Multi-Functional ATC CNC Router With Four-Axis Saw Blade, Oscillating Tool and Ccd Vision System

4x8ft ATC Linear CNC Router With 4-Axis Saw Blade, Oscillating Tool, and Vision System

[Function Description]

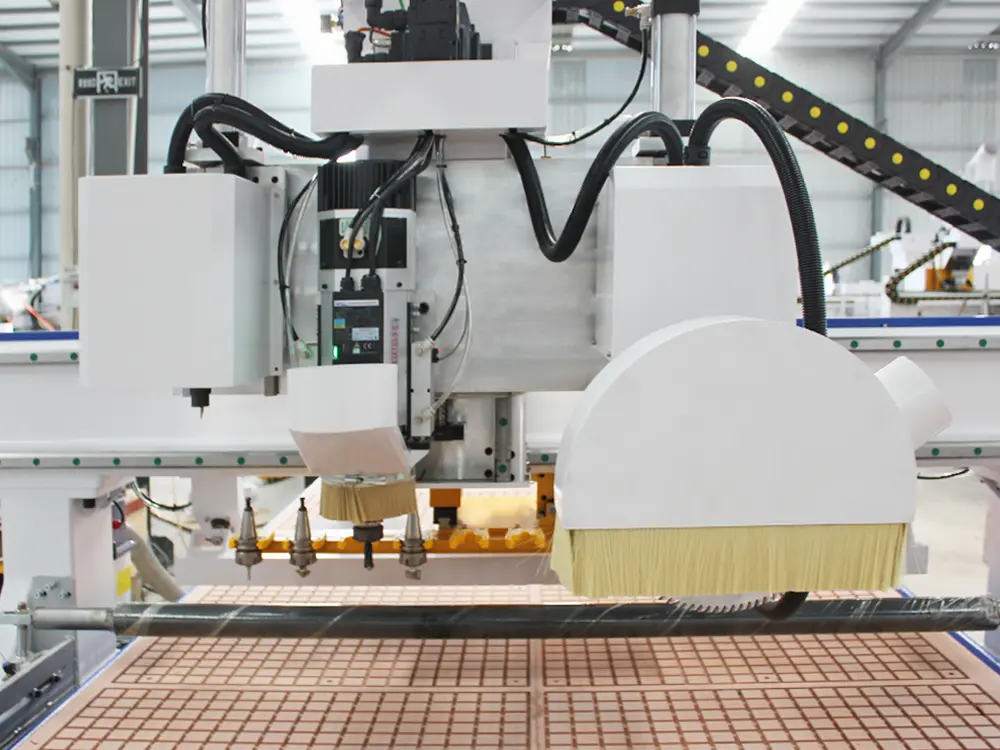

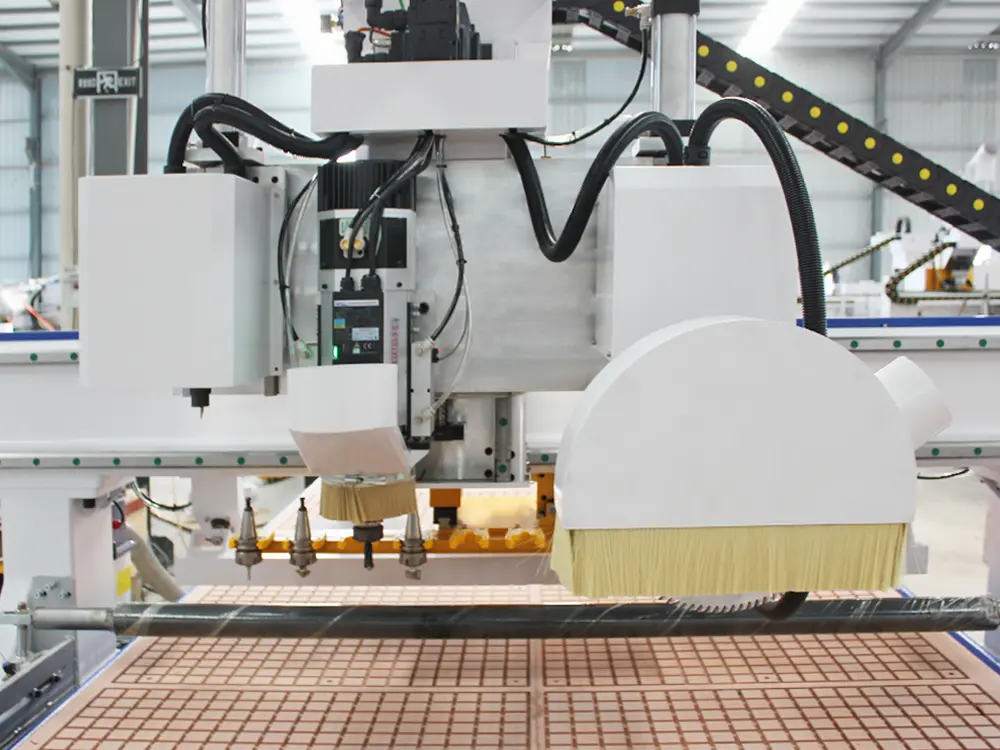

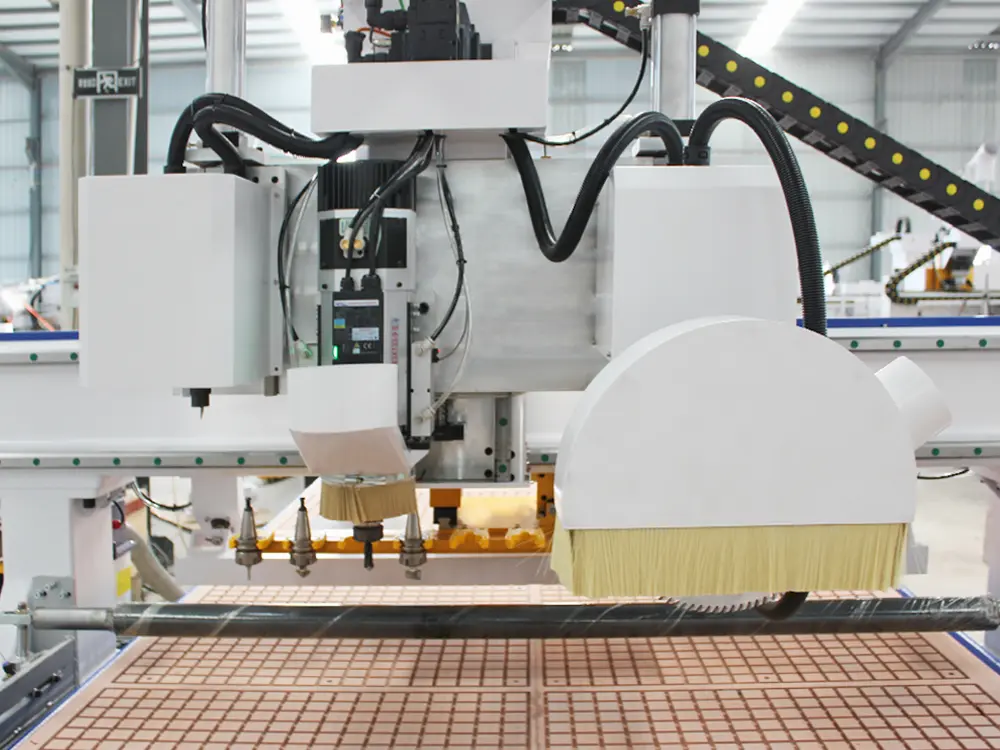

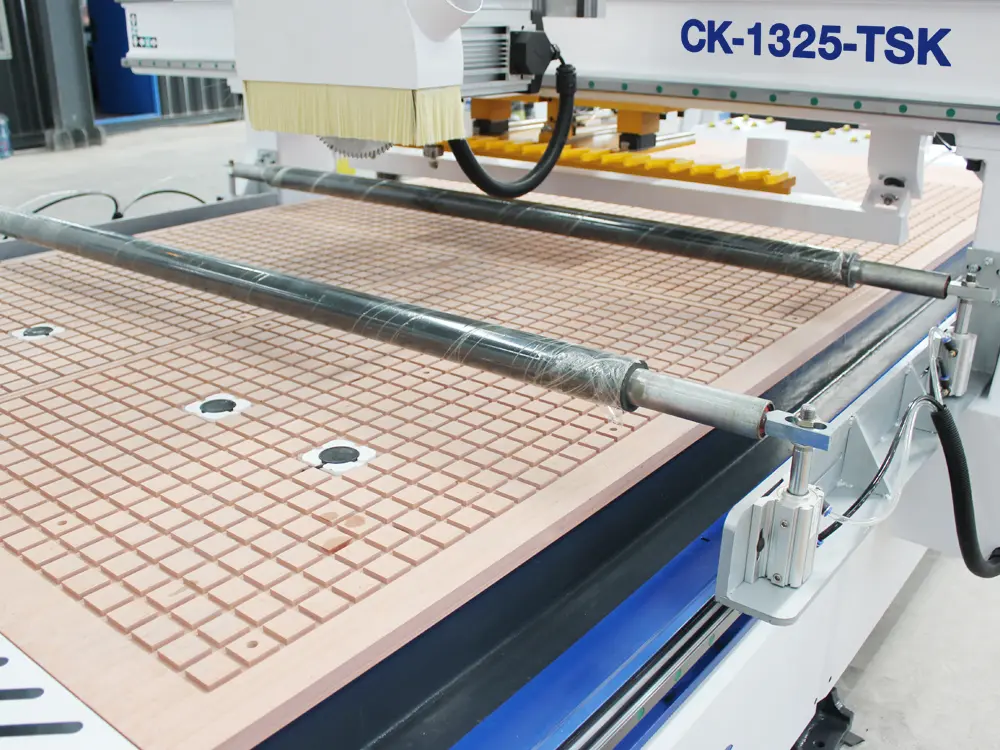

The CK-1325-TSK is a high-performance multi-functional CNC router that integrates an automatic tool-changing kit, a 4-axis rotary cutting saw blade, a CCD vision positioning system, and an oscillating tool cutting device. It is capable of processing both flexible and rigid materials simultaneously, meeting diverse machining needs.

The CNC router machine is equipped with a 9KW automatic tool-changing spindle and a linear tool magazine with 12 tools, making it suitable for cutting, drilling, grooving, and milling various rigid materials such as MDF, OSB boards, wood panels, acrylic, PVC, aluminum, and copper. Additionally, its four-axis rotary cutting saw blade supports cross-cutting and rip-cutting on the horizontal plane, enabling the completion of multi-layer panel cutting tasks in a single operation, significantly improving panel processing efficiency.

