7×10 CNC Wood Router with HSD Spindle and Automatic Tool Changer

7X10 ATC CNC Wood Router Machine with HSD Spindle

[Function Description]

With the advancement of industry and changes in decoration materials, the processing size of the common 4×8ft CNC router (1325 series) has become insufficient to meet the demands for processing larger panels. Nowadays, routers with processing sizes of 4×9ft, 5×10ft, and 6×10ft have emerged in the market. The CK-2130 model CNC router is a larger-sized product developed on this basis. It is equipped with a specially designed 7×10 feet enlarged work platform, with a maximum processing size of up to 2100×3000mm (7×10 feet), almost capable of meeting the processing needs of panels of any size.

The 7×10ft CNC router adopts a high-precision gear rack transmission system, effectively ensuring processing accuracy. At the same time, its base is specially designed and treated to effectively reduce resonance generated during processing, further ensuring processing accuracy. The equipment also uses an advanced anti-electromagnetic interference system, allowing for stable operation over long periods. Whether in the woodworking industry, advertising cutting field, or other processing needs, the 7×10ft CNC wood router can provide you with flexible and efficient solutions.

Advantages of the Oversized CNC Router with HSD Automatic Tool Change Spindle

- Equipped with automatic tool change function, it can automatically switch tools according to processing needs, capable of assembling 8/12/16 tools at once to meet all processing requirements.

- Designed with a thickened steel tube welded bed, treated with high temperature and stress relief, ensuring the stability and processing accuracy of the equipment during long-term use.

- Uses a vacuum adsorption work platform, specially designed with 9 zones and 30 hole positions, each zone equipped with an independent control switch, capable of handling the processing of panels of various sizes.

- Configured with an efficient dual-barrel dust collector, ensuring the surface of the parts and the ground are clean and dust-free after processing, making it more environmentally friendly.

- Comprehensive functions, capable of completing various processing techniques such as engraving, cutting, drilling, milling, and grooving, meeting the diverse processing needs of complex parts.

- Compatible with various software, such as artcam, jdpaint, type3, Aspire, and other CAD/CAM type software.

- Supports power-off memory function, in case of unexpected situations such as power failure during processing, it can continue working after restarting, effectively avoiding material waste.

- CATEKCNC provides comprehensive after-sales guidance and free training, and offers three years of free warranty and lifetime free maintenance services.

