5x10ft Large Format CNC Wood Router with Vacuum Worktable

5x10ft CNC Wood Router Machine with Vacuum Worktable

[Function Description]

The 5*10 feet CNC router (CK-1530-V) is a CNC wood router developed on the basis of the 1325 model router. Compared to the 4*8 feet CNC router, it has increased processing width and length, achieving a processing size of 5*10 feet (1500*3000mm), allowing for larger size processing and creative production. The 1530 model CNC wood engraving machine is controlled by a CNC system, adopting a classic gantry structure, and uses ball screws, helical racks, and gear transmission to process products with high-speed water-cooled/spindle air-cooled spindles, meeting various needs such as engraving, cutting, drilling, and grooving. The 5*10 CNC router can significantly enhance industry productivity (including furniture manufacturing, advertising production, etc.), reduce production costs, and it is inexpensive and easy to operate, making it easy for even CNC beginners to master. It can also withstand various harsh production environments, making it popular among many countries and customers.

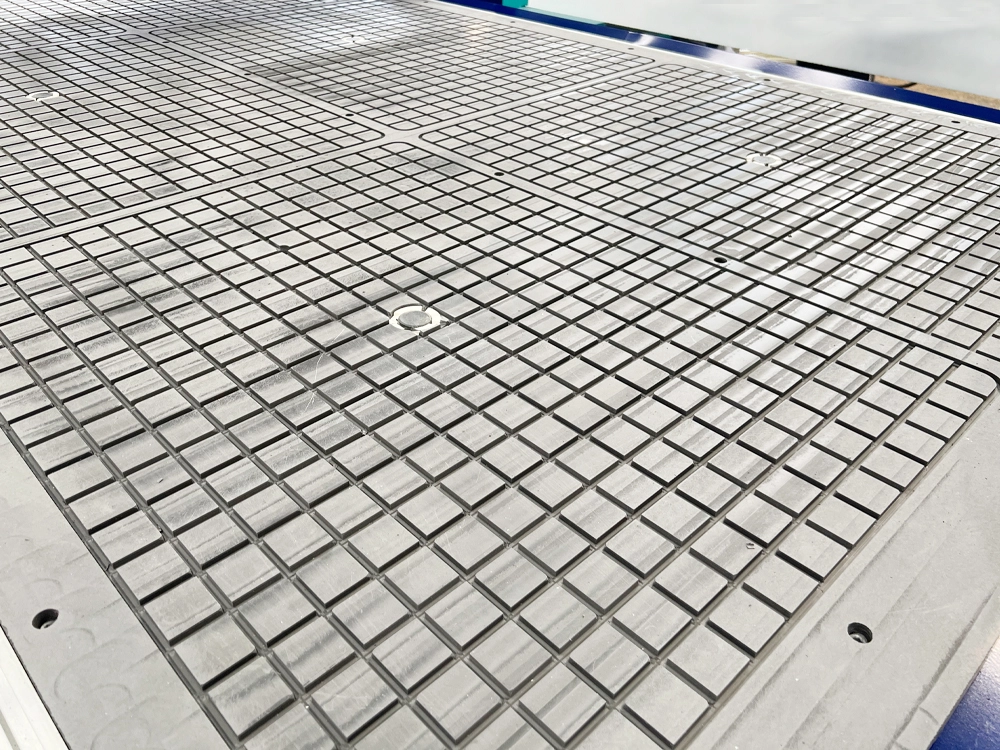

What is a Vacuum Adsorption Worktable?

The core of the vacuum adsorption work platform is to extract air from the table surface through a vacuum pump, forming a closed vacuum environment and creating negative pressure. When the vacuum negative pressure reaches a certain value, the workpiece will be firmly fixed on the worktable, facilitating subsequent processing operations.

- Adsorption and Release Process:

-

Adsorption Process: When the workpiece is placed on the worktable and tightly sealed, the vacuum pump starts to extract air, rapidly reducing the air pressure between the wood board and the platform, forming negative pressure. The workpiece is adsorbed onto the work disk due to atmospheric pressure.