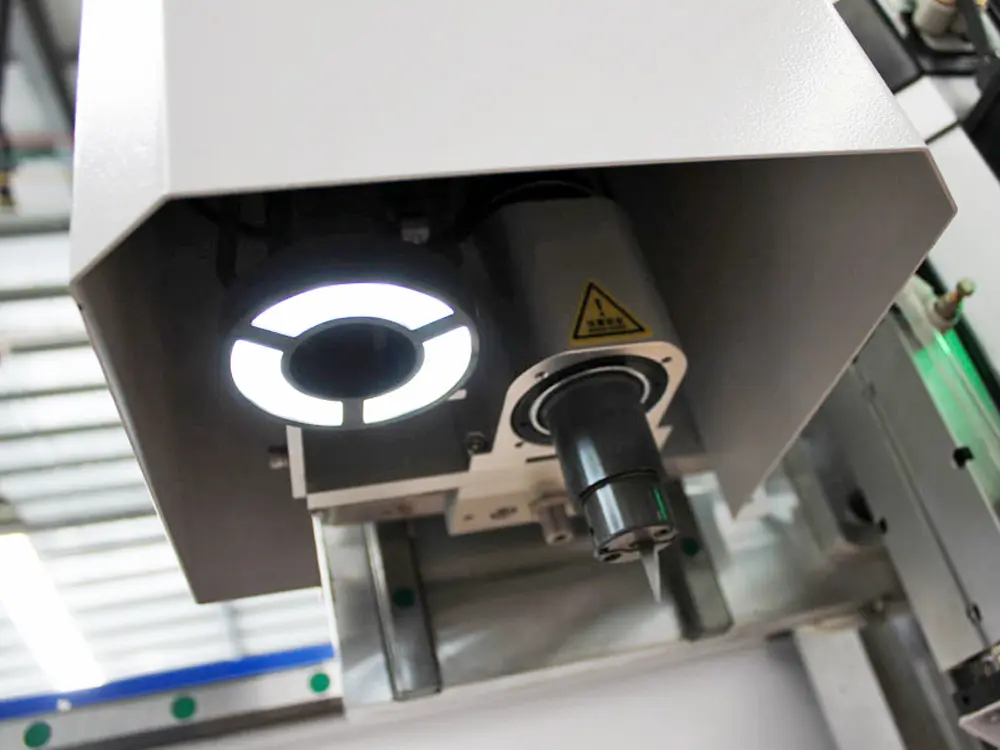

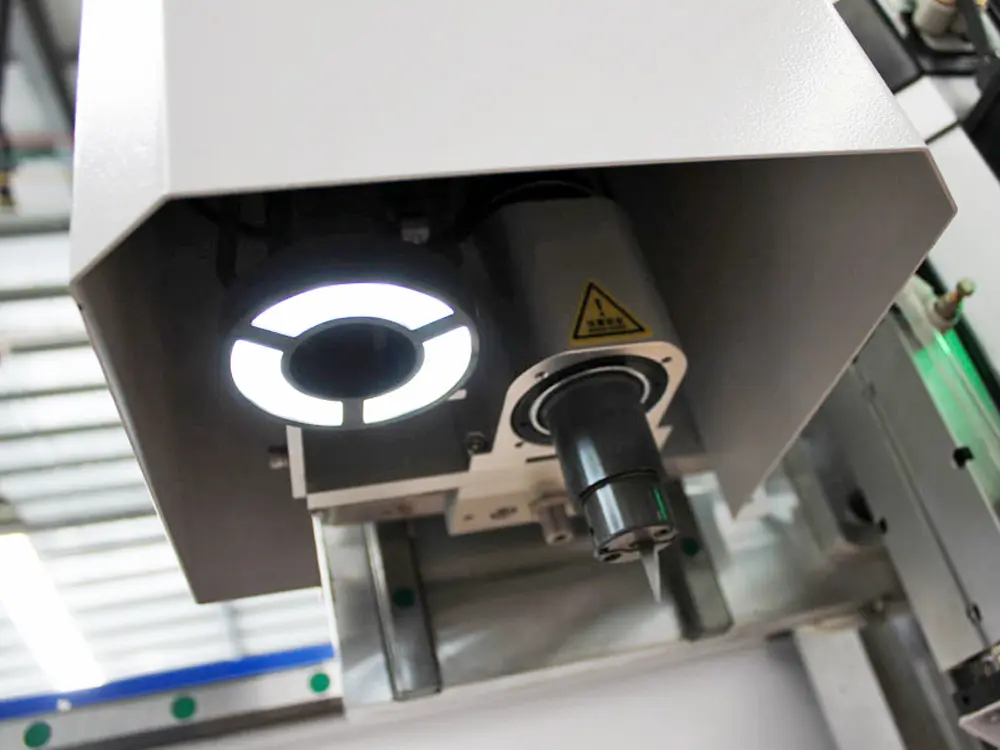

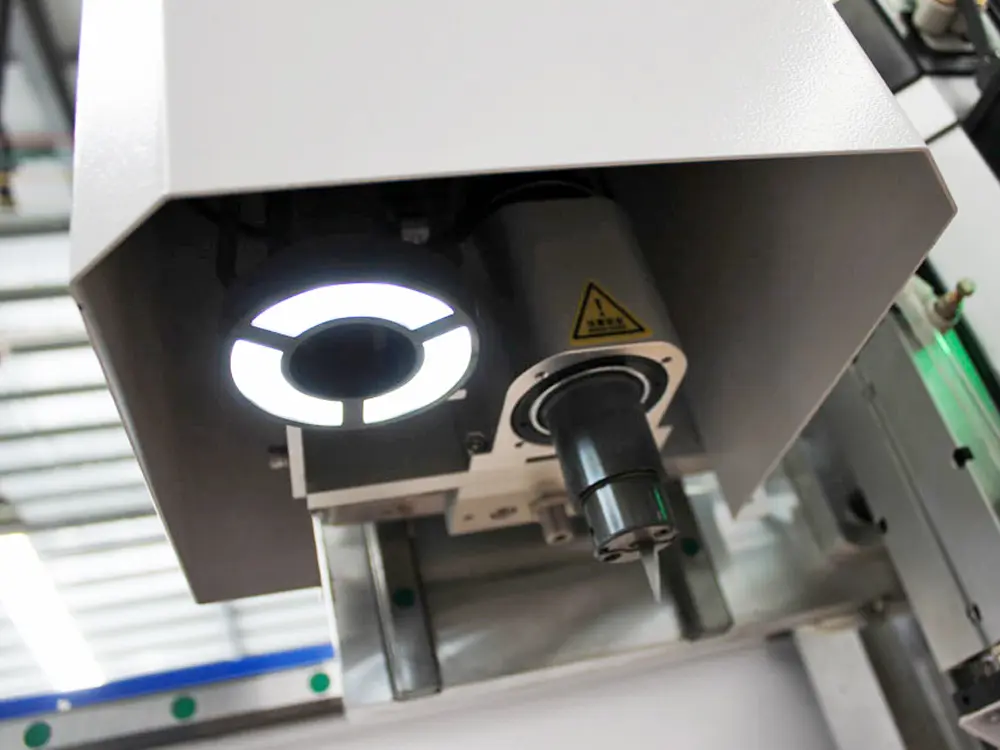

The CCD vision positioning system and oscillating tool cutting device are specifically designed for flexible materials. The CCD system automatically recognizes the outer contours of pre-printed patterns, achieving precise cutting without the need for drawing layout or programming. The oscillating tool cutting device, on the other hand, is ideal for processing materials such as fabric, foam, leather, and cardboard.

