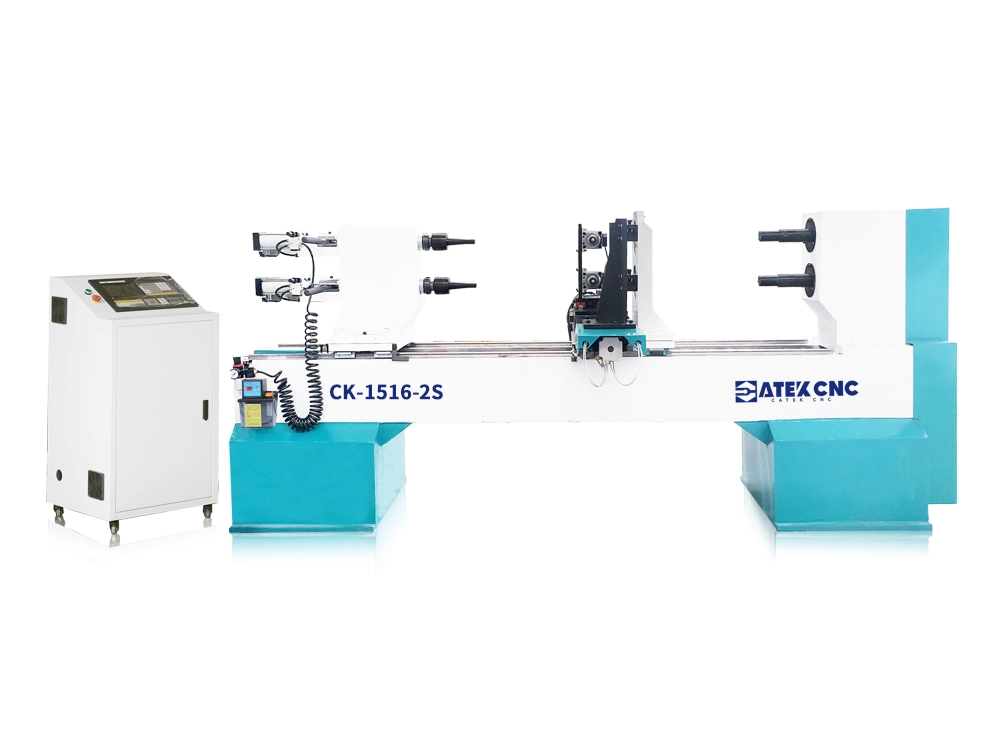

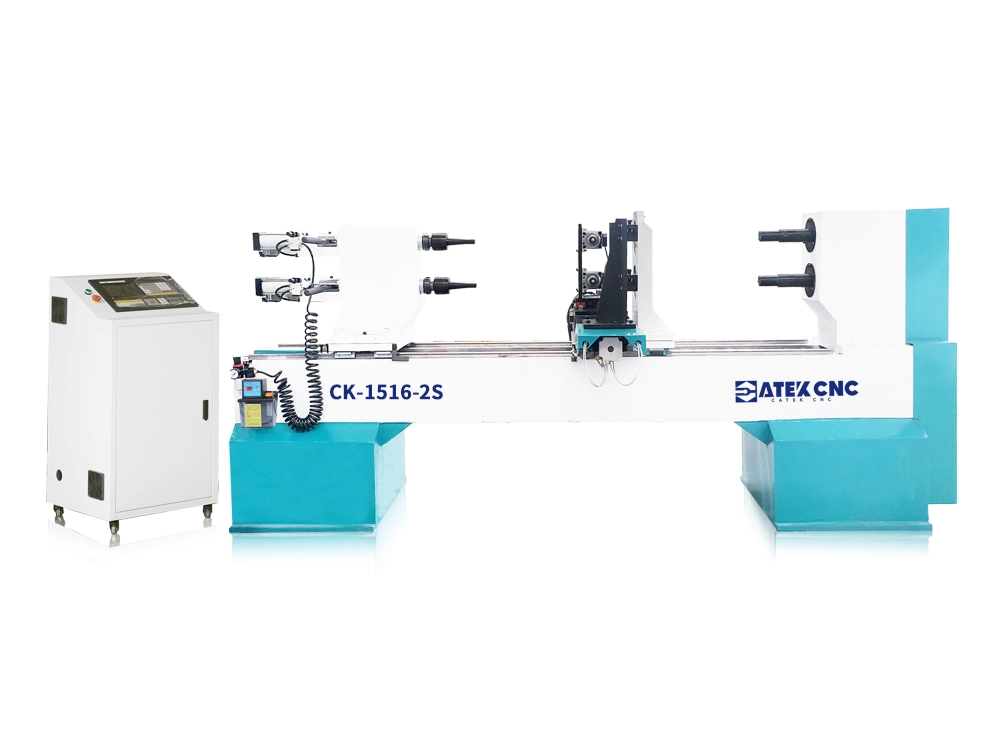

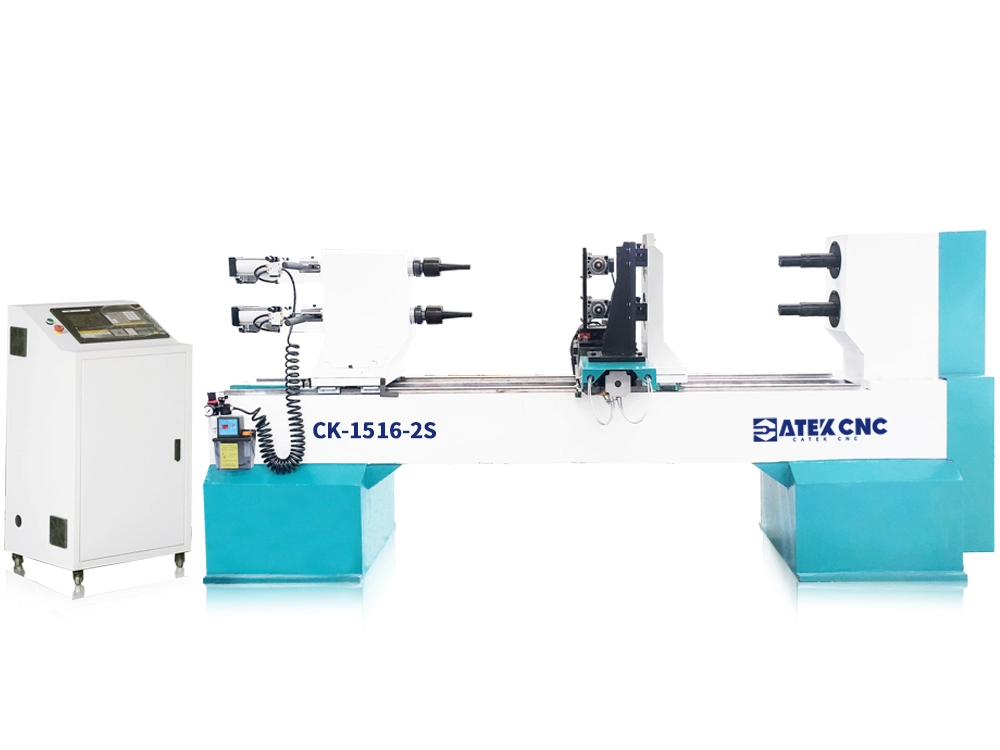

Two-Spindle CNC Lathe with Turning and Carving Combo

2-Station CNC Woodworking Lathe with Turning and Carving

[Function Description]

The 2-station turning and carving CNC woodworking lathe is an efficient and multifunctional CNC woodworking machine that integrates turning, milling or carving functions. It has two processing stations and can process two identical workpieces at a time. The processing efficiency is twice that of an ordinary lathe. In addition to the turning tool, it is equipped with two multifunctional spindles. When processing complex workpieces, a single clamping can complete the turning, drilling, milling, carving and other tasks of the workpiece, shortening the production cycle. The turning and carving multifunctional CNC woodworking lathe uses a high-precision high-speed servo motor and a high-speed air-cooled spindle. It can cope with the processing of wood or other synthetic materials of various hardness. The finished product is of good quality and high surface finish, saving time for subsequent sanding and polishing.

Features of 2-Station Turning and Carving Combined Wood CNC Lathe

- Use heavy gray cast iron bed, headstock , tailstock and other key parts are cast with gray cast iron. The designed casting structure ensures that the machine will not shake even if the spindle rotates at high speed.

- Use two 3.5kw air-cooled spindles, controlled by inverter, the speed can be adjusted arbitrarily, the speed is stable, and the processing quality is good.

- 4KW high-speed rotating servo spindle, can support speed mode or switch A-axis rotation mode, easy to use, high positioning accuracy.

- Full English operation interface control system, visual operation, equipped with letter keyboard, can be manually programmed, or use U disk to input processing drawings, flexible to use.

- External pulse handwheel, easy to use for calibrating tools, the adjustment range can be accurate to 0.01mm.

- Automatic lubrication system, regular lubrication of the transmission parts of the machine to prevent untimely lubrication during manual maintenance.

- The spindle uses ER32 tool holder, the tool holder clamping range is 1/2 inch, and can clamp tools of various lengths and shapes, which can be freely replaced according to the processing conditions.

- TBI ball screw transmission, the Z axis can choose to use 32mm TBI ball screw or high-precision helical gears and racks.

