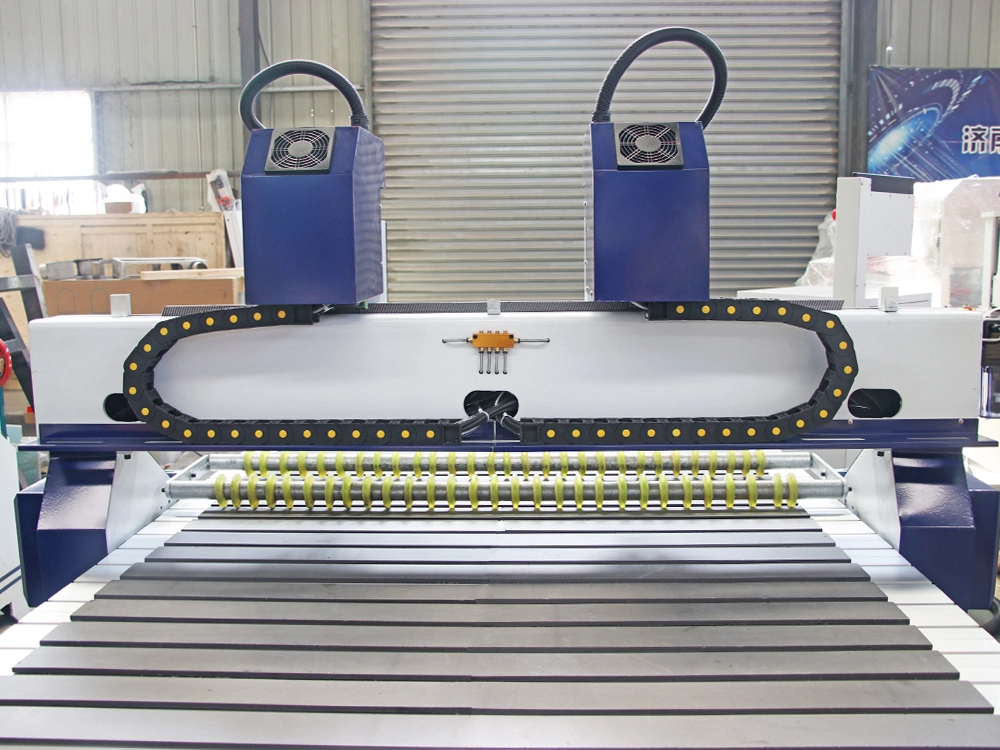

2-Station CNC Wood Router With Pressure Rollers and Independently Controlled Spindles

CNC Router With Two Independently Controlled Spindles and Pneumatic Roller

[Function Description]

CK-1325-2 CNC router machine is an additional spindle that can be independently controlled on the basis of CK-1325 CNC wood router, which is 1300*2500mm On the basis of the worktable, the pneumatic double rod pressure roller device is installed to fix the materials. The pneumatic pressure roller can automatically lift and press the plates through the cylinder control when cutting the plates, so as to prevent the movement of raw materials during the processing of the plates, resulting in the waste of materials, and it is no longer necessary to use the manual pressing plate to fix the materials, which can effectively save the waste time of fixing materials. The additional spindle can be used to process two workpieces at the same time, and the two spindles can work at the same time, processing two identical workpieces at a time, effectively improving the processing efficiency and increasing the output. Of course, the number of spindles can provide customized services for you, whether you need more spindle power or need additional processing spindles, you can customize them.

What Is an Independent Spindle and How Does It Differ From Two Spindles on a Single Controller?

- Independent spindle head

- The cost is relatively high. Each CNC engraving head is equipped with an independent Z-axis and X-axis drive system. It adopts a split mechanical structure and can control the movement trajectory of each head individually. Because the independent head uses an independent drive system, it has stronger vibration resistance and is more suitable for high-speed cutting and processing. And because each head can independently control the movement, the precision control is more precise. When processing multiple identical tasks, each head can independently control the tool calibration, which is more suitable for high-demand and high-precision processing tasks.

