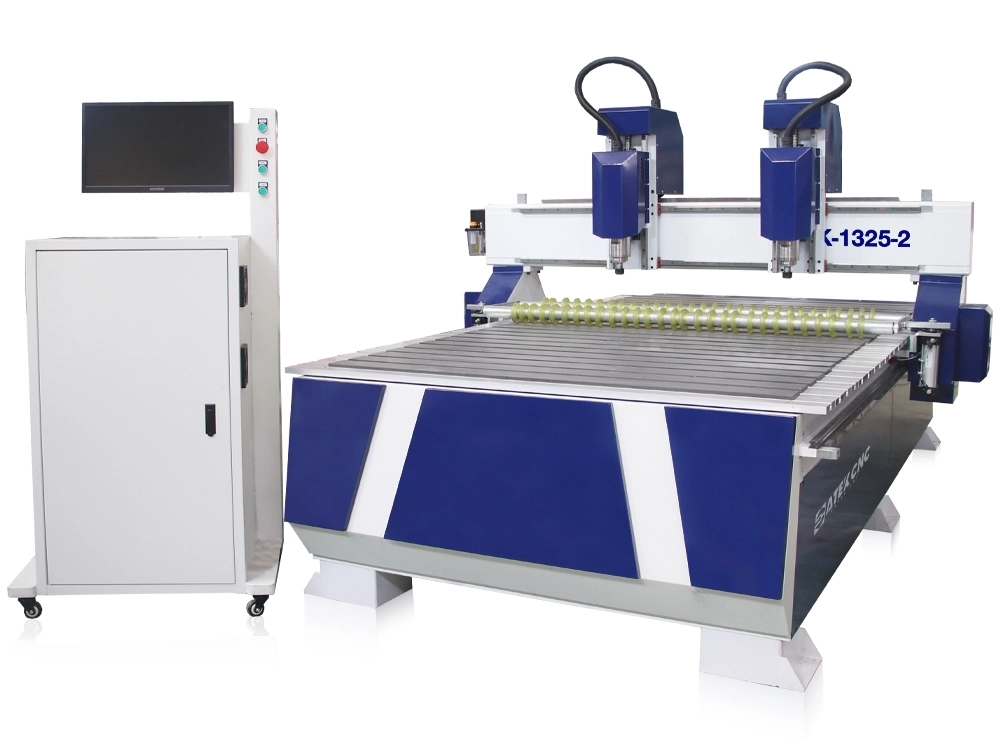

CNC Machines That Can Cut Both Soft and Hard Materials

CNC Router Machine with Oscillating Knife for Cutting Cardboard and Cloth

[Function Description]

The CNC router with oscillating knife cutting kit is equipped with a spindle and a oscillating knife head, which can be switched to be used for different product processing. The spindle clamps various milling cutters and engraving knives for cutting, engraving, drilling, grooving, etc. of wood, plastic, acrylic, synthetic materials, MDF boards and other materials. The oscillating knife can be used for cutting flexible materials, such as foam board, sponge, corrugated paper, plastic paper, leather, cloth, carbon fiber, etc. This type of machine achieves high-speed and high-precision engraving and cutting through an automated control system, reduces material waste, and improves material utilization. The addition of the oscillating knife greatly improves the functionality of the machine, expands the application range of the machine, and saves space and improves the utilization efficiency of the machine. It only requires one person to operate, and it is easy to get started. You only need to use cad/cam type software to make drawings (supports dxf, nc, txt and other format files), and then read the international G code, and the machine can directly recognize and process.

