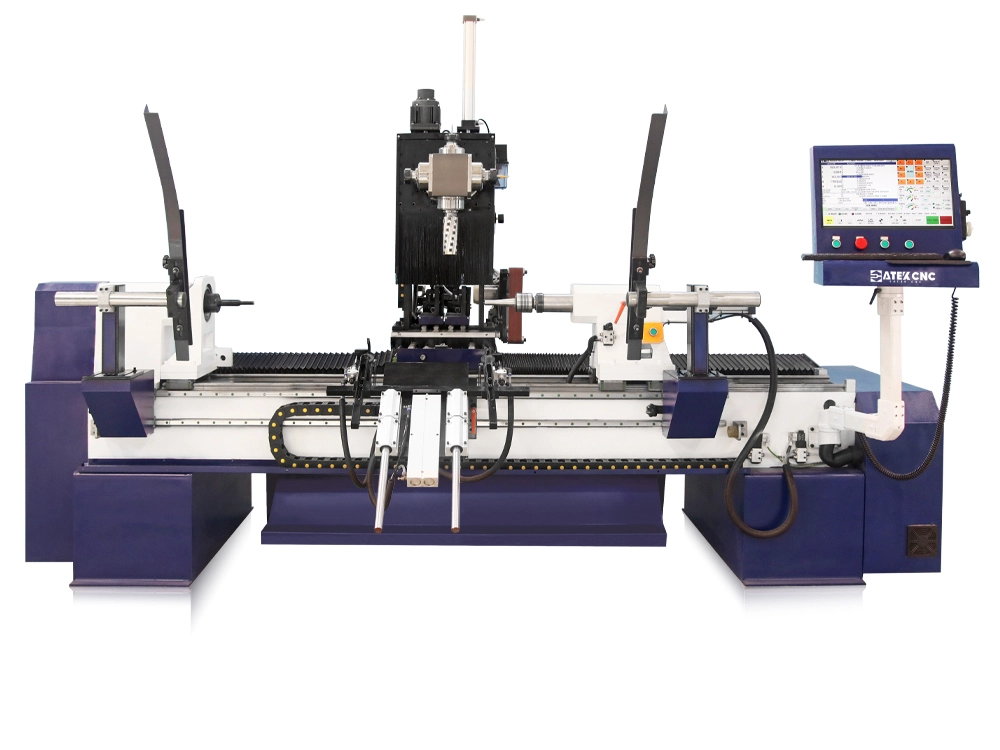

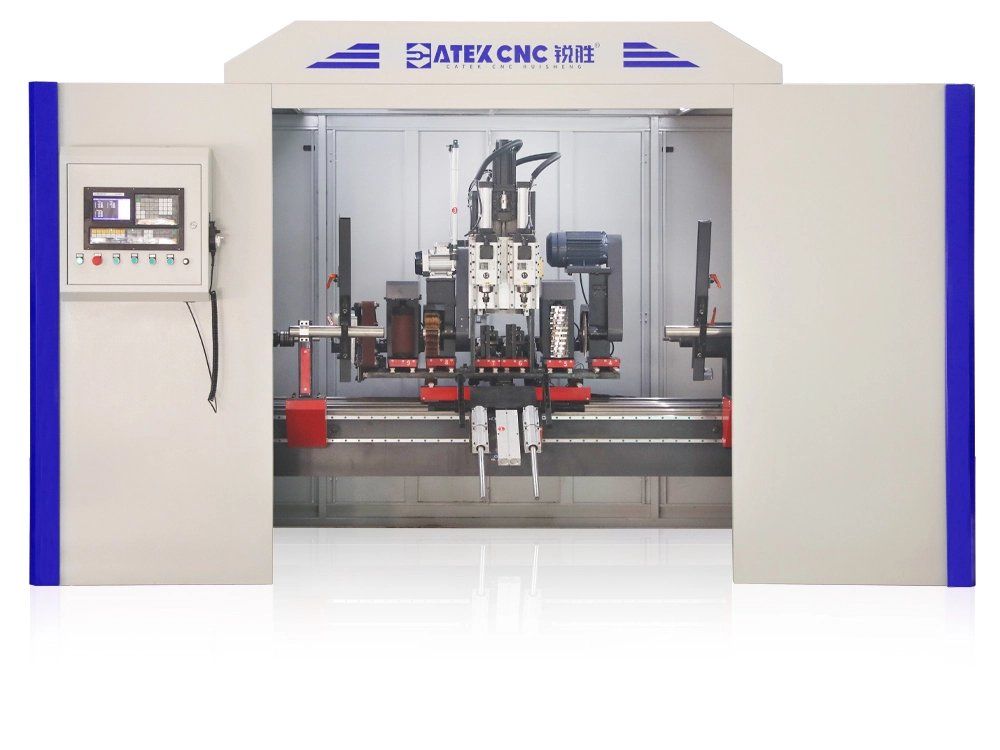

Enclosed Multifunctional Computerized Woodworking Lathe

Fully Automatic 4-in-1 CNC Wood Turning Machine with Safety Enclosure

[Function Description]

