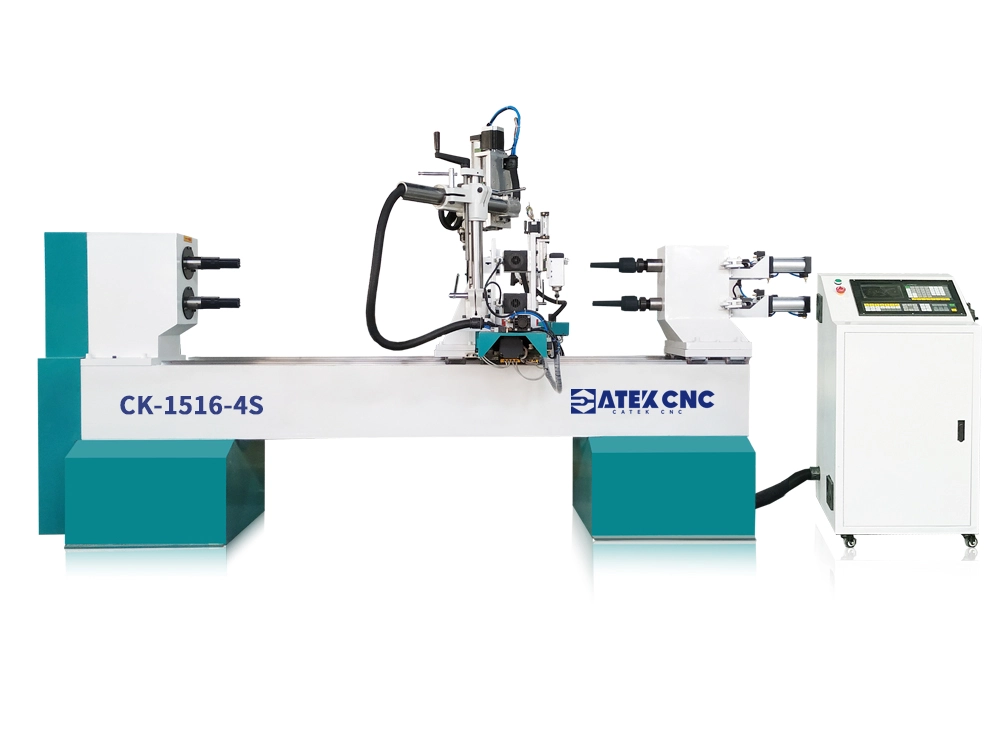

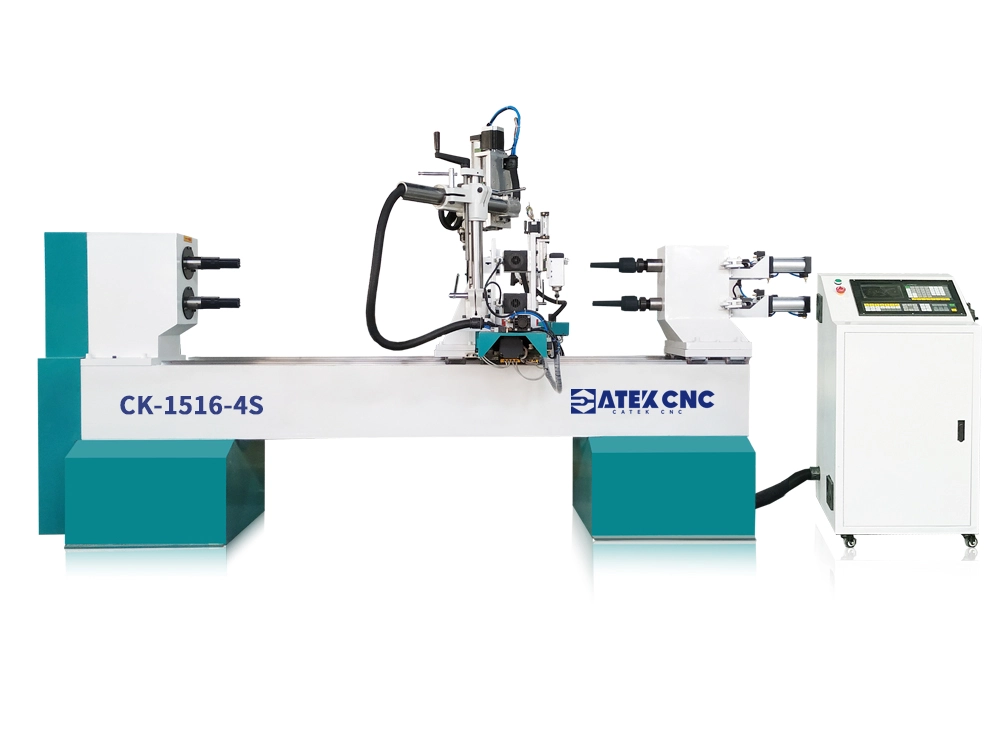

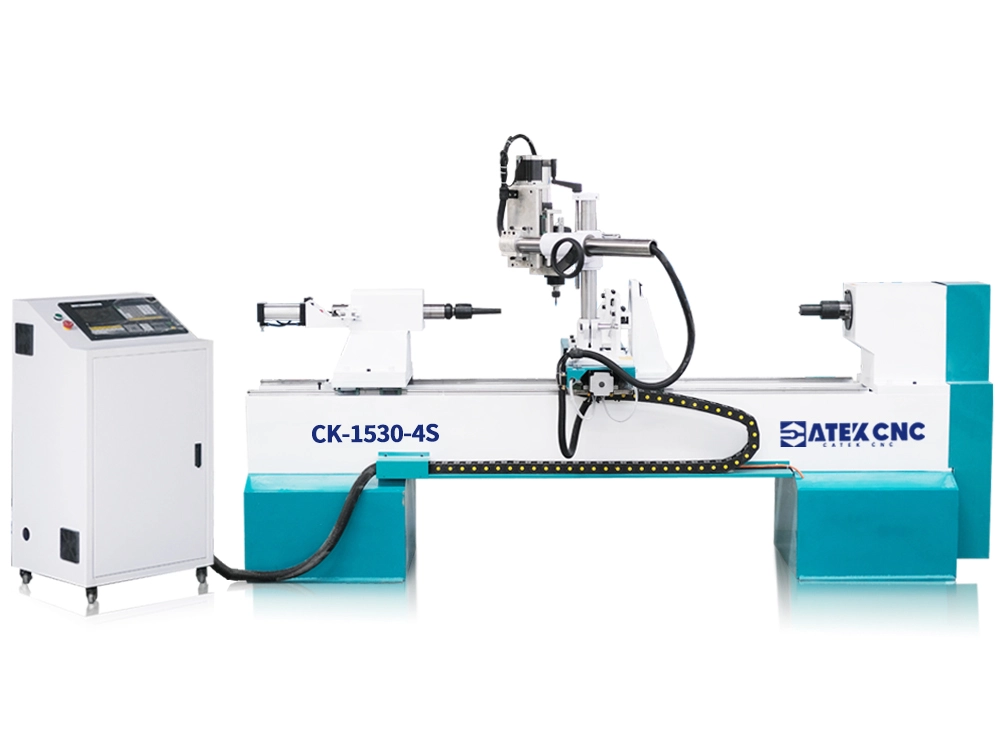