Release Process: When the workpiece processing is completed and the workpiece needs to be removed, the vacuum pump is turned off, stopping the air extraction. The worktable naturally fills with air, causing the negative pressure in the suction cup to disappear or turn into a slight positive pressure, thereby releasing the adsorption force, and the workpiece can be easily removed.

- Composition of the Vacuum Adsorption Platform:

-

The vacuum adsorption worktable is usually composed of a vacuum pump, an adsorption platform, connecting pipes, etc. To improve the adsorption effect, it is necessary to ensure the flatness of the worktable and the sealing of the structure to avoid air leakage.

- Partition Adsorption Function:

-

The vacuum adsorption worktable equipped with the 1530 model CNC router supports partition adsorption, with each partition equipped with an independent control switch. It can be independently controlled to open or close according to the size of the processed product, making it more convenient to use.

- Advantages of the Vacuum Adsorption Worktable:

-

- Time-saving: Compared to using traditional clamp fixtures with screw fixing, the vacuum adsorption platform does not require manual fixing of the workpiece, improving production efficiency.

- High stability: Strong adsorption force, especially suitable for materials that are prone to warping or deformation (such as fabric, paper, etc.). Through vacuum adsorption, even materials that have already deformed can be flattened by adsorption, not affecting the processing.

- Wide range of applications: Whether it is wood, MDF boards, furniture boards, plastic, or other special materials, the vacuum adsorption worktable can perform adsorption processing.

Features of the 5x10 Feet CNC Router with Vacuum Adsorption Worktable

- The bed is constructed from high-strength thickened steel tubes welded together, treated at high temperatures, and processed using a CNC large gantry milling machine for the guide rail platform and rack platform, ensuring machine operation accuracy and long-term use stability.

- The large-format design of 5x10 feet (1500*3000mm) allows for processing larger sized panels.

- Equipped with a 3.5KW high-speed water-cooled spindle (air-cooled spindle optional), more suitable for long working hours. The water-cooled spindle has better heat dissipation performance, with a speed of up to 24000rpm, ensuring the smoothness of the finished product.