Advantages of 4x8ft CNC Router With Oscillating Knife

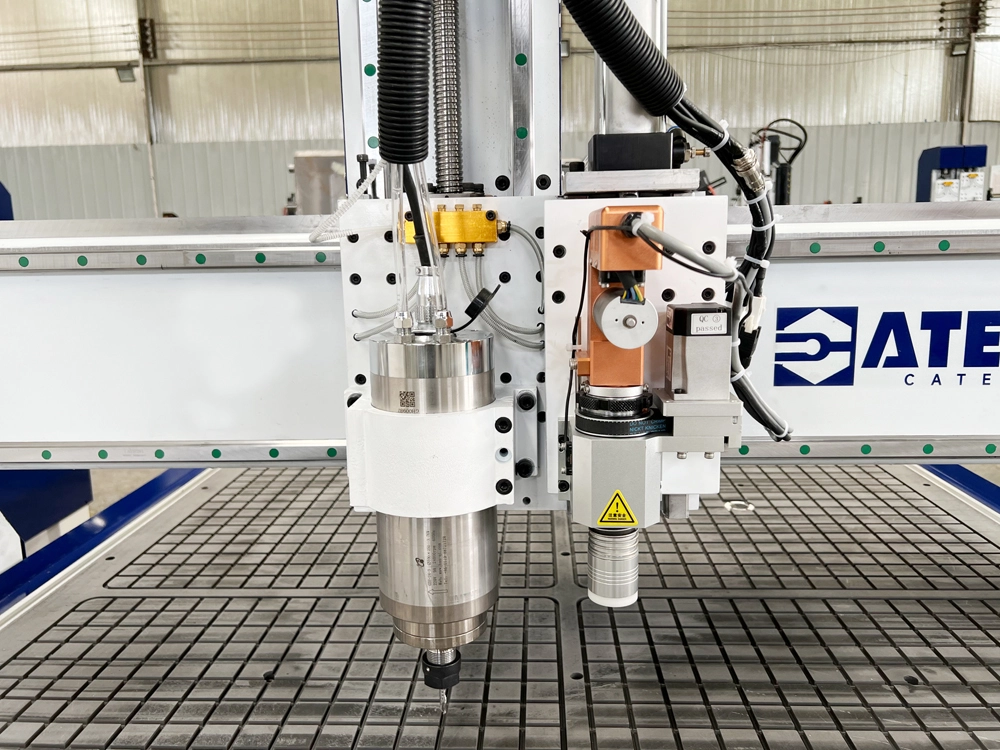

- Use 3.5KW water-cooled spindle, equipped with water circulation cooling system, better heat dissipation performance, lower noise, maximum speed of 24000rpm, can quickly process various materials.