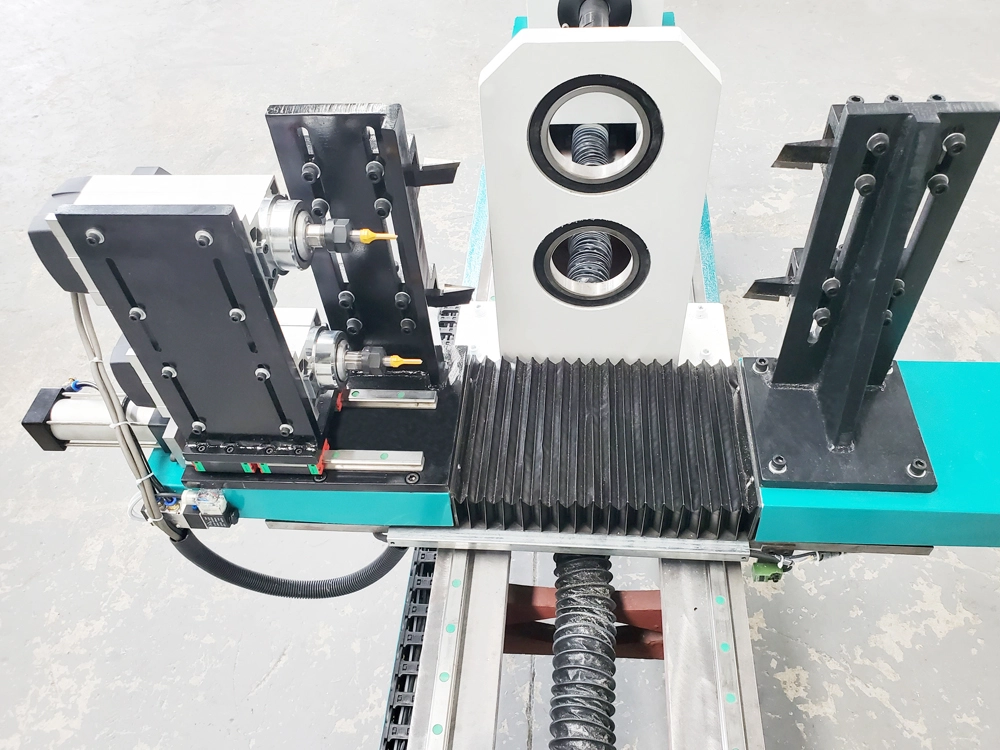

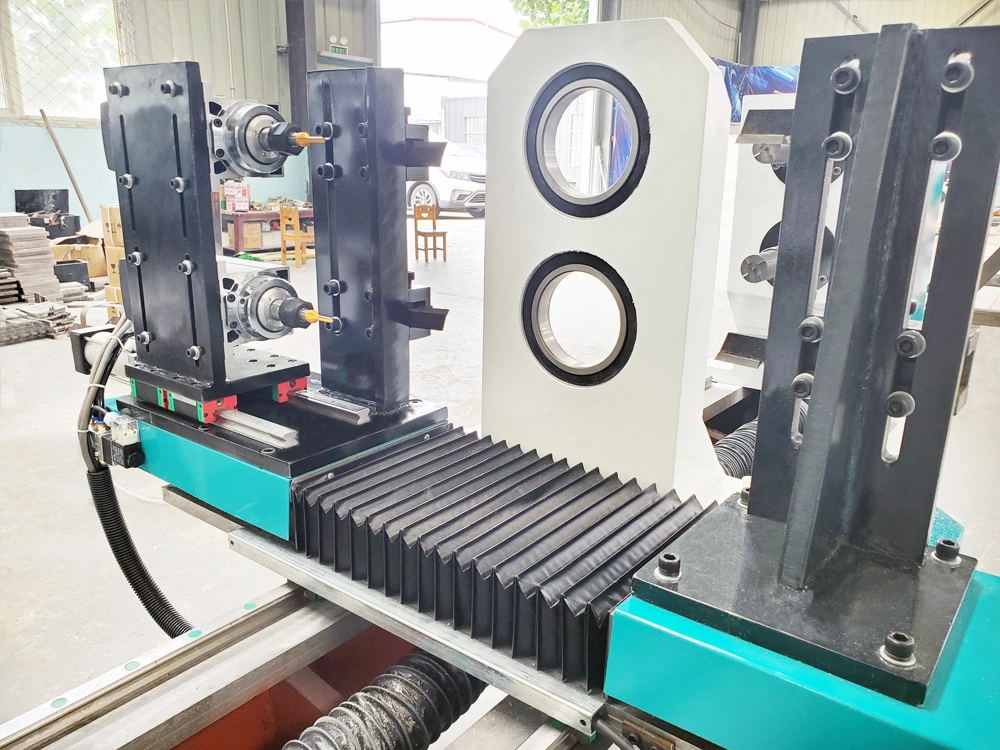

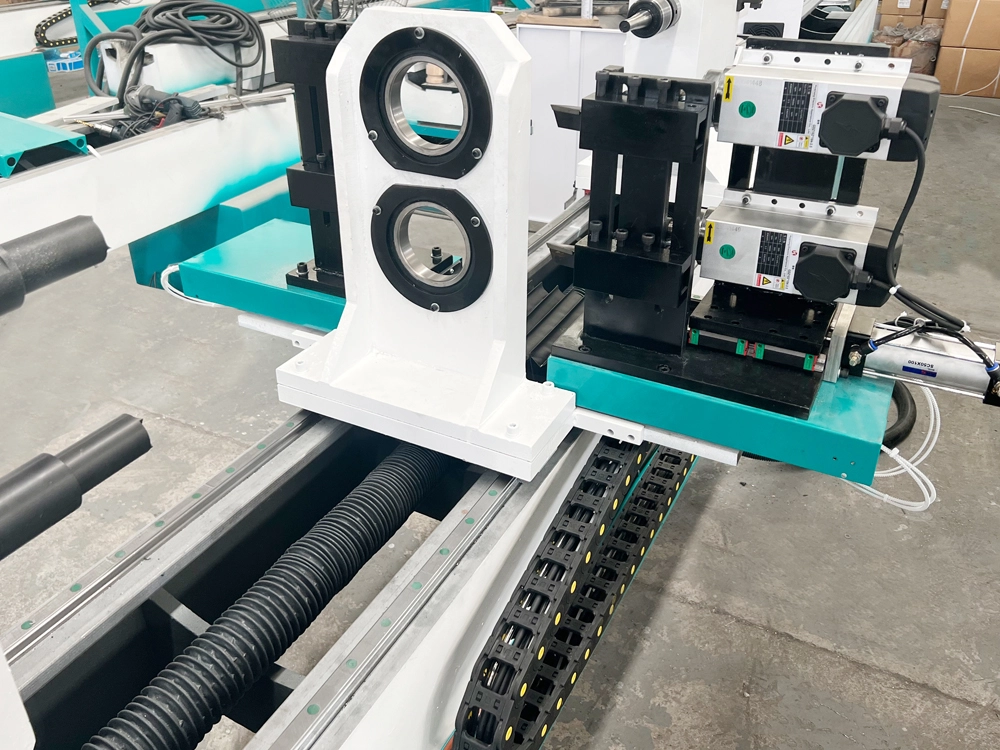

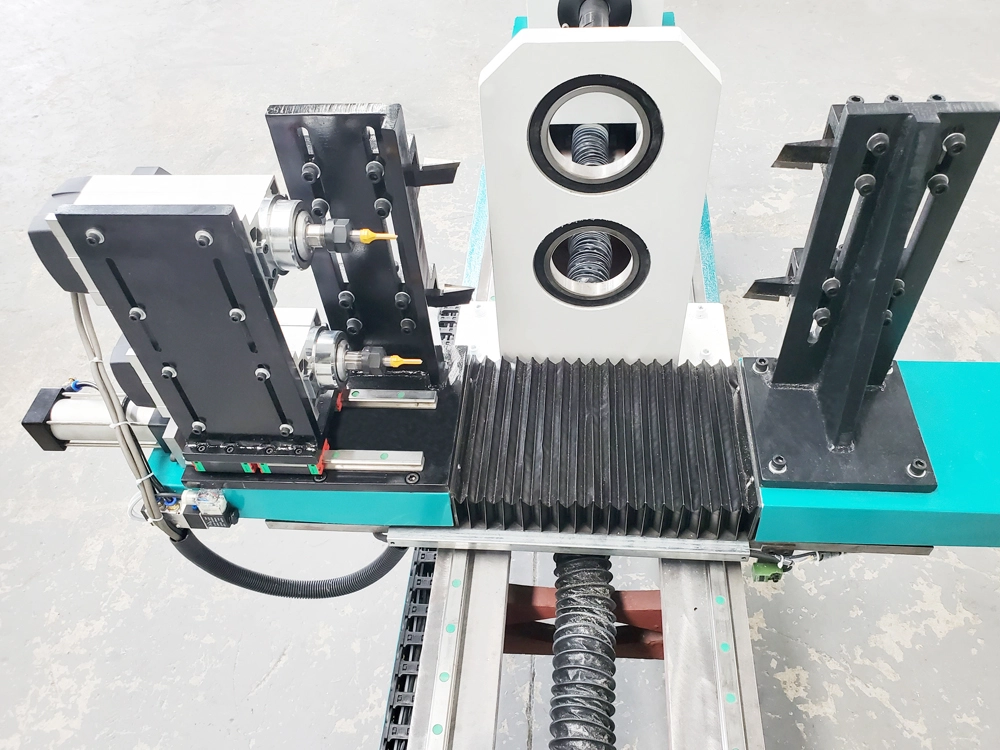

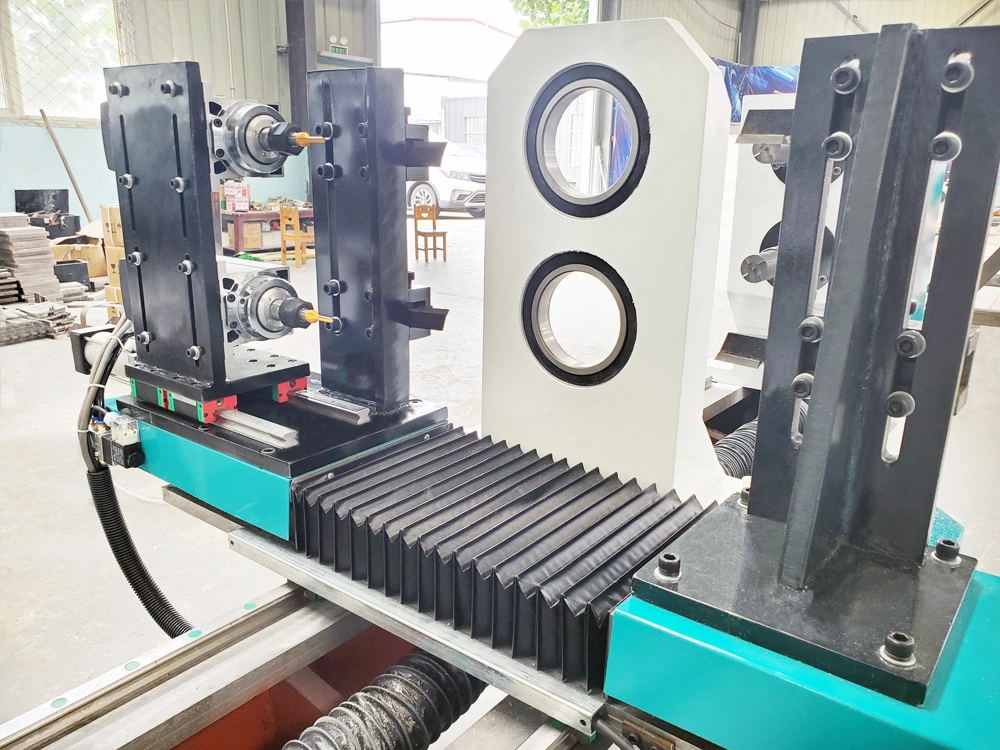