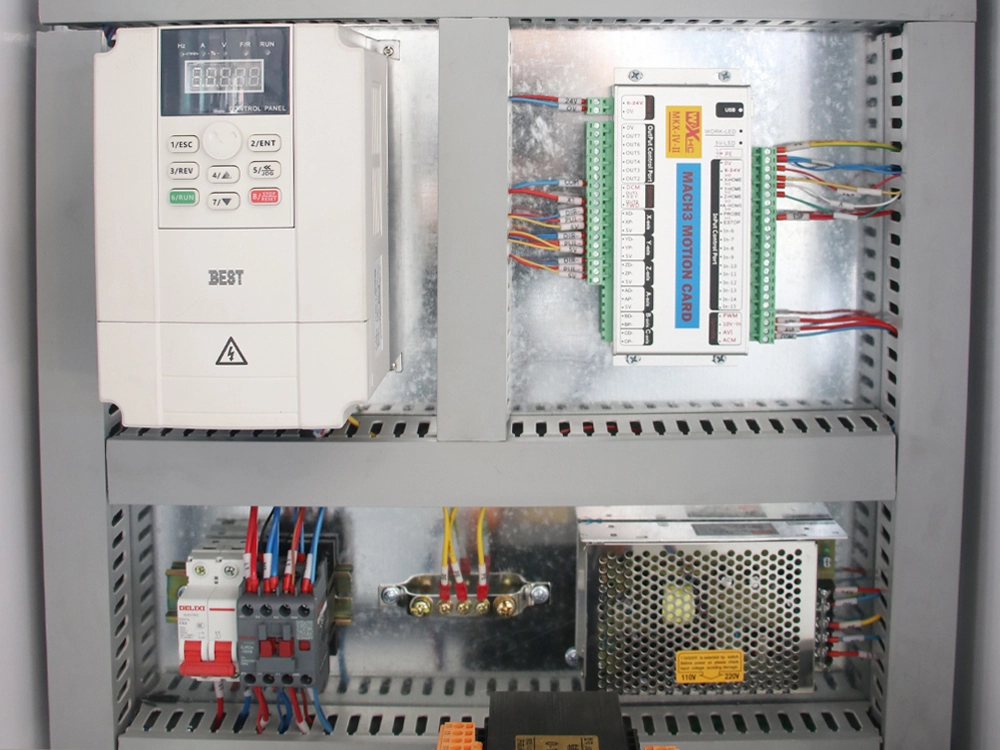

- Uses an independent anti-interference control cabinet. All electrical components are independently distributed in the control cabinet, offering better anti-interference performance compared to being placed in the machine base, along with better dustproof performance.

- NC Studio CNC system (DSP optional), easy to operate. The CNC router is connected to a PC for operation, allowing the same PC to be used for drawing and machine operation, making it more convenient to use.

- Vacuum adsorption worktable, with a 6-zone + 6-hole design, each zone can be independently controlled, offering more flexibility and energy efficiency.

- Uses Leadshine motors/drivers, simple structure, high reliability, fast response speed, and stable operation.

- Uses Best inverter, with quick spindle speed start-up, adjustable speed, allowing for processing at different speeds according to different materials.

- TBI ball screws, high-precision rack/gear, making the CNC router's processing accuracy higher, ensuring product processing consistency.

- Taiwan Hiwin guide rails/linear bearings, low operating noise, high positioning accuracy, enabling high-precision processing.

- Electric automatic lubrication system, automatically lubricates the transmission parts of the CNC router, maintaining better motion performance.

- Wide software compatibility, supports various CAD/CAM type software including artcam, jdpaint, mastercam, type3.

Details of 5x10 CNC Router with Vacuum Adsorption Worktable

- Water-cooled spindle

-

3.5KW high-speed water-cooled spindle, maximum speed up to 24000rpm, four ceramic bearing design, stable speed, low noise.

- Vacuum adsorption workbench

-

6-zone vacuum adsorption worktable, easy to use, can use a certain zone independently according to the size of the part.

- Vacuum pump

-

High-power water ring vacuum pump: high-speed vacuum extraction, stronger suction.

- Zone switches of vacuum pump workbench

-

Independent switch for each zone of the vacuum adsorption worktable, controls the opening and closing of the adsorption holes in each zone.