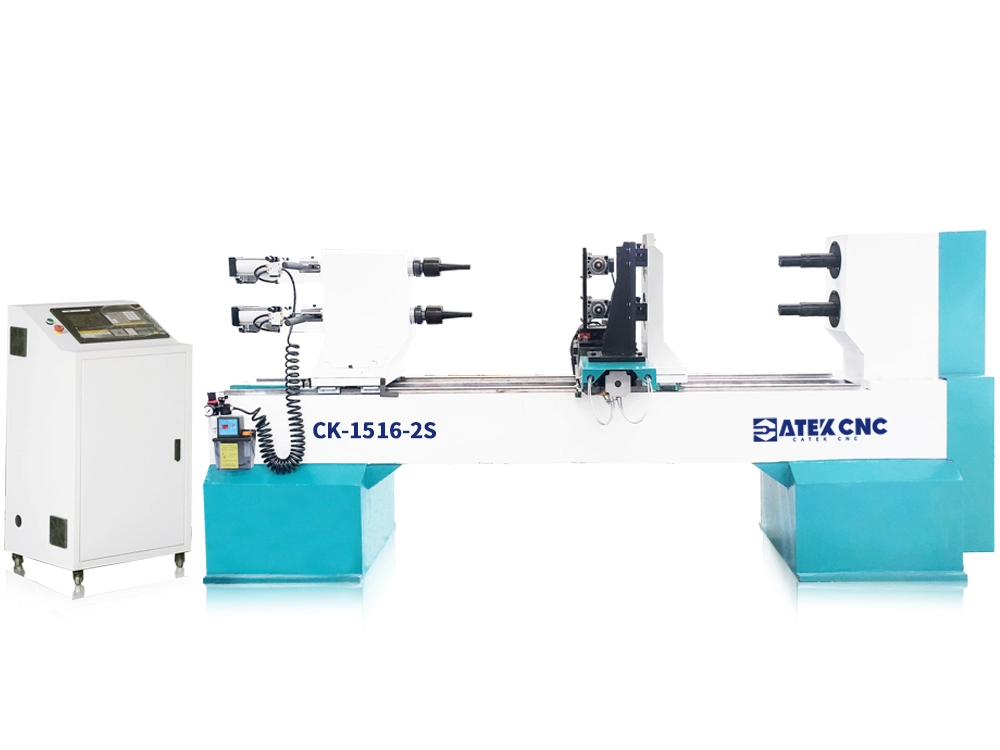

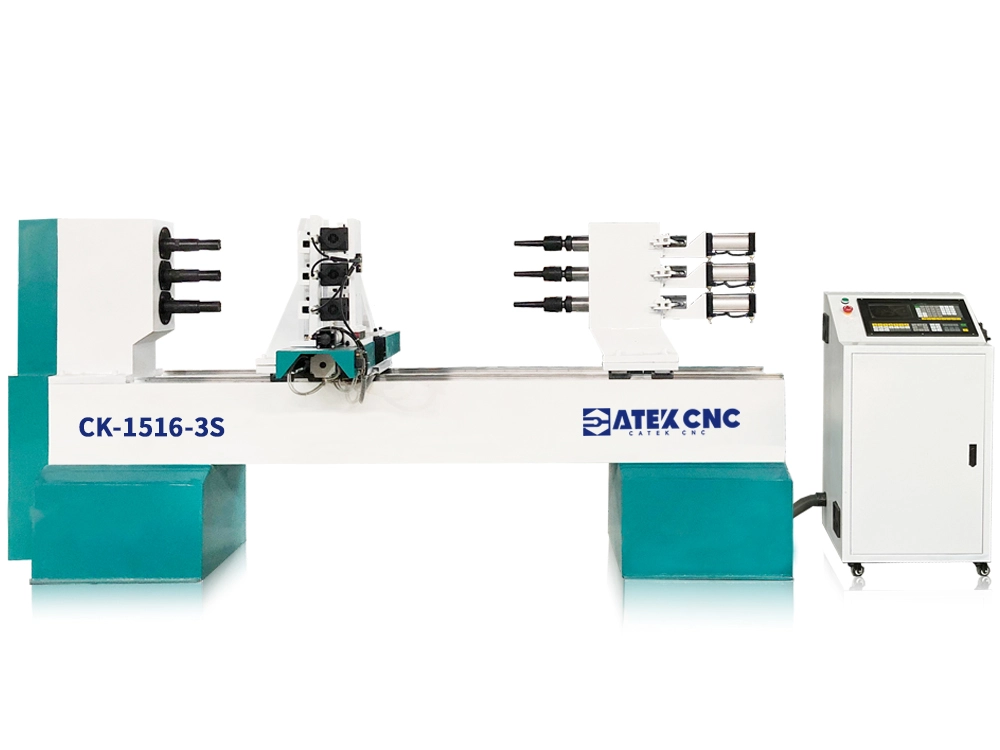

2026 Best Selling 2-Station Wood Sculpting Lathe Machine for Sale

2-Station Four-Axis Linkage CNC Wood Engraving Lathe

[Function Description]

