Most-Popular Linear ATC CNC Router with Automatic Loading And Unloading

Best-Selling Linear ATC CNC Router with Automatic Loading and Unloading

[Function Description]

Feature of 4*8 Linear ATC CNC Router with Automatic Loading & Unloading

- The 9KW air-cooled automatic tool-changing spindle can quickly process various materials, offering high torque, large cutting depth, and high processing efficiency.

- TBI high-precision ball screws, high-precision helical racks, and gears, combined with 30mm guides and 30mm linear bearings, ensure fast operation, low processing noise, and high positioning accuracy.

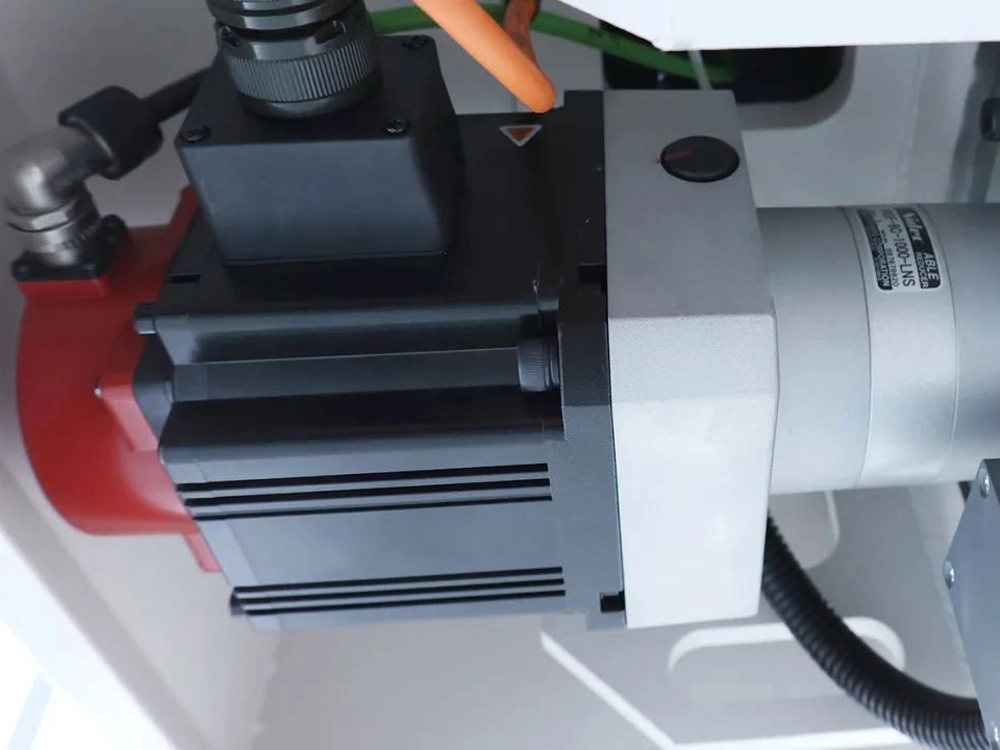

- The XYZ axes are all driven by 1.5KW high-power servo motors, with the Z axis using a brake motor. Paired with Japanese-made Shimpo planetary gear reducers, the system achieves higher precision, shorter braking time, and stable operation.

- The machine features a heavy-duty square steel welded bed base, treated at high temperatures and processed by five-face gantry milling machine. It uses a heavy-duty thickened gantry and reinforced support columns, ensuring more stable processing, greater durability, and no deformation.

- An 11KW high-power water-ring vacuum pump and a 6-zone, 24-hole vacuum adsorption table allow for normal adsorption and processing of wood boards of different sizes within the maximum processing dimensions. Each zone can be independently controlled for convenience.

- Equipped with 4+2 positioning cylinders, it can process full-size 4*8 sheets more conveniently, eliminating the need for manual placement of sheets in fixed positions each time, saving time.

- The CNC woodworking router-specific automatic tool setting device enables one-click tool setting and automatic processing, regardless of tool size or length, eliminating the need for manual tool calibration and making operation more convenient.

- The automatic loading platform, with hydraulic-controlled lifting, automatically adjusts the height based on the thickness of the board. It works in conjunction with the machine's loading suction cup device to achieve fully automatic board loading.

