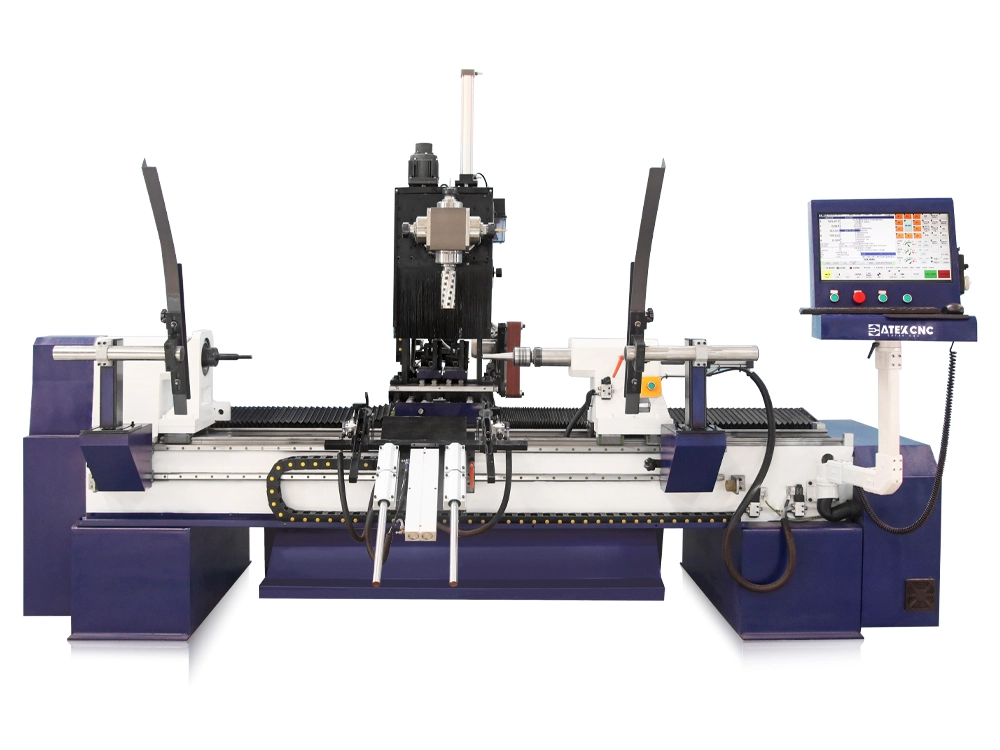

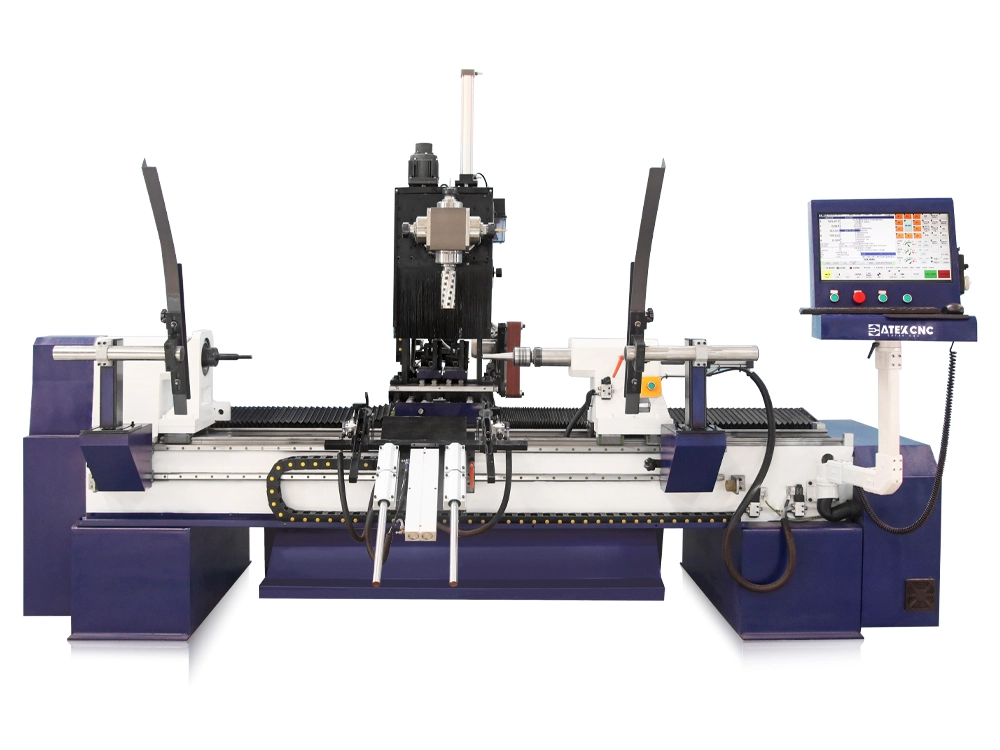

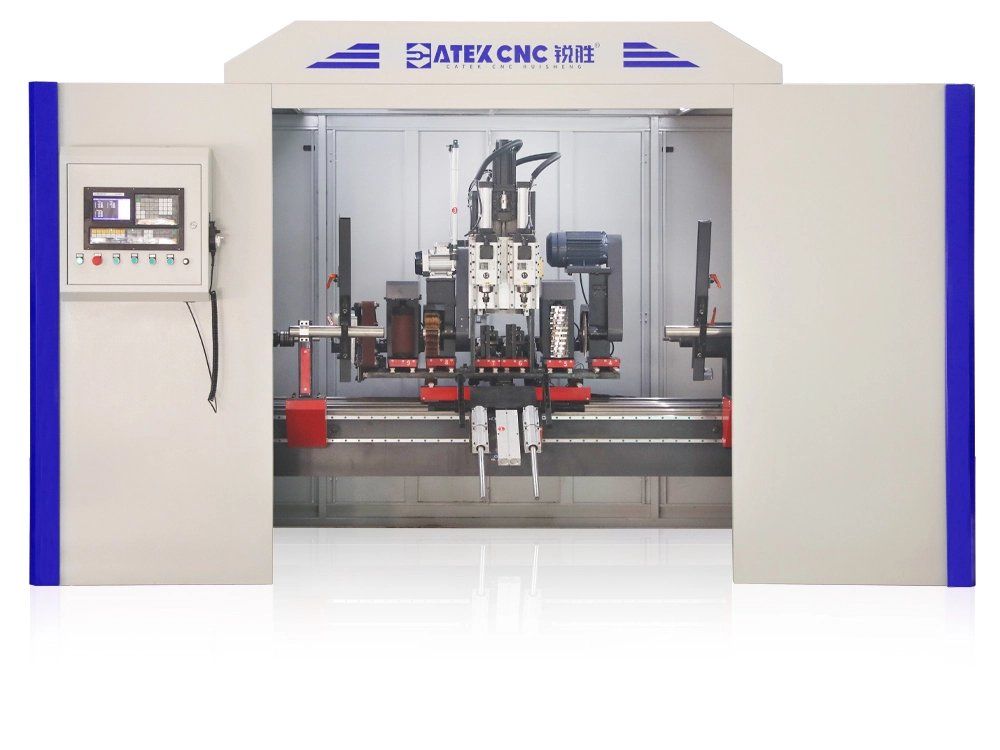

Five-Axis CNC Woodworking Lathe for Turning and Milling

Most Powerful 5-Axis 7-in-1 Multifunctional CNC Wood Lathe

[Function Description]

The CK-1530-7T-5AXIS Multi-Function 5-Axis CNC Wood Lathe is a high-performance, cost-effective, and powerful CNC woodworking machine introduced by CATEKCNC. It integrates multiple functions, including turning, milling, drilling, grooving, planing, flat engraving, 3D carving, angled drilling, and angled grooving, into a single system. Additionally, this lathe is equipped with a 5-axis RTCP (Rotational Tool Center Point) function, which compensates in real-time for tool center point displacement caused by rotational axis movements, ensuring the tool center point remains precisely at the predetermined position during the machining process.

Leveraging 5-axis simultaneous machining technology, this multi-function 5-axis CNC wood lathe enables the complete machining of complex workpieces in a single setup, efficiently executing all 3D surface machining processes. This not only significantly improves efficiency but also, with the combined capabilities of 5-axis RTCP and automatic multi-function switching for continuous machining, fundamentally eliminates errors caused by multiple setups. It ensures maximum machining accuracy and workpiece consistency while effectively increasing production efficiency by over 50%. As a core CNC machine for high-quality and batch production of complex wooden products, it can handle over 98% of complex machining tasks in furniture manufacturing, staircase production, and woodcraft processing. It is widely used in high-end furniture, architectural decoration, and handicraft manufacturing industries.

What Is a 5-Axis CNC Wood Lathe, and What Are Its Advantages Compared to a 4-Axis Model?

