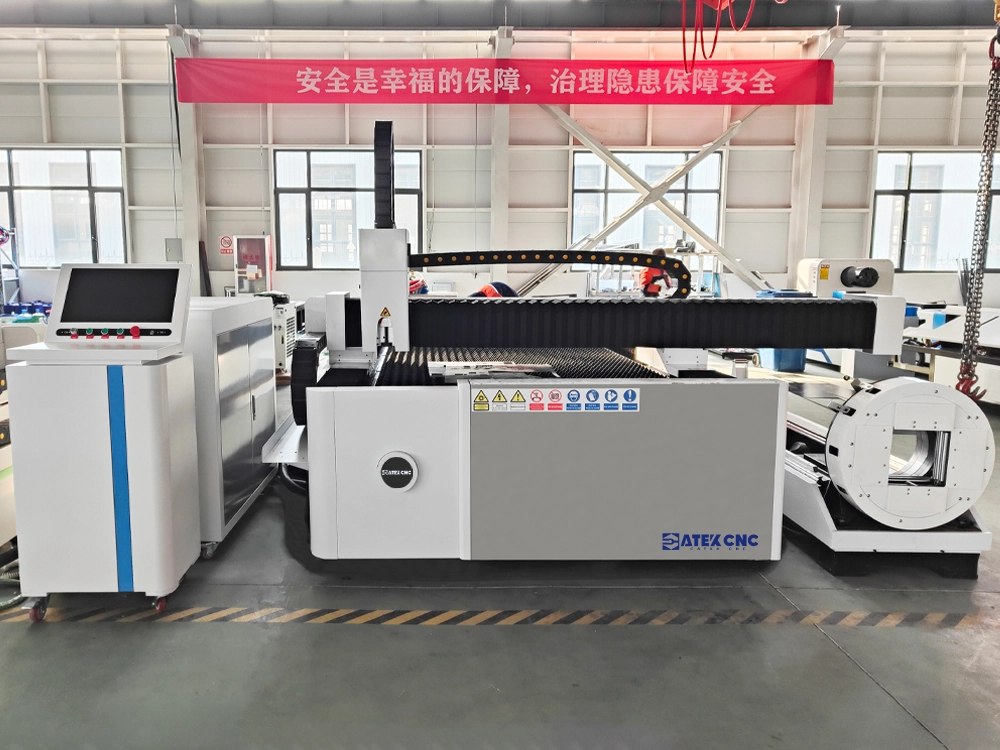

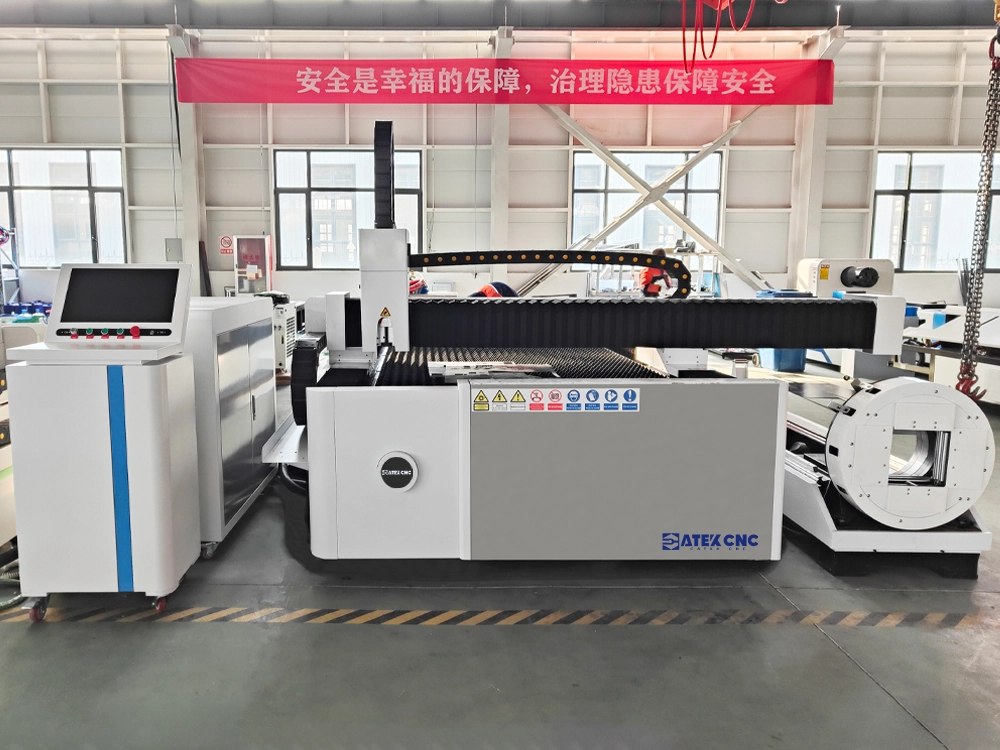

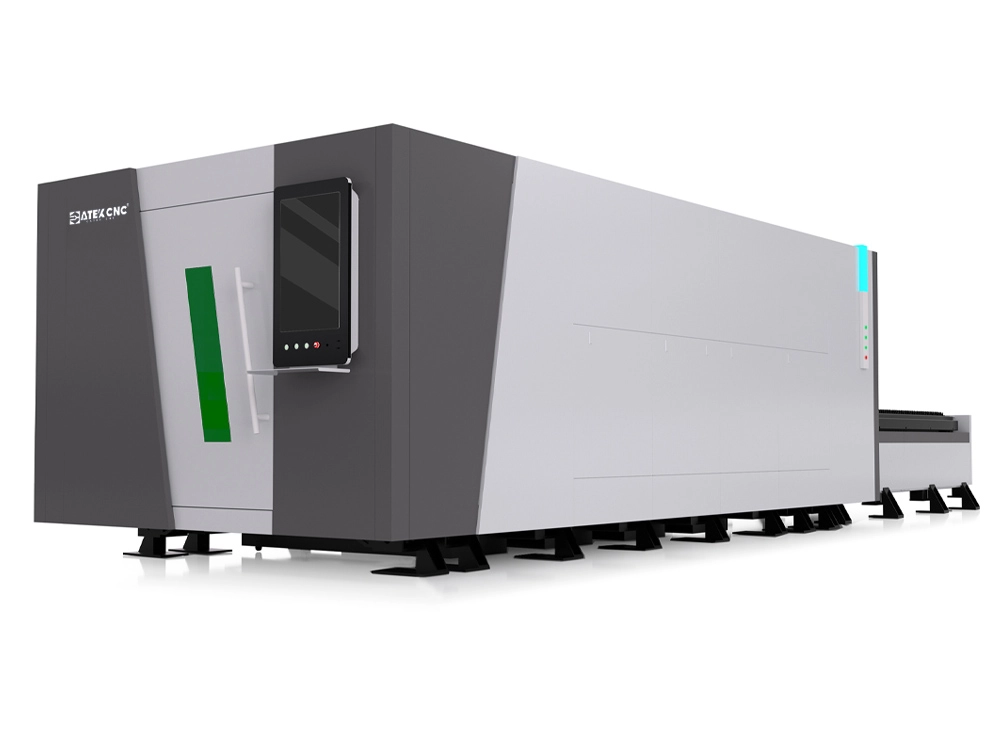

Fiber Laser Cutting Machine for Both Sheet and Tube Cutting

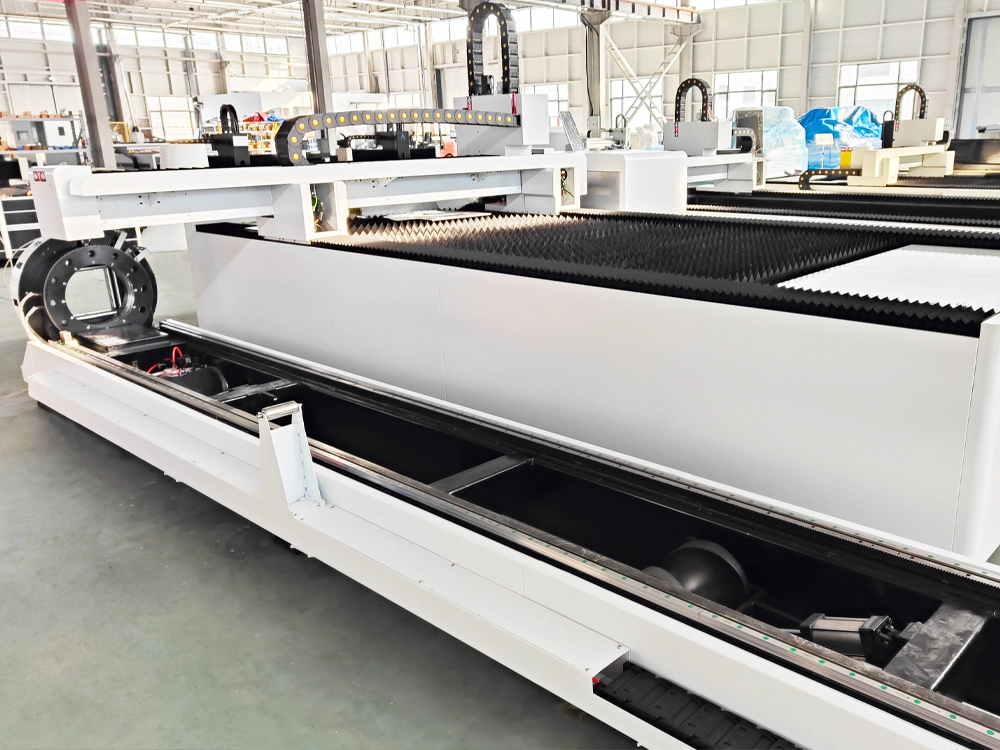

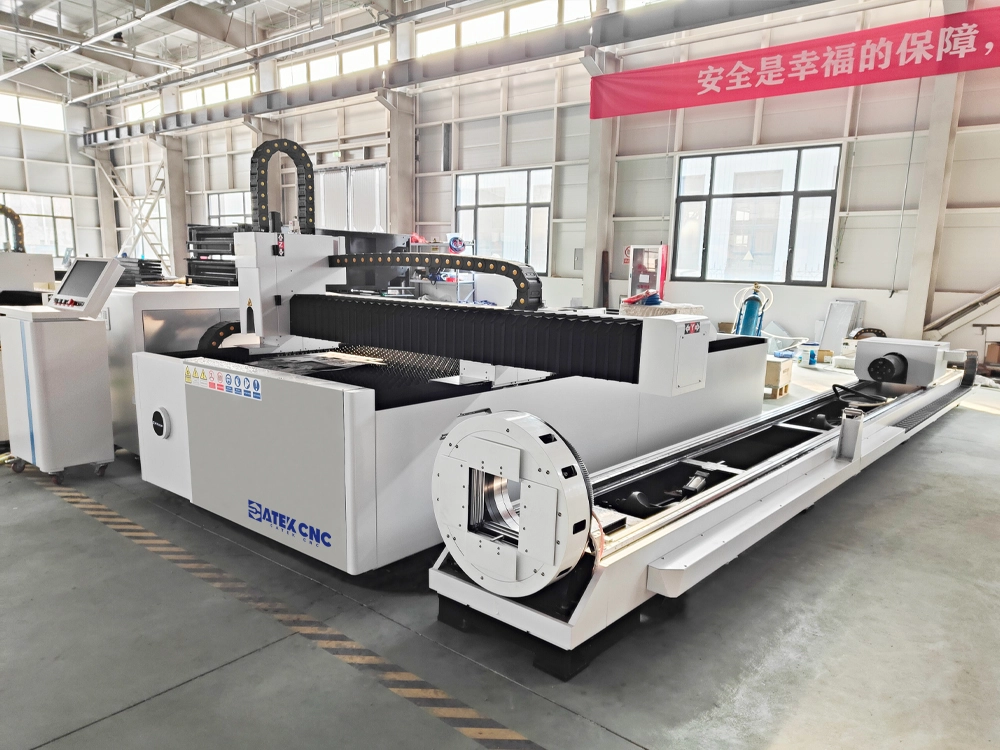

5x10 Multi-Function Fiber Laser Plate and Tube Cutting Machine

[Function Description]

The fiber laser sheet and tube cutting machine is a highly efficient and multifunctional metal laser cutting device that integrates sheet cutting and tube cutting. It uses a fiber laser as the laser source to output a high-energy continuous laser beam. The laser beam is transmitted through the fiber to the laser cutting head, where it is focused onto the surface of the workpiece, causing the irradiated spot to melt instantly. The CNC system controls the movement of each axis to adjust the position of the laser spot, enabling automatic cutting of metal.

In the metal cutting industry, there is not only a huge demand for sheet cutting but also a significant need for cutting and drilling tubes. However, most laser cutting machines on the market are single-function, capable of processing only sheets or tubes. If there is a need to cut both, different cutting equipment is required, which increases costs, occupies more space, and reduces