Features of the Industrial-Grade 7x10 ATC CNC Router

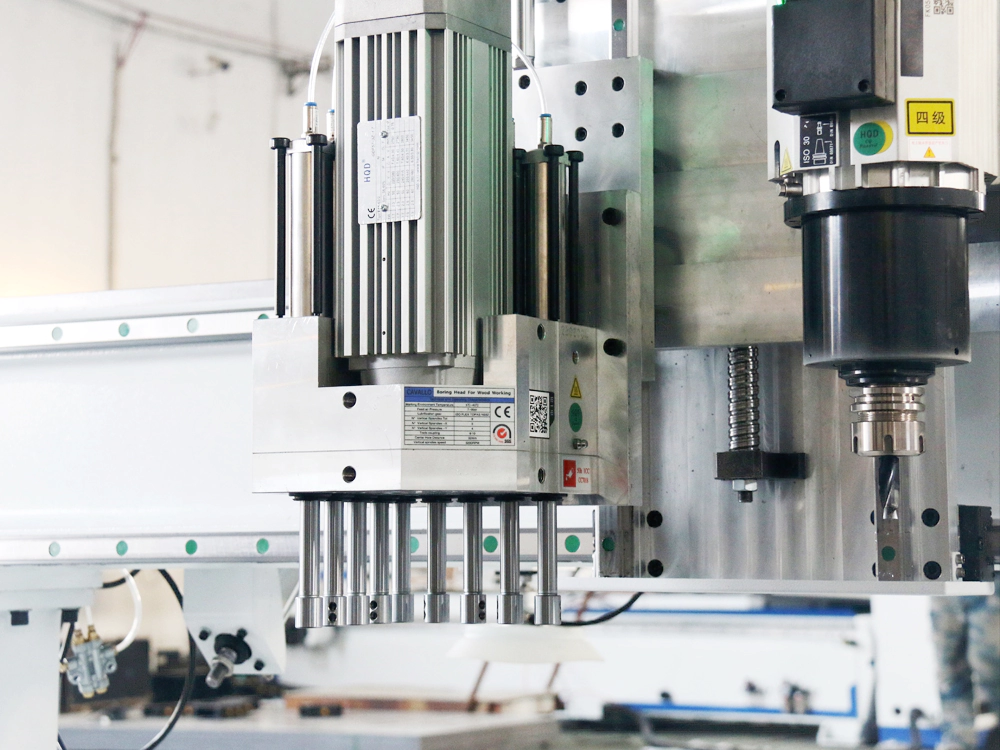

- Equipped with an Italian HSD 9KW automatic tool change spindle, featuring air-cooling technology and low-noise design, eliminating the need for water cooling, with a maximum speed of up to 24000rpm, capable of meeting high-speed processing demands, while also possessing strong cutting force and high precision characteristics.

- XYZ three-axis all use Japanese Yaskawa servo motors, offering high speed and high torque along with exceptional motion control capabilities, enabling precise position, speed, and acceleration control.

- TBI ball screw transmission, with transmission efficiency exceeding 90%, using high-precision grinding tracks (precision up to 0.1 microns), ensuring excellent repeat positioning accuracy.

- Uses high-precision Hiwin guide rails and linear bearings, suitable for various working environments including heavy load, high speed, and low speed, and possesses good shock resistance.

- Uses a SYNTEC's CNC system, with a user-friendly interface, easy to get started, employing advanced control algorithms, capable of achieving high-precision control of CNC equipment, ensuring processing quality.

- Installed with planetary gear reducers, using helical gear design, enabling silent operation and high torque output.

- Equipped with a high-power water ring vacuum pump, easy to use and maintain, with low noise (optional Beck vacuum pump, vacuum air pump, etc.).

- Central lubrication system, fully automatic timed lubrication of machine transmission parts, avoiding maintenance delays due to human factors.

Details of the 7x10 Automatic Tool Change CNC Nesting Machine

- HSD automatic tool change spindle

-

Italian HSD spindle, high precision, long lifespan, low noise, minimal vibration.