A multi-function 5-axis CNC wood lathe is a numerical control equipment that achieves complex wood processing through the simultaneous movement of "3 linear axes (X/Y/Z) + 2 rotational axes." Compared to a 4-axis simultaneous CNC wood lathe, its core advantage stems from the addition of a B rotational axis, which drives the cutting tool through a ±90° rotation. This enhancement in machining freedom translates into breakthroughs across multiple dimensions, including machining accuracy, efficiency, and process range, better meeting the woodworking industry's demands for processing complex shaped parts and challenging 3D curved surfaces.

Breakthrough in Machining Freedom

A 4-axis lathe uses a "3 linear axes (X/Y/Z) + 1 rotational axis (A-axis)" configuration, allowing only single-direction rotational machining of the workpiece. When encountering inclined surfaces, multi-faceted irregular structures, or vertical/inclined surface features, machining blind spots that tools cannot reach easily occur. This often necessitates multiple adjustments to the workpiece clamping angle or even switching to other equipment to complete the processing.

In contrast, a 5-axis CNC wood lathe, through the simultaneous movement of its two rotational axes (A+B axes), can precisely control the tool movement along complex curved paths. It allows for synchronized changes in the tool tip point trajectory and the tool axis direction, enabling the adjustment of the tool-to-workpiece angle in 3D space according to process requirements. This comprehensive coverage of all machining positions on the workpiece eliminates the need for process splitting or machine changes, completely solving the "unreachable" problem inherent in 4-axis lathes.

Superior Accuracy and Part Consistency

When machining complex parts on a 4-axis CNC wood lathe, repeated re-clamping accumulates positioning errors, which significantly impacts the machining accuracy of precision wood components like furniture joinery structures.

Relying on 5-axis simultaneous control and the RTCP function, the 5-axis CNC wood lathe can not only access hard-to-reach areas by adjusting the tool axis angle but also maintain the optimal cutting angle between the tool and the machined surface. This results in higher surface finish quality and faster machining efficiency. It avoids errors introduced by multiple workpiece handlings, ensuring better dimensional consistency of the parts and eliminating the need for substantial subsequent manual correction and sanding.

Enhanced Efficiency and Material Utilization

When processing complex operations (e.g., drilling on vertical faces, grooving on inclined surfaces) on a 4-axis machine, it is often necessary to change to different types of machines or adjust programs, which consumes time and is prone to errors.

Building upon the capabilities of 4-axis machining, the multi-function 5-axis CNC wood lathe additionally covers the machining needs of vertical surfaces, inclined surfaces, and complex curves. Its processing efficiency is increased by over 50% compared to 4-axis wood lathes. Furthermore, 5-axis machining allows for more flexible tool path planning, improving material utilization by over 15% compared to 4-axis machining, effectively reducing production costs.

Significantly Expanded Machining Capabilities

Limited by its single rotational axis, a 4-axis wood lathe cannot achieve complex processes such as intricate 3D hollowing or machining angled holes.

5-axis machining can easily accomplish advanced requirements like angled machining, vertical/end face machining, and continuous smooth curved surface processing. It perfectly realizes various complex 3D models designed in CAD/CAM software, enabling the production of high-value-added, high-end, and customized products, thereby enhancing product competitiveness.

Advantages of The Most Powerful Fully-Automatic 5-Axis CNC Wood Lathe

1. Reinforced Fully-Cast Bed for Superior Stability

The bed is manufactured using a single piece of gray cast iron, featuring a double-row, four-guideway design supplemented by reinforced supports. This fundamentally enhances its resistance to deformation.

After forming, the bed undergoes strict artificial aging treatment to thoroughly eliminate internal stresses.

Subsequent precision machining of the guideway and rack mounting surfaces is performed by a 5-face gantry milling machine. This ensures the transmission system always operates on an absolutely flat and vertical reference plane, providing a solid foundation for high positioning accuracy and long-term, high-speed stable operation.