efficiency. The fiber laser sheet and tube cutting machine is a multifunctional professional device designed for both sheet and tube cutting. Based on the common sheet laser cutting machine, it is additionally equipped with a tube rotary cutting device, allowing it to cut both sheets and tubes (such as square tubes, round tubes, channel steel, angle steel, I-beams, etc.). With one machine serving multiple purposes, it offers greater advantages over other equipment. This machine can efficiently and precisely cut most sheets and tubes, making it widely popular in countries and regions such as the United States, Canada, Brazil, the United Kingdom, India, and the Middle East.

Advantages of Multifunctional Fiber Laser Plate and Tube Cutting Machine

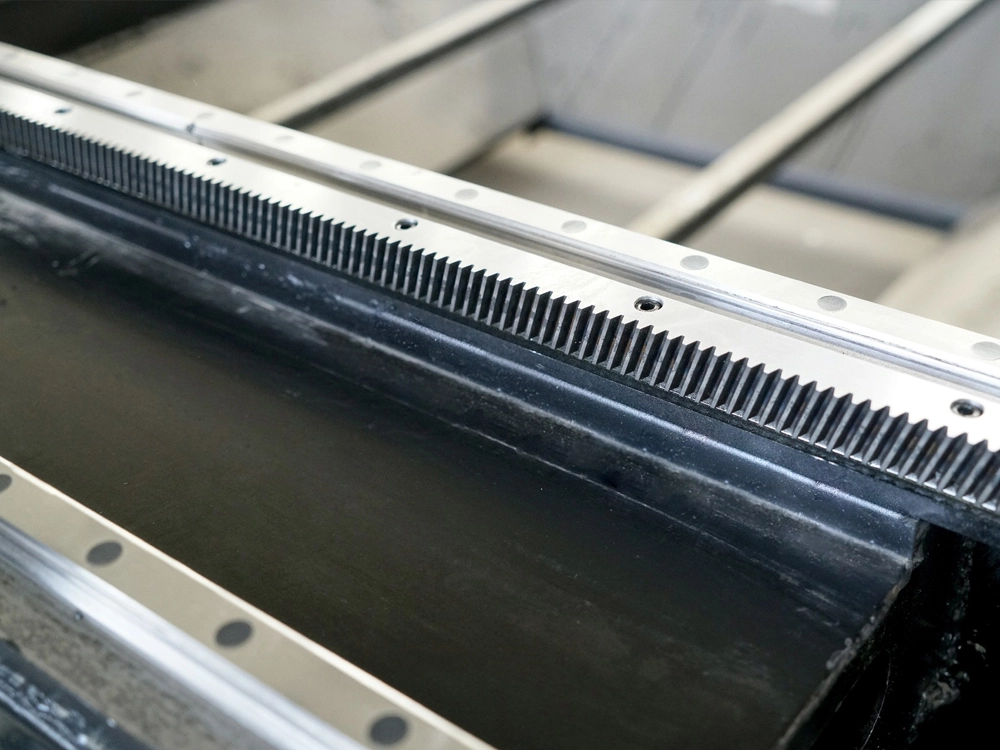

- Utilizes high-precision ground helical racks and imported square guides, achieving extremely high cutting accuracy with a positioning accuracy of 0.05mm and repeat positioning accuracy of 0.03mm.

- The laser source has a lifespan of over 100,000 hours, featuring a highly integrated design that supports 24-hour continuous operation.

- Equipped with a constant-temperature water-cooling system, maintaining the laser's operating temperature at 20-25°C, effectively protecting the laser source and cutting head.

