Combined Wood Turning and Engraving CNC Machine

Standard Size CNC Woodworking Lathe with Turning and Engraving

[Function Description]

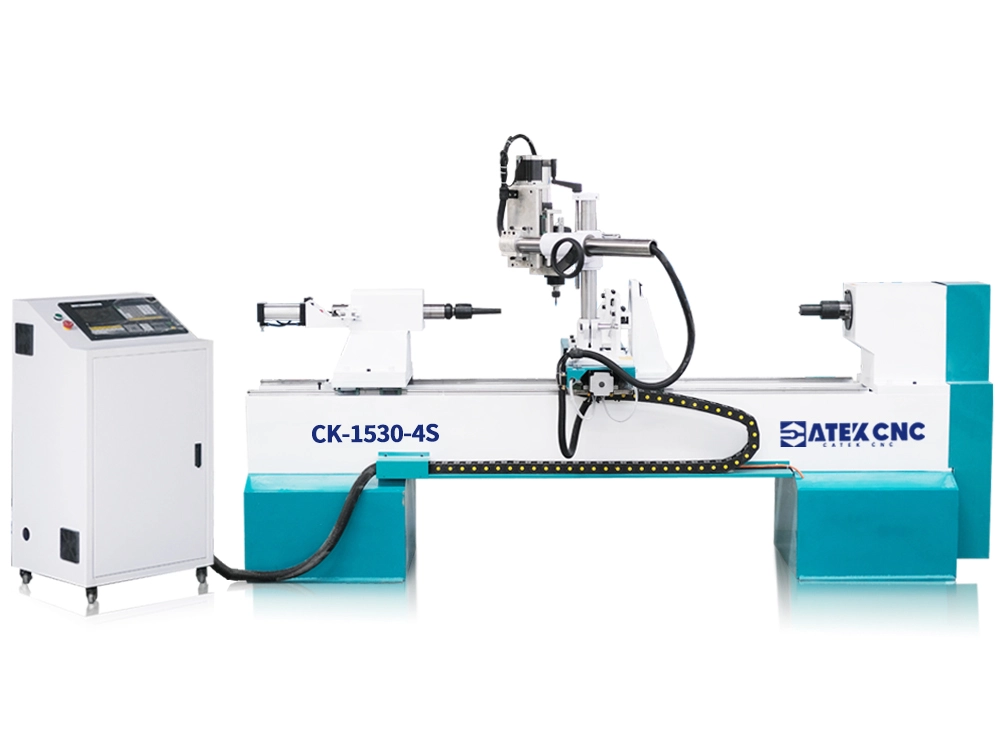

In addition to turning tools, it also features a multi-functional spindle, and the drive spindle has been replaced with an A-axis capable of indexed rotation. It can perform operations such as turning, drilling, grooving, milling, and engraving. This machine is suitable for tasks requiring profile turning and simple engraving, such as processing stair columns with patterns or grooves, axe handles, hammer handles, as well as bassoons and flutes that require drilling.

{{(goodsPrice)}}

Advantages of Turning and Carving Combination CNC Wood Lathe

- Single-station design, one blank can be processed at a time, easy to use

- Turning, milling, milling shape, drilling, milling groove, slotting, 3D carving multifunctional integration.

- 4KW servo motor, speed 6000rpm, the speed can be adjusted arbitrarily.

- Processing length 1500mm, diameter 300mm, can be adjusted arbitrarily within the processing range.

- CNC system dedicated to CNC woodworking lathe, simple operation.

- 3.5KW air-cooled spindle (optional water cooling), using independent cylinder control switching, can be freely switched with turning tool.

- Electric lubrication maintenance system, automatic timed lubrication.

- Heavy gray cast iron bed, special structural design, stress relief treatment, stable use without deformation.

- Servo motor dedicated servo frequency converter, speed mode and a-axis angle mode can be switched arbitrarily.

- The spindle uses a large torque inverter, the speed control is stable, and the startup speed is fast.

- Two turning tools, one for roughing and one for finishing, with higher processing efficiency.

- Steady rest, according to wood diameter, processing slender products to prevent product shaking.

- TBI ball screw, Taiwan guide rail, linear bearing, high positioning accuracy.

- Morse center, four-jaw chuck, can be replaced according to the diameter of the processed product.

- Use CATEKCNC dedicated servo motor for linear axes, precise position control.

- Support various voltages, 110v/220v/380v/415v/440v, etc.

- Each axis is equipped with safety limit to prevent collision problems due to improper machine operation.

- Equipped with emergency stop button, one-click shutdown in case of emergency, safe to use.

Details of CNC Wood Lathe with Turning and Carving

- Processing tools

Double tool turning profile, spindle drilling, milling, slotting, 3D carving

- Optional electric tool holder

The four sides of this device can each hold a tool, and the tools are switched by rotating during the machining process.