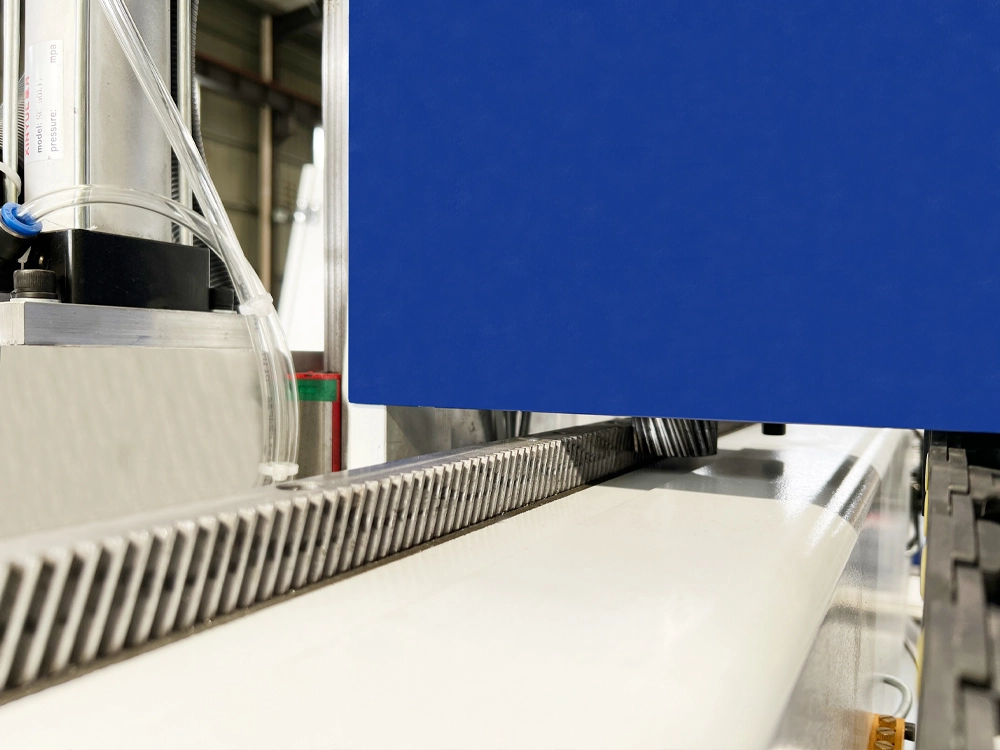

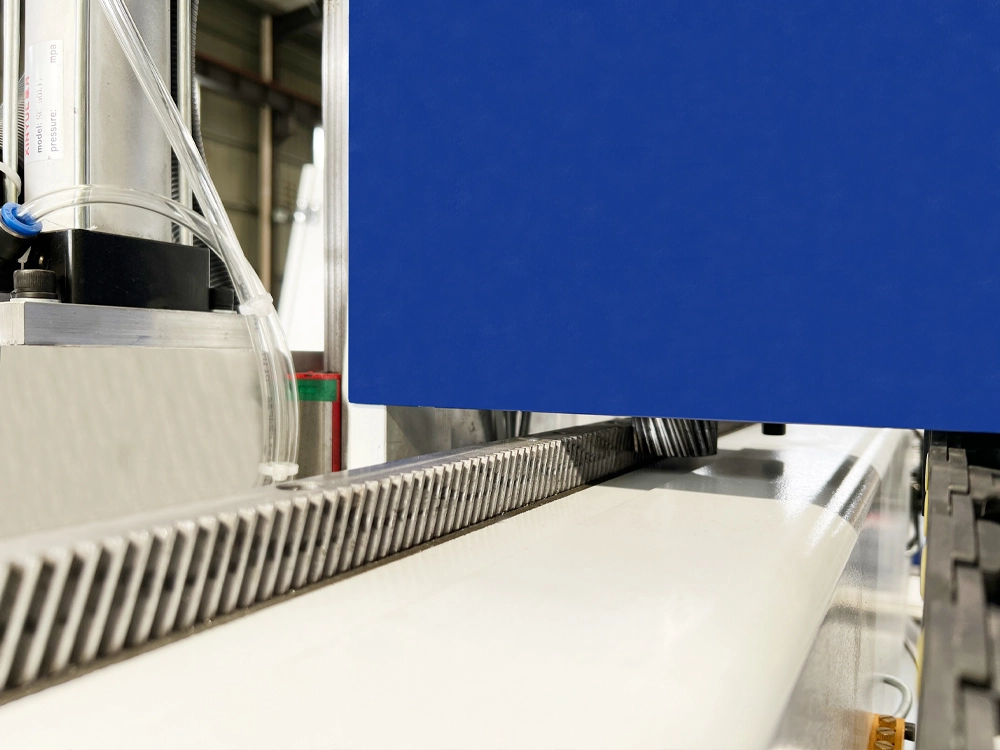

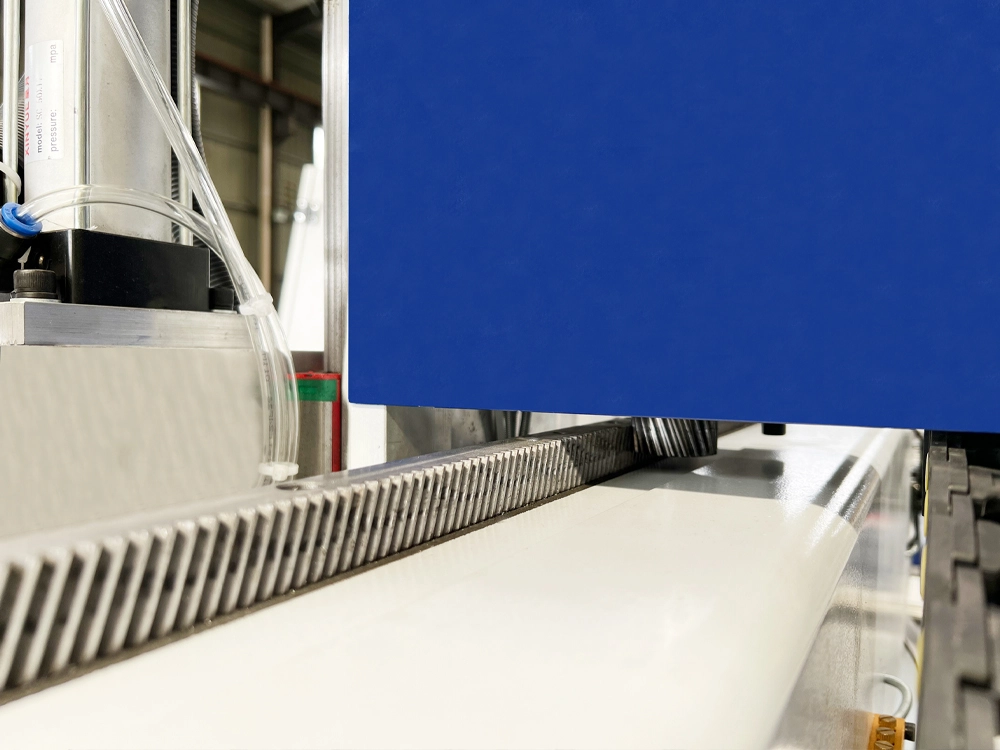

- Transmission system

-

High-precision ground helical rack/gear: The tooth profile of the helical rack is different from that of the straight rack. The helical design can better distribute the load during transmission, thereby improving transmission smoothness, reducing noise, and enhancing load capacity.

- Lubrication system

-

Automatic lubrication oil pump, operators only need to pour lubricating oil into it on time, and the machine can automatically lubricate the moving parts.