- Single controller dual head (hanging plate type multi-head)

- Multiple engraving heads are installed on the same spindle hanging plate, sharing a Z-axis drive system, and multiple heads are synchronously driven by the control system. The spacing adjustment of each head and the unified adjustment of the spindle height require manual screwing, and the adjustment efficiency is low. Since the height and spacing between multiple spindles can only be adjusted manually, the accuracy is lower than that of independent heads. However, this type of one-to-two multi-head has low cost and can achieve low-cost mass production, which is suitable for users who pursue cost-effectiveness.

What Are the Advantages of a CNC Router With Two Independent Spindles and Pneumatic Rollers

- Equipped with two 2.2KW high-speed water-cooled spindles, four ceramic bearings design, extremely low running noise, speed of 24000r/min, can quickly process various materials.

- It can be equipped with different tools to process different workpieces, and can easily handle milling, engraving, drilling, cutting, engraving and other processes.

- The CNC router has a 1300*2500mm aluminum alloy T-slot workbench, which can hold full-size plates of 4*8 feet, as well as small-size materials of various sizes.

- Each spindle is equipped with an independent switch, so you can use only one spindle or both spindles at the same time.

- Independent computer control chassis, the screen is fixed on the chassis, can draw pictures, program, control the machine operation, more convenient to use.

- Support various CAD/CAM type software, run using international standard G code, and support various format files such as NC/TAP/TXT.