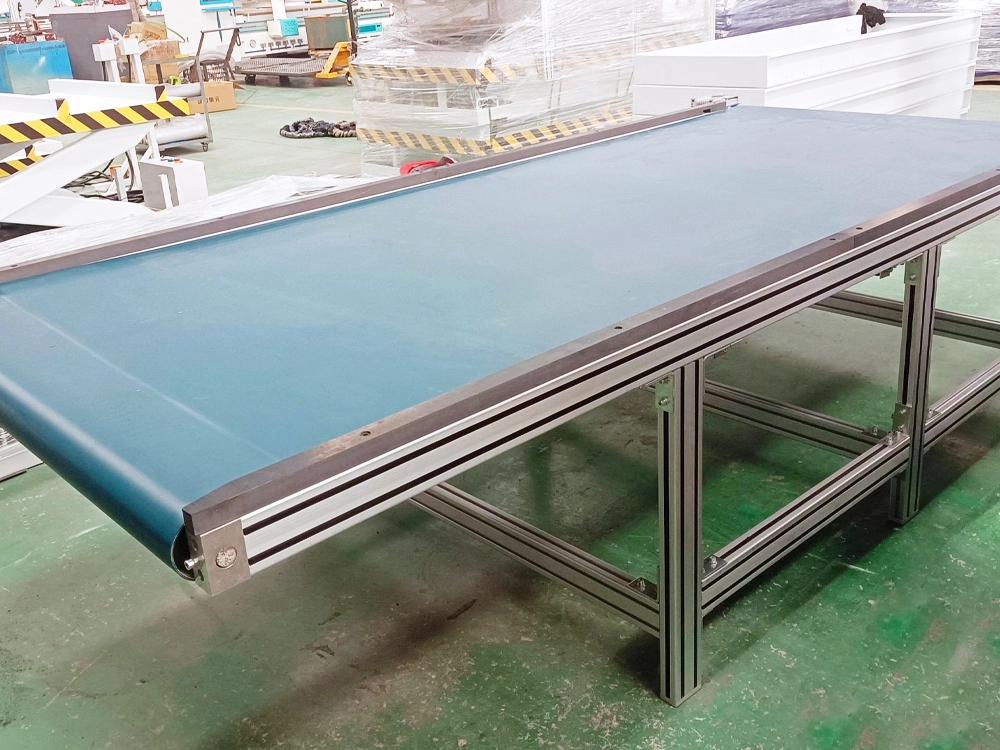

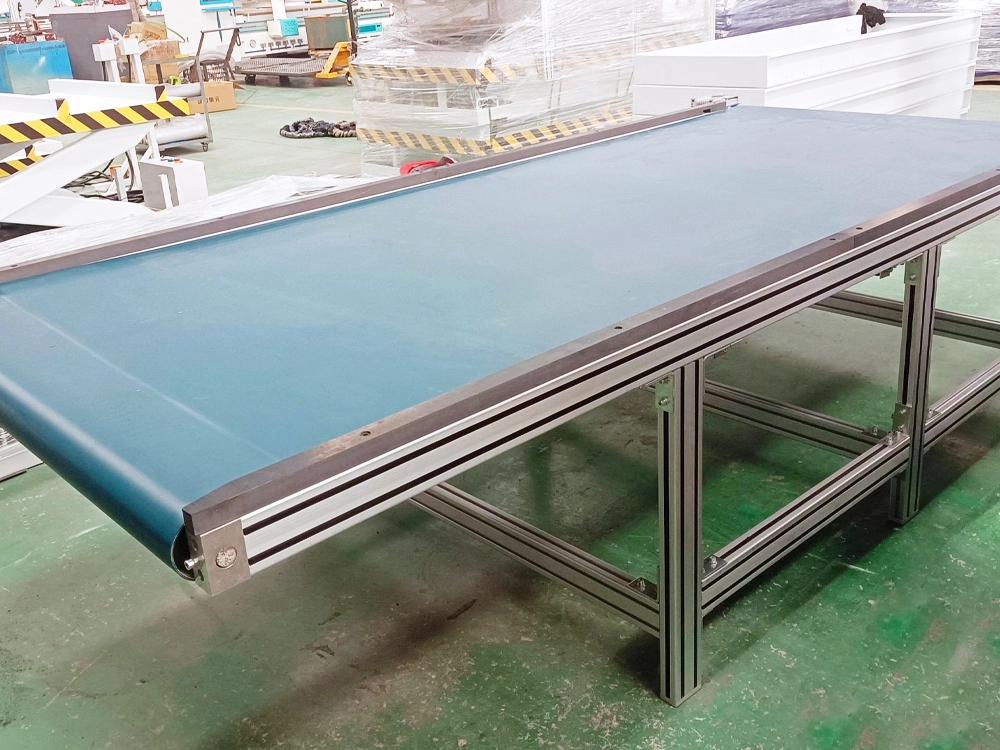

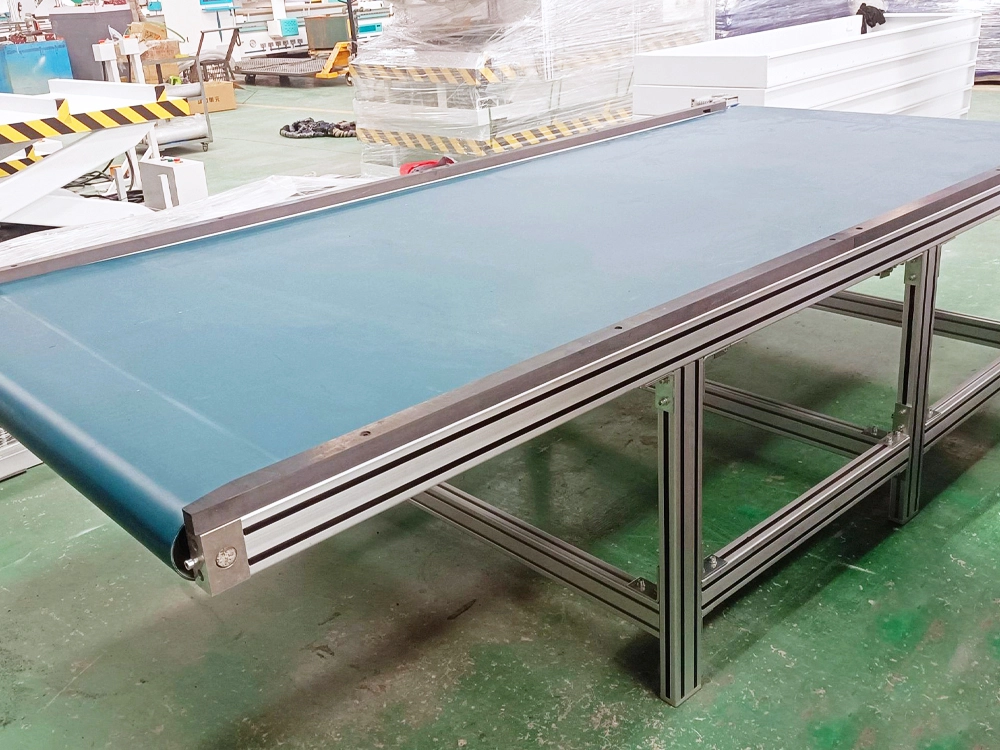

- The conveyor belt type unloading platform, combined with the machine's automatic material pushing device, automatically transfers processed boards to the unloading platform, eliminating the need for manual unloading and saving time, thereby improving machine efficiency.

- The Taiwan LNC CNC system offers expanded functionality and user-friendly design, enabling true intelligent control with one-click automatic startup, requiring no complex operations.

