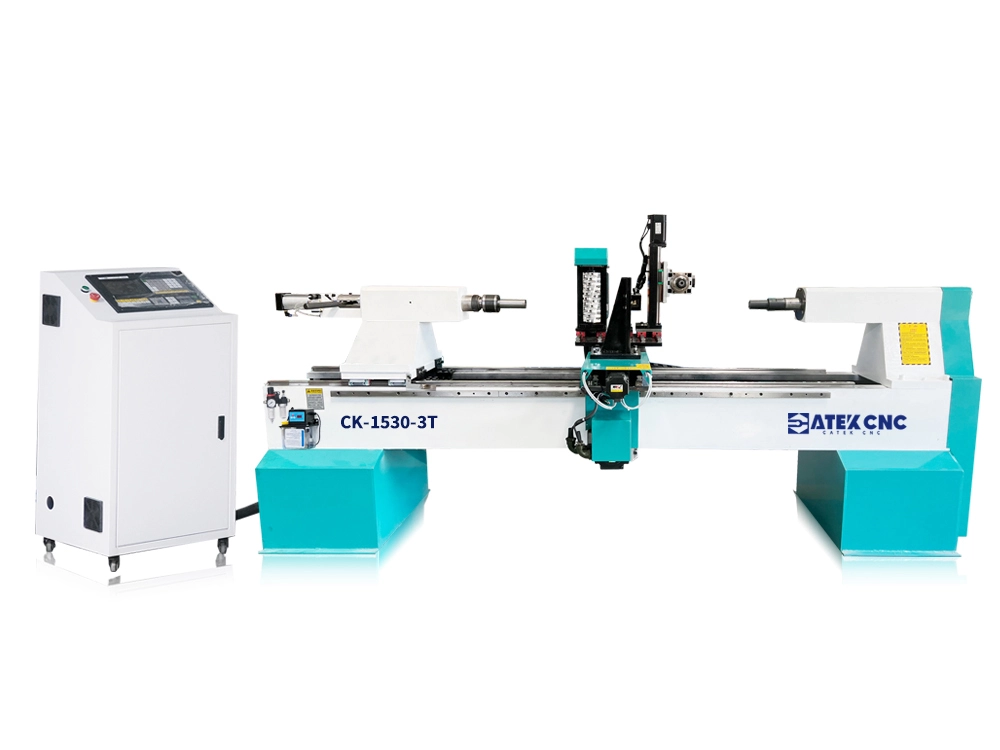

Automated CNC Woodworking Lathe with Three Switchable Functions

3-in-1 Automatic CNC Wood Lathe for Special-Shaped Table Legs

[Function Description]

CK-1530-3T is a multifunctional CNC wood lathe with three functions: turning tool, multifunctional spindle and planer. It can use turning tool to turn wood, and is used to turn some common products such as stair railings, table and chair legs. The spindle can be used for 3D carving, drilling, grooving, etc. The planer can be used to plan, mill spiral twist surfaces, etc., or process irregular shaped blanks into standard wooden cuboids. The three functions can be used separately or continuously. The operation of the woodworking lathe is controlled by the full English CNC system. When processing products that only require a single function, the corresponding function can be directly selected according to the processing technology. When processing complex products, the system can be used to control multiple functions for continuous processing. The turning, planing, drilling and grooving of complex parts can be completed in one clamping, there is no need to clamp the turned workpiece to other machines for drilling, grooving and other tasks, which saves the trouble of secondary clamping and secondary calibration of tools, effectively improves processing efficiency and reduces production costs. Only one person is needed to operate this machine, without the need for professional personnel. Even beginners can operate it. Even if multiple processing steps are required, only the space occupied by one machine is required, and the cost of use is low.

Advantages of 3-in-1 CNC Woodworking Lathe

- Two turning tools, one for roughing and one for finishing, with faster turning speed.

- 3.5KW air-cooled spindle, stable speed, can drill, mill, engrave, and 3D carving.

- 230mm high large planer, can plan various materials, driven by 2.2kw three-phase asynchronous motor, with large torque.

- Professional-grade lathe dedicated CNC system, can control various functions to process materials in layers, simple to operate.

- Heavy gray cast iron bed, stress relief treatment, German imported gantry milling guide rail mounting surface, high precision.