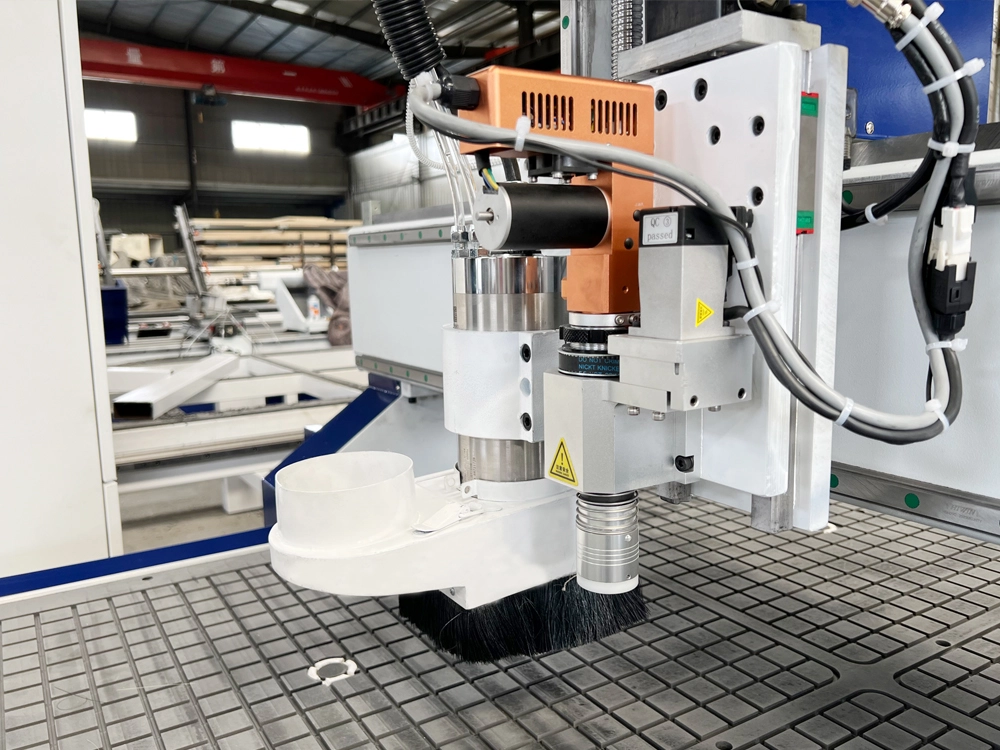

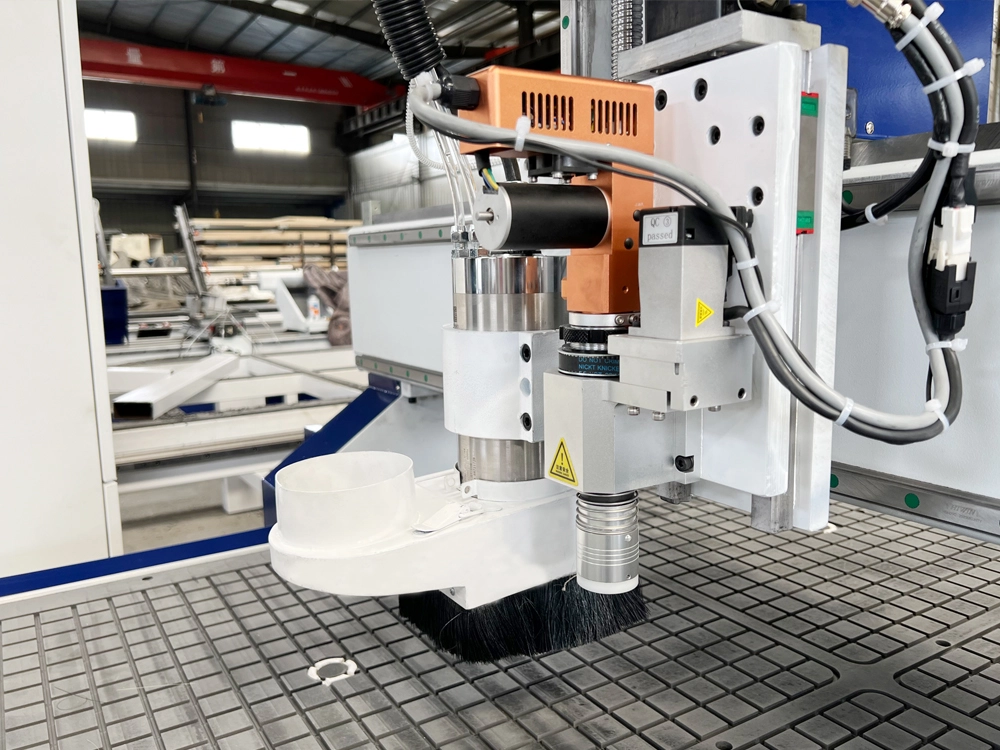

- Equipped with oscillating knife cutting device, flexible materials are cut by high-frequency oscillation of the blade, the oscillation frequency is 18000vpm, which can be applied to various flexible materials, meet different materials and process requirements, and expand the functionality of the machine.