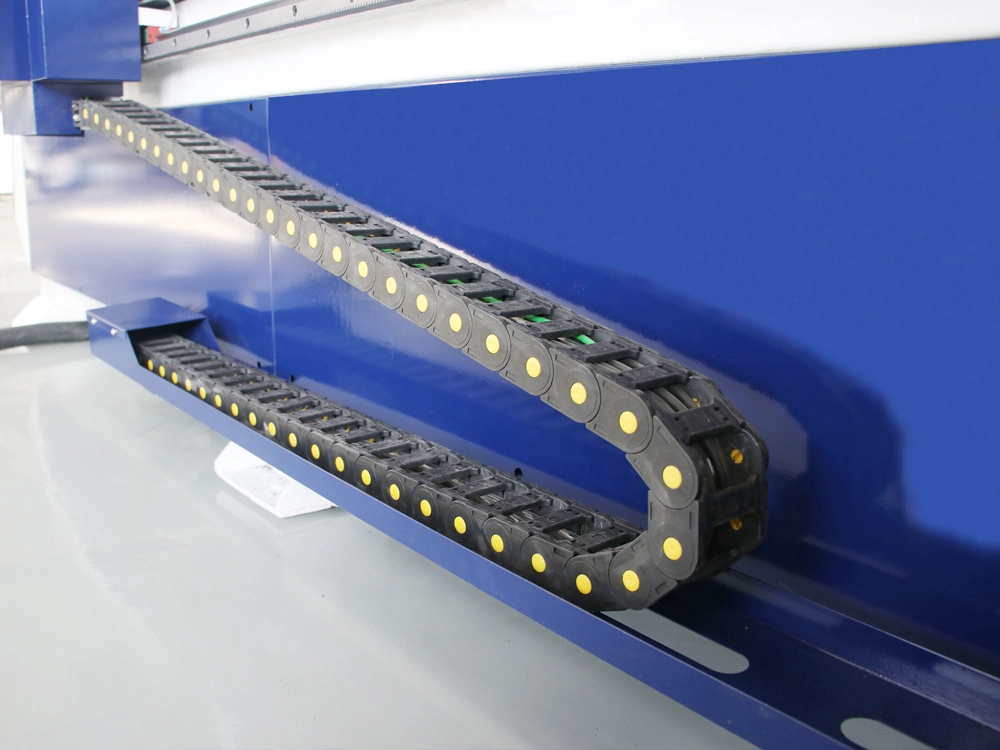

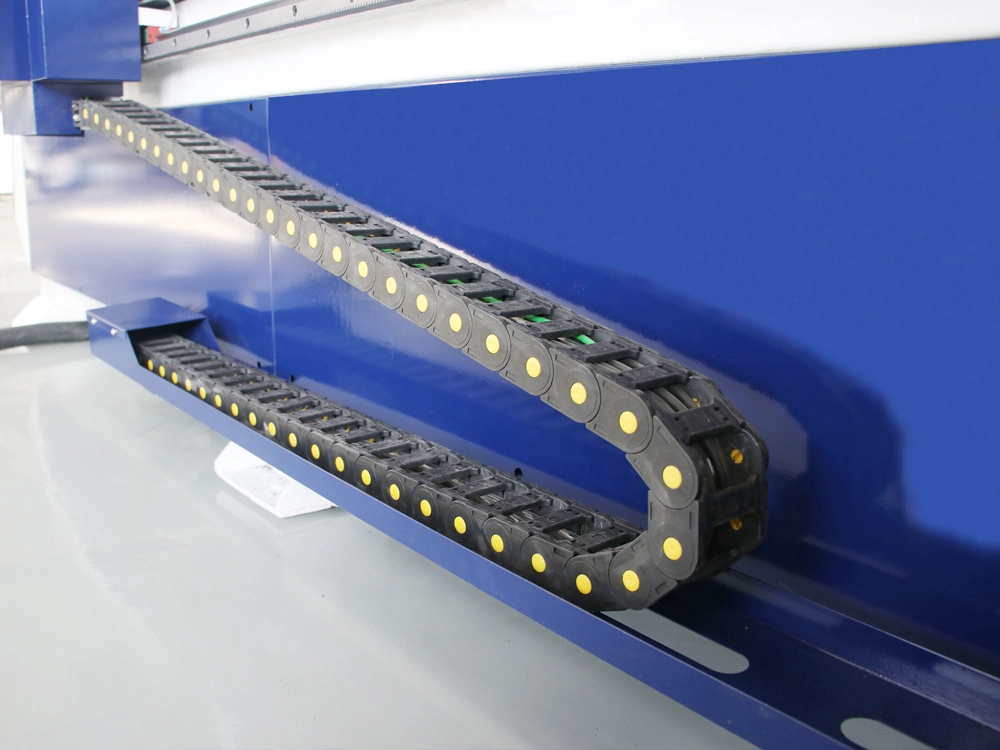

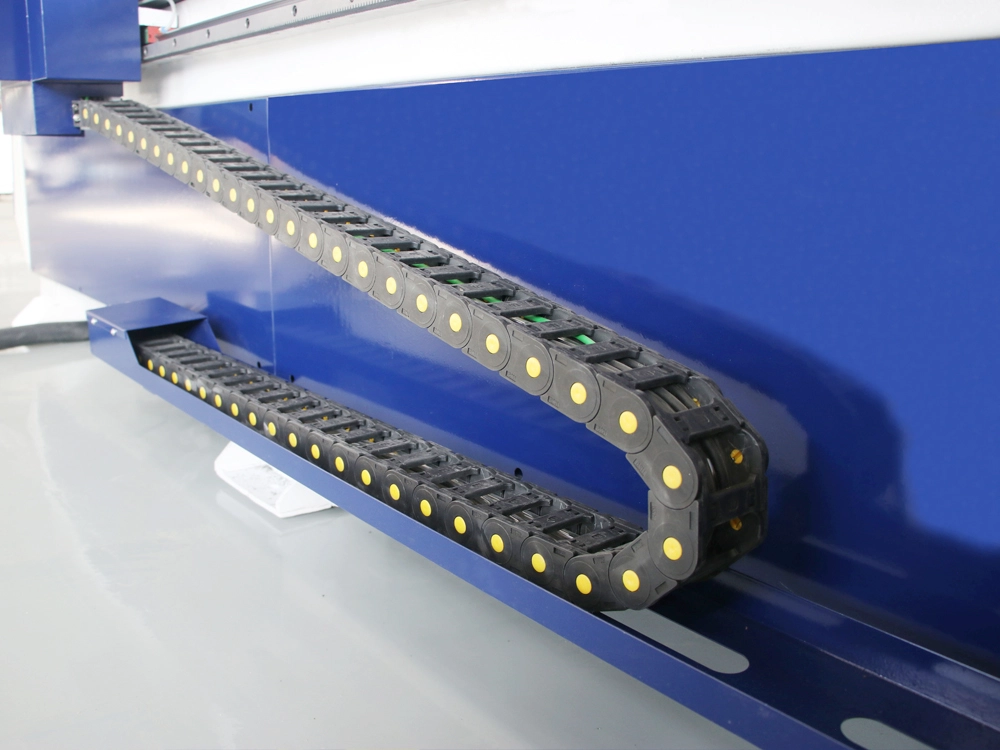

- Drag chain

-

Using reinforced nylon tank drag chain, with high compressive strength, high tensile load, high toughness, high elasticity, and high wear resistance, and good flame retardant performance, more suitable for factory use.

- Control system

-

RichAuto DSP controller and Mach3 control board.

Technical Parameters of 5x10 CNC Router with Vacuum Adsorption Worktable

| Model | CK-1530-V |

|---|---|

| XYZ Working Travel | 1500*3000*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle (air cooling optional) |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Yako/Leadshine motor driver |

| Frequency Converter | Best/Hpmont inverter |

| Table | Vacuum adsorption worktable (6 zone + 6 holes) |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) / Richauto DSP A11 / Mach3 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1460kg |

| Dimensions | 3600*2280*1750mm |

Application Scope of 5x10 CNC Router with Vacuum Adsorption Worktable

Applicable Materials:

Solid wood, bamboo, MDF board, particle board, multilayer board, cork, artificial stone, aluminum plate, copper plate, acrylic, PVC, PCB, EVA foam, carbon fiber, glass fiber and other materials.

Applicable Industries:

- Advertising industry: production of billboards, signboards, crystal characters, acrylic light boxes, medals, road signs, etc.

- Furniture manufacturing: carving furniture decorative patterns, carving classical furniture hollow lattices, MDF furniture cutting, cutting and production of bookshelves, cabinets, wardrobes, cabinets, etc.

- Crafts production: production of sculptures, crafts, decorations, ornaments, decorative signs, wooden boxes, etc.

- Model toy production: production of sand table models, aircraft models, building models, ship models, puzzles, etc.

| Model | CK-1530-V |

|---|---|

| XYZ Working Travel | 1500*3000*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle (air cooling optional) |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Yako/Leadshine motor driver |

| Frequency Converter | BEST/Hpmont inverter |

| Table | Vacuum adsorption worktable (6 zone + 6 holes) |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) / Richauto DSP A11 / Mach3 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1460kg |

| Dimensions | 3600*2280*1750mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.