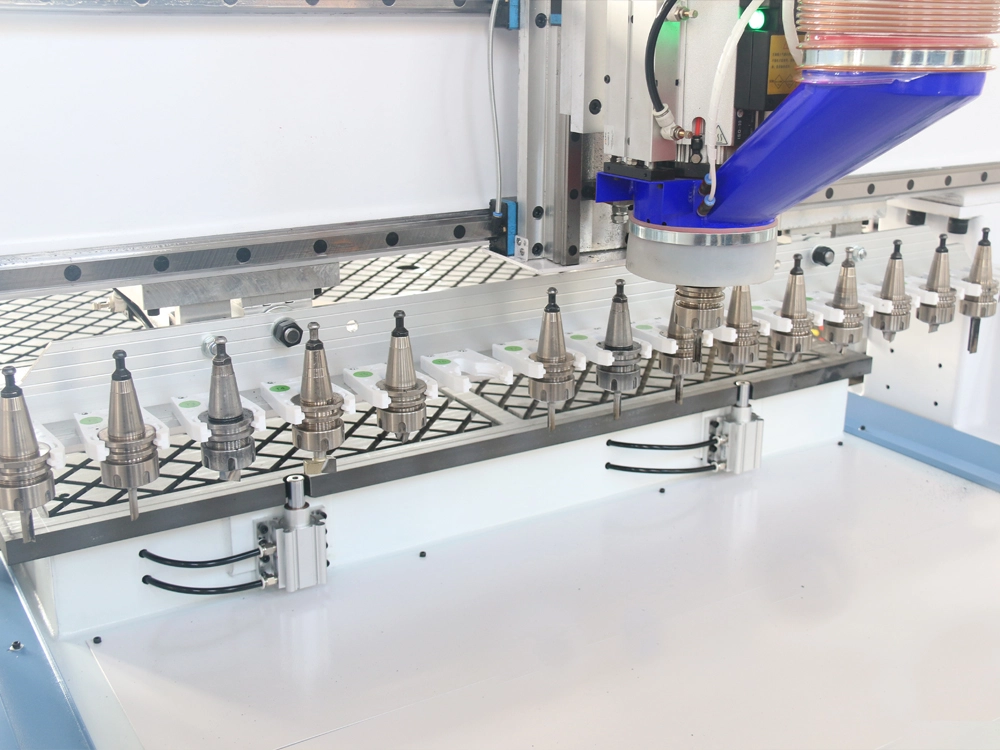

- The linear tool changer can hold 8/12/16 tools, enabling automatic tool changes. A single setup and startup can complete products requiring multiple processing steps.

Advantages of ATC CNC Router With Automatic Loading & Unloading

- Fully automatic loading and unloading save time on manual material handling, improve processing efficiency, and reduce production costs.

- Capable of processing various materials, such as MDF, engineered wood, particleboard, plywood, aluminum, copper, and other types of boards, with a wide range of applications.

- When paired with specialized nesting software for furniture and cabinets, it reduces manual drawing, enables automatic layout, and improves material utilization.

- Optimizes complex processing workflows and can be integrated with automatic labeling machines, six-sided drills, edge banding machines, and other furniture production equipment.

- Performs various functions such as cutting, engraving, drilling, milling grooves, shaping, and surface milling, offering comprehensive capabilities.

- Uses specialized nesting software for CNC routers and supports various CAD/CAM software types, ensuring broad file compatibility.

- All tools required for processing can be pre-installed in the tool magazine, reducing time wasted on manual tool changes and lowering labor costs.

- Equipped with an automatic central dust collection system that collects wood chips and waste generated during processing, ensuring environmentally friendly operation and compliance with environmental certification requirements.

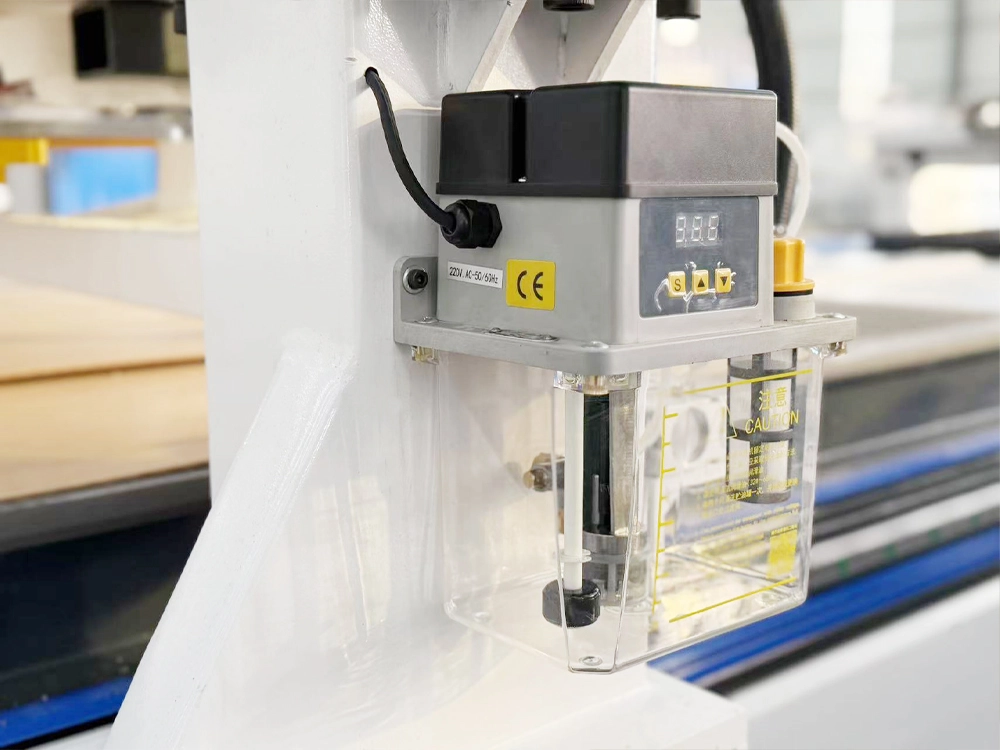

- Automatic lubrication system performs comprehensive lubrication based on usage frequency, effectively extending the machine's service life.