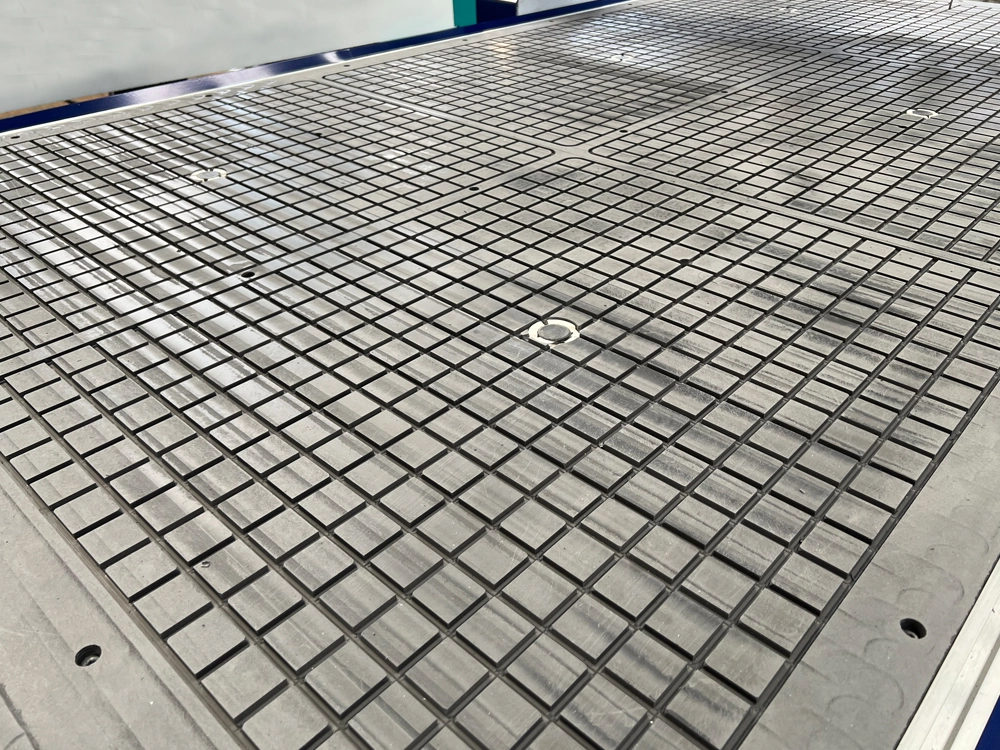

- Use vacuum adsorption workbench + T-slot workbench, vacuum adsorption workbench can be used to adsorb materials, or T-slot fixtures can be used to fix workpieces, the fixing method is flexible and easy to use.

- Equipped with high-strength gantry bracket, processed by five-sided gantry milling machine imported from Germany. Heavy-duty thickened steel pipe bed, high installation and operation precision, can be used for more than 50 years without deformation.

- Use Hiwin guide rail/slider, XY axis uses high-precision helical rack, Z axis uses high-precision TBI ball screw, fast running speed and high positioning accuracy.

- Using XDW four-axis CNC system, the interface is friendly, supports multi-axis control, can realize multiple modes of control such as position, speed and force, and is suitable for various high-precision and complex motion work scenes.

- The air-cooled spindle is equipped with a dust collector to automatically collect dust, and the oscillating knife is smokeless and dust-free during the cutting process, which meets the EU environmental protection ROHS requirements.

- By optimizing the design layout and cutting method, it can reduce material waste, effectively improve material utilization and processing efficiency, increase material utilization by more than 10%, and reduce costs.

- Supports use under various voltages, such as 110v/220v/380v/415v/440v, etc., and the machine can be adapted.

- Using an anti-interference stand alone electrical control cabinet, the electrical parts are completely isolated from the machine, effectively isolating electromagnetic interference.