2. High-Precision Transmission System

-

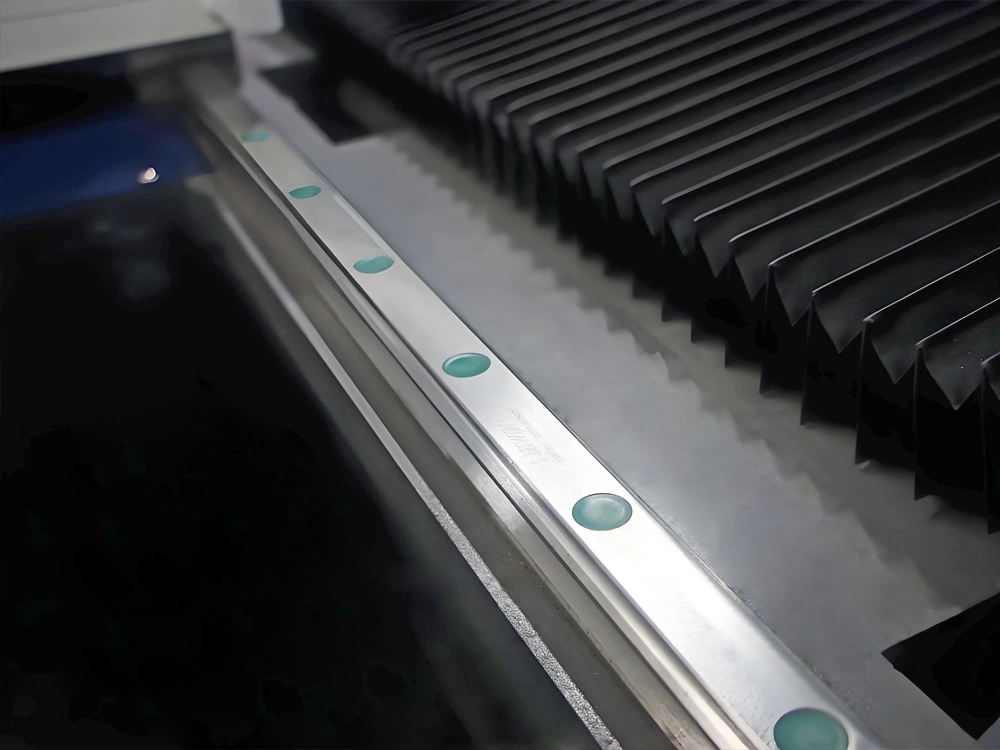

Guideways: Equipped with 4 HIWIN (Taiwan) square linear guideways, each 30mm wide, and flange-type linear bearings. This configuration better withstands radial loads generated during milling and turning.

The 4 guideways are installed parallel and symmetrically, offering greater total load capacity.

The contact area of the flange linear bearings is over 30% larger than that of standard linear bearings, distributing the working load evenly to the guideways. This prevents localized stress concentration that can cause slider sticking or guideway wear, thereby extending the service life of transmission components.

-

Ball Screws: Utilize TBI (Taiwan) precision-ground grade ball screws with low friction coefficients. Positioning accuracy is <0.05mm, and they offer excellent load-bearing performance, capable of withstanding combined loads from the machine itself and cutting forces, ensuring stable positioning and machining accuracy.

-

Rack and Pinion: Employ high-precision, ground-grade helical racks and pinions.

Helical teeth engagement results in lower impact loads and minimal operational vibration (amplitude ≤0.001mm), ensuring smoother operation.

The helical rack and pinion system offers higher transmission rigidity, allows operational speeds exceeding 60,000 mm/min, and produces extremely low vibration and noise, making it more suitable for fine woodworking.