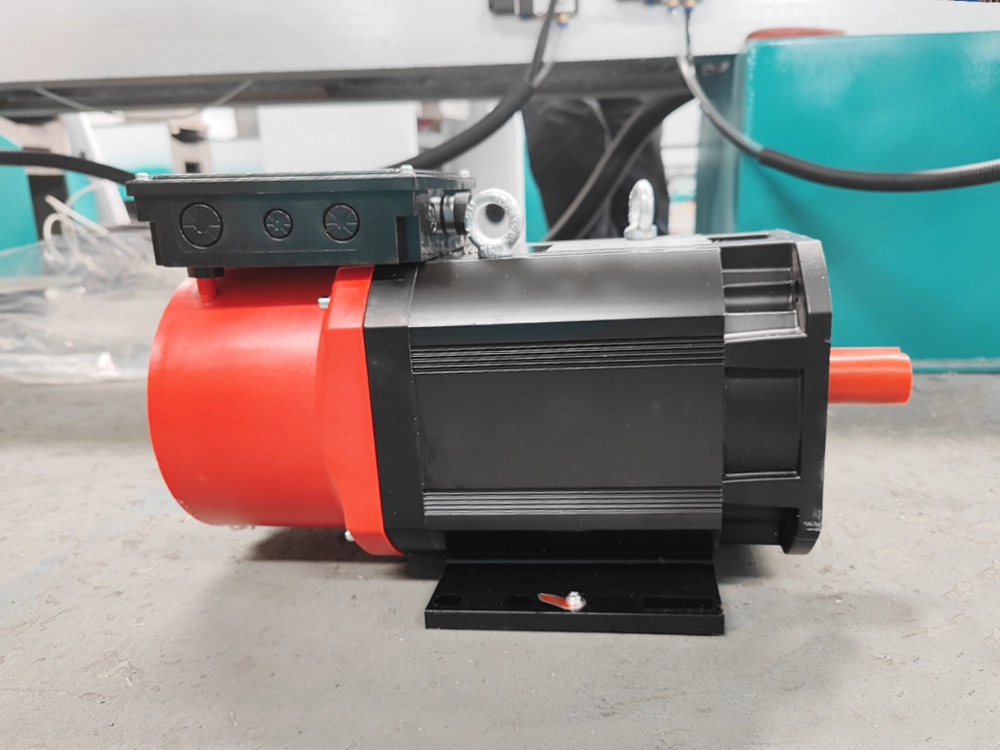

- Main motor and related controller and inverter

Since the driving spindle is indexable, a servo motor is used to provide power.

Technical Parameters of CNC Wood Lathe with 3D Carving Device

| Model | CK-1530-S |

| Processing Dimensions | 1500mm length * 300mm diameter (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1300*1500mm |

Application Scope of Combination Lathe Milling Machine

The turning and carving composite CNC wood lathe is widely used and can be used to process various woods, plastics, PVC, acrylic, synthetic materials, etc. The following are some common processing products and case photos for you.

- Furniture: furniture table legs, sofas, tables, chair legs, bed legs, stools, round legs, tapered furniture legs, furniture accessories, chair back support columns, etc.

- Decoration building materials: stair columns, Roman columns, stair railings, balcony fences, fences, etc.

- Crafts: wooden bowls, vases, pen holders, wooden basins, jars, sculptures, etc.

- Musical instrument accessories: drumsticks, drum sticks, erhu, flute, bassoon, Hulusi, etc.

- Sports/outdoor equipment: baseball bats, axe handles, hammer handles, shovel handles, mop handles, etc.

| Model | CK-1530-S |

|---|---|

| Processing Dimensions | 1500mm length * 300mm diameter (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1300*1500mm |

YOU MAY ALSO LIKE

This lathe features turning tools and a multi-functional spindle, with an A-axis drive spindle for indexed rotation. It performs turning, milling, drilling, grooving, engraving, and more.

