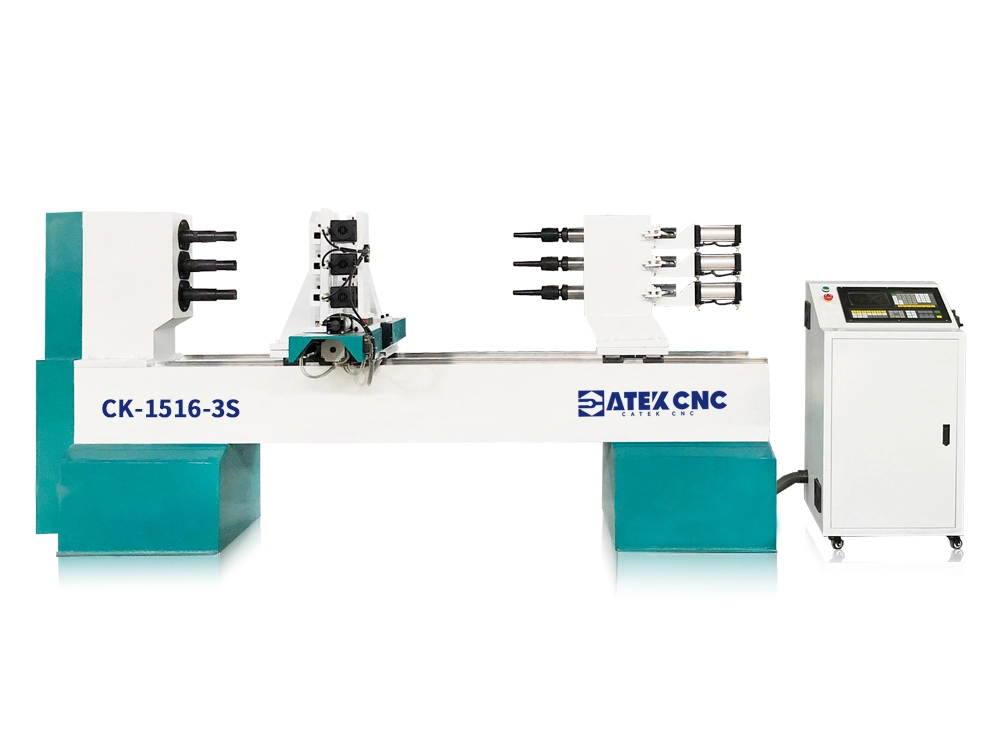

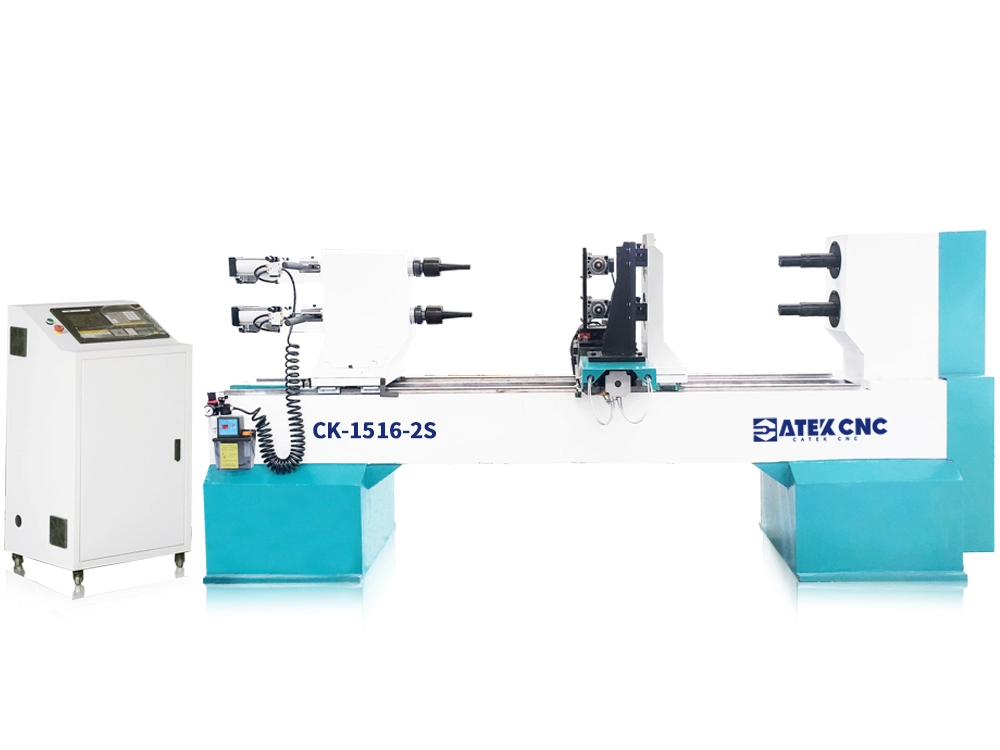

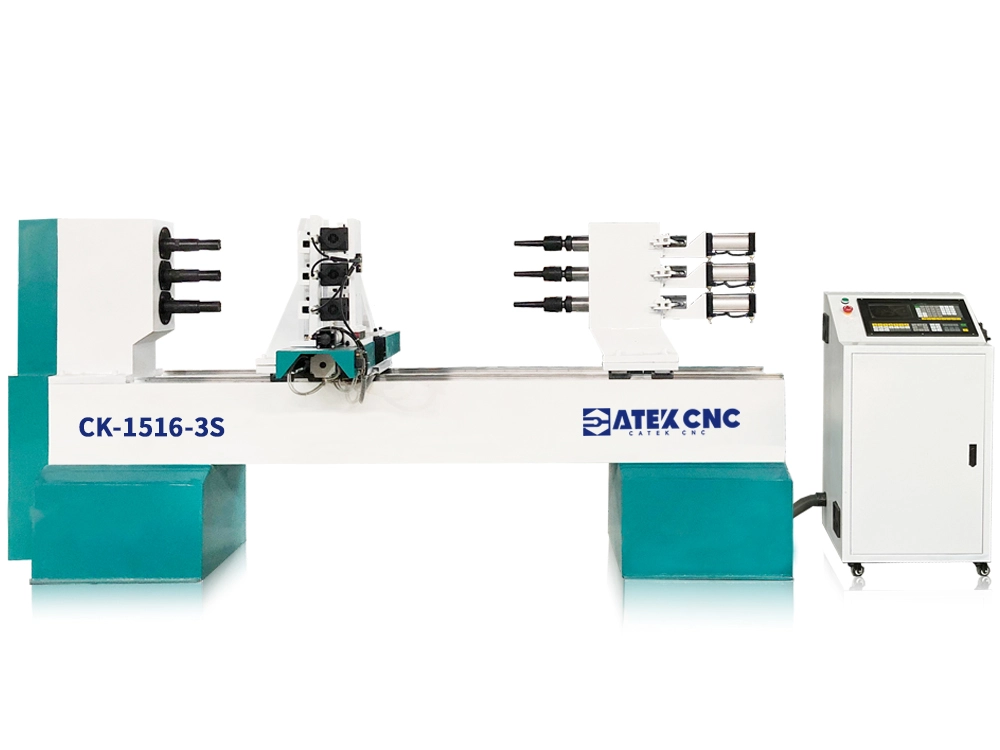

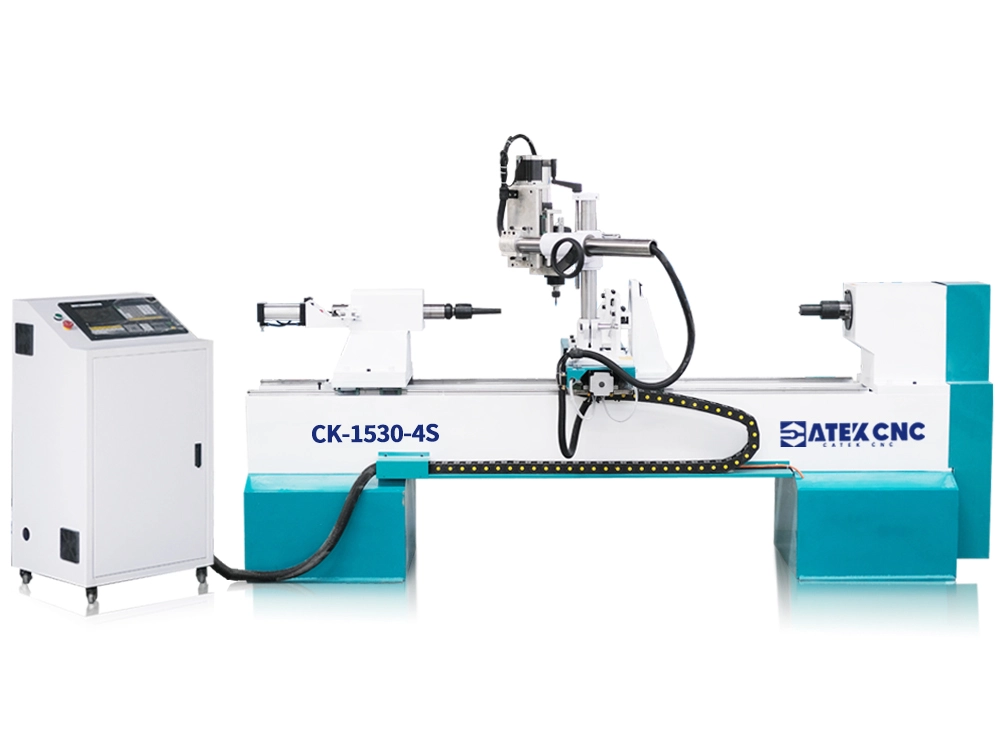

Computerized Wood Lathe with Three Machining Stations for Turning and Carving Combo

3-Station CNC Woodworking Lathe with Turning and Engraving

[Function Description]

Overview of the Most Productive Three-Station CNC Woodworking Lathe with Three Milling Spindle Kit

The three-station CNC wood lathe with trning and carving function is specially designed for batch production and processing. It is suitable for batch production of stair columns, sofa legs, table legs and other products. It can process three identical products at a time and perform turning, drilling, slotting, milling, 3D carving and other work on the products. It is more friendly to some products that need to be mass-produced, and can effectively improve production efficiency and save labor. Compared with ordinary single-spindle lathes, it can triple the processing efficiency at a time. The machine is designed with six turning knives for processing, and is equipped with three 3.5KW high-speed air-cooled spindles. After the turning is completed, the product can be punched, slotted, 3D engraved and other processing, making the processing process simpler. It also is equipped with a three-hole large-diameter steady rest, which is specially designed for some thinner and longer products, and perfectly solves the jitter problem during processing. Whether you are a processing factory or a personal studio, the CK-1516-3S three-station turning, milling and carving CNC woodworking lathe can greatly help your work and bring you higher production efficiency and lower labor costs.