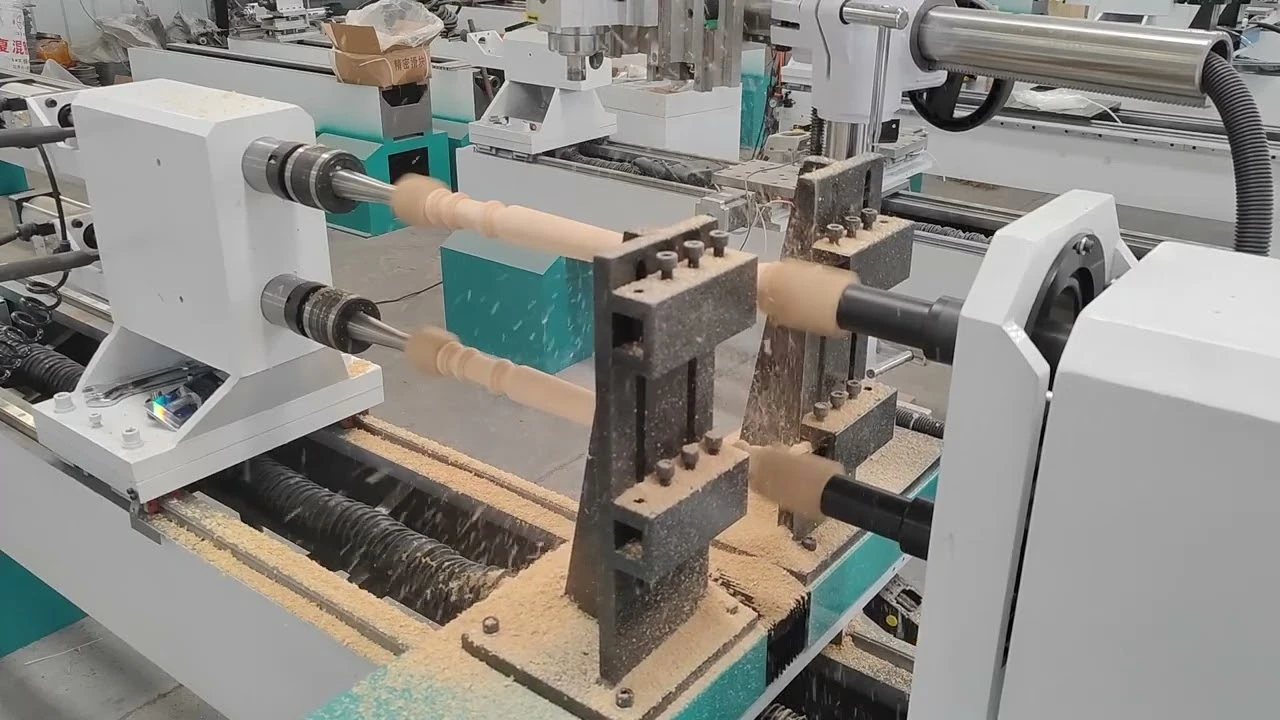

The two-station multifunctional CNC woodworking lathe has two processing stations and can process two identical products at a time. It is equipped with three multifunctional spindles in total, and two 3.5KW air-cooled spindles on the side, which can be used for three-axis engraving, side drilling, side grooving, wire drawing and other operations. The top is also equipped with a four-axis four-linkage spindle that can move vertically up and down, which can process some complex crafts or other products that require four-axis linkage engraving. Each station of the lathe is equipped with two turning tools. During processing, two turning tools are used for rough turning, and the other two tools are used for fine processing. After turning is completed, you can directly switch to the two high-speed air-cooled spindles on the side to perform other types of processing on the product, such as 3D cylindrical engraving, milling twist lines, etc., or make some table leg-type products. Complex products can be completed by turning + spindle processing at one time. After turning is completed, there is no need to read the spindle processing drawings and proofread the tools, which saves the time of changing drawings or tools and avoids the trouble of secondary processing.