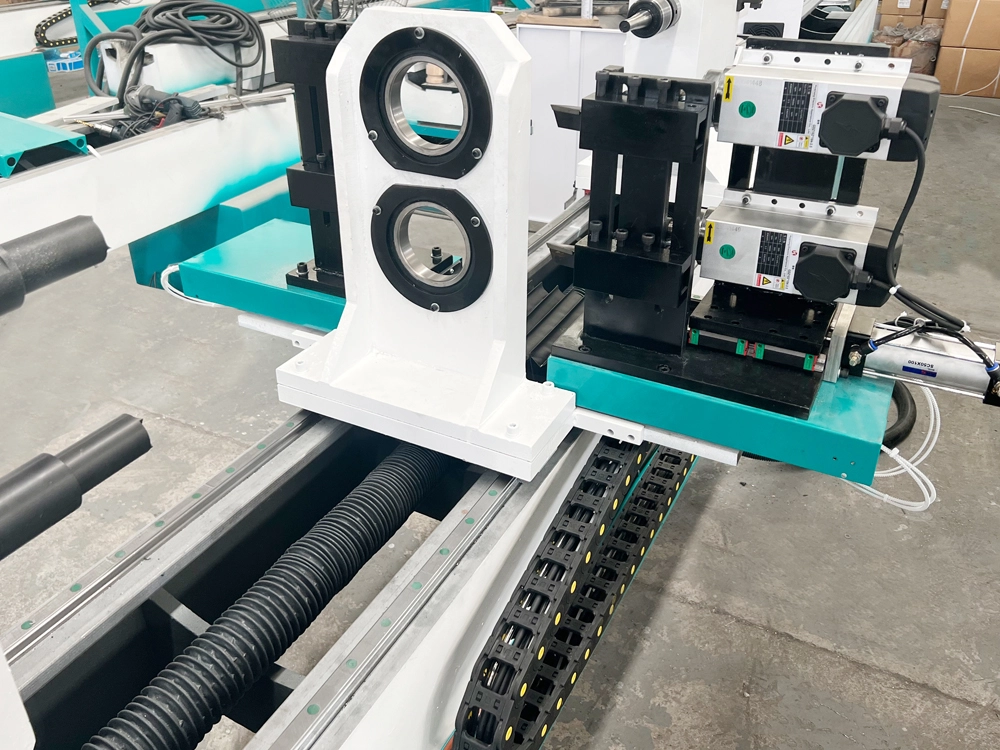

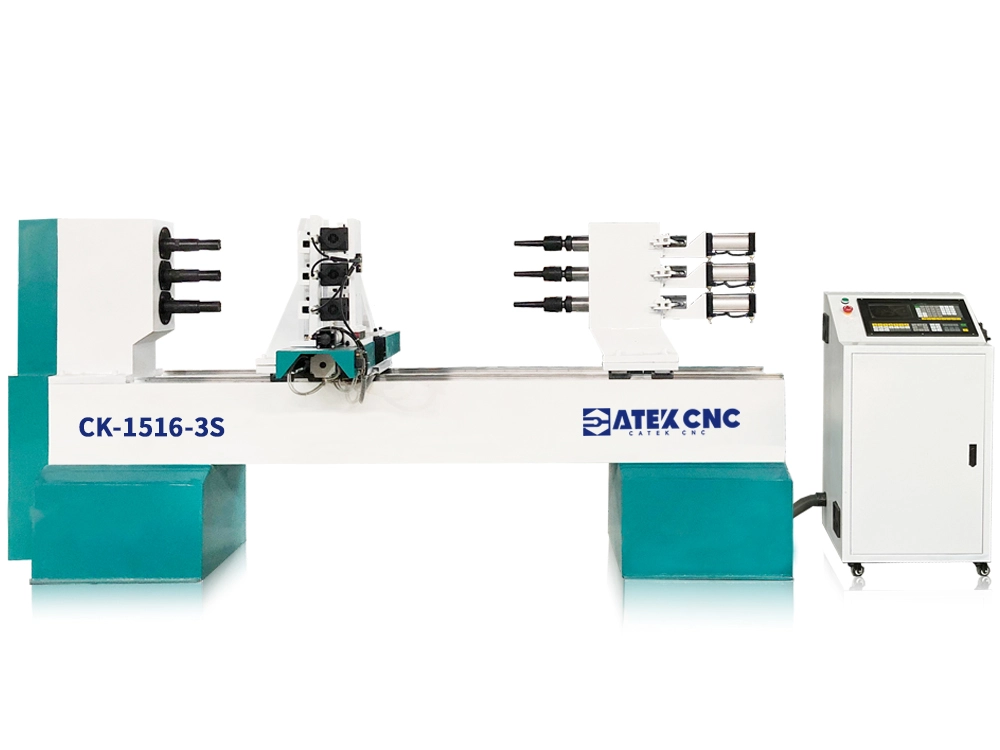

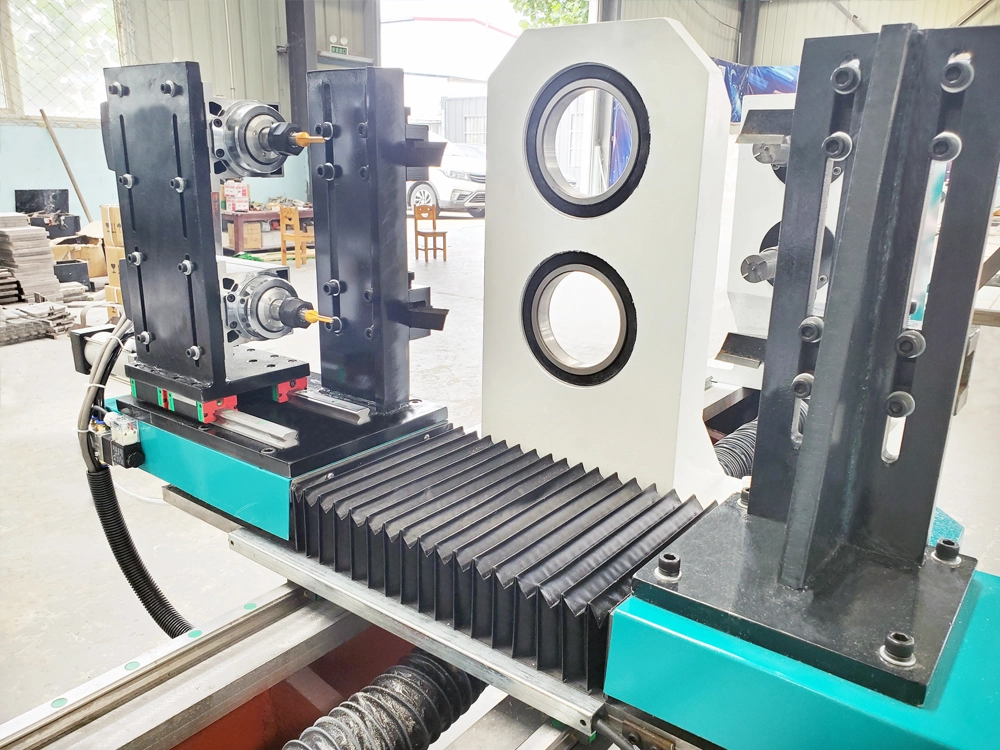

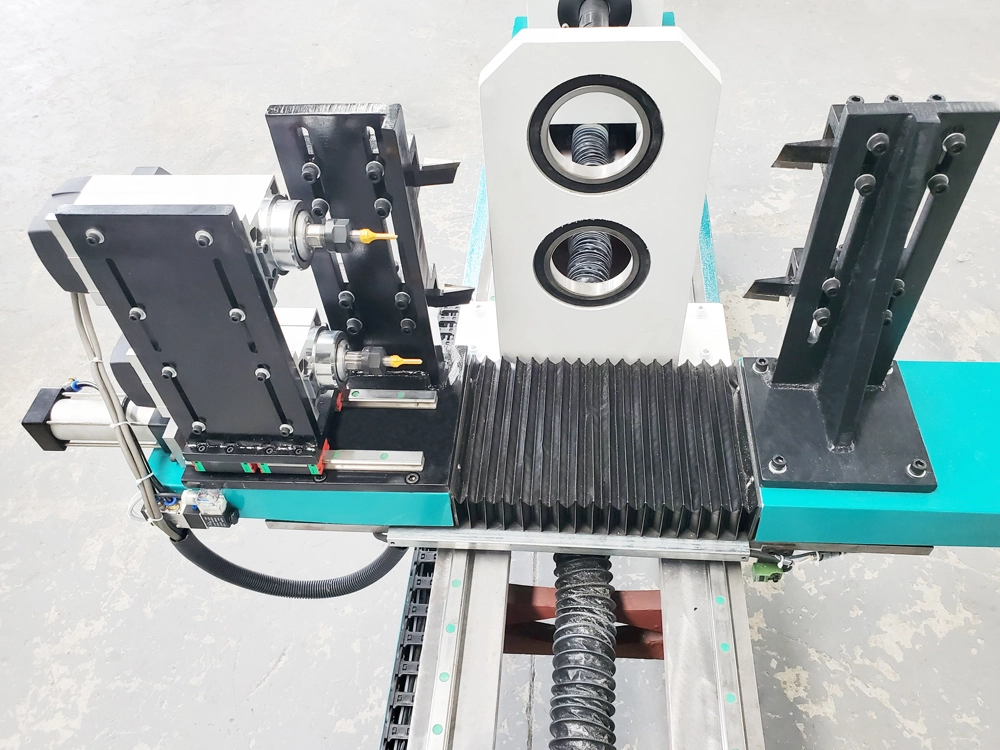

- Two station, four turning tools, two tools for rough machining on the x-axis, and two tools for fine machining on the y-axis, with good machining effect and faster speed.

Details of 2-Station CNC Wood Lathe with Turning and Carving Function

- Two station and four turning tool

Four turning tools, equipped with a steady rest, solve the problem of low product quality caused by shaking when processing slender products.