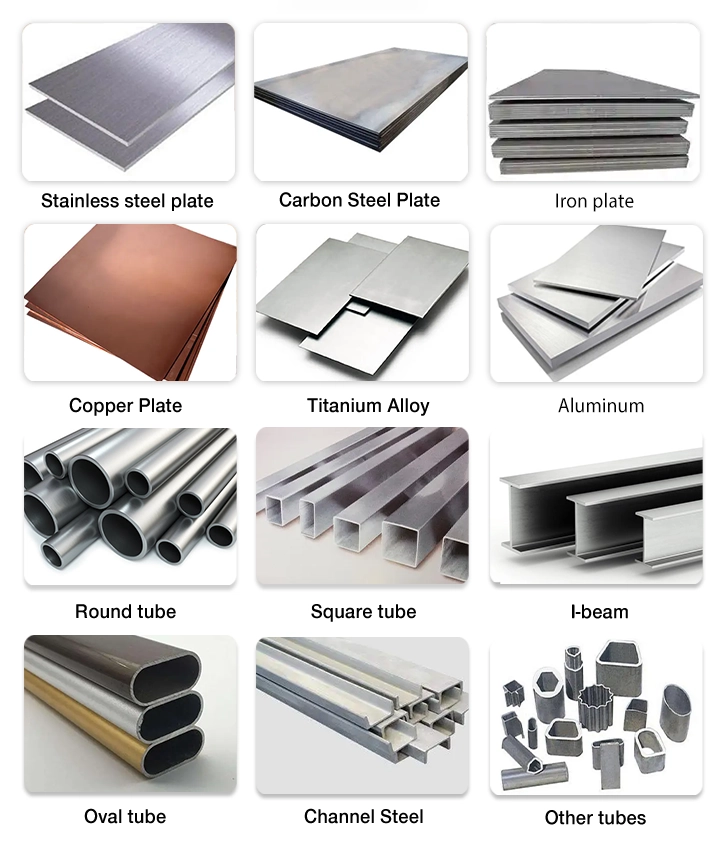

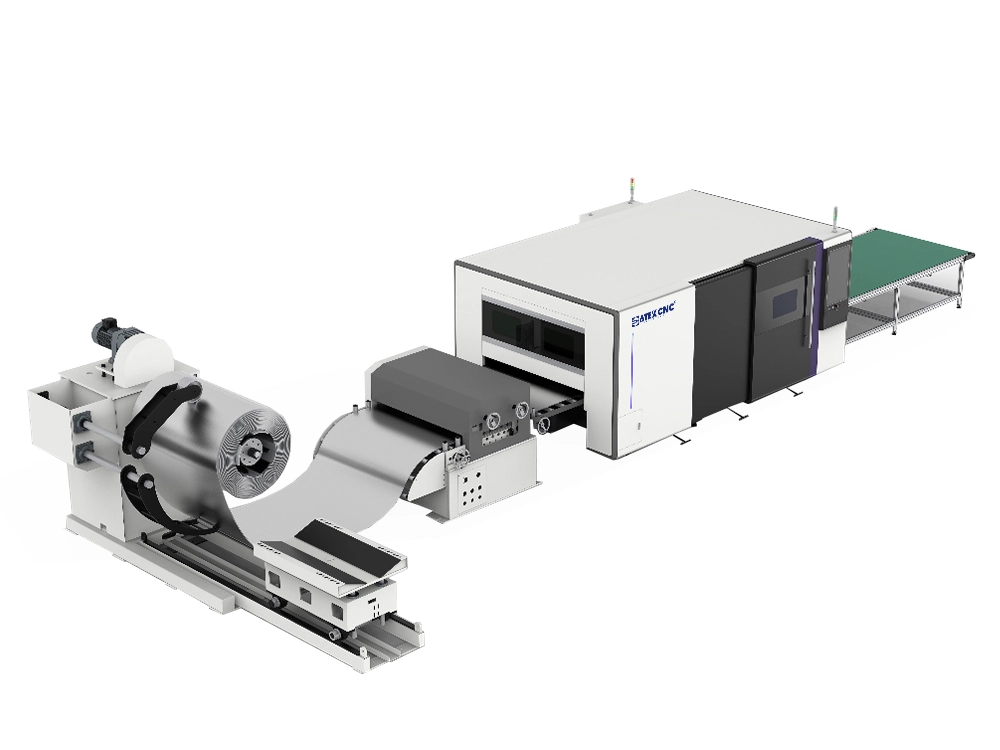

- Integrates sheet and tube cutting functions, capable of processing round tubes, square tubes, elliptical tubes, I-beams, angle irons, L-shaped steel, and various types of sheets. A versatile machine that is easy to use.

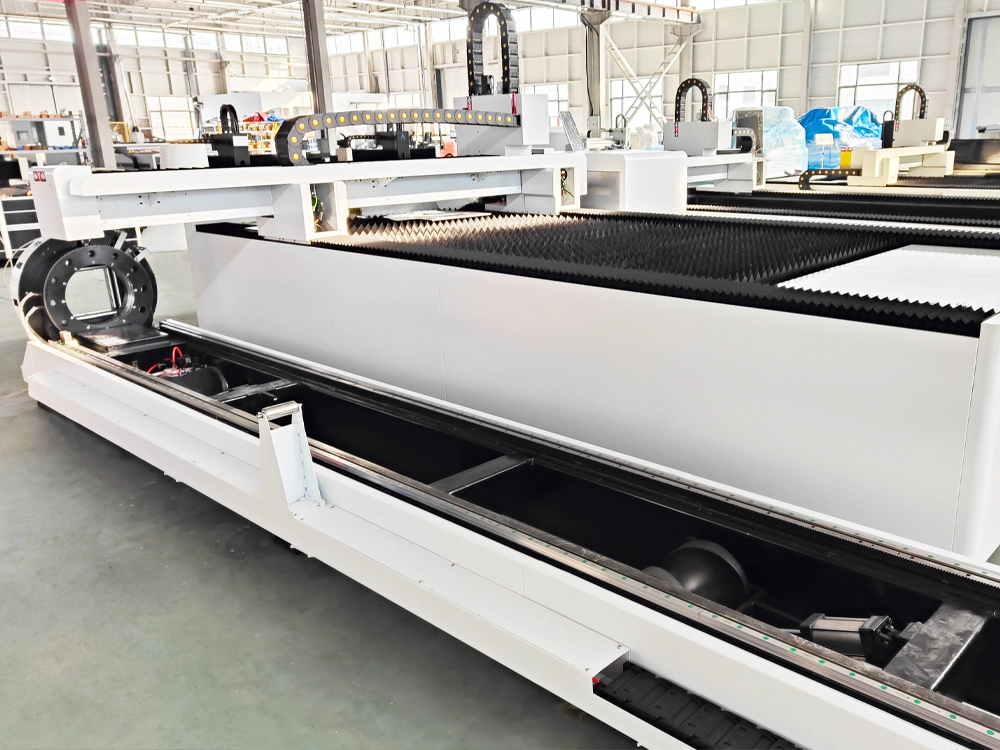

- Heavy-duty thickened square steel welded slope bed, annealed and milled using imported large gantry milling machines for higher installation precision.

- Aerospace-grade aluminum alloy beam, subjected to artificial aging and solution treatment, processed by gantry milling machines, ensuring excellent integrity, rigidity, toughness, and stability.

- Capable of processing internal, external, X-shaped, and Y-shaped bevels, even for pipes with poor roundness.

- Customizable options for laser sources, laser heads, and control systems of different power levels and brands.

- Automatic lubrication system provides full lubrication for all transmission parts, simplifying maintenance.