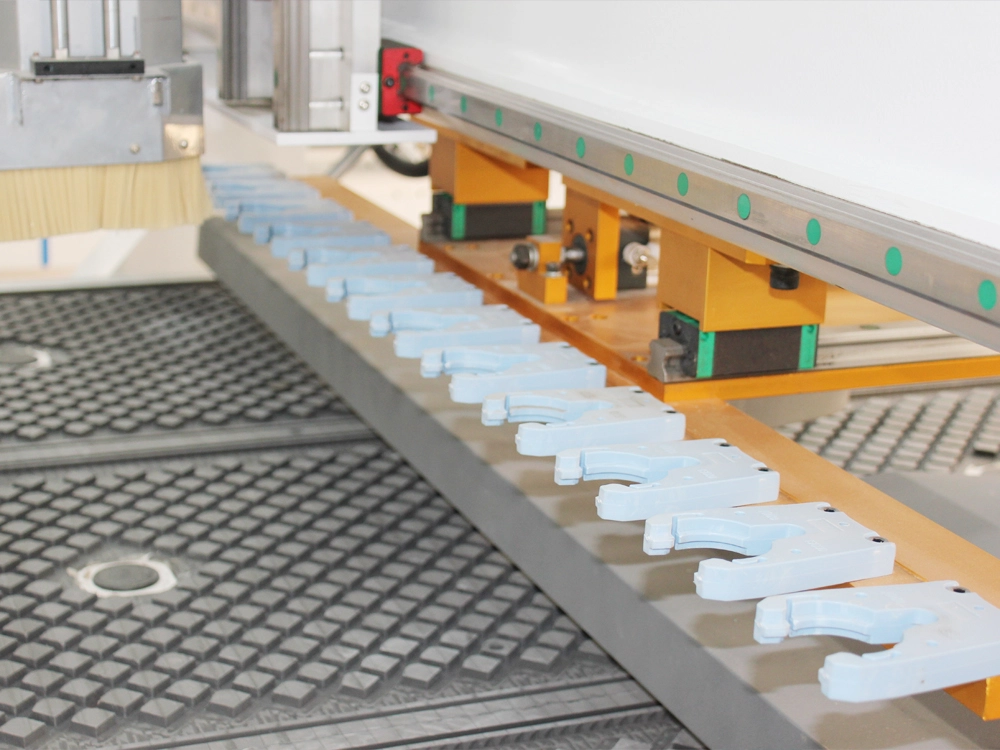

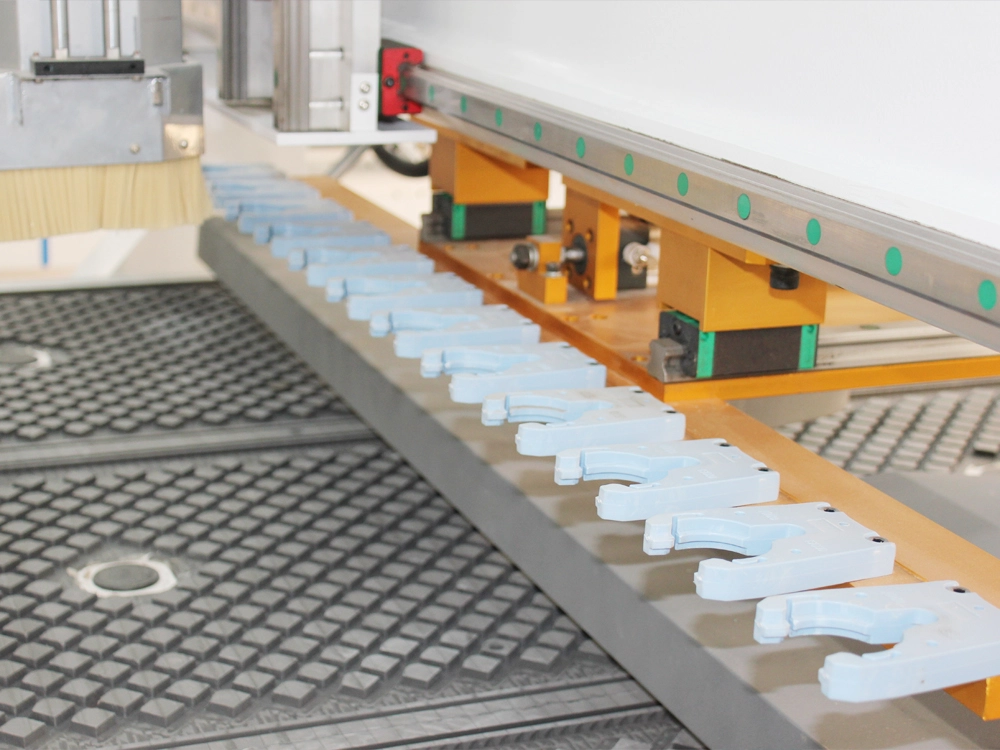

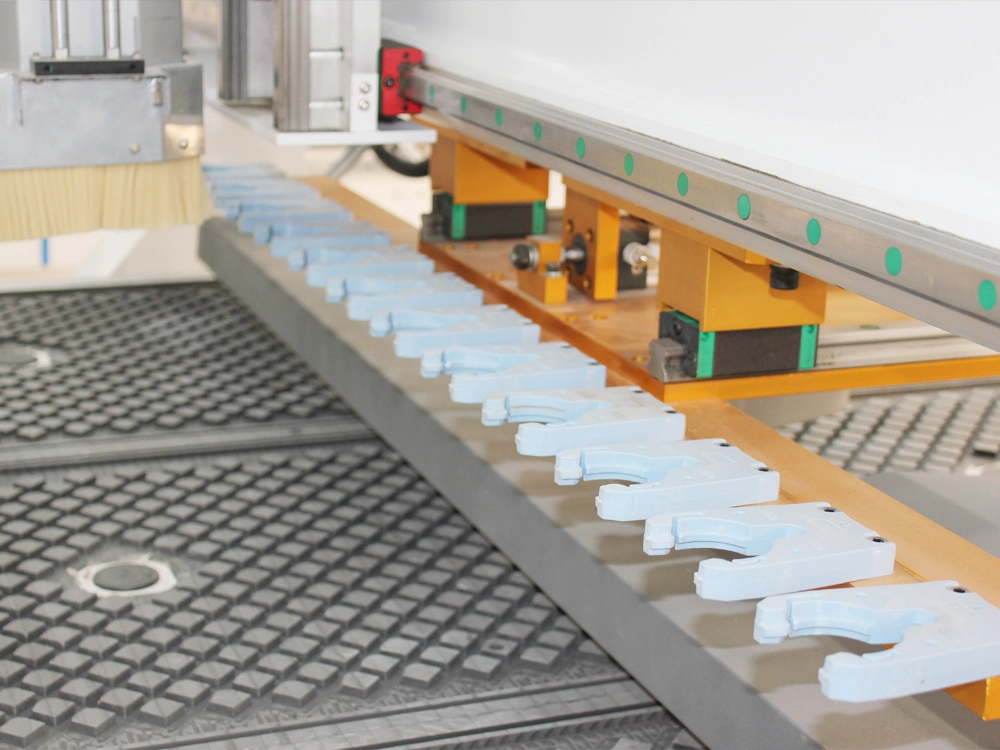

- Linear automatic tool changer

-

Compared to the carousel-type automatic tool change kit, it offers faster tool change speed, simpler maintenance, and reduces the need for an additional servo motor and reducer, making it relatively more cost-effective.

- 9-zone vacuum adsorption work workbench

-

Each zone is independently equipped with one or more air holes, making material fixation more convenient.

- Vacuum adsorption zone control valve

-

Independent control switches for the vacuum adsorption worktable, each zone can be independently opened or closed.

- Automatic lubrication oil pot

-

Central automatic lubrication oil pump, fully automatic lubrication and maintenance of the machine, simple to use.

- Control button group

-

Emergency stop button, positioning cylinder button, vacuum adsorption button, processing start button.

- Clamping device for separating the tool and the holder

-

When separating the blade from the knife holder, this device can be used to clamp the knife holder to facilitate removal of the blade.