$5,295.00~$5,880.00

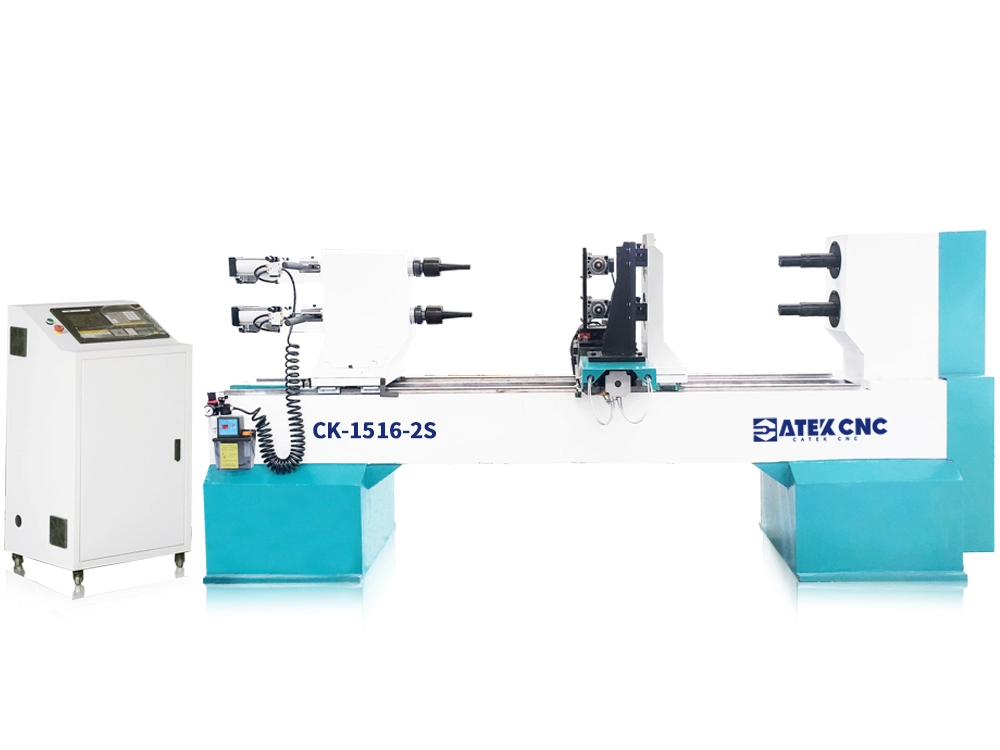

It features two workstations, each equipped with two turning tools, an indexable A-axis, and a lateral 4-directions multi-functional spindle, while sharing an overhead 6-directions multi-functional spindle.

$5,880.00~$7,350.00

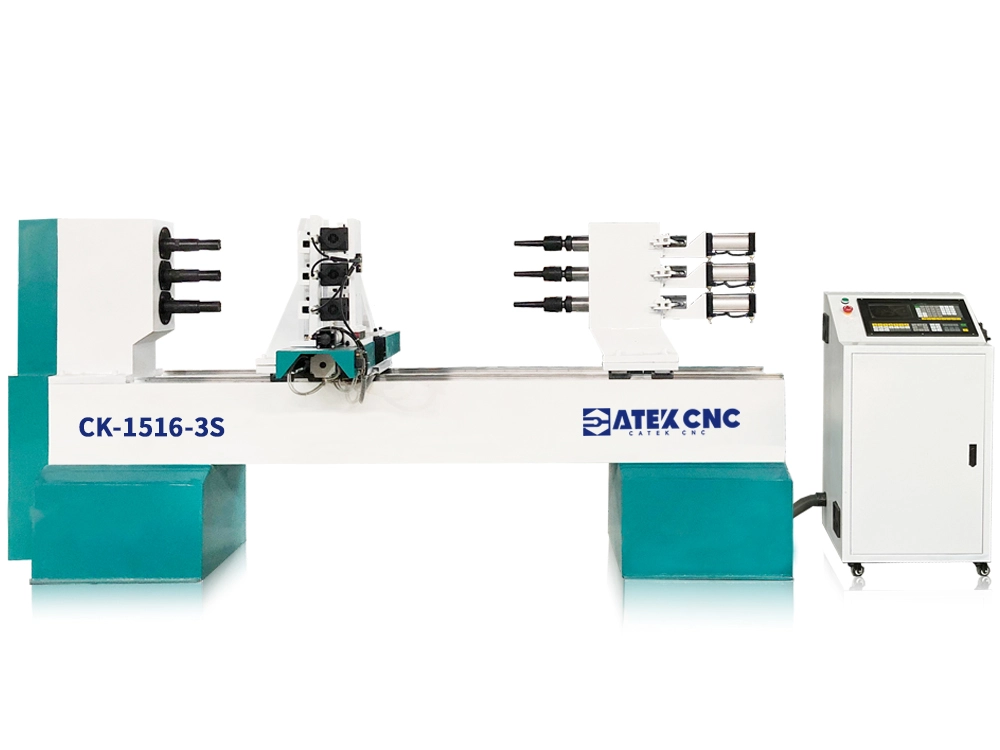

It features three workstations, each with an indexable A-axis, two turning tools, and a multi-function spindle, enabling simultaneous turning and milling operations on three workpieces.

$5,880.00~$7,058.00

This lathe features a multi-function spindle and an indexable A-axis, with the spindle capable of linear movement in six directions, allowing for complex grooving and engraving on flat surfaces.

$5,588.00~$6,350.00

It features two workstations, each with an indexable A-axis, two turning tools, and a multi-function spindle, enabling simultaneous turning and milling operations on two workpieces.

$5,588.00~$6,800.00

REVIEWS

Let more people know what you share.