Features of 5x10 Fiber Laser Plate-and-Tube Cutting Integrated Machine

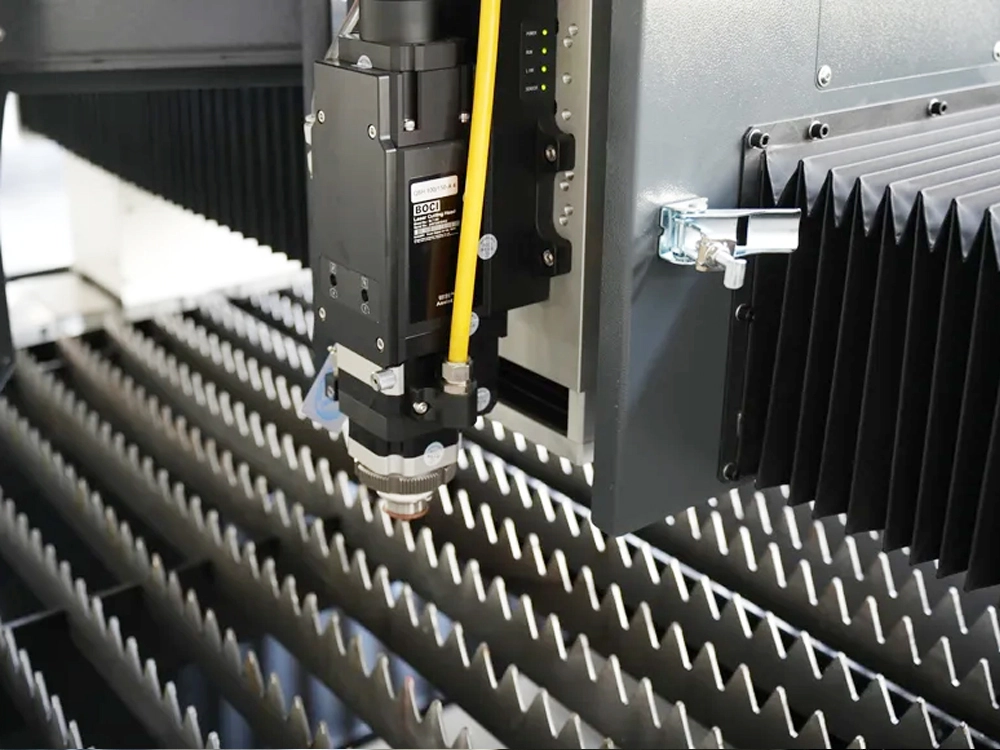

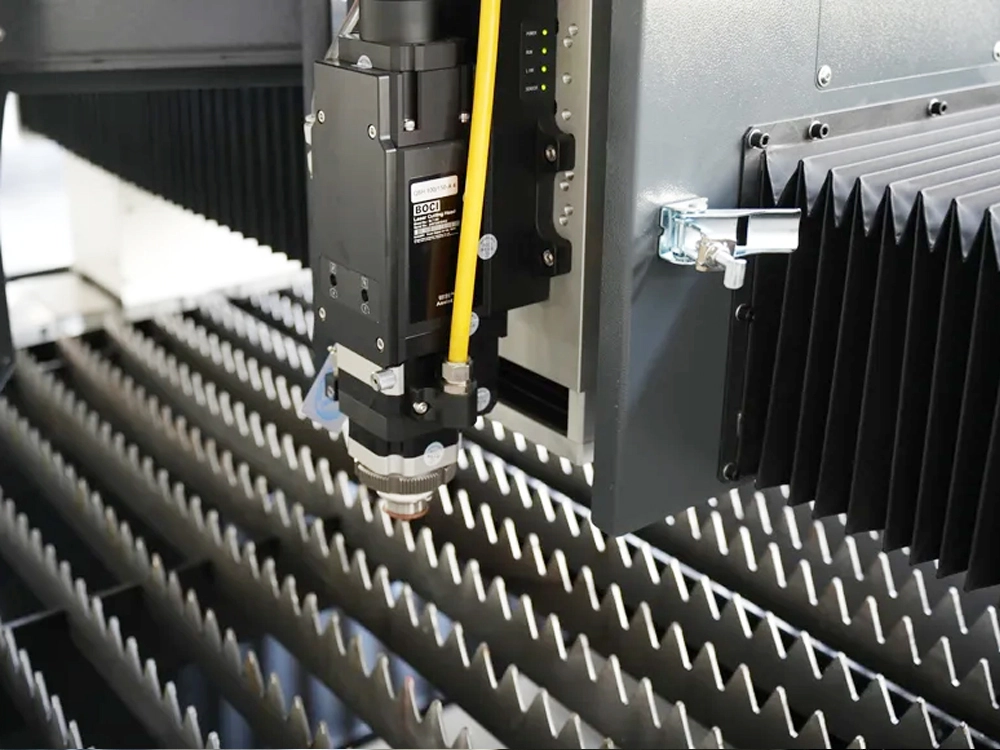

- The laser cutting head is equipped with obstacle avoidance and collision protection features, enhancing equipment safety, reducing accidents.

- When the equipment is in an abnormal working state, it will automatically trigger an alarm function and push the alarm information to the control panel, improving the efficiency of troubleshooting equipment anomalies, reducing potential safety hazards, and lowering maintenance costs.

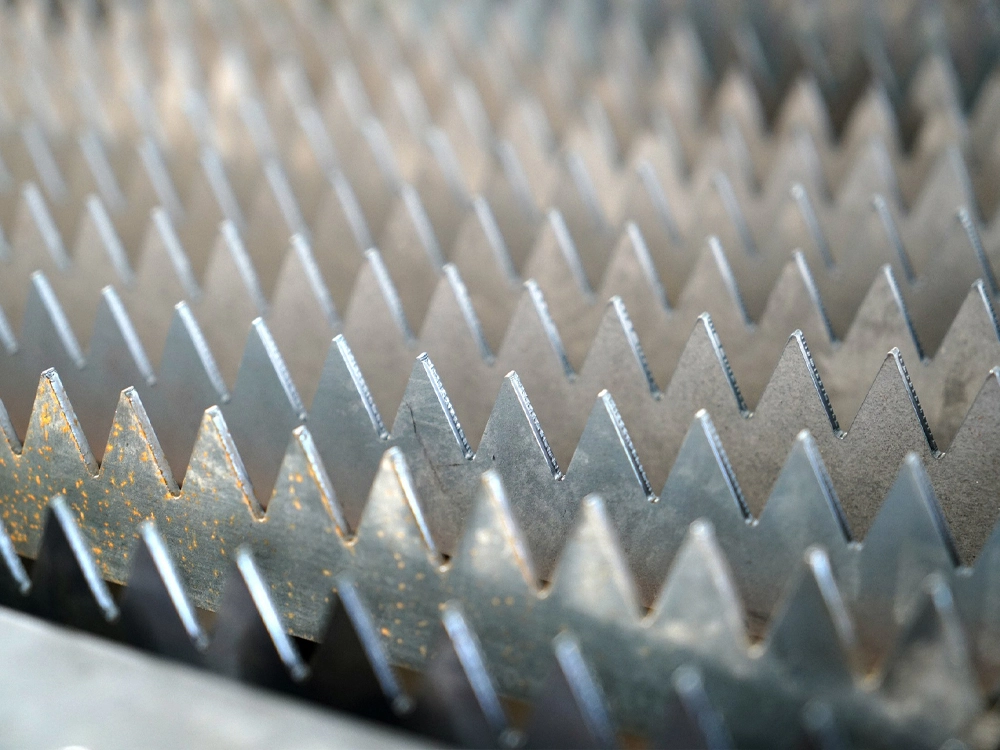

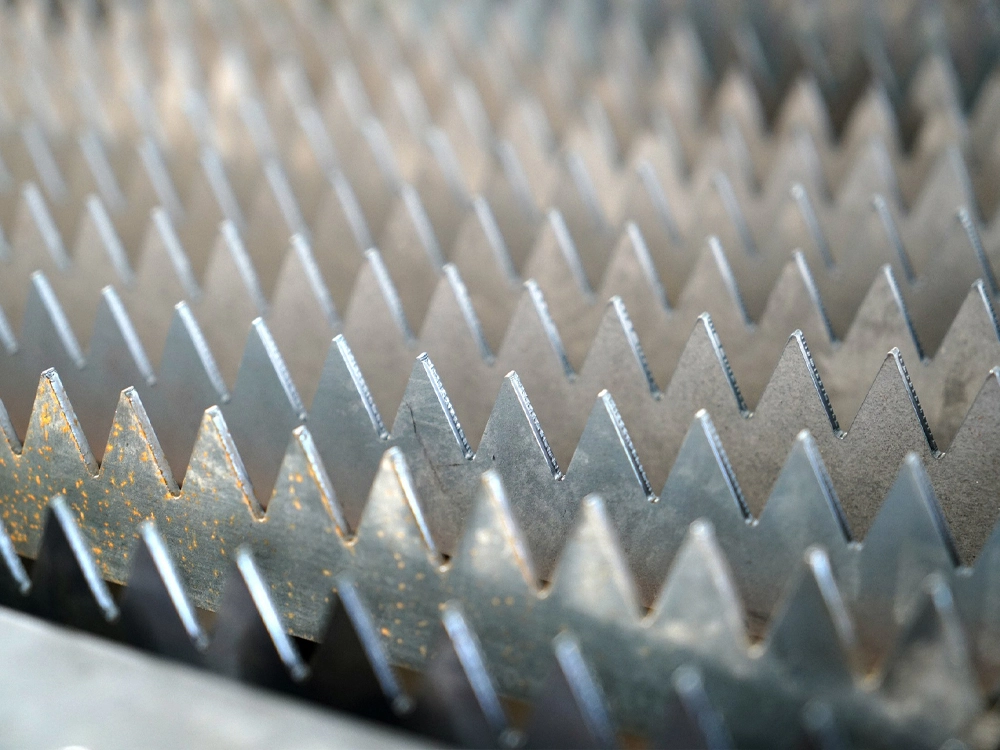

- During processing, the laser beam is focused into a very small spot, achieving extremely high power density at the focal point. The material is rapidly heated to vaporization and evaporates to form a hole. As the spot moves, a very narrow kerf (only 0.1-0.2mm wide) is formed, saving more material.