- Servo motor drive, low running noise, high positioning accuracy, faster processing speed.

- Timed automatic lubrication and maintenance system, simpler machine maintenance.

- Compatible with various types of cad/cam software, running G code, supporting various formats of documents such as .dxf, .dbf, .txt, etc.

- Self-developed special CNC turning software, easy to use, only need to input length, shape, diameter, the software can automatically match.

- The spindle speed and wood speed can be adjusted arbitrarily, matching more suitable rotation speed according to different processing materials.

- CNC wood lathe supports customization, optional various processing sizes, control systems, spindles, servo motor brands, optional automatic feeding and grinding devices.

Details of Three-Function Switchable CNC Wood Lathe

- Three switchable functions

Three functions can be switched at will: turning tool, planing tool and multi-function spindle.

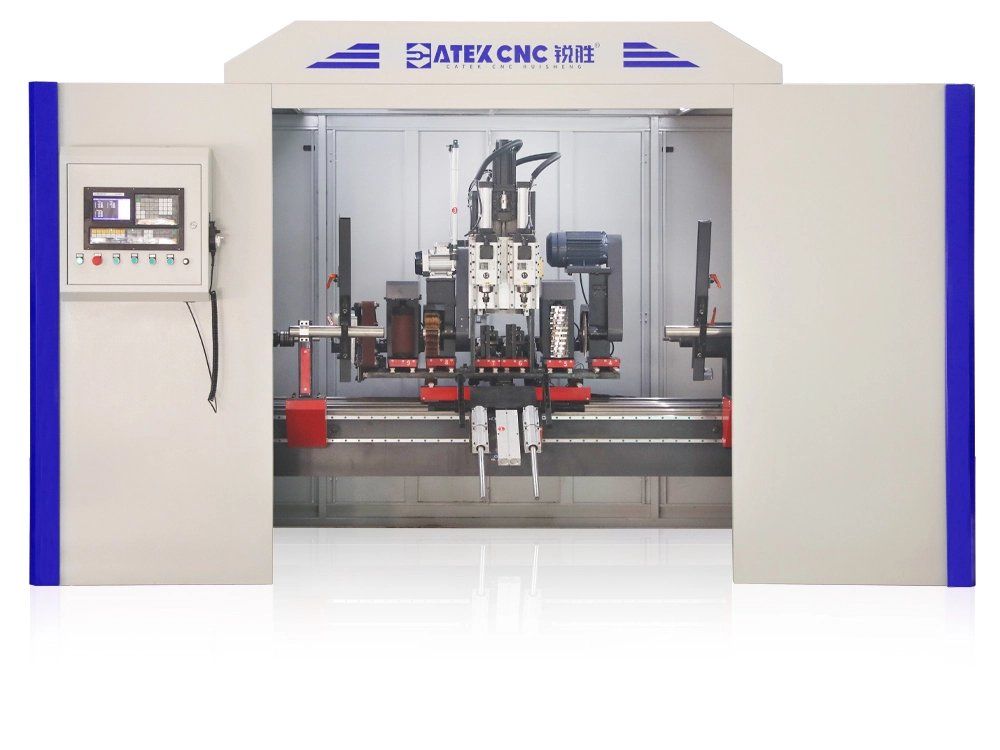

- Four-function CNC wood lathe with sanding wheel

Four functions can be switched at will: turning tool, planing tool, multi-function spindle, sanding wheel.

- Five-function CNC wood lathe with sanding wheel and two multifunctional spindles

Five functions can be switched at will: turning tool, planing tool, two multi-function spindle, sanding wheel.

- Five-function CNC wood lathe with automatic feeding

It has five functions: turning tool, planer, multi-function spindle, sand belt, and automatic feeding.