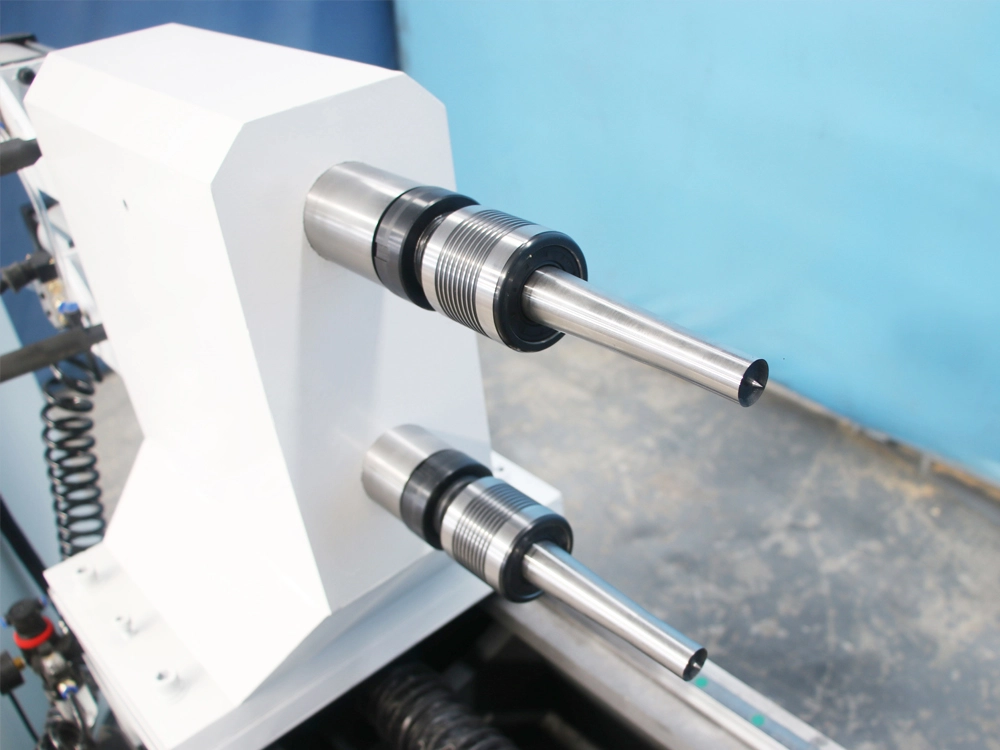

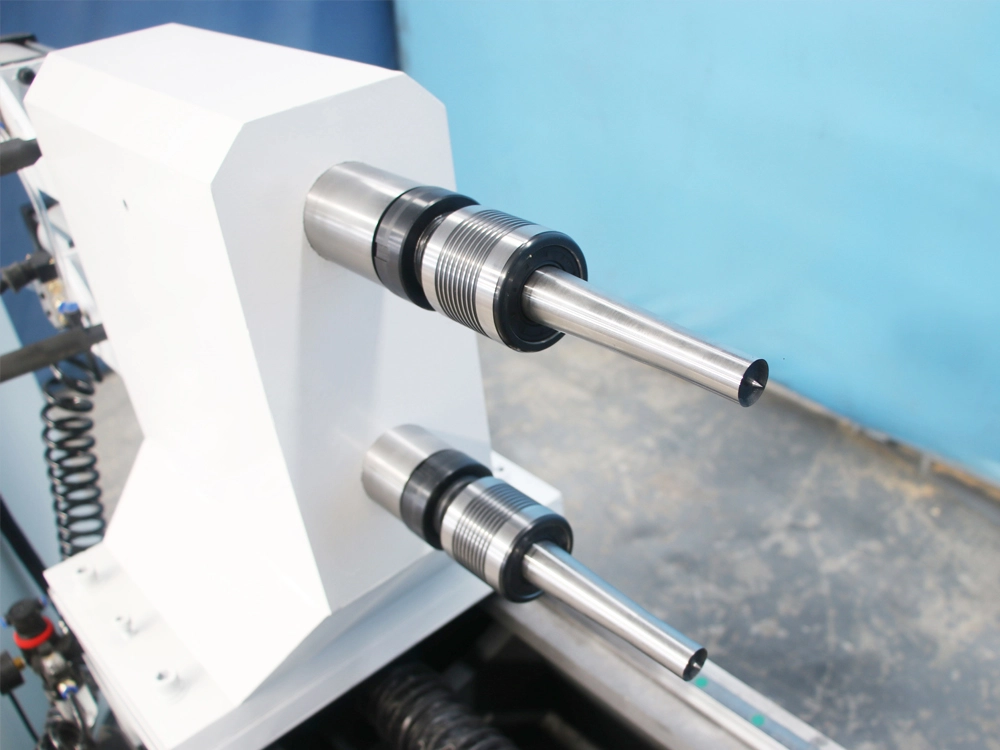

The two-station four-axis CNC woodworking lathe machine uses high-precision linear guides and precision ball screw drive systems to effectively ensure processing accuracy, and is equipped with a frequency converter to adjust the main motor speed, which can support arbitrary adjustment of 0-6000rpm. The three important structural components of the machine (bed base, headstock, and tailstock) are all cast with thickened gray cast iron. The unique rigid structure and shock-absorbing design also ensure high processing precision. After tempering and stress relief treatment, even if the main motor speed reaches 6000 rpm, the machine will not shake, ensuring the processing effect.

Advantages of CNC Wood Lathe With Three Multi-Function Spindle

- Four turning tools are fed in two stations, and three high-speed air-cooled spindles are configured. Turning, milling, 3D engraving, plane engraving, and four-axis four-linkage functions are integrated into one.

- The dual multi-function spindles on the side are driven by independent cylinders to move, and the universal bracket can independently drive a four-axis multi-function air-cooled spindle to achieve complex functions such as four-axis four-linkage.

- Using a 4KW high-speed servo motor with a speed of up to 6000r/m, the speed can be adjusted arbitrarily according to processing requirements, and the processing quality is higher.

- Using an industrial LCD large-screen CNC system, the standard G code drives the machine to run, which is simple and easy to use, and is compatible with various cad/cam software.

- Equipped with a double-hole large-diameter follow-type steady rest, it can be used in conjunction with processing slender products to prevent shaking.

- CATEKCNC dedicated high-torque drive motor, large-size products can also be easily fed, turning is more powerful, and processing efficiency is higher.

- The standard model can process workpieces with a maximum length of 1500mm and a diameter of 300mm. Various processing sizes can be customized according to needs, and the machine has a wider range of applicability.

- It can be connected to a dust collector or equipped with a protective cover to reduce dust pollution and ensure the safety of operators.

- The electric lubricating oil pot can automatically lubricate and maintain the transmission parts at regular intervals.

- The turning and carving CNC wood lathe has a wide range of applications, can be used for processing a variety of wood products, handicrafts, furniture fittings, especially suitable for factories that require mass production or complex process processing.