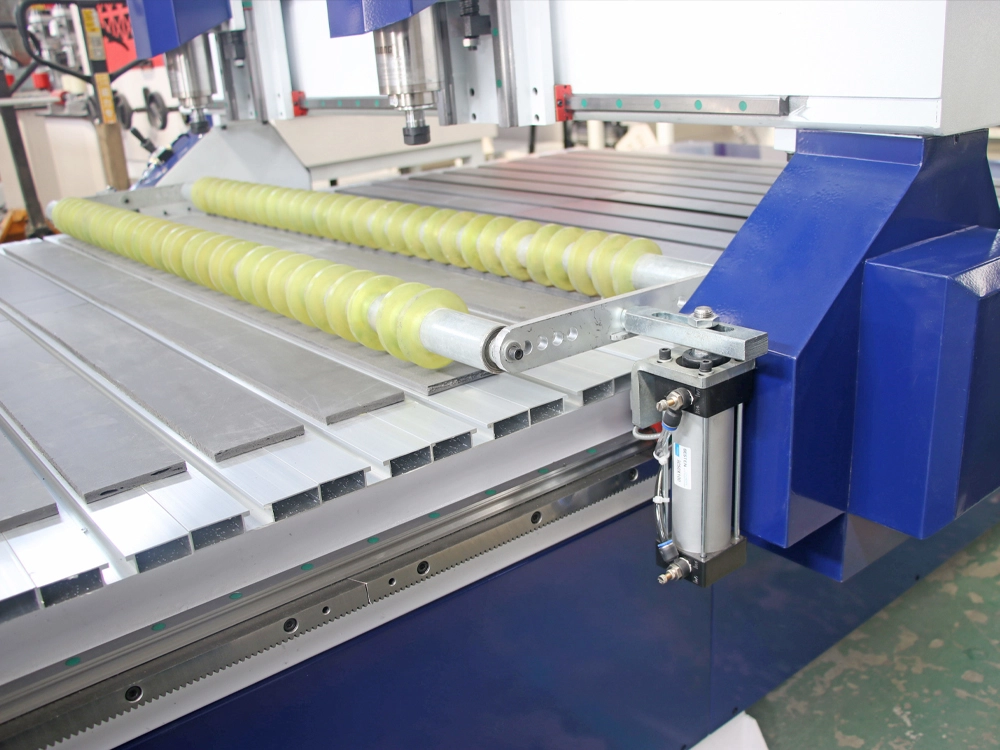

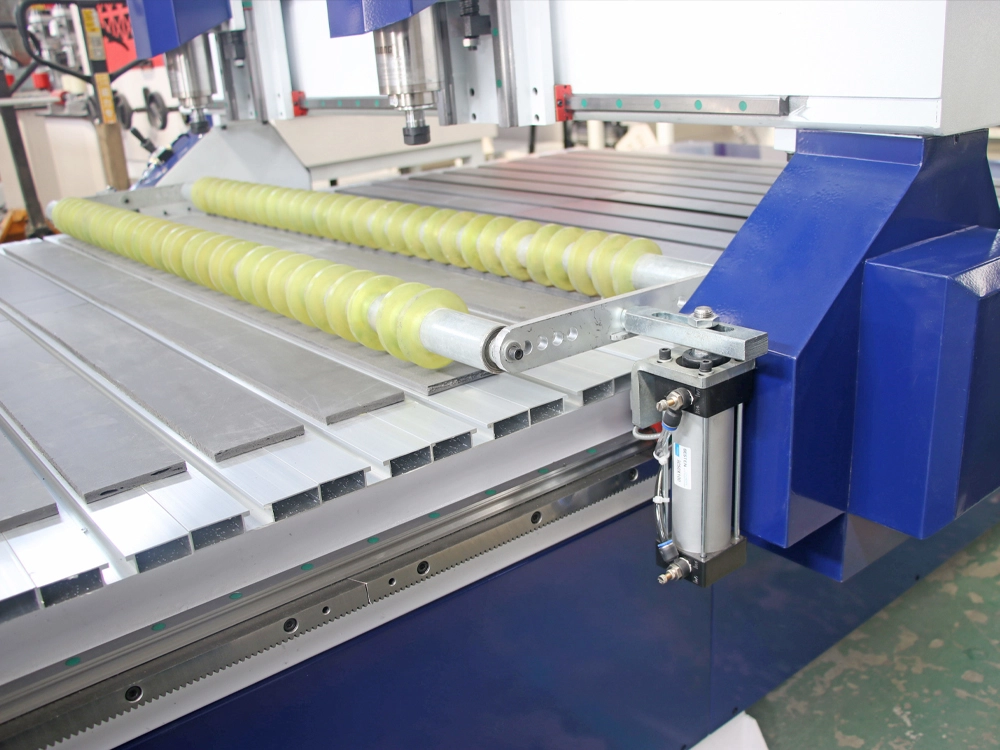

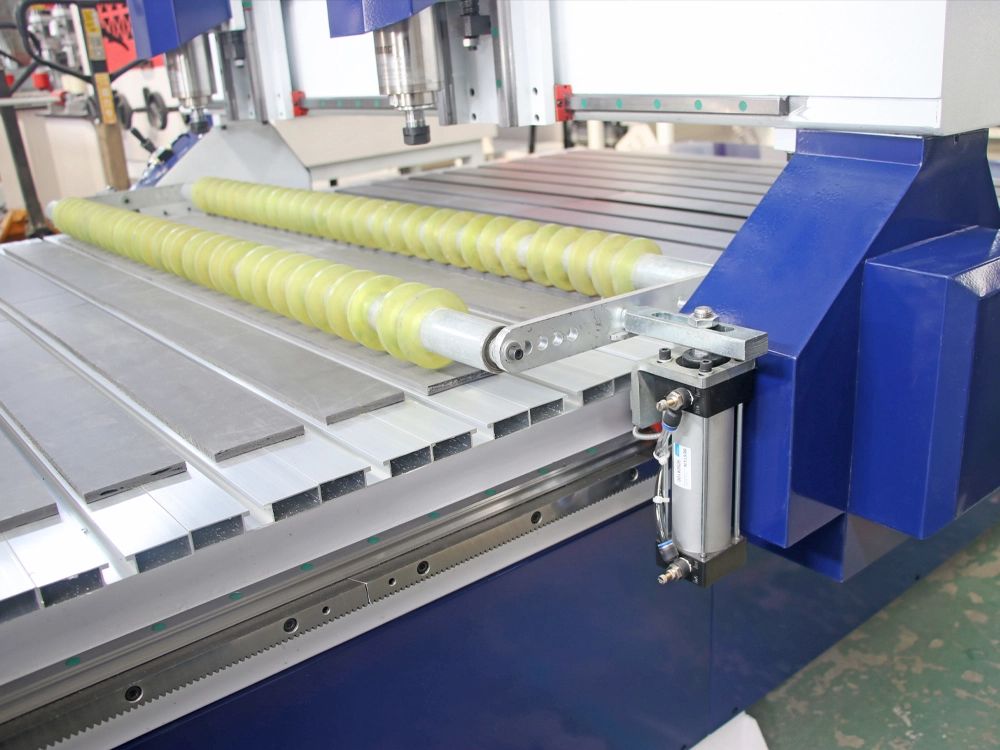

- Pneumatic double-rod roller device, fully automatic control of roller lifting, eliminating the need for manual fixing of the pressure plate, saving material fixing time.

- XYZ axes all use Taiwan Hiwin linear guides/linear bearings, high-precision ground helical racks, and the Z-axis drive uses TBI ball screw.

- The bed frame is welded with thickened steel pipes and annealed. A large five-axis gantry milling machine is used to process the guide rails and