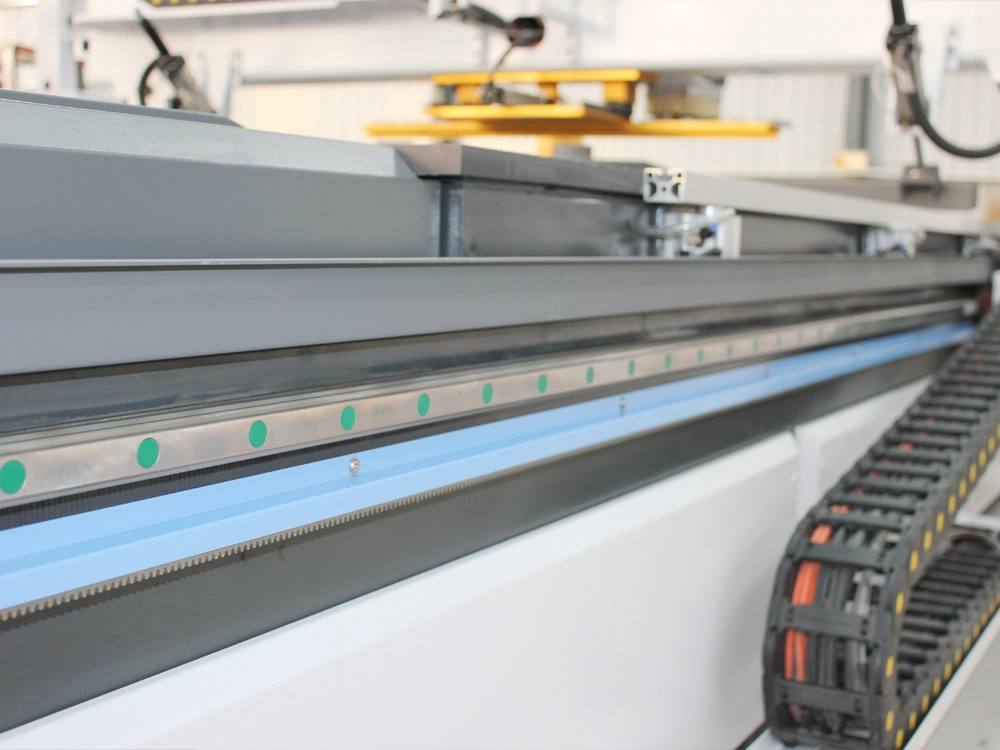

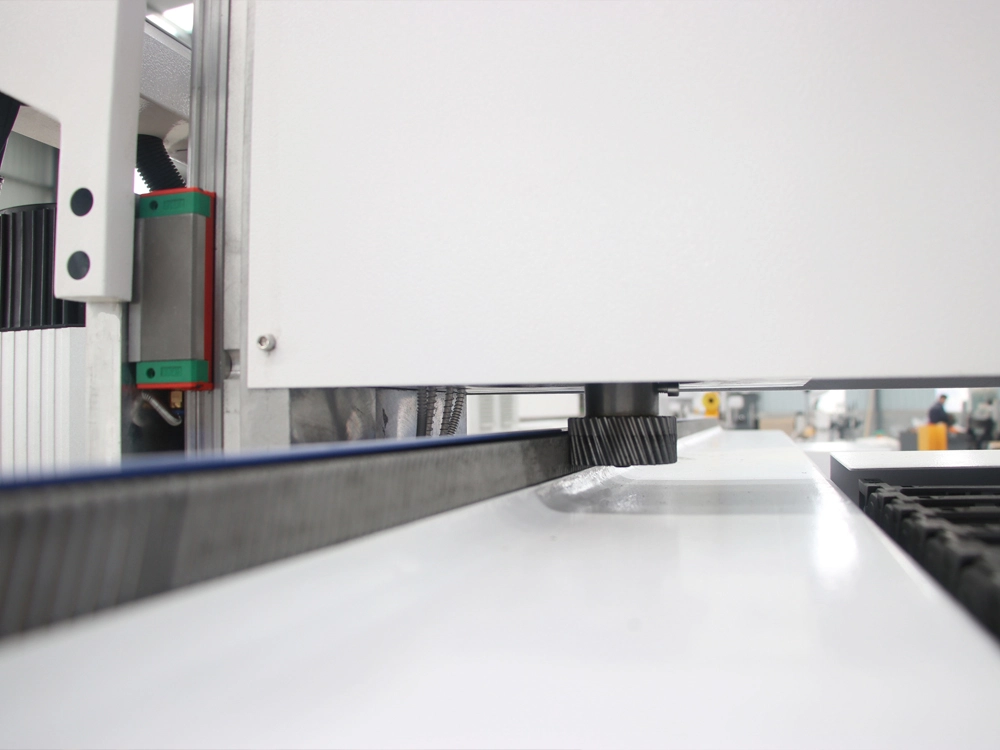

- Transmission system

-

High-precision helical racks and gears, Taiwan Hiwin 30 guide rails.

- Electrical components

-

High-quality electrical components, multiple inverter brands available.