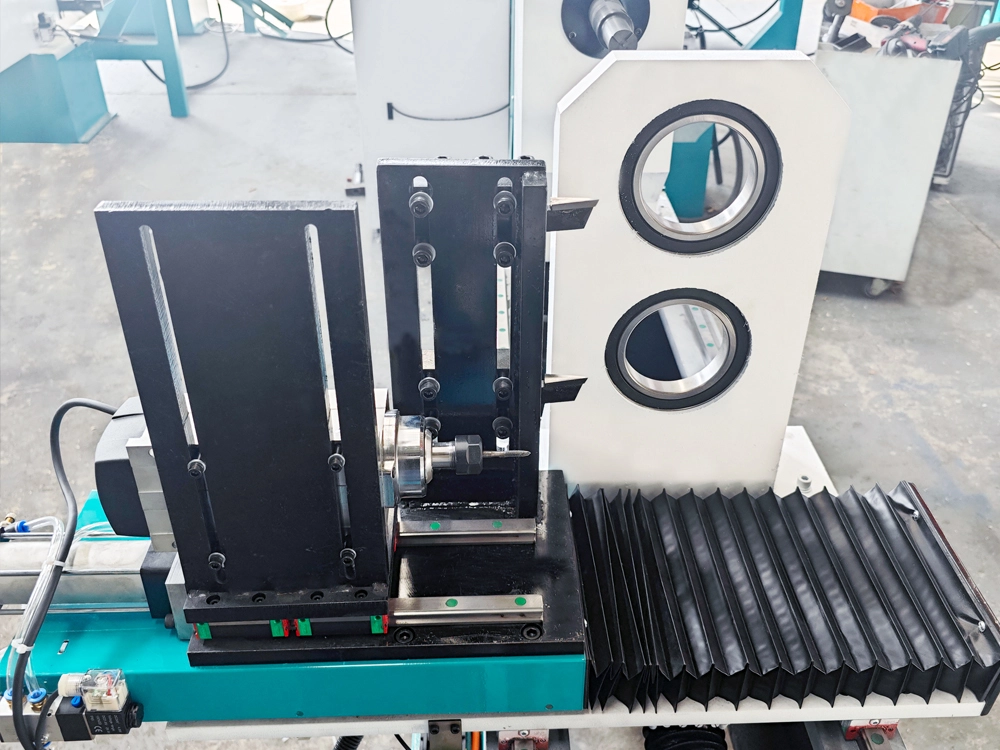

- Two multifunctional spindles

Two 3.5KW high-speed air-cooled spindles, the tools can be replaced at will according to processing requirements, such as ball cutters, straight cutters, milling cutters, carving sharp knives, etc.

- CK-1000TC CNC system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

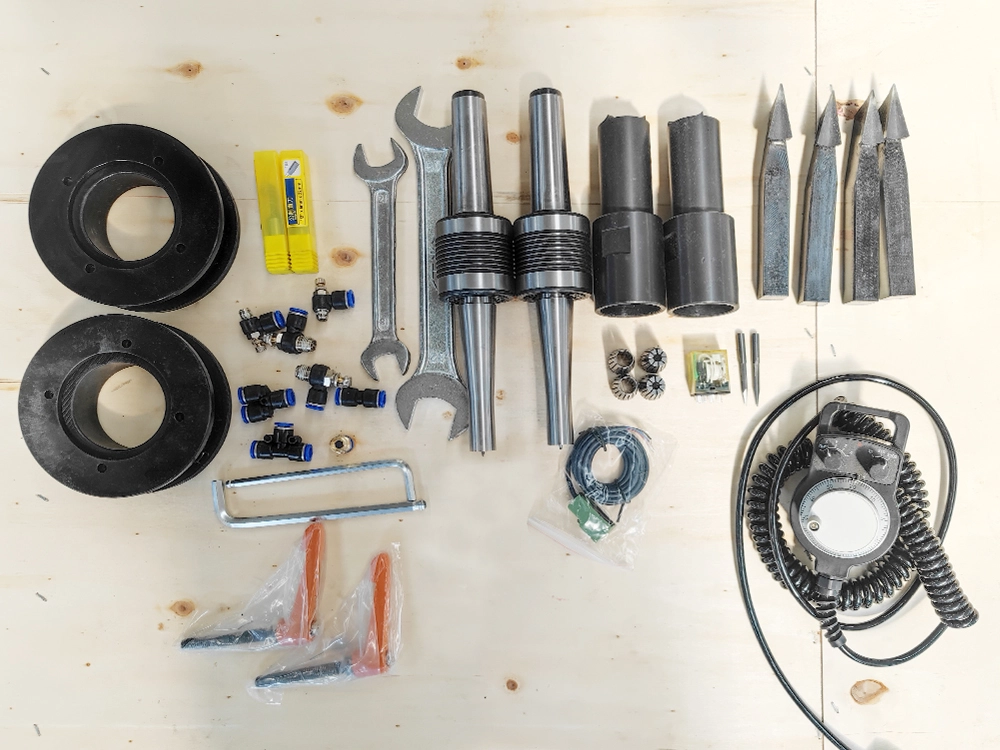

- Accessories

Before shipment, the relevant processing tools and lathe centers will be disassembled, and these parts and other accessories will be included with the machine when it is shipped.

- Optional Yaskawa servo

The optional Yaskawa servo drive system provides faster operation, lower noise and more precise positioning.