By combining multiple functions into one machine, it not only saves workshop space but also reduces the cost of purchasing multiple pieces of equipment, making it particularly suitable for small factories. The CK-1325-TSK CNC router not only offers high efficiency and precision in machining but also represents a highly space-efficient and cost-effective integrated solution.

Furthermore, the CK-1325-TSK CNC router is equipped with the XDW control system, which supports a multi-language operation interface. Even operators with no prior experience in CNC equipment can quickly master it within a short period. With this system, users can easily set machining parameters according to different materials, meeting the processing requirements of various materials, thereby effectively enhancing production efficiency and product quality.

Features of the ATC CNC Router with 4-Axis Saw, Oscillating Tool, and Vision System

1. Ultra-High-Strength Welded Bed & Heavy-Duty Gantry Beam

- Bed: Constructed from ultra-high-strength, thickened square steel with multi-pass welding on all seams to ensure weld integrity. The entire structure undergoes stress relief annealing and vibration aging to effectively eliminate internal stresses. The bed surface is overlaid with an 8mm thick steel plate, and the guide rail mounting surfaces and beam guiding surfaces are processed via a large 5-axis gantry milling machine through rough milling, fine milling, and grinding, guaranteeing high flatness accuracy.

- Beam: Fabricated from low-carbon, high-strength steel, it undergoes secondary aging and straightening processes, controlling straightness error to <0.01mm/m. The guide rail and rack mounting surfaces are precision-machined with a gantry milling machine, ensuring the perpendicularity and horizontality of the transmission system's installation baseline, laying the foundation for high-precision, high-speed operation.

2. High-Precision Transmission System for Accurate Positioning & Stable Operation

- Guideways: The CNC router machine utilizes 30mm linear guideways/linear bearings from Taiwan's Hiwin throughout. The design incorporates four rows of balls in an internal recirculation system, enabling it to withstand the complex loads generated by the high-frequency vibration of the oscillating tool and the heavy cutting forces of the saw blade.

- Ball Screw: The Z-axis employs a Taiwan TBI ball screw, offering 40% higher anti-bending rigidity than standard screws, resulting in superior overall rigidity. With a backlash of ≤0.005mm, it meets high-precision requirements for scenarios ranging from delicate engraving to heavy-duty cutting.

- Rack & Pinion: Grinding-grade, high-precision helical racks and gears are used, providing high rigidity and strong impact resistance. The helical gear overlap ratio reaches 1.6, increasing load capacity by 40% compared to spur gears, effectively compensating for load fluctuations during processing and ensuring machining accuracy.

3. Feed Axis Drive System for Precise Synchronization & Rapid Response

- Servo Motors: Equipped with four sets of 1500W high-torque Leadshine servo systems. The Y-axis features dual-side drive for higher response frequency and enhanced load capacity. The system automatically optimizes output based on the processing load, reducing machine vibration during operation. The built-in fault diagnosis function in the drivers facilitates quick troubleshooting and lowers maintenance costs.

- Reducer: Shimpo planetary gear reducers, which work in synergy with the servo motors to deliver higher output torque. They feature high transmission efficiency and minimal temperature rise during prolonged operation, meeting the demands of high-precision engraving and high-load cutting, effectively reducing transmission error and improving machining quality.