Advantages of Three-Station Turning and Carving Wood CNC Wood Lathe Machine

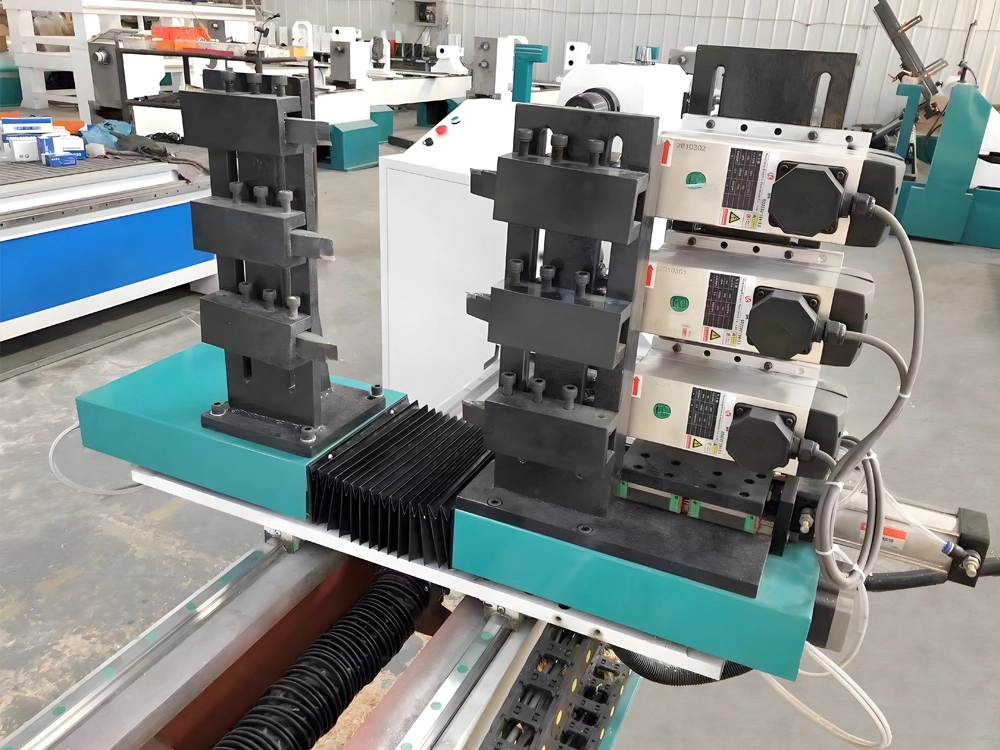

- There are three turning tools on each X-axis and Y-axis, and a high-torque drive motor is used. Roughing and forming can be done in one step, which is more efficient.

- Three 3.5KW spindles on the side are switched using independent cylinder control, with a maximum speed of 18000rpm/m, which can easily process materials.

- Using a 4KW high-speed servo motor, it supports position mode/speed mode, and the dual mode can be switched at will. The indexing control of the A-axis rotation angle in the position mode can be accurate to 0.001°.

- Each independent processing station uses an independent cylinder to control the material clamping, which makes material loading and unloading simpler. Three blanks can be processed at the same time or only one blank can be used for processing.

- An automatic centering frame can be optionally installed, and the material center point installation is simpler. You only need to put the material close to the fixture to align the center point, and turn on the cylinder switch to clamp the wood.

- Supports a variety of CAD/CAM software, such as Type3, Artcam, powermill, autocad, etc., compatible with various types of G codes, and flexible to use.

- It can automatically complete various complex processing tasks, reduce manual intervention, and improve production efficiency.

- The Z axis can choose to use high-precision helical rack or TBI ball screw, with high positioning accuracy and fast moving speed.

Details of Three-Station CNC Wood Lathe Machine with Turning, Grooving, Milling, 3D Carving

- Three 3.5KW high-speed air-cooled spindles

Three 3.5KW high-speed air-cooled spindle motors, up to 18000rpm, can quickly process and mill parts with high processing quality.

- Six turning tools and steady rests

Three-station, six turning tools, three steady rest, effectively prevent the blank from shaking during turning.

- Automatic lubrication oil pot

The lubrication interval and lubrication duration can be set to automatically lubricate the transmission parts of the machine.

- Control system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

Technical Parameters of CNC Wood Lathe with Three Stations and Three Spindles

| Model | CK-1516-3S |

| Processing Dimensions | 1500mm length * 160mm diameter * 3 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 3 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*1400*1650mm |