rack mounting surfaces. The machining accuracy of the machine can be controlled within ±0.05mm.

- The XYZ axis is driven by a high-power servo motor with high positioning accuracy and precise operation, which can ensure high-speed operation and high-precision processing of the machine.

- Fully automatic electric lubrication and oil injection maintenance system automatically lubricates the machine in all directions without manual lubrication and maintenance.

- Optional vacuum adsorption workbench, DSP control system, dust collector and other additional configurations.

Details of CNC Router With Two Independent Heads and Pneumatic Roller

- Two 2.2KW high-speed water-cooled spindles

Spindle speed 24000r/min, using er25 tool holder, can clamp various tools according to processing requirements.

- Two independent head control

Each spindle can be used independently, or two spindles can be started at the same time, which is easy to use.

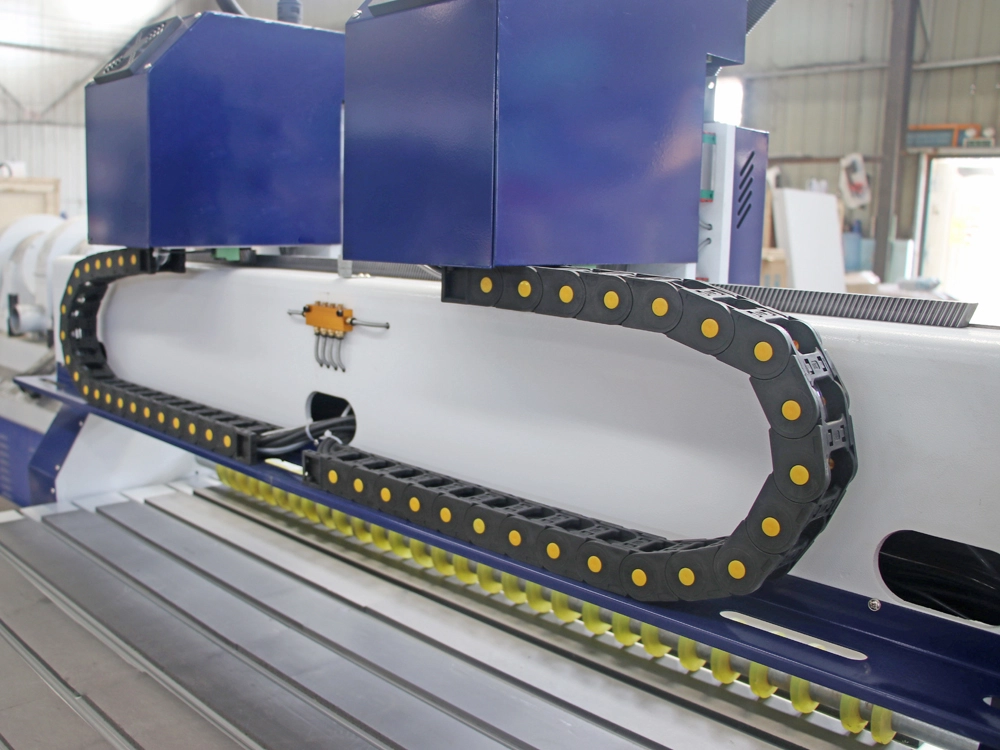

- Double-rod pneumatic roller

Using cylinder to automatically control lifting and lowering, eliminating the complex steps of using pressure plate to fix materials, saving more time.