Details of CNC Router With Oscillating Knife

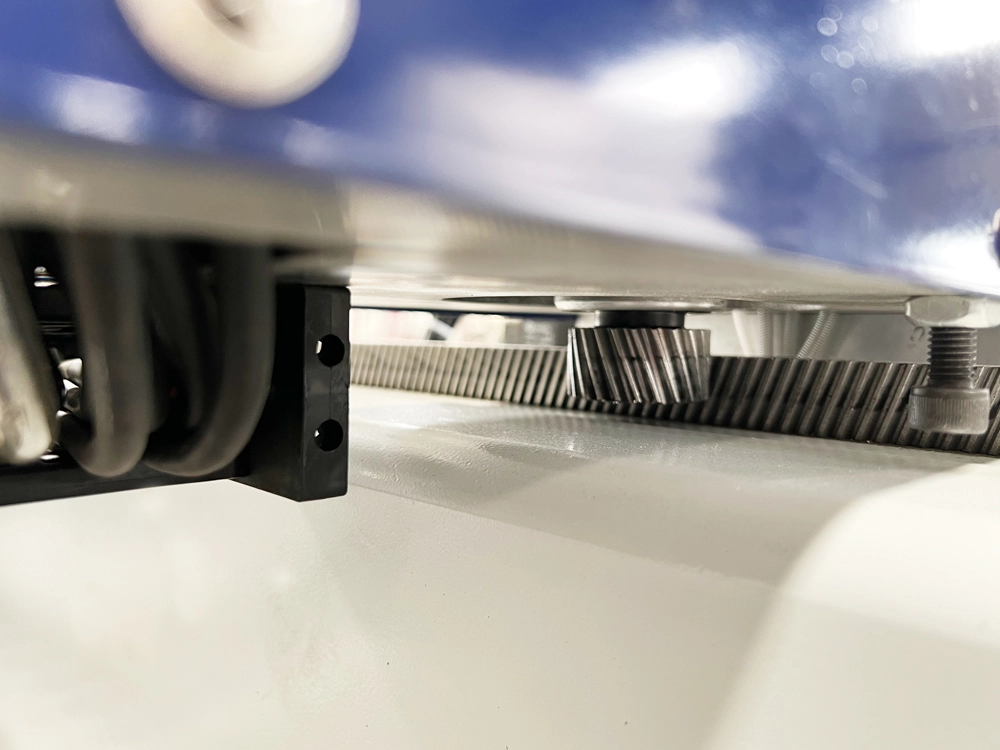

- Transmission system

-

High-precision helical racks and gears, fast moving speed.