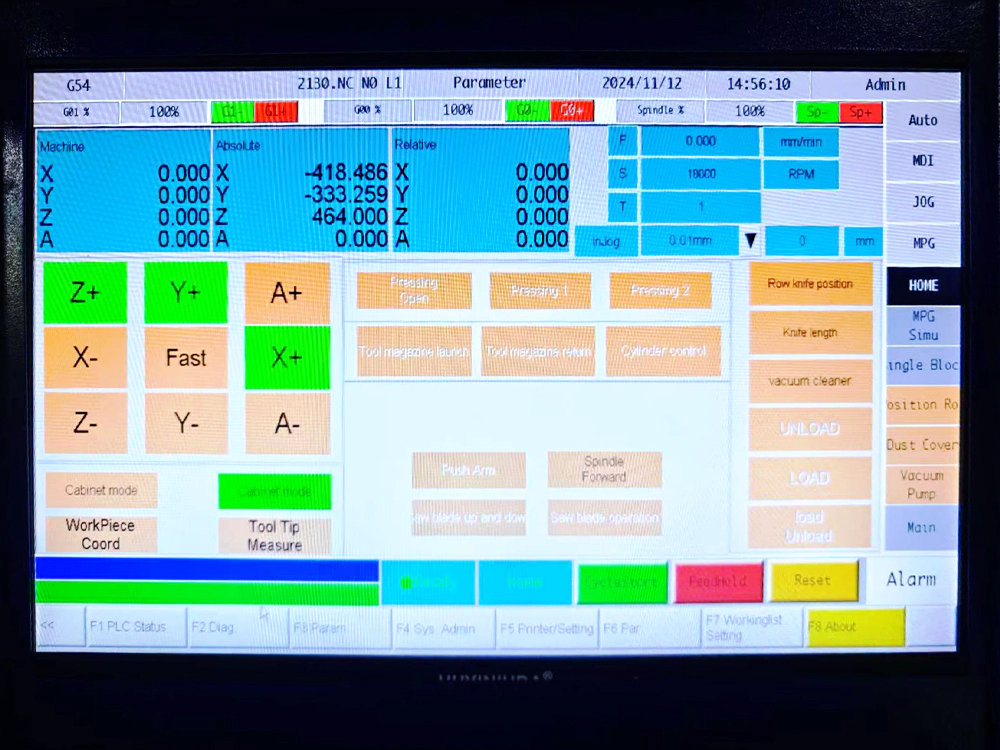

- SYNTEC's CNC control system

-

Taiwan SYNTEC's CNC router control system, easy to operate, supports multiple programming languages and file formats, making program editing and operation more convenient.

- Optional 5+4 pneumatic drill bank

-

Drilling directly into the wood.

- Optional German Becker vacuum air pump

-

Higher cost, strong power.

Technical Parameters of 7x10 ATC CNC Router

| Model | CK-2130-T |

|---|---|

| XYZ Working Travel | 2100*3000*200mm |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | HSD 9KW air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Collet | ISO30 ER32 |

| Driving Mode | Yaskawa servo motor drive (Z-axis brake motor) |

| Frequency Converter | Best/Hpmont inverter |

| Reducer | Japan Shimpo reducer |

| Table | Vacuum table 9 zones, 30 holes |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision 30 linear square rail/flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Vacuum Pump | 11KW (or two 5.5KW) water ring vacuum pumps |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Central lubrication oil filling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 30000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3500kg |

| Dimensions | 4300*2800*2250mm |

What Can a 7×10 CNC Router With Automatic Tool Change Kit Do?

Applicable Materials:

Bamboo, wood, plastic, pvc, acrylic, pcb, mdf, osb, aluminum, copper, fiberglass, carbon fiber, synthetic materials, artificial stone, pu, etc.

Applicable Industries:

- Furniture Manufacturing: Cabinet doors, wardrobe doors, screens, window frames, wooden doors, beds, bookshelves, tables, chairs, and other furniture.

- Advertising Production: Advertising signs, advertising light boxes, advertising boards, advertising letters, medals, logos, crystal letters, etc.

- Craft Gift Making: Hanging signs, decorative signs, ornaments, wooden boxes, wooden toys, puzzles, models, etc.

CATEKCNC can provide you with comprehensive CNC customization solutions. We welcome you to contact us and inform us of your needs.

As an OEM factory with 20 years of experience in CNC router production, CATEKCNC can offer you the best service, the most competitive prices, and the highest quality.

| Model | CK-2130-T |

|---|---|

| XYZ Working Travel | 2100*3000*200mm |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | HSD 9KW air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Collet | ISO30 ER32 |

| Driving Mode | Yaskawa servo motor drive (Z-axis brake motor) |

| Frequency Converter | BEST/Hpmont inverter |

| Reducer | Japan Shimpo reducer |

| Table | Vacuum table 9 zones, 30 holes |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision 30 linear square rail/flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Vacuum Pump | 11KW (or two 5.5KW) water ring vacuum pumps |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Central lubrication oil filling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 30000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3500kg |

| Dimensions | 4300*2800*2250mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.