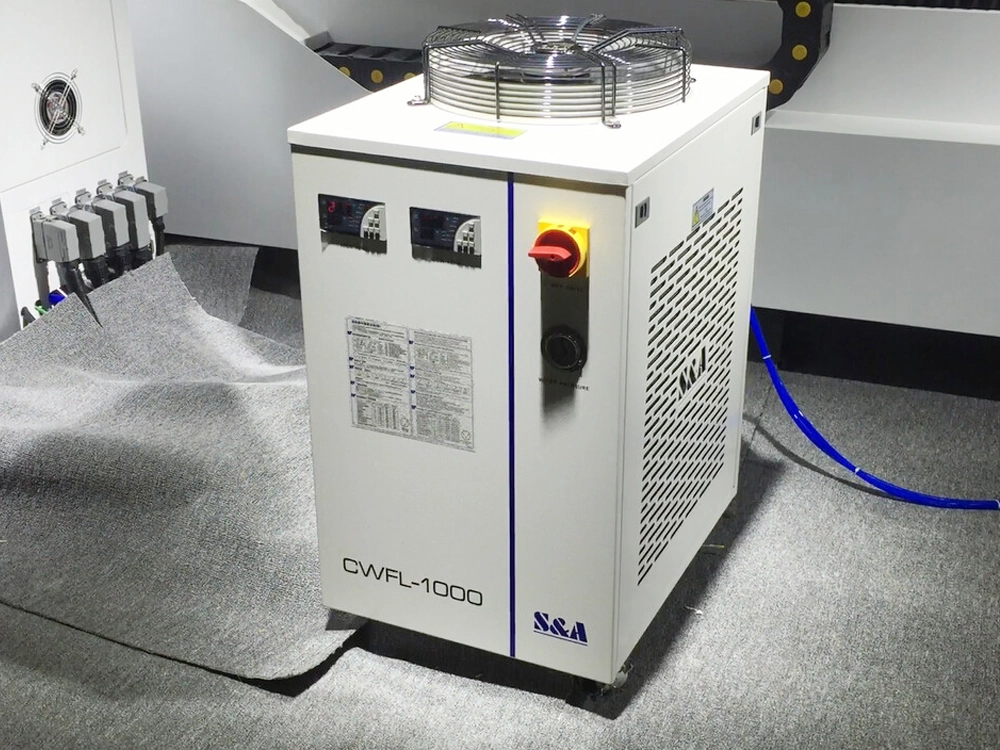

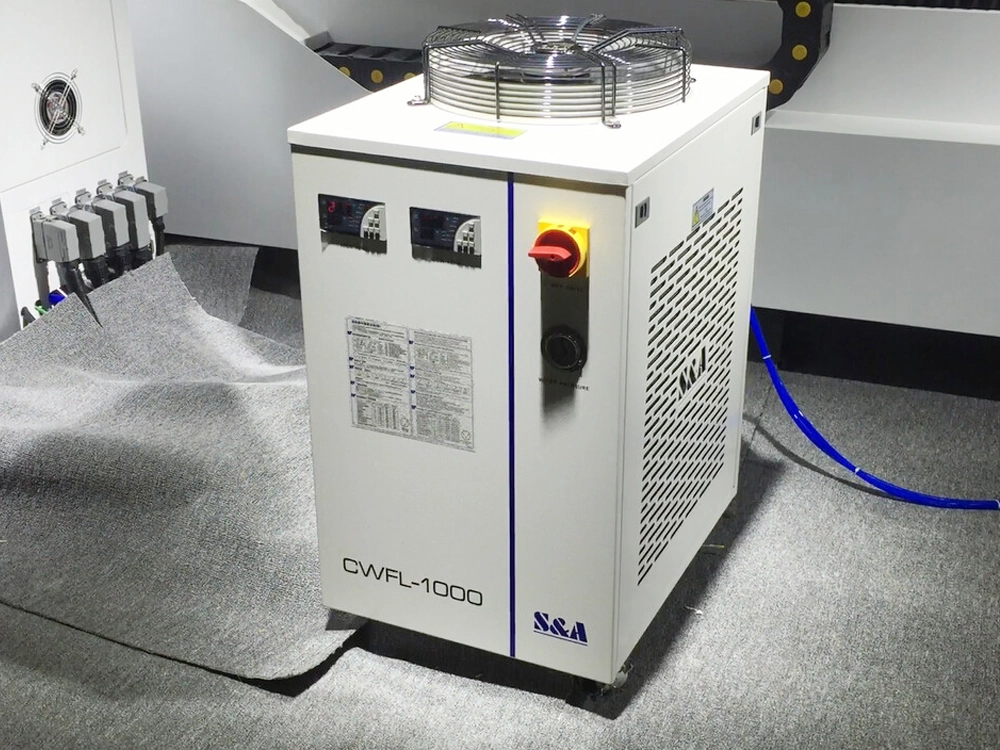

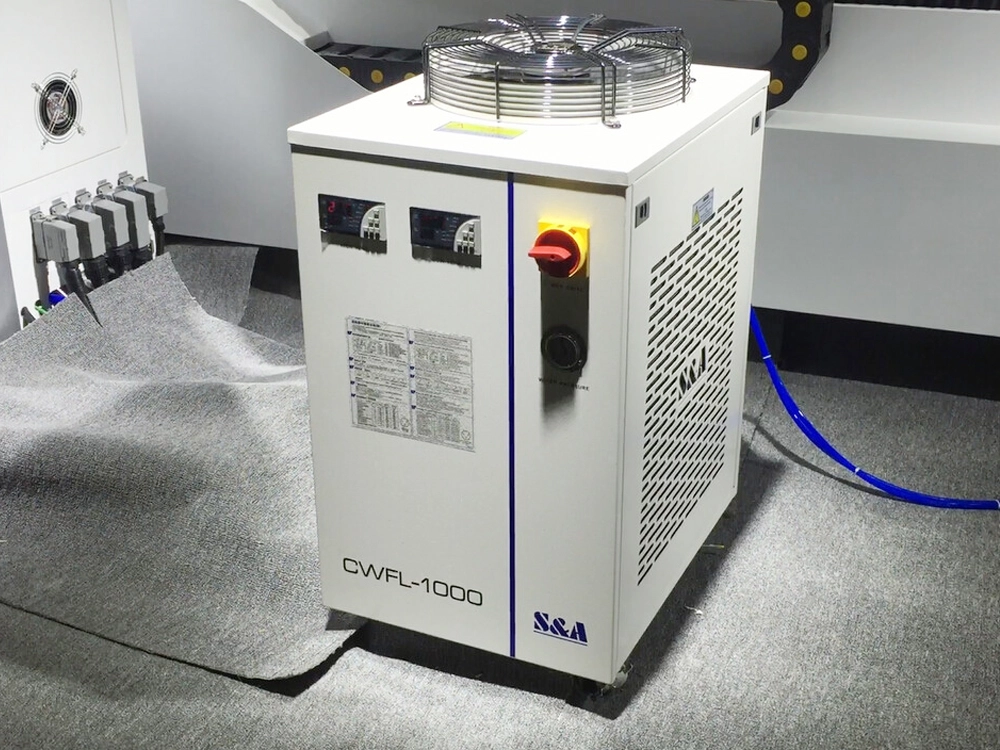

- S & A Chiller

High-precision constant temperature control system with dual-temperature cycle cooling. Two independent temperature control systems simultaneously cool the fiber body and QBH connector. Multiple alarm functions provide comprehensive protection for the laser. Equipped with universal casters for easy mobility and dual-inlet/dual-outlet water circulation interfaces with a water level gauge for convenient use.

Equipped with water pressure gauge: convenient for observing the water pressure of the water pump;

Additional drainage valve: convenient for drainage;

Universal casters: convenient for movement, equipped with dual-inlet and dual-outlet circulating water interface and water level gauge, more convenient to use.