- Laser cutting is a non-contact process, with minimal thermal impact on the cutting edges, resulting in almost no workpiece deformation. The kerf has a high finish, free of burrs and residue, eliminating the need for secondary grinding.

- Laser cutting does not require any molds or tools, reducing consumable usage and effectively lowering processing costs.

- The laser cutting machine uses servo motors and aluminum alloy beams, ensuring high-speed movement with low inertia, capable of cutting over 15,000mm per minute.

- CNC software is used for automatic nesting and programming, maximizing material utilization when cutting a steel plate into multiple products of different shapes.

- Laser cutting is safe and environmentally friendly, producing minimal waste, low noise, and no pollution, ensuring a clean and eco-friendly working environment.

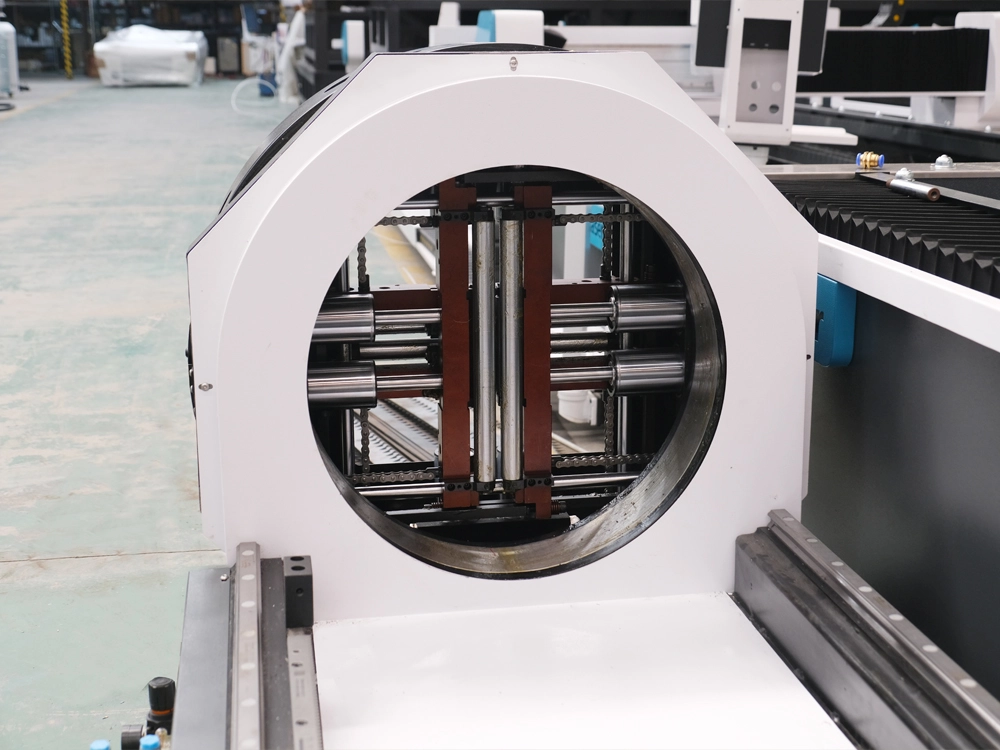

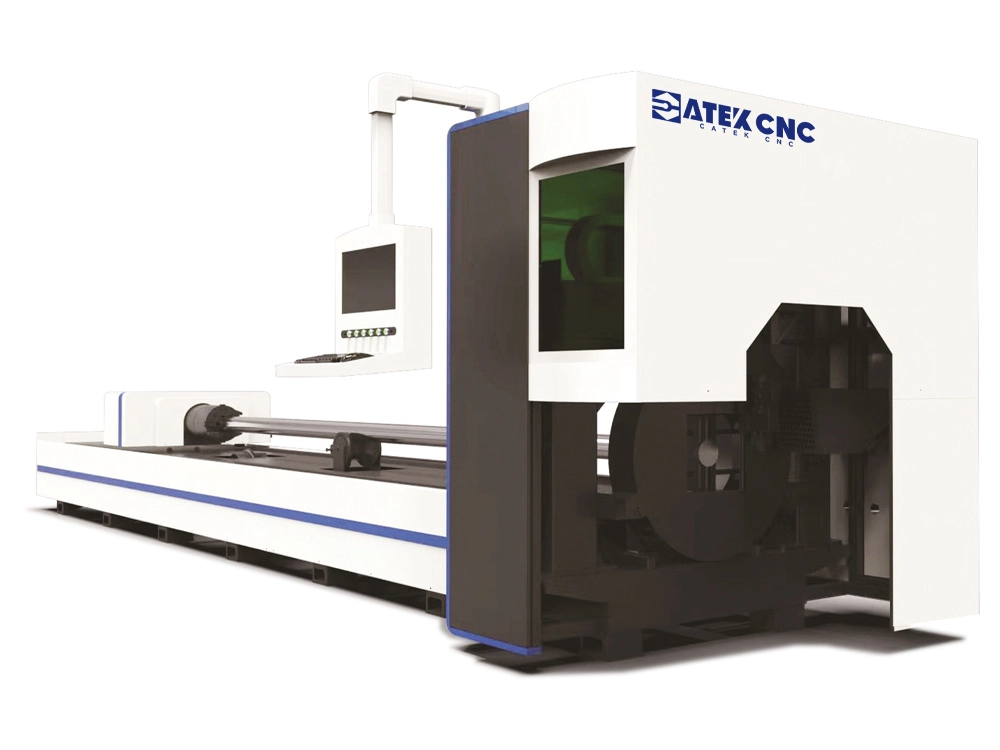

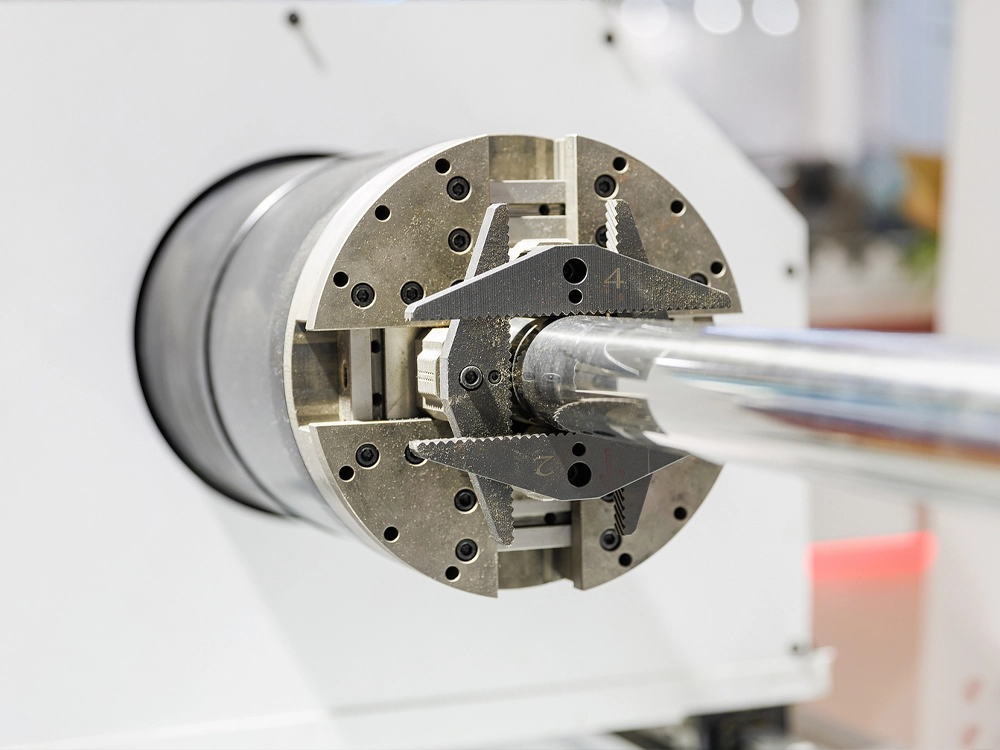

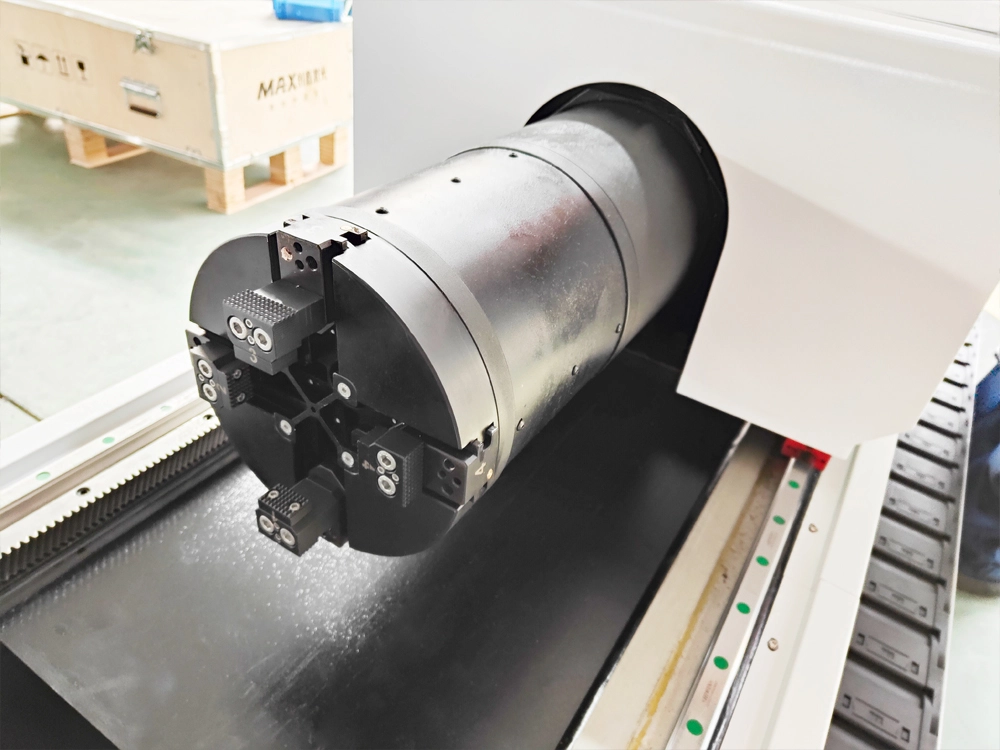

- The tube cutting device can be optionally equipped with electric or pneumatic clamps, with an adjustable range of 20~220mm, supporting custom sizes for processing larger diameter metal tubes. It can automatically locate the tube center, providing strong and constant clamping force to prevent slipping or loosening, even with heavy tubes, ensuring cutting precision. An automatic support system is included to support the center of long tubes during processing, preventing deformation.

- Supports various graphic file formats such as AI, DXF, PLT, Gerber, and LXD, and is compatible with G-code.

- The control system has built-in cutting process parameters, allowing one-click selection without frequent parameter adjustments.

- The user-friendly interface supports both automatic and manual nesting, with multiple nesting methods available.

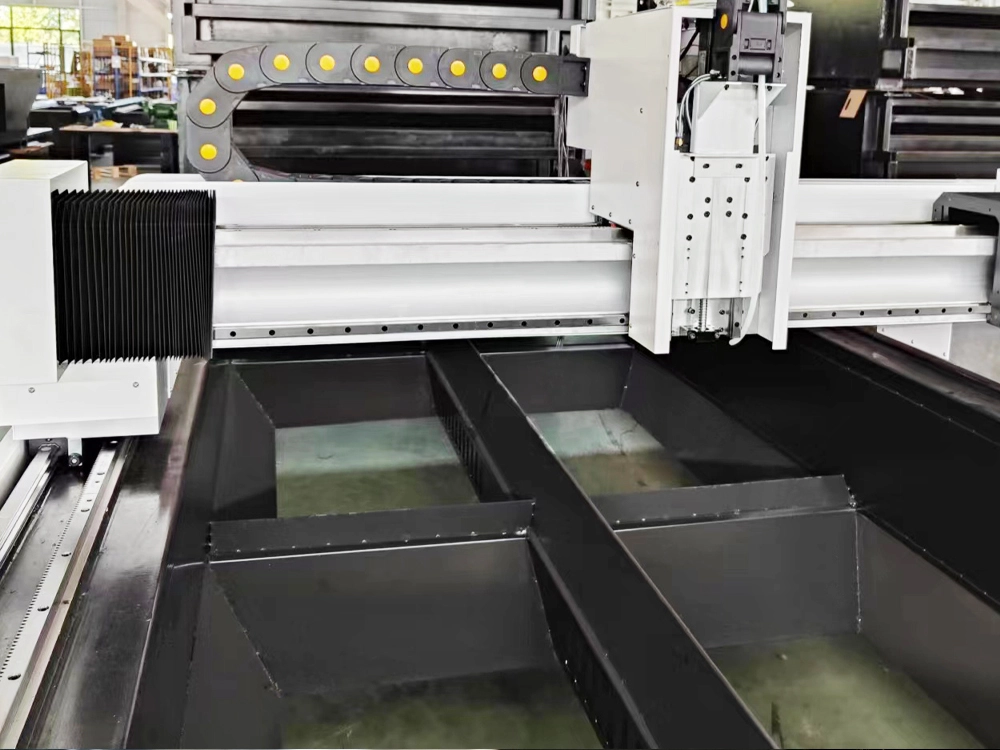

Details on the Versatile Fiber Laser Metal Cutting Machine with Tube Rotary Cutting Device

- Gantry

-

The aviation-grade aluminum alloy crossbeam is light in weight and high in strength, which can greatly increase the moving speed and minimize the inertia of movement while ensuring strength and rigidity.