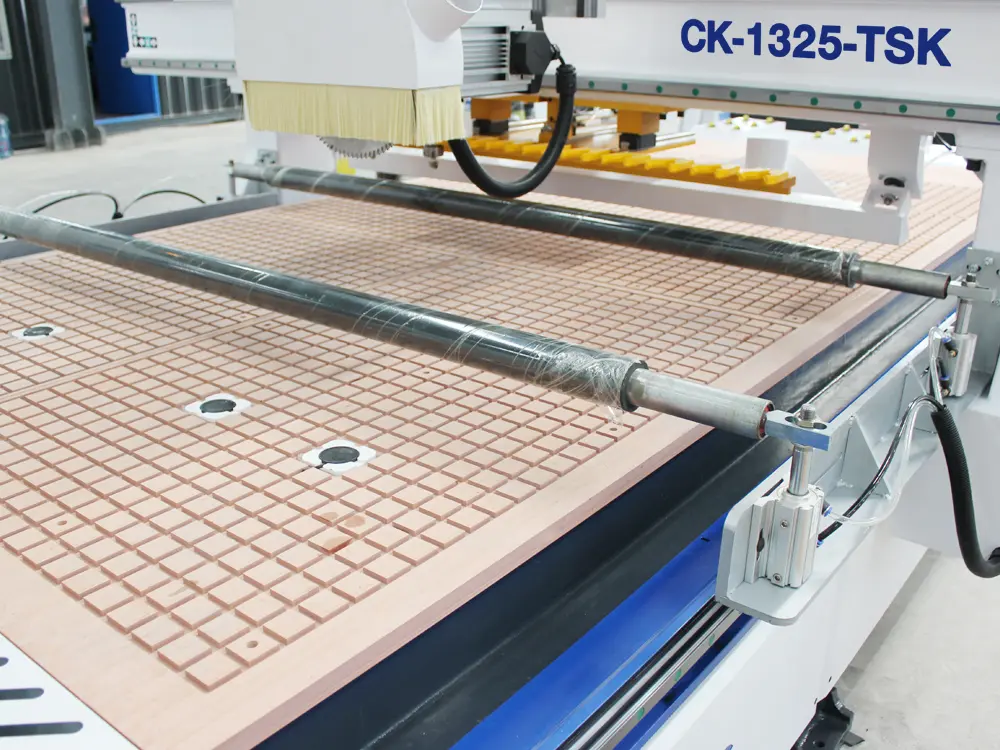

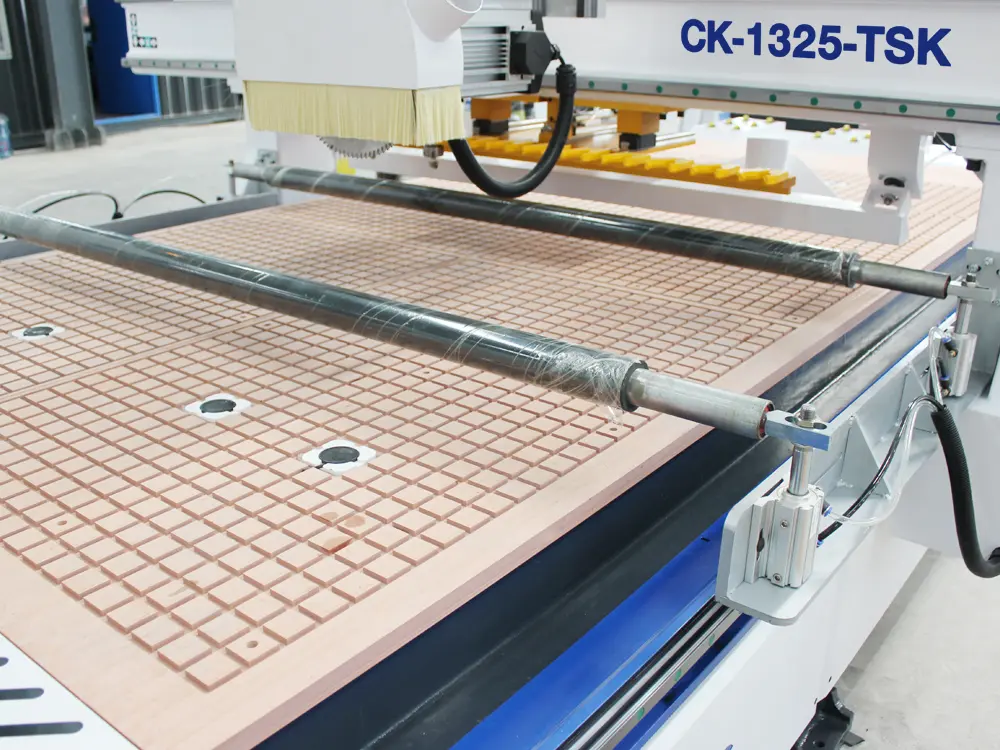

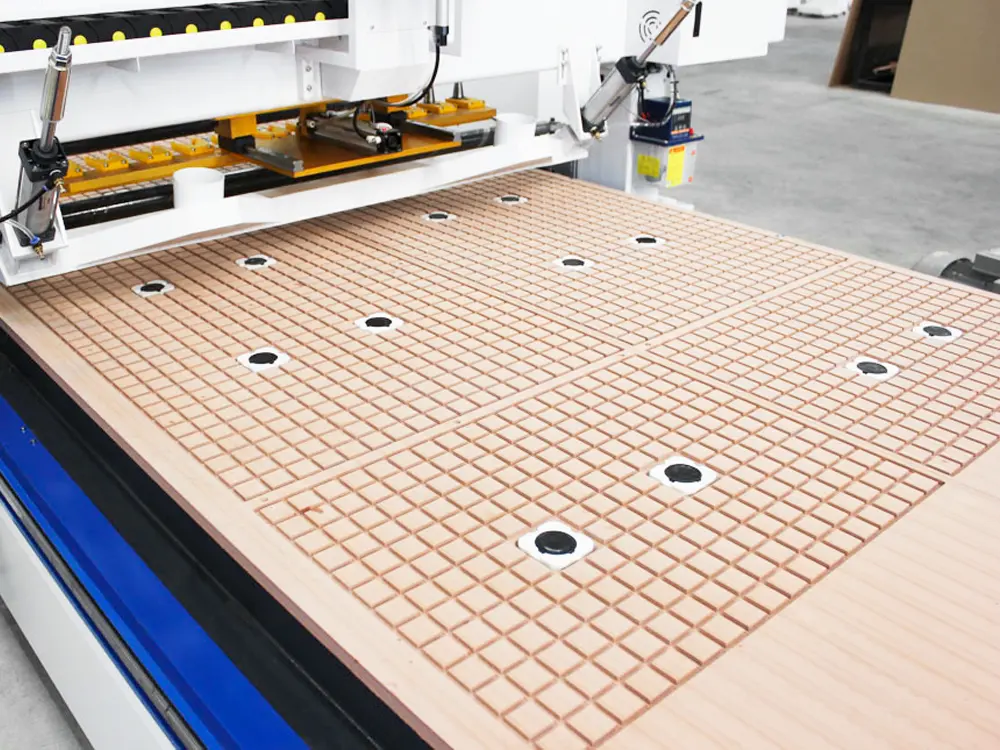

4. Vacuum Adsorption Table & Double-Rod Pneumatic Press Rollers

- Vacuum Table: Configured with a 6-zone, 24-hole vacuum adsorption table, paired with a 7.5KW water-ring vacuum pump. It uses negative pressure to secure workpieces, replacing traditional clamp fixtures, avoiding obstruction of the working area, and enabling fast loading/unloading. It is suitable for flexible materials cut with the oscillating tool as well as rigid materials processed with the saw blade or milling cutter.