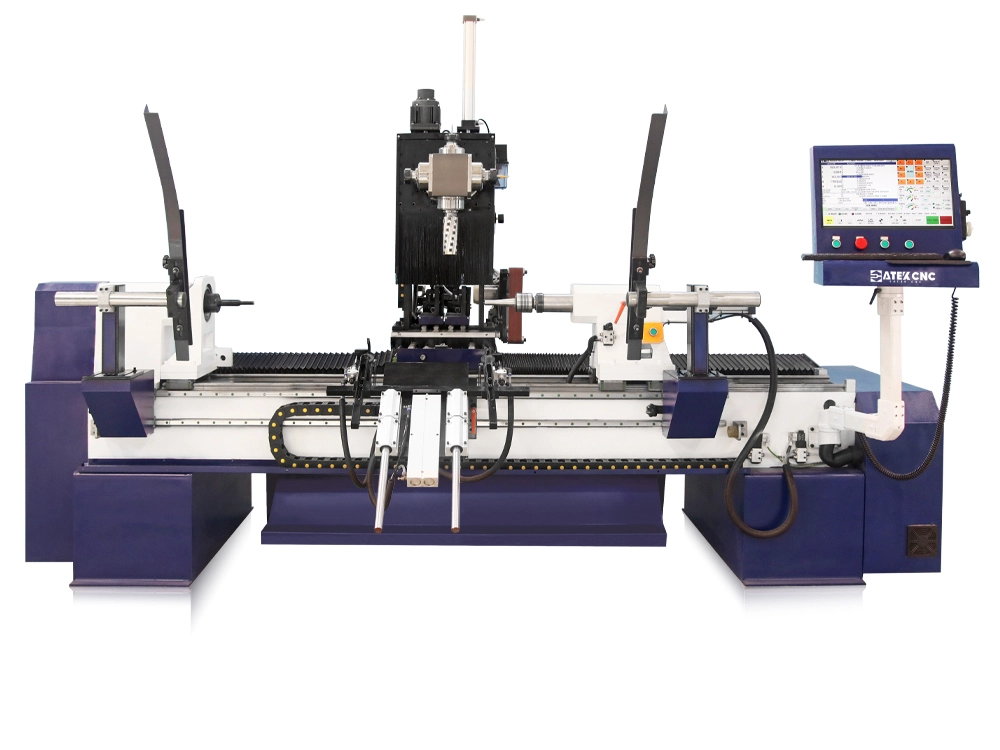

- CK-1000TC dedicated CNC system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

- Pulse control handwheel

The external pulse control handwheel can control the XYZA axis movement of the machine and accurately adjust it to 0.001mm.

Technical Parameters of Three Function Switchable CNC Wood Lathe Machine

| Model | CK-1530-3T |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | The XY axis uses a 750W CATEKCNC high-torque servo motor, and the Z-axis uses a 1.5KW CATEKCNC high-torque servo motor |

| Frequency Converter | BEST/Hpmont frequency converter / pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230 * 50mm, independently controlled sanding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack / TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1850kg |

| Dimensions | 3550*2300*1750mm |

| Functions | Turning, planing, milling, 3D engraving, slotting, drilling |

Application Scope of 3-in-1 Multifunctional CNC Wood Lathe

Applicable Materials:

Suitable for various materials such as wood, bamboo, PVC, plastic, nylon, acrylic, carbon fiber, MDF, synthetic materials, fiberglass, etc.

Applicable Industries:

Furniture: tables, chairs, sofas, beds, stair railings, pool tables, etc.

Musical instruments: drumsticks, flute, suona, cucurbit flute, bassoon, piano, etc.

Sports equipment: pool cues, baseball bats, wooden balls, etc.

Crafts: wooden bowls, vases, cups, pen holders, nesting dolls, wooden guns, candlesticks, etc.

Sculptures: figure sculptures, animal sculptures, totem sculptures, text sculptures, etc.

The multifunctional CNC woodworking lathe can be used to process various complex wooden products, such as solid wood stair columns, solid wood sofa legs, solid wood tables, chair legs, billiard table legs, tiger legs, horse legs, bed legs, Queen Anne legs, special-shaped curved legs, solid wood handicrafts, carved products, various furniture accessories, etc.

What Types of Products Can Be Processed Using a 3-Switch CNC Wood Lathe?

| Model | CK-1530-3T |

|---|---|

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | The XY axis uses a 750W CATEKCNC high-torque servo motor, and the Z-axis uses a 1.5KW CATEKCNC high-torque servo motor |

| Frequency Converter | BEST/Hpmont frequency converter / pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230 * 50mm, independently controlled sanding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack / TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Automatic Loading & Unloading |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1750kg |

| Dimensions | 3550*1550*1450mm |

| Functions | Turning, planing, milling, 3D engraving, slotting, drilling |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.