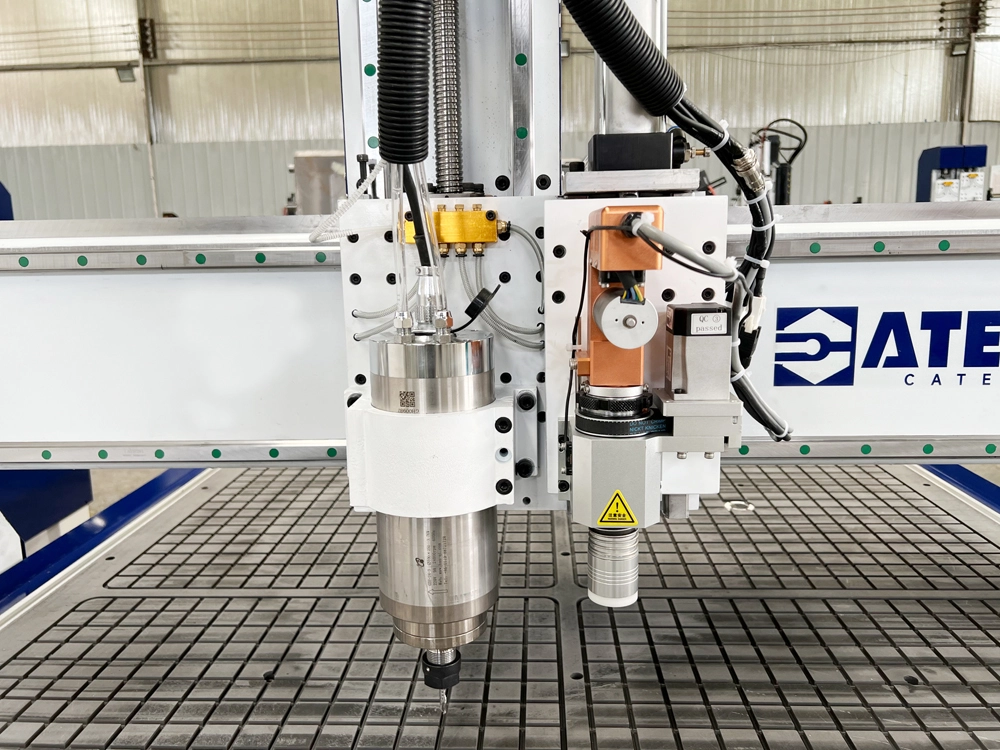

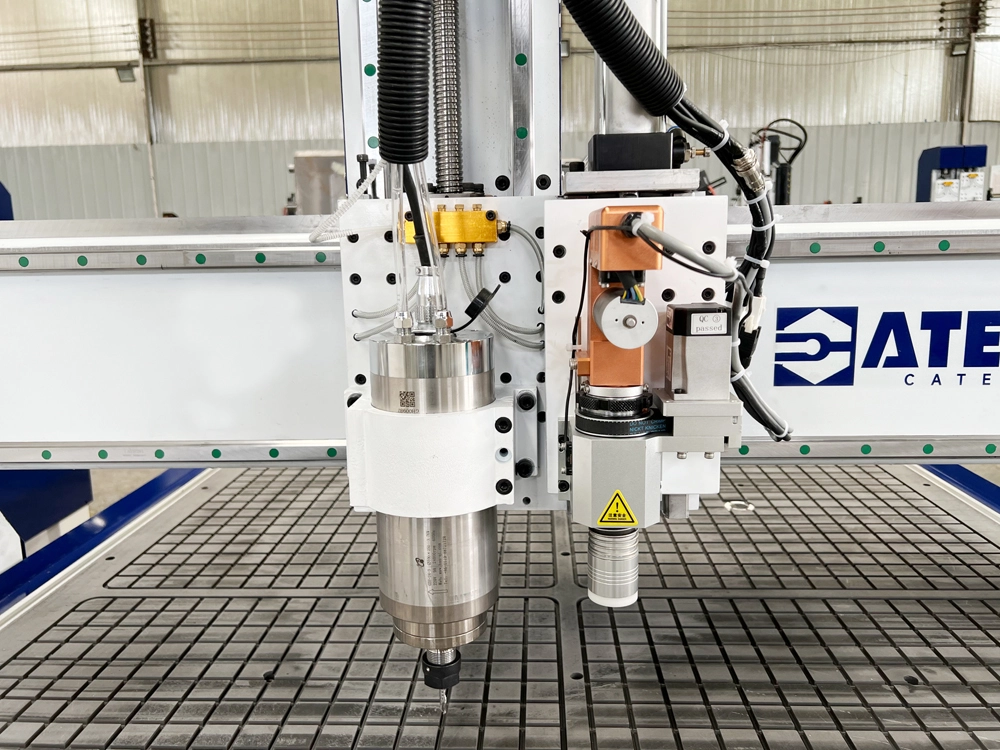

- Spindle + oscillating knife

-

3.5KW high-speed water-cooled variable frequency spindle + high-frequency oscillating knife cutting device.