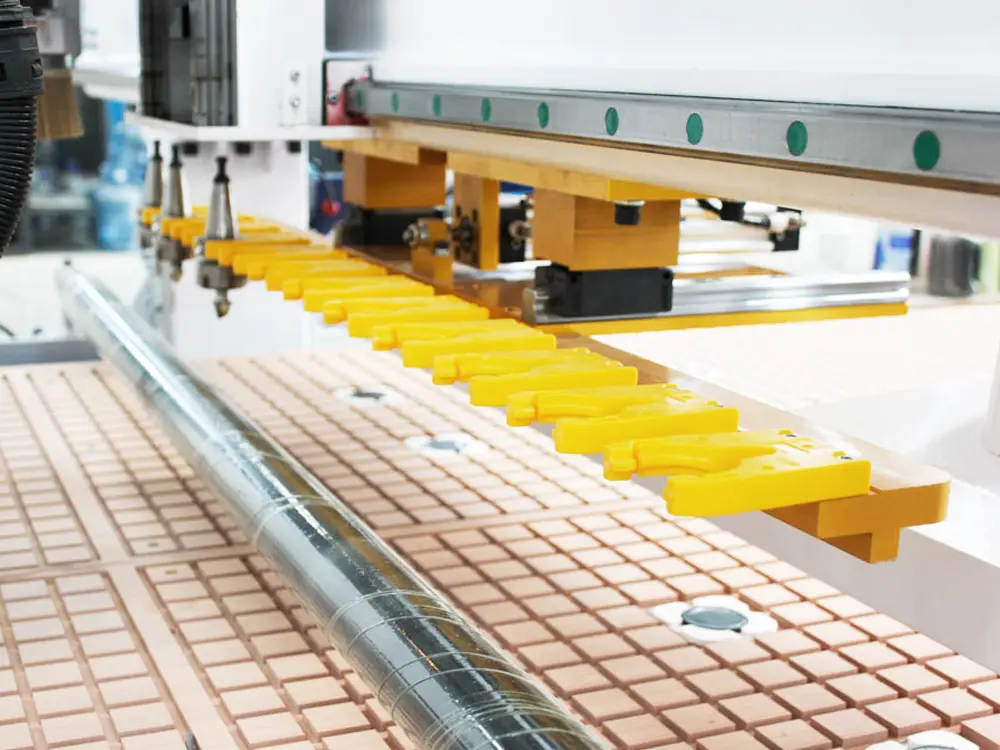

- Double-Rod Pneumatic Press Rollers: Features two independently controllable pneumatic press rollers. Pressure is precisely regulated via air cylinders, enhancing sheet material fixation and preventing workpiece displacement during machining. Working in concert with the vacuum table, they apply uniform top-down pressure, effectively preventing workpiece shifting—whether during multi-layer cutting with the saw blade or single-layer milling with the spindle, ensuring precise toolpath execution.

5. Comprehensive Functions for Full-Range Processing of Flexible & Rigid Materials

- ATC Spindle: Features a 9KW automatic tool-changing air-cooled spindle with a linear tool magazine. It supports ISO30 tool holders and ER32 collets, accommodating up to 12 tools. During batch processing, no manual intervention is needed for tool changes: the system automatically changes tools based, enabling complete workflows (engraving, cutting, drilling, milling) in a single setup.

- 4-Axis Cutting Saw Blade: Driven by a 5.5KW high-speed air-cooled spindle (max 24,000 RPM) with a 280mm diameter blade, it is suitable for cutting multi-layer panels. The fourth rotary axis enables automatic switching between cross-cutting and rip-cutting, applicable to materials like aluminum composite panels, aluminum honeycomb panels, MDF, and wood panels.

- CCD Vision System: Integrates a high-resolution camera that works with the CNC system to automatically recognize the contours of pre-printed patterns on materials and calculate machining offsets, eliminating manual alignment. Effectively solves issues like large manual positioning errors, difficulty aligning complex workpieces, and low efficiency in batch processing.

- High-Speed Electric Oscillating Tool: Utilizes a high-frequency servo-electric oscillating tool with a vibration frequency up to 20,000 VPM. It cuts materials via high-frequency vertical blade oscillation, suitable for flexible materials like leather, EVA, foam, and cardboard. This method reduces friction resistance, prevents stretching deformation of flexible materials and delamination of composites, produces smooth, burr-free edges, and eliminates the need for post-processing grinding.

6. High-Precision Motion Control Solution: XDW Control System

The CNC router machine equipped with the multi-functional XDW control system, which integrates ATC, CCD vision system, oscillating tool cutting, and four-axis saw blade functions. The system supports multiple languages, is user-friendly, offers good openness, and is compatible with various CAD/CAM software. It includes features like toolpath preview, real-time parameter adjustment, drawing simulation, and power-off recovery, meeting the demands of high-precision and complex machining.

7. High-Efficiency Auxiliary parts for the CNC Router

- Dust Collector: Includes a 3KW double-bag-type dust collector, providing consistent suction to effectively capture large chips and fine dust generated during processing, improving the working environment.

- Automatic Tool Setter: A high-precision automatic tool setter measures tool length and automatically generates corresponding compensation values, eliminating the hassle of manual calculation after automatic tool changes.