- Supports one-click start/stop, automatic positioning, and other functions, making operation simple and easy to master even for non-professionals.

Detailed Introduction of Carousel ATC CNC Router With Automatic Loading & Unloading

- Spindle

9KW air-cooled spindle, supports automatic tool changing function.

- Servo motor

The machine is equipped with four servo motors: one for the X-axis, two for the Y-axis (with double-sided guide rails), and one for the Z-axis.

- Material transport device

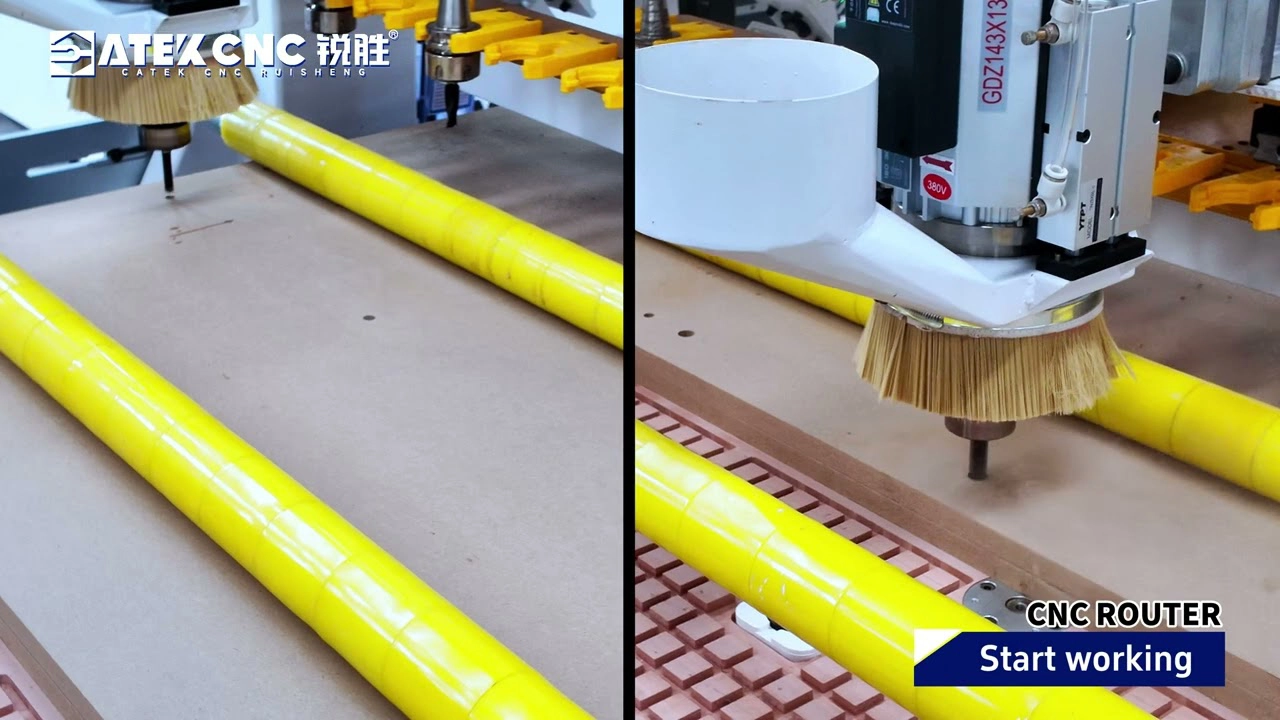

Two suction cups pick up the sheet from the loading platform and drag it to the workbench. The loading roller can effectively reduce the static friction between the sheet and the workbench during the dragging process, making it easier to drag and less likely to cause wear on the sheet.

- Linear tool magazine

The linear tool magazine is fixed on the gantry and can move with the gantry. When the tool needs to be changed, it will pop out from under the gantry, minimizing the required movement distance of the spindle.