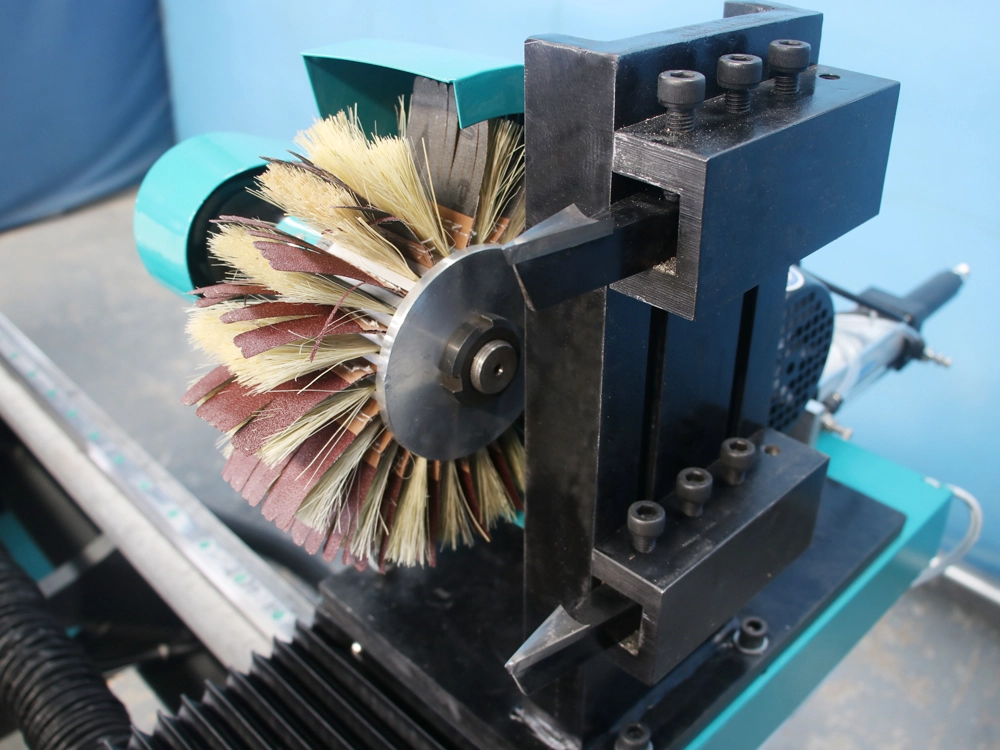

- Optional sanding wheel

After the workpiece is processed, it will be automatically polished, eliminating the need for manual secondary polishing.

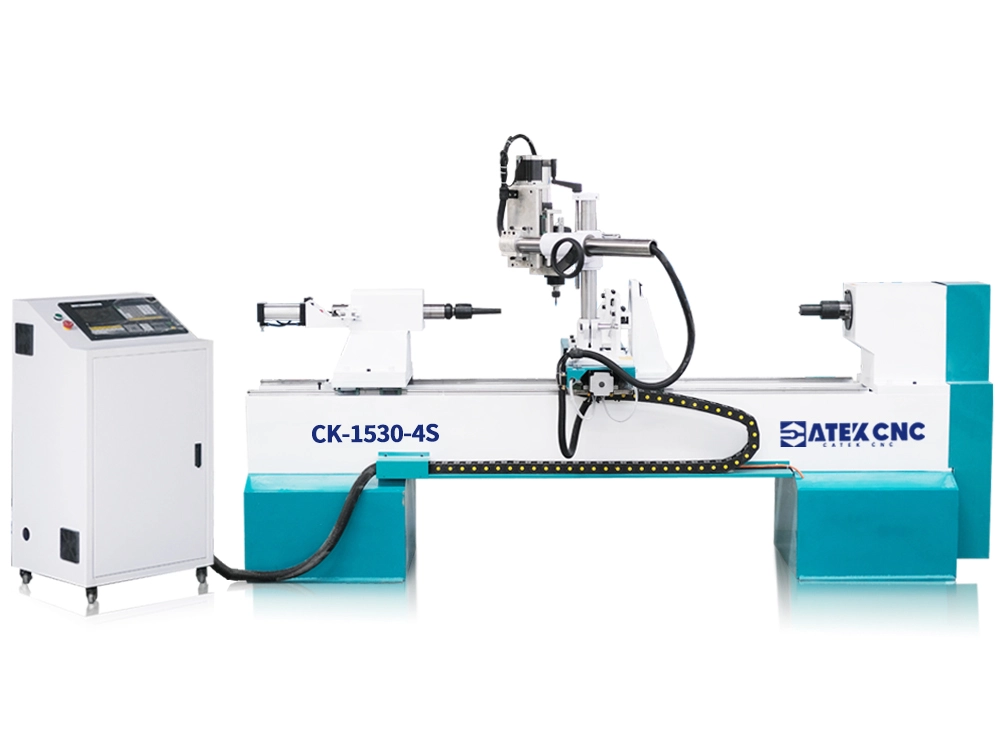

- Variant - 2-sation lathe with single-side turning tools and single spindle

This is a customer-customized machine, which reduces two cutting tools on one side and one multifunctional spindle, lowering the cost.

- Variant - CK-1016-2S

This is a custom machine that was built to reduce the machine length and overall price.

Technical Parameters of CK-1516-2S CNC Wood Lathe with Two Stations and Two Air-Cooled Spindles

| Model | CK-1516-2S |

| Processing Dimensions | 1500mm length * 160mm diameter * 2 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 2 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1550mm |

What Products Can Be Processed by 2-Spindle Turning and Carving Combination CNC Wood Lathe?

Applicable Materials

- Wood: oak, walnut, olive, pine, teak, rubber wood, walnut, red oak, white oak, red toon, beech, beech, ash, maple, mahogany, sandalwood, rosewood, etc.

- Other materials: bamboo, resin, pvc, acrylic, plastic, rubber, artificial wood, mdf, osb, artificial stone, polystone, wood fiber material, carbon fiber, fiberglass, etc.

Applicable Products

Stair columns, chair legs, table legs, bed legs, piano stool legs, piano legs, billiard table legs, sofa legs, wooden columns, Roman columns, support columns, wooden handles, wooden handles, wooden sculptures, handicrafts, wooden bowls, vases, pen holders, wooden basins, wooden jars, candlesticks, coat racks and other products.

The Following Are the Processable Products of 2-station Turning and Carving CNC Wood Lathe

| Model | CK-1516-2S |

|---|---|

| Processing Dimensions | 1500mm length * 160mm diameter * 2 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 2 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1550mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.