The multifunctional CNC wood lathe with safety enclosure has been upgraded on the basis of the original multifunctional CNC woodworking lathe. The design of the fully enclosed enclosure can protect the safety of the operator and prevent injuries caused by splashing objects. At the same time, it can better isolate wood chips and dust. By connecting the safety enclosure to the dust collector, a dust-free and low-noise processing environment can be achieved, which is more environmentally friendly to use. The fully enclosed enclosure wraps the entire machine in all directions without any mechanical parts leaking out, and the machine operation is controlled by an external operating system. The sliding door is equipped with an induction protection switch, and the machine will automatically pause processing once it is opened. The CNC wood lathe with safety enclosure has better operating convenience, processing flexibility and environmental friendliness.

The multifunctional CNC wood lathe with safety enclosure is very suitable for the production of high-quality and highly ornamental wooden products. The high processing accuracy and versatility of this machine make it the preferred equipment for processing wooden parts such as furniture table legs, Queen Anne legs, Chippendale legs, carved decorative columns, etc., which can achieve accurate size and perfect processing effects that match the design, and can adapt to furniture processing of any style or aesthetic needs. In addition to processing furniture, this CNC lathe can also be used to process various types of stair railings, wood crafts, etc.

Advantages of 4-function CNC Wood Lathe with Automatic Hopper Feeding and Safety Hood

- Using a V-type alloy turning tool with a heavy cutting volume for turning operations, this tool offers greater machining capacity compared to conventional tools, significantly improving processing efficiency. The single-pass cutting depth can exceed 50 mm. For small wooden products such as table legs and chair legs, it enables one-pass. For large wooden products, fully automated intelligent layered machining can be achieved with the assistance of a CNC system.

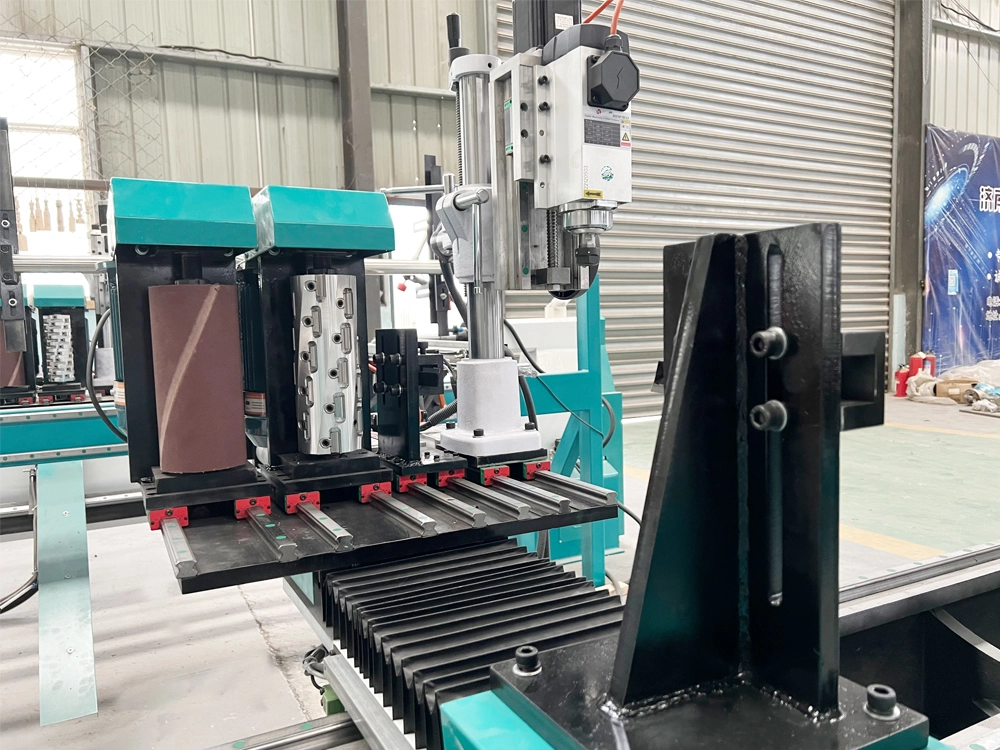

- Equipped with a 240mm high, 90mm diameter large-cutting drum planer, it is equipped with a large number of four-edged blades. The blades are separated from the tool holder, and the blades can be flexibly replaced, which is more convenient to use and has a longer life. Driven by a 2.2KW high-power motor, the wood surface can be quickly planed. The planer can automatically rotate the angle and set the processing depth. It can be combined with other tools to process any plane shape. It can also be used to quickly roughen the wood. It forms a linkage combination with the turning tool, which has higher processing efficiency.