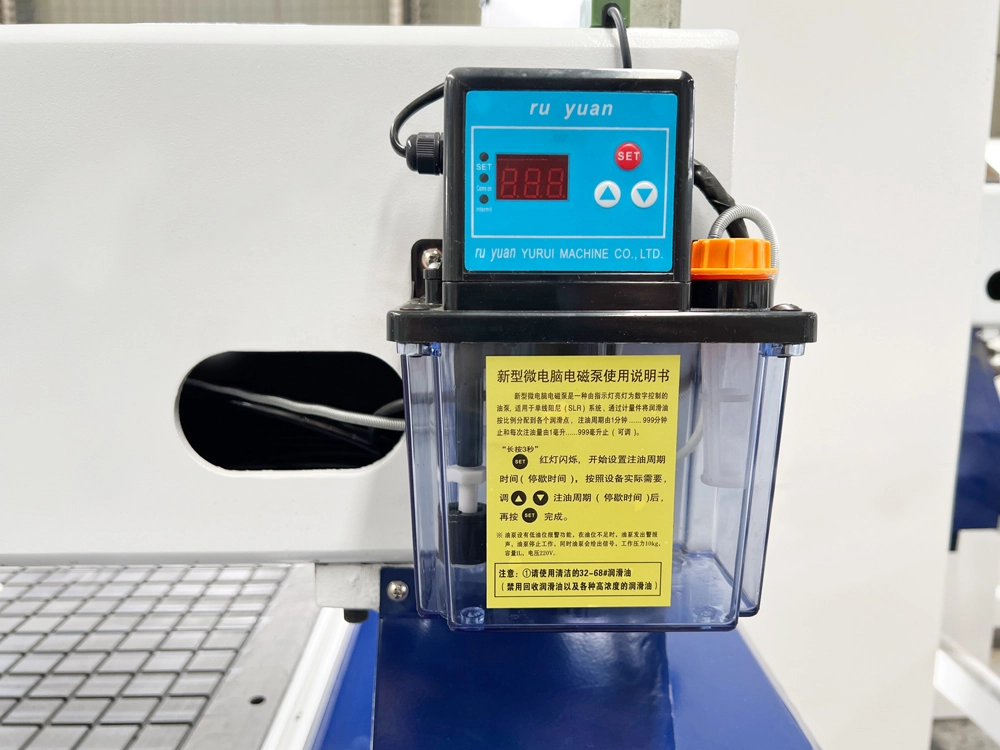

- Automatic lubrication oil pot

-

The lubrication interval can be set according to the machine usage to automatically lubricate the machine transmission parts.

- Vacuum adsorption workbench

-

Vacuum adsorption workbench, 6 partitions, each partition can be opened or closed independently.

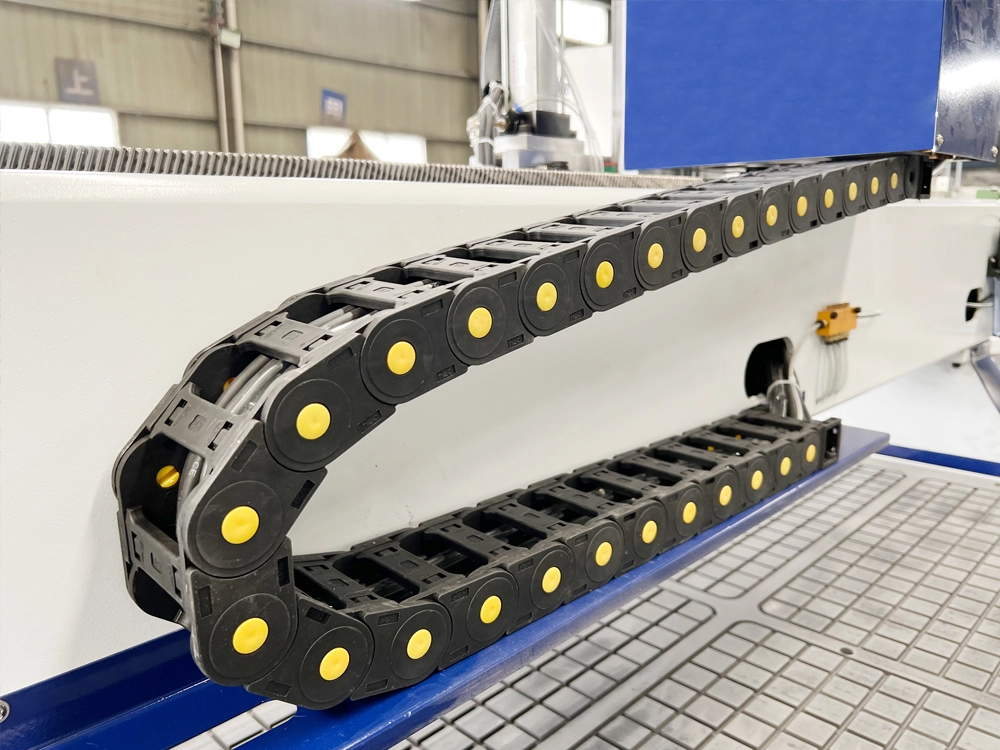

- Cable drag chains

-

High-strength tank drag chain effectively protects cables from damage.

- Control chassis

-

Independent control machine, high power inverter, servo motor driver.

- Accessories

-

Submersible pump, oil-water separator, system connecting wire, relay, open-end wrench, hexagon screwdriver, tool holder, oscillating blade, double-edged milling cutter, engraving knife, air nozzle, lubricating oil pot, etc.