- Independent anti-interference control cabinet

The cabinet is equipped with inverters, drivers, relays and other key machine components, and a built-in computer, which can be directly programmed, drawn, and controlled to operate the machine, making it more convenient to use.

- 19-inch LCD display

The control system is equipped with a 19-inch high-definition industrial-grade LCD display, which is dust-proof, dust-proof and has a long service life.

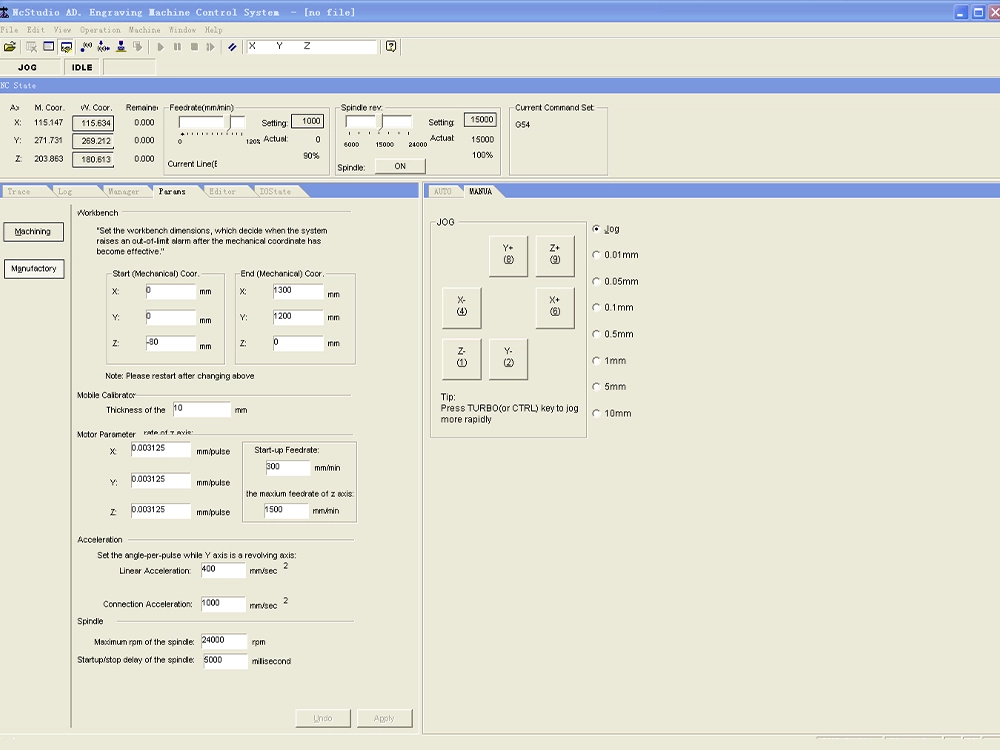

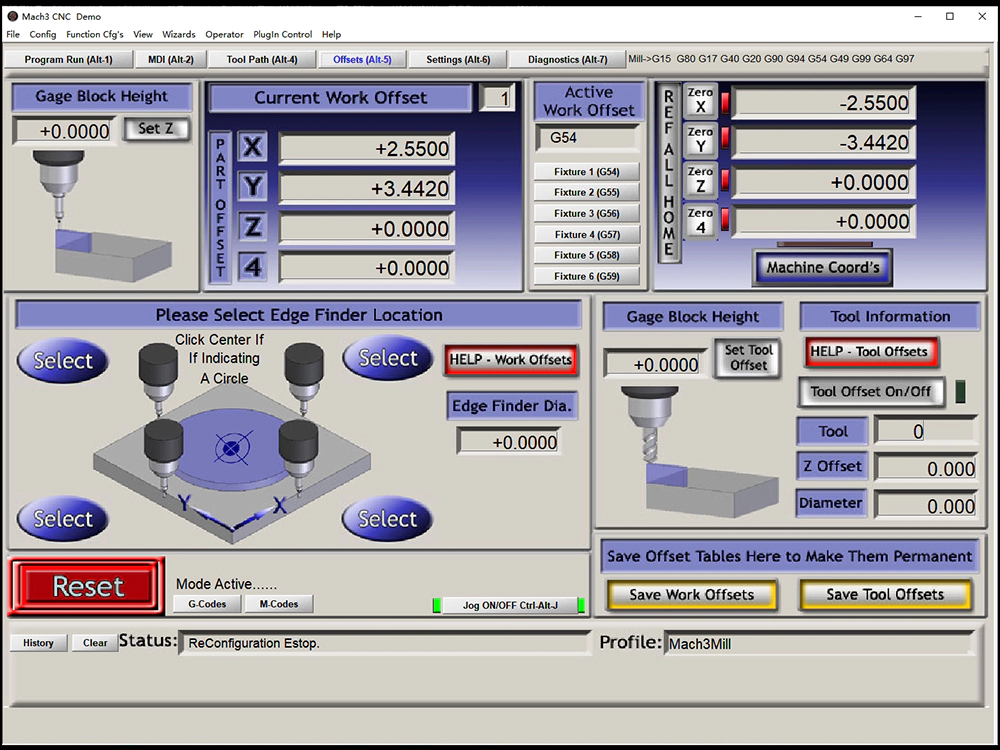

- Control system

You can choose Weihong NCstudio v5.4.49, DSP control handle, NK105, MACH3, etc.

- High-strength flame-retardant cable protection drag chain

Built-in machine control cable to protect the cable from damage and extend the life of the machine.

Technical Parameters of CNC Router With Two Independent Spindles and Pneumatic Pressing Rollers

| Model | CK-1325-2 |

|---|---|

| Working Size | 1300*2500*200mm (Processing size can be customized) |

| Gantry Bracket | Thickened cast iron gantry, cast iron bracket |

| Bed Base | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle Power | CATEKCNC dedicated high-speed water-cooled variable frequency spindle * 2 |

| Drive Mode | High torque servo motor / servo drive |

| Frequency Converter | Best/Hpmont inverter |

| Spindle speed | 6000-24000r/min |

| Pressure Roller | Double rod pneumatic pressure roller |

| Worktable | Aluminum alloy T-slot table (optional: vacuum adsorption platform) |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Highly flexible pure copper anti-bending cable |

| Tool Shank Diameter That Can Be Clamped | 3.175mm, 4mm, 6mm,8mm,10mm, 12.7mm, etc., ER20/ER25 |

| Control System | Weihong V5.4.49 (support breakpoint resume) / Richauto DSP A11 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, artcam, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | All XYZ three-axis photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Cutting Speed | 18000mm/min |