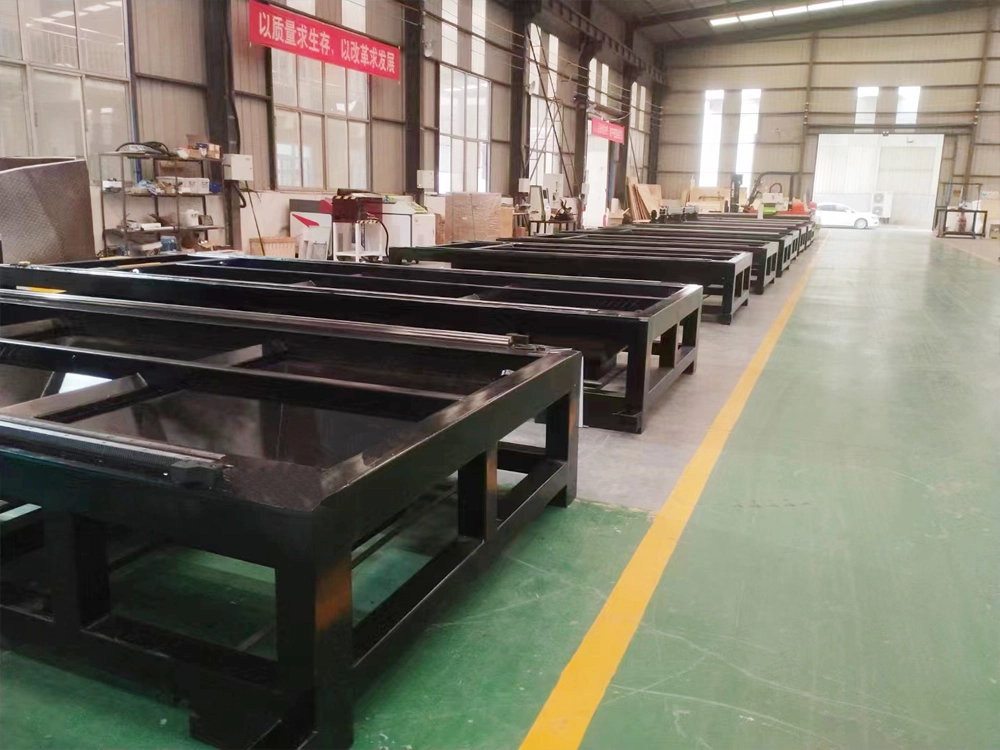

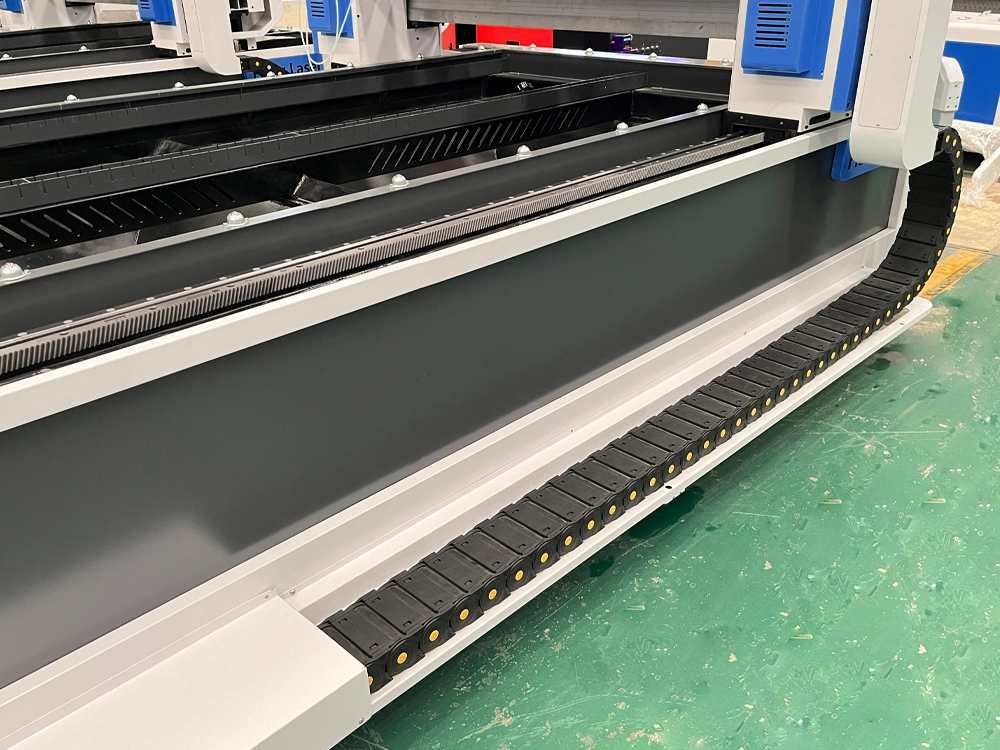

- Frame

The strongest frame of the fiber laser cutting machine. The wall thickness of the rectangular tube is 10mm. The entire bed is processed by gantry milling machine, which greatly increases the stability of the guide rail and effectively avoids deformation of the bed.