- Automatic tool setting instrument

The automatic tool setting instrument can instruct the control system to calculate the corresponding compensation amount according to the length and tool tip position of different tools.

- Transmission system

Hiwin 30 guide rails, TBI high-precision ball screws, high-precision helical racks and gears.

- Vacuum adsorption zone control valve

This valve group can control the opening and closing of each air hole on the vacuum adsorption workbench.

- Lubricating oil pot

The lubrication interval and lubrication duration can be set, and the transmission parts of the machine will be lubricated automatically according to the settings.

- Automatic feeding platform

It can automatically rise and fall according to the thickness and quantity of the plates to ensure that it is level with the workbench height.

- Automatic unloading platform

Combined with the pushing device, the processed plates can be automatically pushed to the unloading platform, and the unloading platform rolls to complete the unloading.

- Weihong control system

It adopts Weihong control system, visual operation interface, simple operation, supports multiple languages such as English, Russian, Vietnamese, and supports multiple file formats such as: MPR, BAN, XML, etc.

Technical Parameters of Linear ATC CNC Nesting Machine with Automatic Loading & Unloading

| Model | CK-1325-TA |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Bed | Independent anti-interference control cabinet for machining center bed (heavy duty bed) |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Table | Vacuum table 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4600kg |

| Dimensions | 9850*2150*2200mm |

Optional Accessories for Linear ATC CNC Router With Automatic Loading & Unloading Technical

| Spindle | Italian HSD spindle/Italian HITECO spindle |

| Control System | Syntec/NCStudio/Mach3 etc. |

| Saw Blades | The saw knife can be rotated to cut the board |

| 5+4 Pneumatic Drilling Kit | HQD 5+4 pneumatic drilling kit/CNC side milling angle head |

| Pressure Roller | Double rod independent pneumatic pressure rollers can be individually controlled to fix the plate |

| Labeling Machine | Fully automatic printing, typesetting and labeling machine |

| Tool Changing Method | Carousel tool changer (6/8/10/12) |

Application of 4x8 Carousel ATC CNC Router Machine in Manufacturing

Applicable Materials

It Can process various materials such as wood, plastic, acrylic, pvc, artificial stone, resin, plexiglass, bamboo, two-color board, aluminum, copper, etc.

Applicable Industries

- Furniture industry:

Cabinets, cabinet doors, wooden doors, mahogany furniture, wooden furniture accessories, whole house furniture customization, office furniture, wardrobes, bedside tables, wine cabinets, sideboards, top cabinets, filing cabinets, glass display cabinets, doors and windows, etc.

- Decoration industry:

Bookshelves, screens, cat climbing frames, wall panels, wooden decorative paintings, wall panels, wall decorations, wooden sculptures, etc.

- Advertising industry:

Advertising word cutting, luminous words, crystal words, acrylic, PCB, gypsum board, acrylic light box, etc.

- Other industries:

Musical instruments, guitars, speakers and other musical instruments or handicrafts production, etc.

The Following Are the Processable Products of ATC CNC Router With Automatic Loading & Unloading for your reference

Frequently Asked Questions

How is the Fully Automatic Loading and Unloading CNC Router Packaged and Shipped?

- After the production is completed and you have confirmed the acceptance of the machine, we will do the final cleaning of the machine and repair the paint surface of the machine to ensure that the machine is in perfect condition before shipment.

- After the machine is prepared, we will use anti-collision foam and waterproof plastic cloth to wrap the machine to prevent the machine from getting damp and rusting during transportation.

- Finally, we will use thickened plywood export-specific fumigation-free wooden boxes to pack the machine as a whole. Prevent the machine from being damaged during transportation.

- After you receive the machine, please unpack the wooden box first and move the machine out of the wooden box before using it.

Delivery Time and Delivery Method of Fully Automatic Loading and Unloading CNC Router

- After receiving your advance payment, we will produce the machine for you as soon as possible, usually within 30 days. If you need it urgently, we can expedite production for you.

- The fully automatic loading and unloading CNC router is larger, and you can choose land or sea transportation for transportation.

| Model | CK-1325-TA |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, steel beams, thickened gantry columns |

| Bed | Independent anti-interference control cabinet for machining center bed (heavy duty bed) |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Table | Vacuum table 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Syntec / NCStudio / Mach3 |

| Lubrication System | Oil injection maintenance system |

| Operating Voltage | AC380V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4600kg |

| Dimensions | 9850*2150*2200mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.