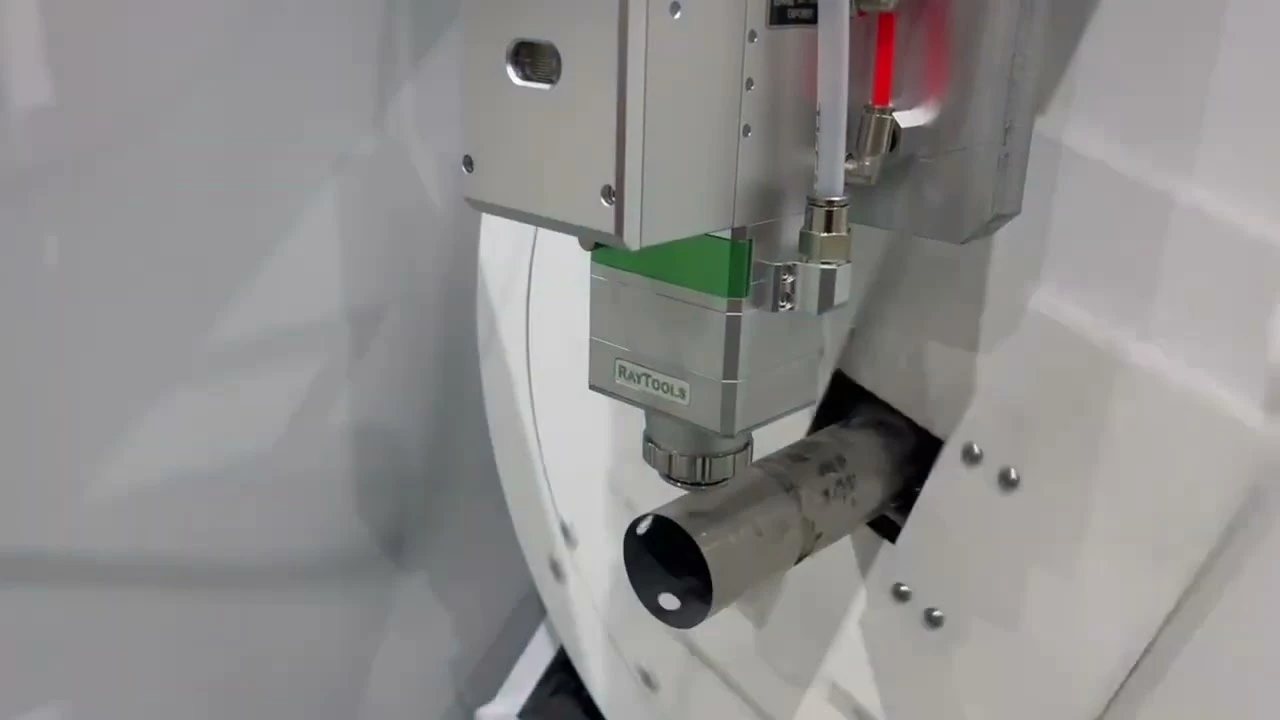

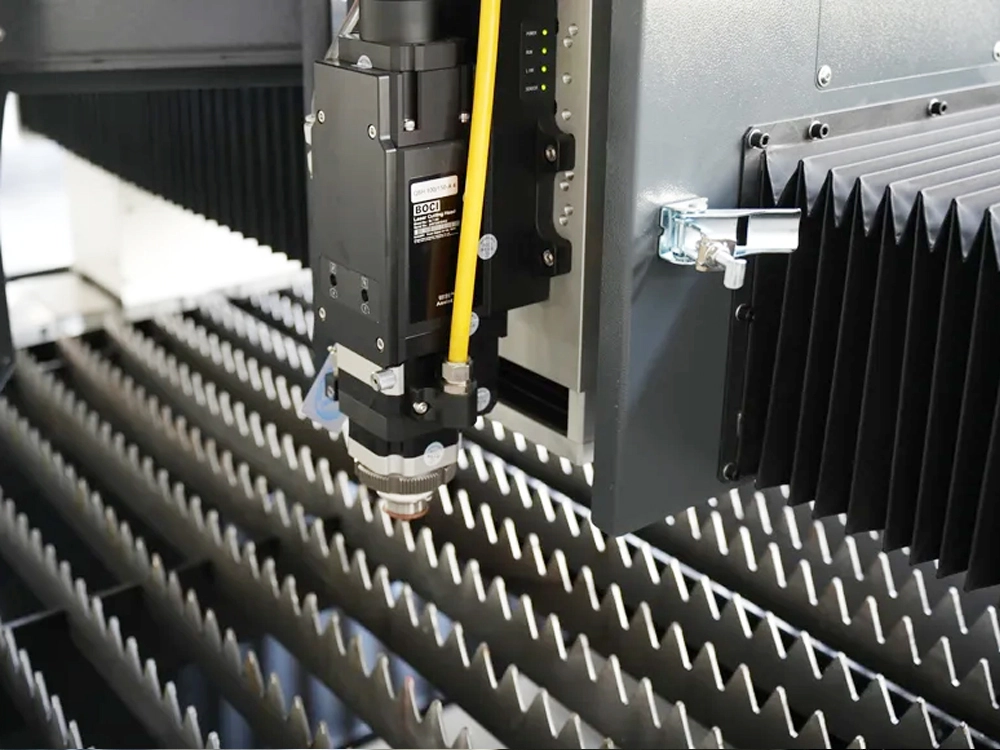

- Laser source and autofocus cutting head

-

There are different brands and power of laser source and cutting heads available.

- Constant temperature S & A water cooler

-

Constant temperature water cooling system ensures the machine works within a suitable temperature range.