The aluminum alloy gantry bracket is manufactured according to aerospace standards. After aging treatment, it is the strongest among all gantries. Aluminum alloy is light in weight, high in strength and does not deform.

- Tooth-type slats workbench

The tooth-type slats design reduces the contact area between the processed material and the platform, effectively ensuring better cutting results.

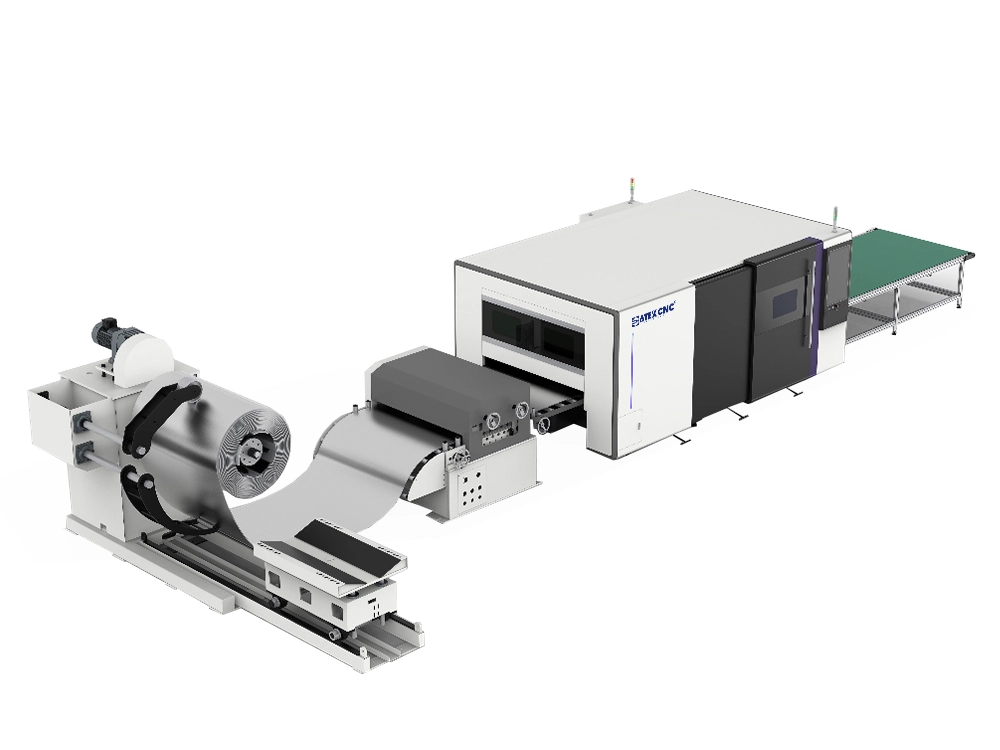

- Auxiliary loading wheel

Universal loading wheels distributed around the worktable make material loading easier and more effortless.

- Dust cover

XYZ axes are equipped with dust covers to prevent smoke and dust from entering during processing.

- Drag chains

The wires and oil circuits exposed to the outside are wrapped with flame-retardant drag chains.

- Control system

Equipped with the FSCUT laser control system and an external wireless handle, supporting advanced functions such as workpiece edge detection, auto-focus control, dual shuttle, breakpoint positioning, QR code generation, and remnant material segmentation. Simple operation, stable performance, and high-quality cutting results.

Application Scope of Fiber Laser Cutter

Applicable Materials

Iron, alloy, carbon steel, Q235, 45# steel, galvanized sheet, electrolytic sheet, stainless steel, 304, 316, 430, aluminum sheet, 5052, 6061, 7075, brass sheet, brass, manganese steel, copper, titanium alloy, TC4, TA2, rare metals and other metal and alloy sheets.