| Maximum Empty Line Speed | 25000mm/min |

| Dimensions | 3100*2100*1750mm |

| Weight | 1750kg |

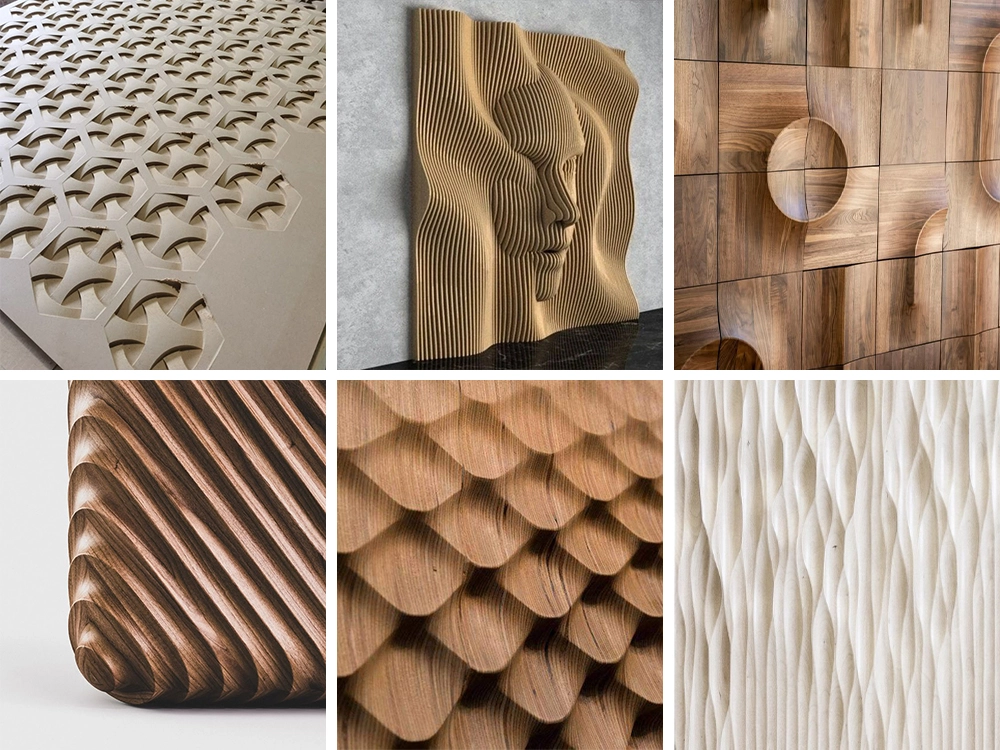

What Products Can the CNC Router With Two Independent Spindles and Pneumatic Roller Be Used to Process

Applicable Materials:

Wood board, MDF board, multilayer board, pine board, PTFE board, PVC, PCB, resin, plastic, acrylic, aluminum-plastic board, honeycomb board, gypsum board, two-color board, aluminum, copper and other materials.

Application Industry:

- Furniture And Woodworking Industry: cabinet doors, wooden doors, screens, Wave board,furniture carving, mahogany furniture, furniture accessories cutting, etc.

- Advertising And Logo: two-color board signs, plexiglass billboards, three-dimensional characters, public facility signs, medals, souvenirs, acrylic luminous characters, acrylic light boxes, etc.

- Musical Instrument Manufacturing: piano panels, guitars, violins, cello panels, etc.

- Architecture And Models: architectural models, mechanical models, sand tables, stone background walls, garden sculptures, gypsum ceilings, etc.

- Electronics industry: insulating parts, plastic chemical parts, printed circuit boards, bakelite boards, PCB circuit boards, audio housings, etc.

| Model | CK-1325-2 |

|---|---|

| Working Size | 1300*2500*200mm (Processing size can be customized) |

| Gantry Bracket | Thickened cast iron gantry, cast iron bracket |

| Bed Base | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle Power | CATEKCNC dedicated high-speed water-cooled variable frequency spindle * 2 |

| Drive Mode | High torque servo motor / servo drive |

| Frequency Converter | Best/Hpmont inverter |

| Spindle speed | 6000-24000r/min |

| Pressure Roller | Double rod pneumatic pressure roller |

| Worktable | Aluminum alloy T-slot table (optional: vacuum adsorption platform) |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Highly flexible pure copper anti-bending cable |

| Tool Shank Diameter That Can Be Clamped | 3.175mm, 4mm, 6mm,8mm,10mm, 12.7mm, etc., ER20/ER25 |

| Control System | Weihong V5.4.49 (support breakpoint resume) / Richauto DSP A11 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, artcam, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | All XYZ three-axis photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Cutting Speed | 18000mm/min |

| Maximum Empty Line Speed | 25000mm/min |

| Dimensions | 3100*2100*1750mm |

| Weight | 1750kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.