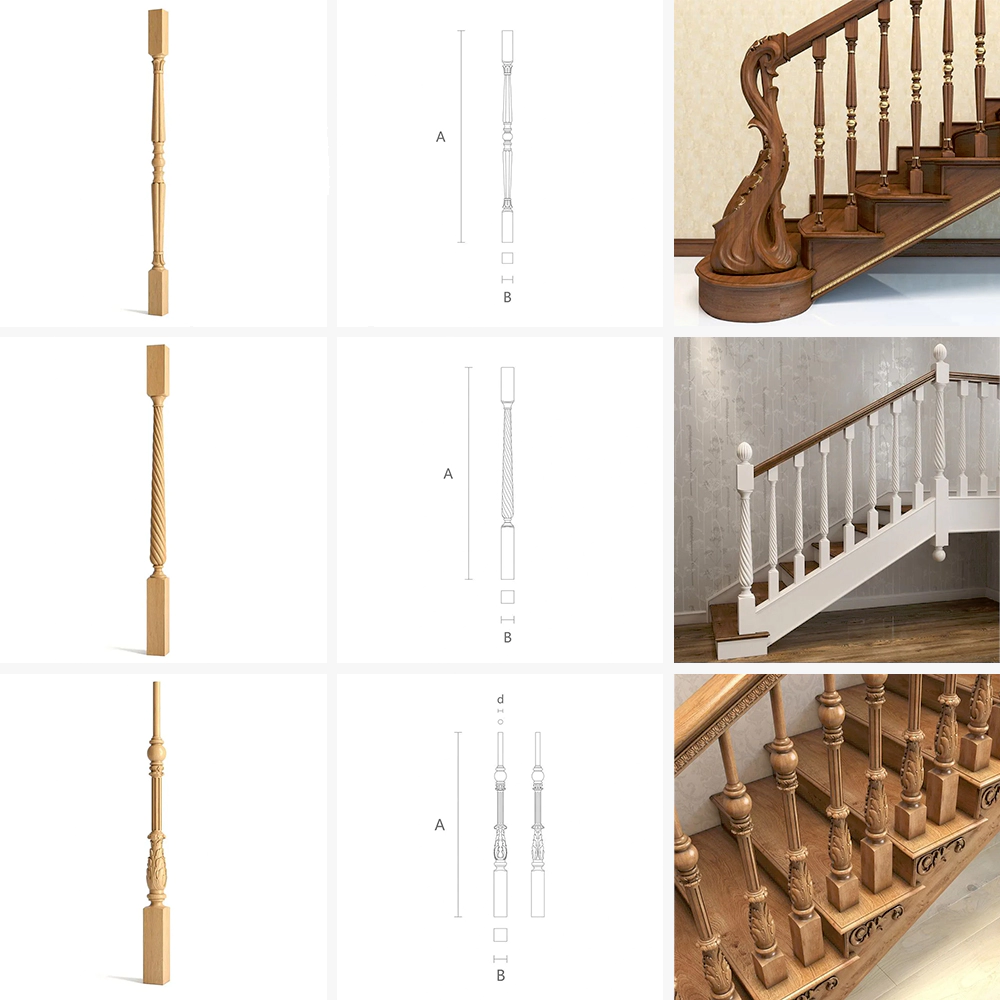

Application Scope of Three-Station Turning and Carving CNC Wood Lathe

- Furniture decoration: tables, chairs, sofas, beds, wooden stairs, stair railings, Roman columns, sofa legs, stool legs, etc.

- Sports and outdoor: axe handles, hammer handles, wooden balls, baseball bats, wooden sticks, trekking poles, etc.

- Music: bassoon, suona, Hulusi, flute, etc.

- Crafts: wooden figures, wooden toys, wooden bowls, wooden basins, vases, pen holders, candlesticks, bases, table lamps, etc.

Some Project Examples of Three-Station CNC Wood Milling Lathe with Multifunctional Spindle

After-Sales Service and Support for Three-Station CNC Woodworking Lathe

- Three-year free warranty. During the warranty period, if the machine has damaged parts, we will provide you with new parts for free replacement.

- After the warranty period, if you need to replace the parts, we will sell them to you at cost price.

- We always provide you with free machine troubleshooting.

- If you have any questions, our technicians will troubleshoot the problem online for free.

- Engineers provide technical support online 24 hours a day, 7 days a week.

- If you need, we can provide you with door-to-door installation, training and maintenance services.

- You can come to our factory to participate in training courses for free.

| Model | CK-1516-3S |

|---|---|

| Processing Dimensions | 1500mm length * 160mm diameter * 3 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 3 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*1400*1650mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.