- It uses a 3.5kw high-speed air-cooled spindle and a 4-ceramic bearing structure, which has a longer service life and a maximum speed of 18000r/m, and can quickly process wood. It supports four-axis four-linkage function and can complete a variety of complex tasks such as grooving, drilling, reaming, 3D engraving, etc. An automatic tool change spindle can also be selected to achieve automatic switching of multiple tools to meet more complex processing needs and ensure perfect processing results.

- There are three sanding methods for you to choose from: sanding wheel, sanding roller, and sanding belt. Of course, you can also equip your machine with multiple sanding methods. They are all driven by independent motors and switched by cylinder control, suitable for round bar sanding and flat surface sanding respectively. It supports multiple sanding of designated parts separately. According to actual processing needs, the finished product can be quickly polished as a whole or polished in layers multiple times, so that the subsequent painting work can proceed smoothly, which can greatly improve efficiency.

- It is equipped with an automatic feeding/automatic unloading system, which realizes automatic processing through the linkage of multiple cylinders. Before processing, you only need to match and adjust the loading bracket with the processing material, and the machine can start automatic processing. One person can operate multiple machines and only needs to continuously place materials on the machine.

- The machine is equipped with a full-enclosed enclosure, which can maximize the protection of personal safety, and at the same time effectively prevent the spread of dust, which is more environmentally friendly. The machine is equipped with an alarm device for opening the door. Before machining on the CNC woodworking lathe, after completing all the tool calibration, close the safety door, and the machine can start automatic machining.

Details of 4-in-1 CNC Wood Lathe with Automatic Hopper Feeding System and Safety Enclosure

- Fully enclosed safety enclosure

Fully enclosed safety enclosure the whole machine is surrounded and protected, safe to use, sliding door design, convenient to observe the processing status.

- CK1000TC CNC system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

- Functional Components

Equipped with all the functions of CK-1530-4T: turning tool(Optional double turning tool), planing tool, sanding device, multi-function spindle, automatic loading and unloading.

- Tailstock

Independent cylinder control, Morse No. 5 taper.

Technical Parameters of 4-in-1 Multifunctional CNC Wood Lathe with Safety Enclosure

| Model | CK-1530-4TE |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | The XY axis uses a 750W CATEKCNC high-torque servo motor, and the Z-axis uses a 1.5KW CATEKCNC high-torque servo motor |

| Frequency Converter | BEST/Hpmont frequency converter / pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230 * 50mm, independently controlled sanding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack / TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Multi cylinder linkage automatic feeding system |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2100kg |

| Dimensions | 3750*2350*1750mm |

| Functions | Automatic hopper feeding, turning, planing, milling, 3D carving, slotting, drilling, sanding, polishing |

Optional Parts for Fully Automatic 4-in-1 Multifunctional CNC Wood Lathe

| Control System | NcStudio/CK2000TC, etc. |

| Spindle | 9KW ATC air-cooled spindle/Italy HSD/HITECO spindle |

| Saw Blade | 230mm milling saw blade |

| Polishing | Sanding wheels/sanding rollers/sanding belts |

| Servo Motor | Yaskawa/Delta, etc. |

| Tool Setting Method | Automatic tool setting instrument |

| Tool Magazine | 4/6 knives automatic tool change |

Uses of Multifunctional CNC Wood Lathe with Safety Enclosure

CNC woodworking lathes are used in all walks of life, and the products processed by them can be seen everywhere in daily life, such as common wooden stairs, sofas, tables, chairs, and stools in daily life; baseball bats, pool cues, and pool tables commonly used in sports, axes, hammers, and shovel handles commonly used in life; musical instruments such as drumsticks, piano legs, flutes, suonas, and guitars; and various common ornaments, such as vases, wooden bowls, pen holders, candlesticks, and wooden blocks.

How to Better Use and Maintain CNC Wood Lathe?

- After processing is completed every day, clean the machine. After the machine is used, a lot of sawdust and dust will remain, so we need to clean the machine in time.

- CNC woodworking lathes are equipped with fully automatic electric lubricating oil pots. When using the machine, the lubricating oil pot can be set according to the processing frequency of the machine. The oiling time and interval time can be set to ensure that the machine can be continuously lubricated.

- During the use of the machine, it is necessary to clean and sweep it frequently to prevent sawdust from accumulating and affecting machine processing.

- Regularly check the transmission parts, such as bearings, gears, etc., and lubricate them with lubricating oil.

- Frequently check the wear of cutting tools and replace them as needed to maintain the accuracy of each processing.

- Regularly check whether the connection of cables and electrical parts is loose to ensure that everything is safe and operating normally.

| Model | CK-1530-4TE |

|---|---|

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | The XY axis uses a 750W CATEKCNC high-torque servo motor, and the Z-axis uses a 1.5KW CATEKCNC high-torque servo motor |

| Frequency Converter | BEST/Hpmont frequency converter / pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230 * 50mm, independently controlled sanding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack/TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Multi cylinder linkage automatic feeding system |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2100kg |

| Dimensions | 3750*2350*1750mm |

| Function | Automatic hopper feeding, turning, planing, milling, 3D carving, slotting, drilling, sanding, polishing |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.