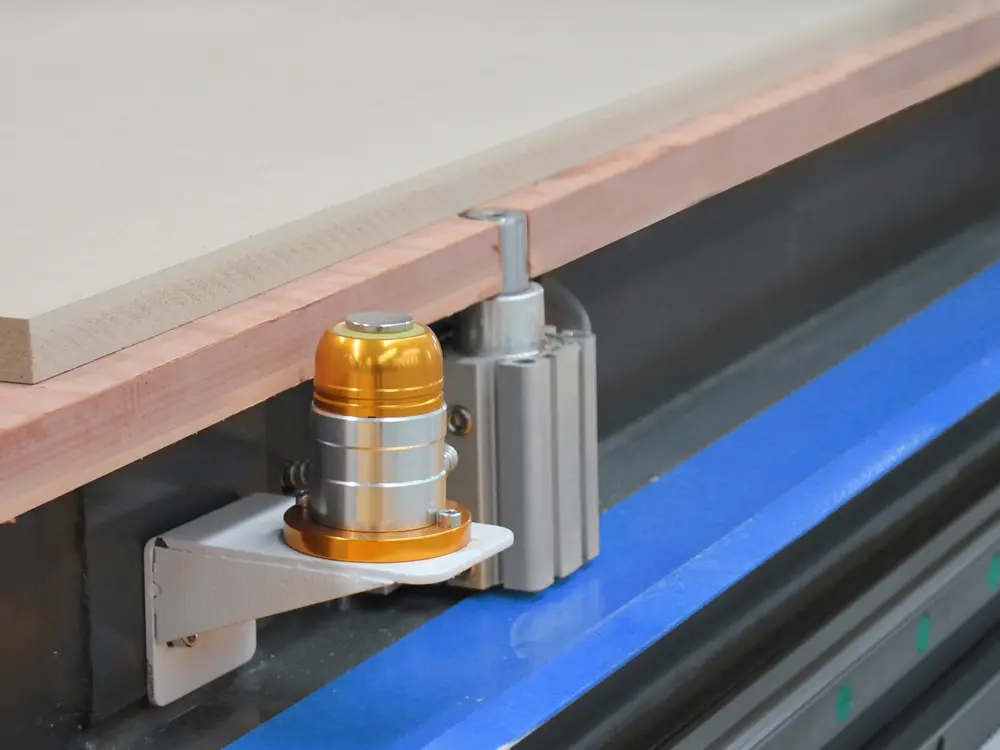

- Positioning Cylinders: Features a 4+2 positioning cylinder setup that works with the vacuum table to quickly position and secure workpieces from the sides and front, ensuring convenient operation.

- Automatic Lubricator: A fully automatic electric timer-controlled lubricator performs lubrication maintenance based on machine usage frequency, requiring no manual lubrication, thus saving maintenance time.

Details of the ATC CNC Router with 4-Axis Saw, Oscillating Tool, and Vision System

- ATC spindle, four-axis saw, oscillating tool & ccd vision system

Multifunctional integration allows this single machine to handle various processing needs for both flexible and rigid materials. Functions are rapidly switched via a pneumatic control system to adapt to different processing requirements: the automatic tool-changing spindle and saw blade cutting device are suitable for processing rigid materials such as wood boards, MDF, acrylic, aluminum, and copper; the oscillating tool cutting device is specifically designed for precision cutting of flexible materials like foam, leather, and fabric.

- Linear tool magazine

The linear tool magazine has a capacity of 12 tools and supports ISO30 tool holders and ER32 collets. During processing, the system automatically changes tools based on the program without manual intervention, significantly reducing tool change time and improving processing efficiency and automation levels.

- Double-Rod pneumatic press rollers

Equipped with two independently controllable pneumatic press rollers, they enable rapid clamping and positioning of workpieces, effectively preventing displacement during processing. Operation is simple and convenient.

- Vacuum adsorption table

Features a 6-zone, 24-hole vacuum adsorption table, paired with a 7.5KW vacuum pump, providing powerful adsorption force to securely hold various sheet materials. Manual clamping is unnecessary, allowing for faster workpiece replacement and positioning, greatly enhancing operational efficiency.

- Vacuum adsorption zone control valves

Each adsorption zone is equipped with an independent valve switch. Users can flexibly activate or deactivate specific zones based on workpiece size, enabling precise control of the adsorption area, saving energy, and improving adaptability.

- Assisted feeding rollers

The table tail is equipped with 7 rows of assisted feeding rollers. Sheets can be easily pushed into the processing area along these rollers, allowing a single operator to complete the loading task effortlessly and efficiently.

- Automatic lubricator

Features a fully automatic lubrication system where lubrication intervals and duration can be set as needed. It automatically lubricates transmission components, preventing insufficient manual lubrication and ensuring long-term stable operation of the equipment.

- Transmission system

Utilizes 30mm linear guideways and linear bearings from Taiwan Hiwin. The XY axes are paired with high-precision helical racks and gears, ensuring accurate positioning and smooth operation, with rapid traverse speeds exceeding 100,000 mm/min.

- High-quality electrical components

Equipped with Leadshine 1500W servo drives and Fuling frequency converters specifically designed for CNC routers, ensuring stable machine operation.

- XDW control system

The CNC router machine is powered by the XDW control system, which is fully functional with a simple and intuitive interface. It is compatible with various CAD/CAM software and supports G-code and multiple image file formats. The system includes advanced features such as file preview, handwheel simulation, and pause/resume carving, comprehensively meeting diverse processing and operational needs.

Technical Parameters of the ATC CNC Router with 4-Axis Saw, Oscillating Tool, and Vision System

| Model | CK-1325-TSK |

|---|---|

| Working Size | 1300*2500*200mm (processing size can be customized) |

| Spindle | 9KW HQD high-speed air-cooled atc spindle |

| Spindle Speed | 0-18000r/min |

| Saw Blade Angle | Horizontal 360° rotation |

| Saw Blade Motor | 5.5KW high-speed motor |

| Saw Blade Speed | 0-18000r/min |

| Oscillating Tool | Servo electric oscillating tool |

| Oscillating Tool Speed | 0-20000VPM |

| Vision System | CCD vision positioning system |

| Spindle Mounting Plate | 75mm thick integral anodized aluminum alloy plate |

| Tool Magazine | 12-tool linear automatic tool magazine |

| Tool Holder Type | ISO30 ER32 φ20 |

| Servo Motor | Leadshine 1500W servo motor / servo driver |

| Control System | XDW multi-function control system |

| Frequency Converter | Fuling 11KW high torque inverter |

| Guideway | 30mm Taiwan Hiwin linear guide / linear bearing |

| Rack | Taiwan YYC 2M rack |

| Z-Axis Screw | Taiwan TBI 3210 ball screw |

| Positioning | 4+2 positioning cylinder |

| Pushing Function | Double cylinder automatic push |

| Bed Structure | 8mm thickened steel plate quenching and sandblasting heavy bed |

| Vacuum Pump | 7.5KW water ring vacuum pump |

| Dust Collection | 3KW high power dust collector |

| Tool Setting Method | Automatic tool setter |

| Max. Rapid Traverse Speed | 100000mm/min |

| Max. Working Speed | 30000mm/min |

| Control Cabinet | Independent anti-interference control cabinet |

| Machine Voltage | 380V/3PH 220V/3PH |

| Dimensions | 3700*2200*2150mm |

| Weight | 2800kg |

Application of the ATC CNC Router with 4-Axis Saw, Oscillating Tool, and Vision System