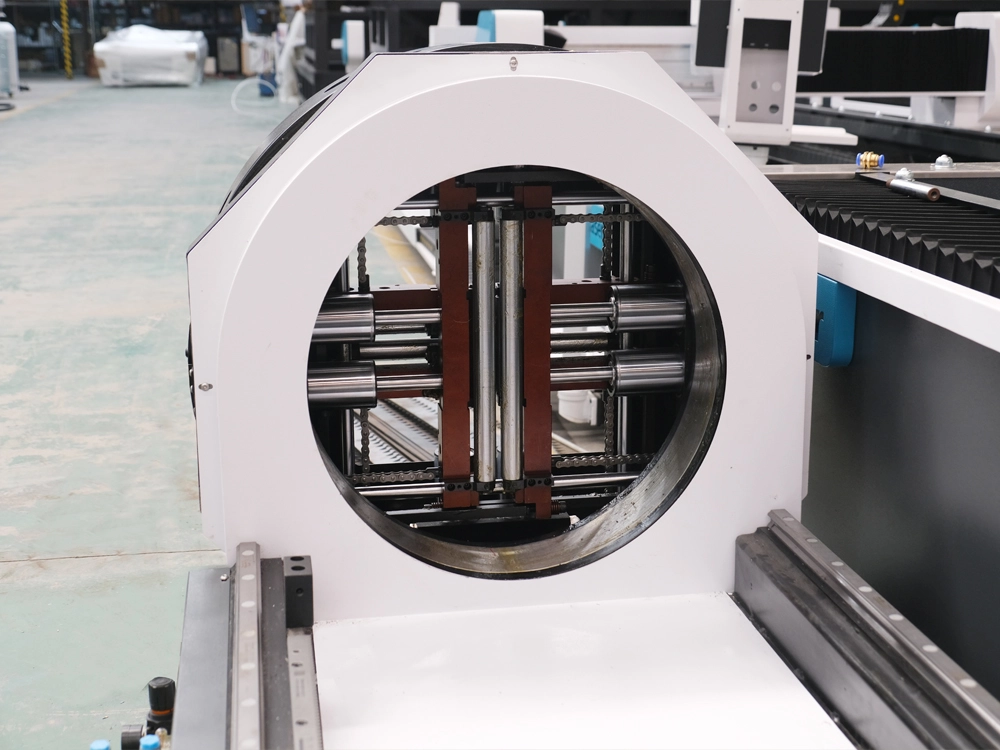

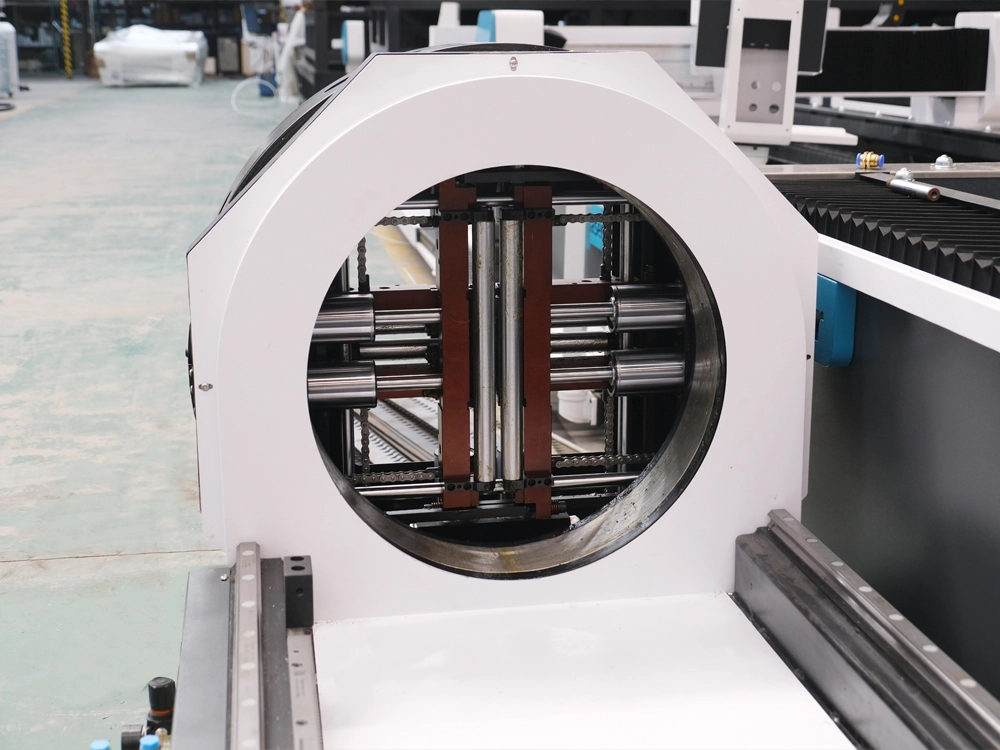

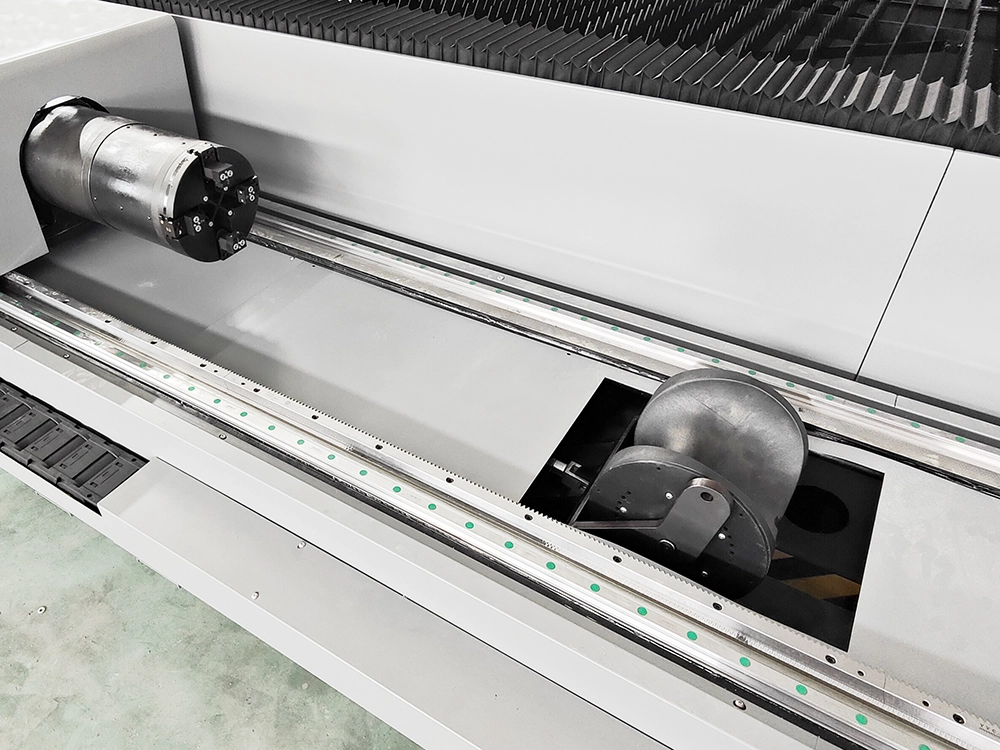

- Independent metal pipe cutting rotary axis in side

-

Self-centering collet chucks can grip a wide variety of tubing types.

The floating support can automatically adjust its height according to the length and diameter of the pipe, providing support to prevent sagging during the cutting of slender pipes.

The jaws of the rear chuck are replaceable to meet the clamping requirements of different pipes.

- Transmission system

-

High-precision spiral rack effectively guarantees accuracy and service life.

- Drag chains

-

Protect and store cables, oil pipes, etc. to prevent line clutter and wear.

- Vertical LCD control system display

-

FSCUT laser-dedicated system supports sheet and tube cutting.

Technical Parameters of Fiber Laser Sheet And Tube Integrated Cutter

| Model | CK-1530-FT |

| Cutting Area | 1500mm*3000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | Leadshine servo motor*4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | Japan Shimpo reducer |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Electrical Components | Schneider |

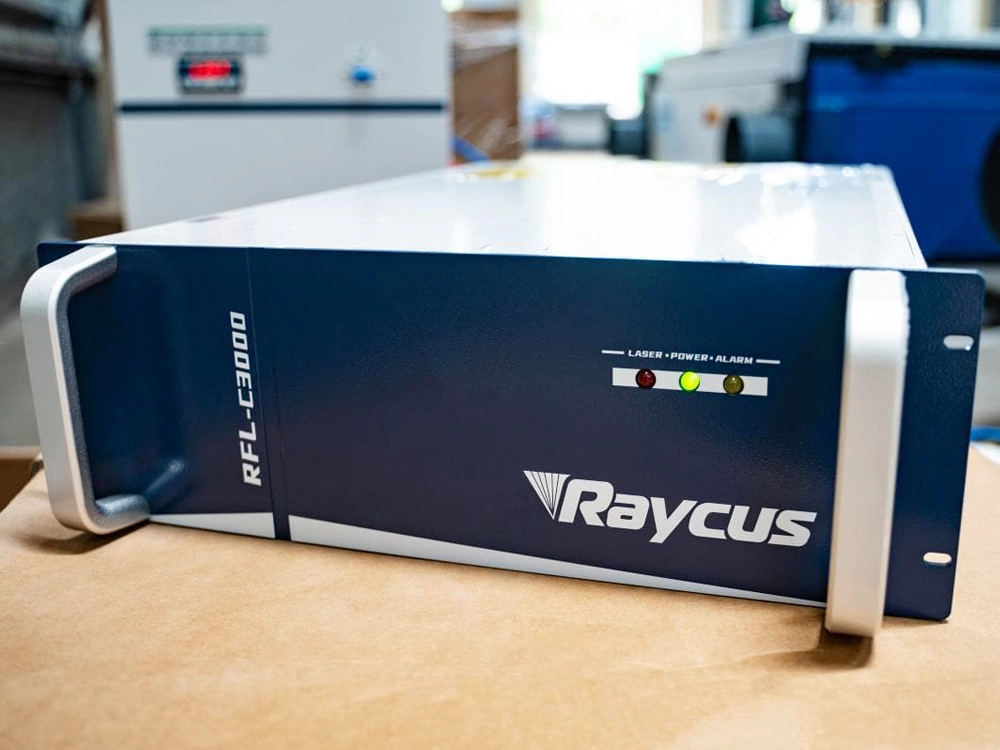

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 4400kg |

| Dimensions | 5100*3050*2150mm |

Optional Specifications

| Processing Size | 2000*3000/1500*4000/2000*4000/2000*6000/2000*12000 etc. |

|---|---|

| Laser Power | 1500w/2000w/3000w/6000w/12000w etc. |

| Pipe Processing Length | 3000/4000/5000/6000/8000mm etc. |

Application Scope of Fiber Laser Sheet And Tube Integrated Cutter

Applicable Materials:

- Carbon steel: Applicable to carbon steel, manganese steel, spring steel plates of various thicknesses, including thin plates, medium plates and thick plates.

- Stainless steel: Including different types of stainless steel plates and pipes such as 304 and 316.

- Aluminum plate: Applicable to aluminum plates of various thicknesses, including aluminum alloys.

- Copper plate: Applicable to copper alloy materials such as brass and copper.

- Galvanized plate: Applicable to galvanized steel plate and aluminum-zinc plate.

- Titanium alloy: Applicable to titanium and its alloy materials.

- Alloy steel: Including special alloy materials such as manganese alloy and chromium alloy.

- Rare metals: Such as nickel-molybdenum alloy, etc.

- Other metals: Such as precious metal materials such as silver and gold.

Applicable Industries:

- Mechanical Industry: Agricultural machinery, textile machinery, construction machinery, medical equipment, refrigeration equipment, environmental protection equipment, and other related industries.

- Manufacturing Industry: Automotive, shipbuilding, elevators, chassis cabinets, fitness equipment, mechanical parts, electrical cabinets, computer cases, and other related industries.

- Advertising Industry: Decoration engineering, advertising signs, steel structures, advertising letters, and other related industries.