Technical Parameters of CNC Router With Oscillating Knife

| Model | CK-1325-K |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mechanism | Yako/Leadshine motor |

| Variable Frequency Drive | BEST/Hpmont inverter |

| Table | Vacuum adsorption 6 zones 24 holes + aluminum alloy T-slot |

| Transmission Mechanism | XY axis high-precision ground helical rack + Z axis high-precision TBI ball screw |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Oscillating Knife | Four-axis rotating high-frequency oscillating knife |

| Control System | XDW CNC system |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Working Speed | 18000mm/min |

| Max. Rapid Traverse Speed | 25000mm/min |

| Weight | 1400kg |

| Dimensions | 3100*2100*1750mm |

Uses of CNC Router with Spindle Tool and Oscillating Knife Cutting Kit

The multi-function CNC router has two processing tools: spindle tool and oscillating knife, which can be applied to different materials respectively. Below is a list of some of the common materials and products that are processed:

- Material:

-

- Spindle tool: wood board, mdf board, pvc, pcb, acrylic, synthetic materials, gypsum board, plastic board, aluminum-plastic board, osb board, bakelite board, artificial stone, carbon fiber, ABS, PP, PE, polypropylene, plexiglass, two-color board, bamboo, ivory, leather, bone, marble shell, rubber, foam, etc.

- Oscillation knife: leather, corrugated paper, carbon fiber, cloth, carpet, foam, fiber cotton, pearl cotton, graphite, paper, soft leather, artificial leather, pp paper, cardboard, stickers, stickers, imitation leather, ABS plastic, sponge, EVA rubber and plastic insulation cotton, honeycomb paperboard, non-woven fabrics, felt, pearl cotton, composite board, PP hollow board, KT board, acrylic, EVA, high foaming material, nylon, PVC cloth, EVA rubber, carbon fiber prepreg, glass fiber, denim and other materials.

- Products:

-

- Spindle tool: wooden doors, wardrobes, cabinets, wood carvings, solid wood furniture, mahogany furniture, antique furniture, wooden doors, solid wood floors, acrylic billboards, three-dimensional billboards, large blister characters, signs, sand table building models, aircraft models, background walls, etc.

- Oscillation knife: carpet mats, sofa fabrics, car seat mats, shoemaking, advertising, textiles, packaging, composite materials, cartons, wire loops, soft felt, blackout cloth, banners, flags, UV cloth, car stickers, cardboard, imitation leather, thin plastic, rubber stickers, reflective stickers, corrugated boxes, graphite gaskets, polytetrafluoroethylene gaskets, rubber gaskets, asbestos gaskets, clothing cutting, jeans, cheongsams, leather cutting, etc.

Precautions When Using 4*8 CNC Router with Oscillating Knife

- When processing hard materials, such as MDF boards, we use high-speed water-cooled spindles to clamp various tools for processing, use straight knives to cut materials, use carving sharp knives to perform 3D carving and relief carving on materials, use round bottom knives and other various modeling tools to mill materials, and use flat bottom milling cutters to mill materials. There are many types of tools, and you can choose to process according to actual processing needs.

- When processing soft materials, we can switch to high-frequency oscillating knife for processing through the cylinder. When processing, the high frequency oscillation of the knife driven by servo motor can effectively cut the flexible material. It can be used to cut and process all kinds of daily life products, such as bags, car cushions, clothes, leather shoes and other various products.

- Before formal batch processing, it is recommended to conduct small-scale test processing to check whether the processing effect meets expectations and avoid material waste caused by direct batch processing.

- Regularly check the oscillating knife tool and spindle tool to avoid material waste caused by tool abnormalities.

- Check and replenish lubricating oil regularly. If there is abnormal operation or poor engraving effect, check the current, voltage or tool status.

- If you encounter any difficult problems that cannot be solved, you are welcome to contact our after-sales engineers to provide you with a complete solution to avoid losses caused by machine processing problems.

| Model | CK-1325-K |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mechanism | Yako/Leadshine motor |

| Variable Frequency Drive | BEST/Hpmont inverter |

| Table | Vacuum adsorption 6 zones 24 holes + aluminum alloy T-slot |

| Transmission Mechanism | XY axis high-precision ground helical rack + Z axis high-precision TBI ball screw |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Oscillating Knife | Four-axis rotating high-frequency oscillating knife |

| Control System | XDW CNC system |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Working Speed | 18000mm/min |

| Max. Rapid Traverse Speed | 25000mm/min |

| Weight | 1400kg |

| Dimensions | 3100*2100*1750mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.