ATC Spindle & Four-Axis Saw Blade

Applicable Materials:

Wood, bamboo, plastic, acrylic, PVC, MDF, OSB, PP, ABS, EVA, honeycomb panels, bakelite, gypsum board, particle board, plywood, resin board, aluminum, copper, and various other types of materials.

Applicable Products:

Wardrobes, cabinets, TV stands, nightstands, screens, door panels, wooden boards, skirting boards, ceiling shaped panels, feature wall carved panels, acrylic illuminated signs, PVC decorative moldings, gypsum board shapes, honeycomb panel partitions, speaker casings, musical instrument casings, wooden ornaments, models, display racks, and various other products.

Electric Oscillating Tool + CCD

Applicable Materials:

Leather, fabric, denim, EVA, sponge, foam, rubber, silicone, self-adhesive vinyl, PP, foam board (KT board), PE foam, corrugated cardboard, cardstock, fiberglass, carbon fiber fabric, stickers, and various other flexible materials.

Applicable Products:

Curtains, tablecloths, sofa covers, shoe insoles, shoe soles, automotive interiors, car floor mats, yacht interiors, gaskets, imported rubber mats, floor mats, carpets, wallpaper, tarpaulins, kites, flags, felt, foam, plush toys, color boxes, labels, clothing, jeans, leather shoes, and various other products.

Service and Support for the Multi-functional ATC CNC Router

To ensure the stable operation of the equipment throughout its entire lifecycle, CATEKCNC has established a comprehensive service and support system covering pre-sales, mid-sales, and after-sales processes. The specific details are as follows:

1. Pre-Sales Service

- Needs Consultation: Our professional sales team will provide suitable machine configuration recommendations based on the user's processing scenarios, production capacity requirements, and precision needs. They will collaborate with the technical department to develop a reasonable purchase plan for the user.

- Sample Processing: We offer sample processing services using the corresponding machine model according to the user's specific requirements. Users can visually inspect the product dimensions, appearance, and processing quality through physical samples to ensure the equipment meets expectations.

2. Mid-Sales Service

- Production Follow-up: Professional engineers will track the entire equipment production process and provide users with regular progress updates, ensuring manufacturing quality is controlled and information is transparent.

- Machine Debugging: After production is completed, engineers will perform precision debugging on the entire machine and conduct accuracy checks on key modules such as the spindle, tool magazine, and CCD vision positioning system to ensure compliance with factory standards.

- Test Run: Every CNC router machine must undergo over 12 hours of continuous operation testing before delivery to comprehensively verify its stability and processing performance. Only after passing these tests will the machine be shipped.

3. After-Sales Service

- 24/7 Technical Support: We provide 24-hour multi-channel technical support. Users can receive assistance at any time via WhatsApp, email, phone, and other methods.

- Warranty Service: The entire machine comes with a three-year (36-month) free warranty. During the warranty period, any quality issues with main components (excluding wear parts) will be replaced free of charge.

- Maintenance Service: We offer lifetime free maintenance consultation and troubleshooting support to assist users in resolving various issues encountered during equipment operation.

- Software Service: Lifetime free system software updates and download services are provided.

- Upgrade Service: Based on the user's increased production capacity or process change requirements, we can provide functional upgrade services for existing models to extend the equipment's service life.

- Training Service: Upon equipment delivery, a complete user manual and operational videos are included, along with free remote training. If needed, we can also arrange for engineers to provide on-site technical support.

| Model | CK-1325-TSK |

|---|---|

| Working Size | 1300*2500*200mm (processing size can be customized) |

| Spindle | 9KW HQD high-speed air-cooled atc spindle |

| Spindle Speed | 0-18000r/min |

| Saw Blade Angle | Horizontal 360° rotation |

| Saw Blade Motor | 5.5KW high-speed motor |

| Saw Blade Speed | 0-18000r/min |

| Oscillating Tool | Servo electric oscillating tool |

| Oscillating Tool Speed | 0-20000VPM |

| Vision System | CCD vision positioning system |

| Spindle Mounting Plate | 75mm thick integral anodized aluminum alloy plate |

| Tool Magazine | 12-tool linear automatic tool magazine |

| Tool Holder Type | ISO30 ER32 φ20 |

| Servo Motor | Leadshine 1500W servo motor / servo driver |

| Control System | XDW multi-function control system |

| Frequency Converter | Fuling 11KW high torque inverter |

| Guideway | 30mm Taiwan Hiwin linear guide / linear bearing |

| Rack | Taiwan YYC 2M rack |

| Z-Axis Screw | Taiwan TBI 3210 ball screw |

| Positioning | 4+2 positioning cylinder |

| Pushing Function | Double cylinder automatic push |

| Bed Structure | 8mm thickened steel plate quenching and sandblasting heavy bed |

| Vacuum Pump | 7.5KW water ring vacuum pump |

| Dust Collection | 3KW high power dust collector |

| Tool Setting Method | Automatic tool setter |

| Max. Rapid Traverse Speed | 100000mm/min |

| Max. Working Speed | 30000mm/min |

| Control Cabinet | Independent anti-interference control cabinet |

| Machine Voltage | 380V/3PH 220V/3PH |

| Dimensions | 3700*2200*2150mm |

| Weight | 2800kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.