- Processing Industry: Sheet metal processing, furniture, kitchenware, household appliances, metal crafts, hardware tool processing, and other related industries.

- Precision Industry: Aerospace, railway locomotives, precision components, electronic appliances, and other related industries.

- Hardware and Building Materials: Elevator manufacturing, building exterior wall cutting, metal wrought iron gates, hardware accessories, construction accessories, etc.

- Furniture and Home Appliances: Air conditioner casings, washing machine and refrigerator casings, stainless steel furniture, wrought iron furniture, etc.

The Following Are the Processable Products of Fiber Laser Sheet And Tube Integrated Cutter

What Should You Consider Before Buying a Fiber Laser Cutting Machine?

- Confirm the material type: You need to confirm the type of cutting material and the main cutting material (such as stainless steel, carbon steel, aluminum, copper, etc.). Different metals have different absorption rates for fiber lasers.

- Confirm the cutting size: Select a suitable flat cutting table according to the length and width of the plate to be processed, select a suitable rotary cutting device according to the length and diameter of the pipe to be processed, and select a suitable laser power according to the maximum thickness of the plate and pipe.

- Consider subsequent upgrades: Consider whether it can be easily upgraded to ensure that a higher-power laser can be replaced when there are new processing needs in the future.

- After-sales service: Choose a factory with a complete after-sales service system to avoid purchasing through dealers. Confirm the after-sales method and machine warranty method before purchasing.

- Trial cutting: Before purchasing, ask the factory to provide cutting samples of the same material, thickness and shape to observe whether the cutting quality meets the requirements. CATEKCNC provides completely free trial cutting, sample processing, and video recording.

- Budget considerations: Consider the machine price, operating costs (such as electricity and gas consumption), and maintenance costs. Find a balance between performance and price, and don't blindly pursue high configuration.

- Ease of use: Especially for CNC laser novices, the ease of use, compatibility, and support for offline programming and simulation of the operating system are very important. In addition, whether the supplier provides training and technical support is equally important.

| Model | CK-1530-FT |

|---|---|

| Cutting Area | 1500mm*3000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | Leadshine servo motor*4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | Japan Shimpo reducer |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Electrical Components | Schneider |

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 4400kg |

| Dimensions | 5100*3050*2150mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.