Applicable Industries

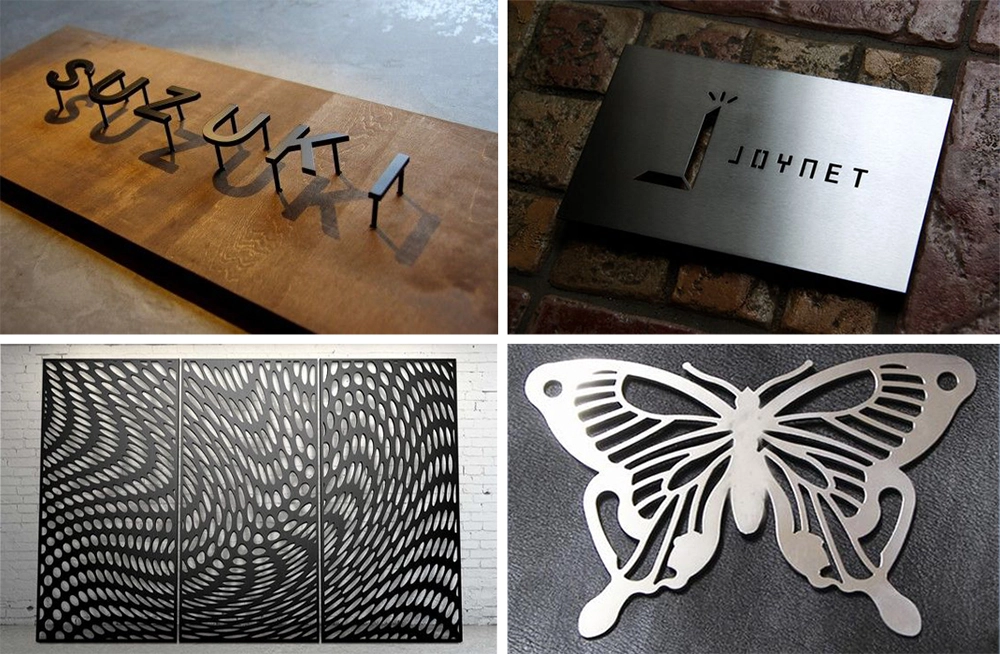

- Automobile manufacturing: body sheet metal, car battery tray, car door, gear, seat bracket, etc.

- Hardware construction: metal signs, elevator panels, door and window frames, metal advertising characters, metal screens, iron gates, building sidings, decorative panels, etc.

- Engineering machinery: agricultural machinery accessories, metal brackets, engine blades, wind power gearboxes, photovoltaic brackets, etc.

- Shipbuilding: decks, hull guard plates, hull pipes and other parts.

- Kitchen appliances: refrigerator shells, washing machine shells, home appliance accessories, stainless steel furniture, etc.

- Electronics industry: mobile phone middle frames, laptop shells, LED light bar brackets, heat dissipation substrates, etc.

Technical Parameters of High Power Fiber Laser Cutter

| Model | CK-1530-F |

| Cutting Area | 1500mm*3000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | Leadshine servo motor*4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | Japan Shimpo reducer |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Electrical Components | Schneider |

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 4000kg |

| Dimensions | 5100*2250*2150mm |

Optional Configurations of Fiber Laser Cutting Machines

| Servo Motor | Yaskawa/Delta/HCFA/Fuji/Panasonic etc. |

|---|---|

| Reducer | France Motoreducer |

| Laser Generator | Raycus/Maxphotonics/JPT/BWT/Reci etc. |

| Laser Head | Empower/WSX/AU3TECH, etc. |

| Air Compressor | Integrated screw air compressor for optical fiber cutting machine |

| Voltage Stabilizer | High Power Voltage Stabilizer |

| Control system | Cypcut/Raytools/NC-studio etc. |

| Rotary axis | Double chuck metal tube cutting rotary axis |

Metal Thickness That Can Be Cut by Fiber Laser Cutting Machines of Different Powers

| 1500W | 2000W | 3000W | 6000W | 8000W | 10000W | 12000W | 15000W | 20000W | |

|---|---|---|---|---|---|---|---|---|---|

| Carbon Steel(Q235B) | 16mm | 20mm | 25mm | 30mm | 30mm | 40mm | 45mm | 50mm | 60mm |

| Stainless Steel(US304) | 8mm | 10mm | 12mm | 20mm | 25mm | 40mm | 45mm | 50mm | 60mm |

| Aluminum(6061) | 5mm | 6mm | 8mm | 16mm | 30mm | 35mm | 40mm | 50mm | 65mm |

| Brass | 4mm | 6mm | 8mm | 16mm | 18mm | 20mm | 25mm | 30mm | 35mm |

The Following Are the Processable Products of the CNC Fiber Laser Cutter

| Model | CK-1530-F |

|---|---|

| Cutting Area | 1500mm*3000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | Leadshine servo motor*4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | Japan Shimpo reducer |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Electrical Components | Schneider |

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 4000kg |

| Dimensions | 5100*2250*2150mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.