Details of Ck-1516-4S Model Multi-Function CNC Wood Turning Machine

Technical Parameters of 2-Station CNC Wood Lathe with Four-Axis Engraving Function

| Model | CK-1516-4S |

| Processing Dimensions | 1500mm length * 160mm diameter * 2 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled spindle * 3 (support four-axis four linkage) |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*1400*1750mm |

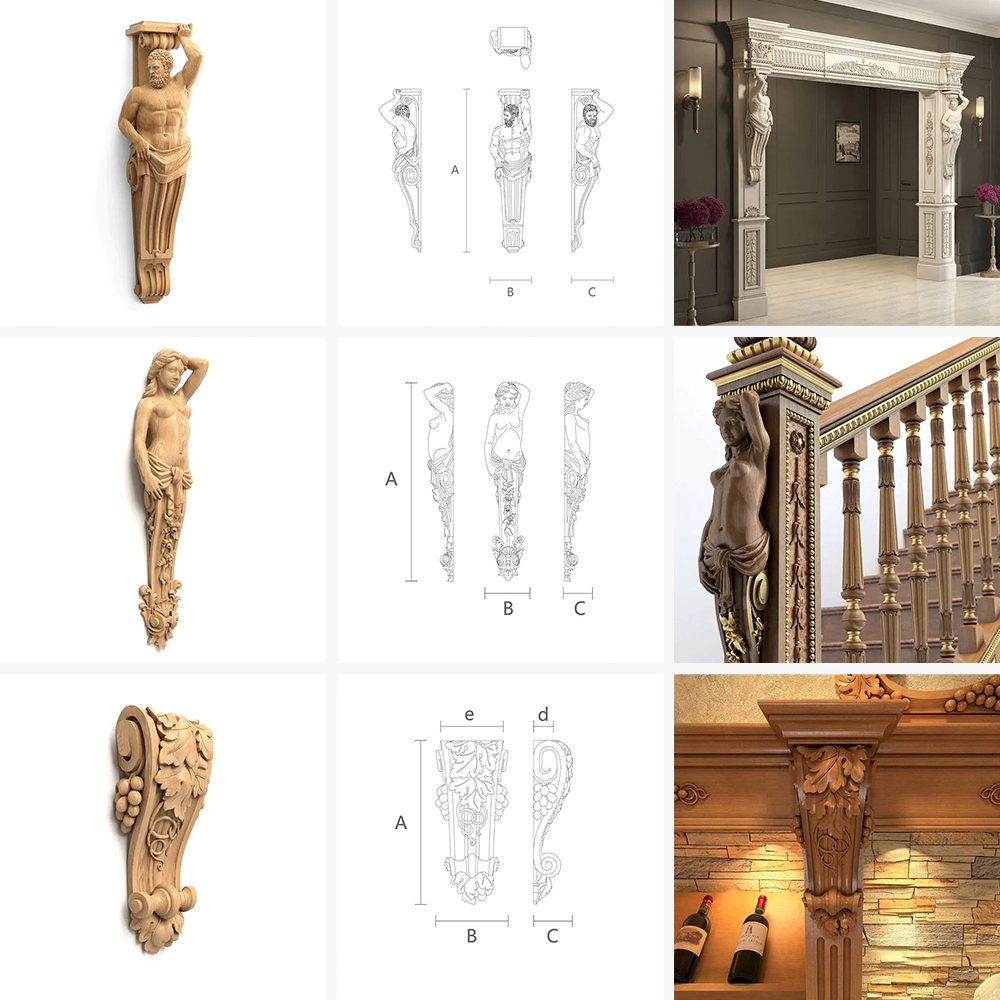

Application Scope of 2-Station Multifunctional CNC Wood Lathe With Four-Axis Linkage

It is suitable for processing various materials such as wood, plastic, synthetic materials, etc. It can process various complex products such as stair columns, sofa legs, table and chair legs, bed legs, wooden crafts, wooden handles, carved products, special-shaped curved legs, crafts, wooden handles, etc.

The Following Are the Processable Products of 2-Station CNC Wood Lathe With Four-Axis Linkage

| Model | CK-1516-4S |

|---|---|

| Processing Dimensions | 1500mm length * 160mm diameter * 2 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled spindle * 3 (support four-axis four linkage) |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*1400*1750mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.