3. Feed Axis Drive System: Linear and Rotary Axes in Precise Coordination

-

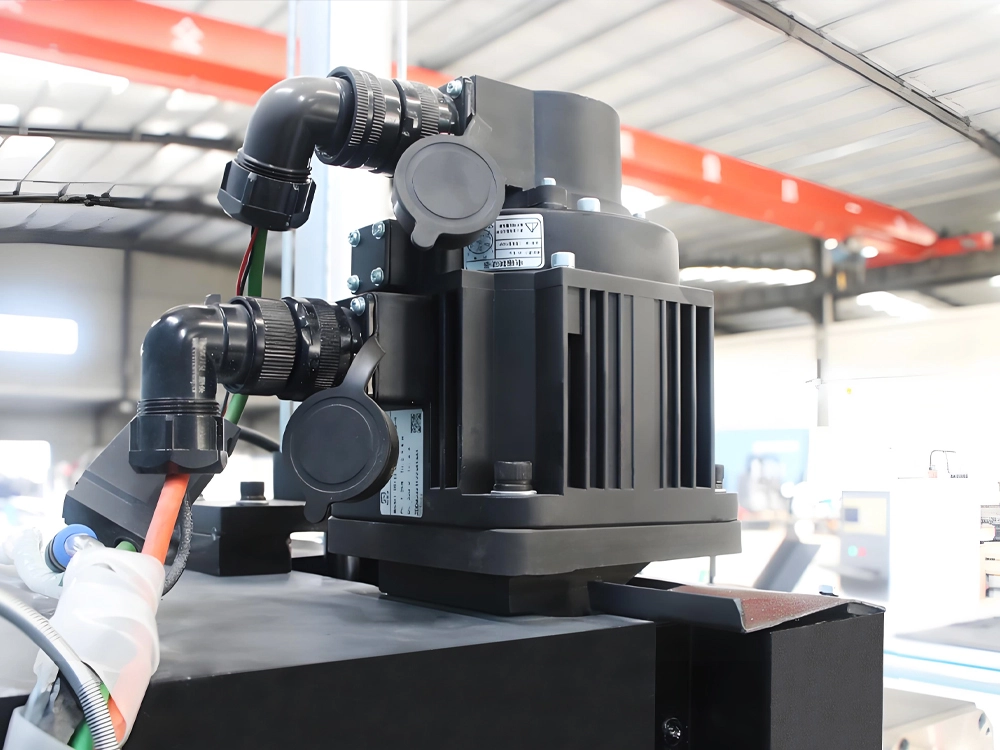

Servo Motors for Linear Axes: The X, Y, and Z axes are equipped with 1500W bus-type absolute high-power servo motors, while the 5th axis (B-axis) uses a 750W servo motor.

These motors provide superior multi-axis synchronization, real-time dynamic response, and anti-interference capability.

They adapt better to load variations common in wood processing and possess strong load-bearing capacity, perfectly suited for everything from low-load engraving to heavy-load milling and turning, ensuring high-precision machine operation.

-

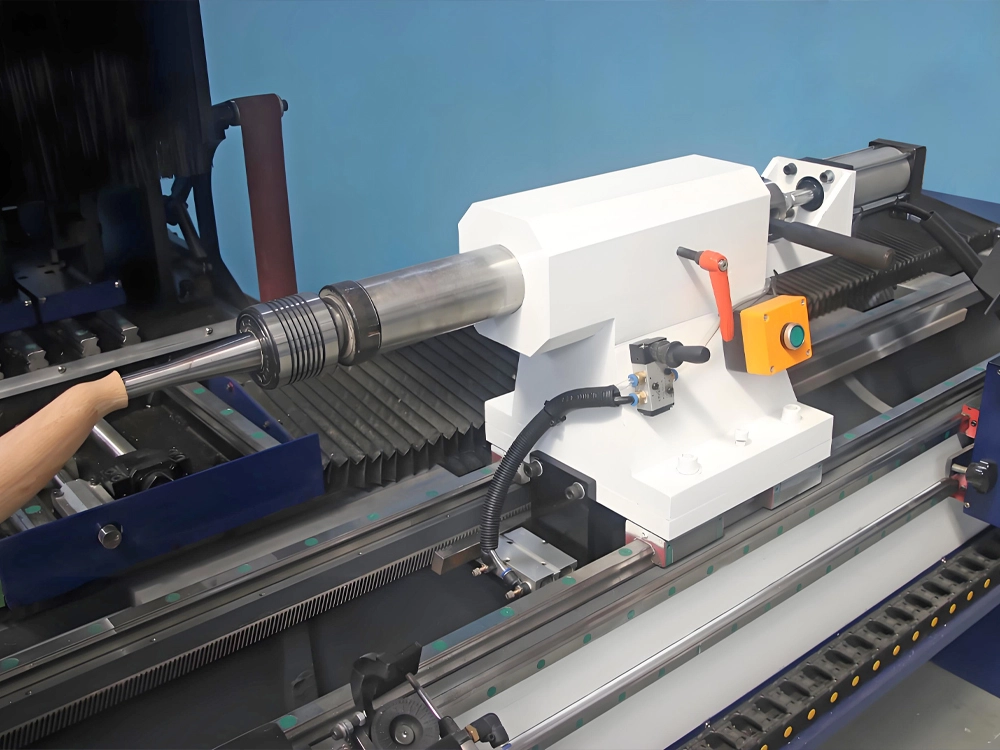

Servo Motors for Drive Spindle: The A-axis uses a 4000W high-torque servo spindle motor with a maximum speed of 6000 RPM.

It supports switching between position mode and speed mode:

-

In turning operations, it automatically switches to speed mode, utilizing high speed and high torque.

-

For milling, engraving, etc., requiring A-axis rotation, it automatically switches to position mode, controlling rotation accuracy within 0.001°, ensuring smooth operation for turning, milling, and other tasks.

-

-

Reducers: The Z and B axes are equipped with planetary gear reducers, capable of outputting greater torque.

They also offer higher positioning accuracy and impact resistance, effectively countering load fluctuations during wood processing and enhancing the machine's capability for long-term continuous operation.

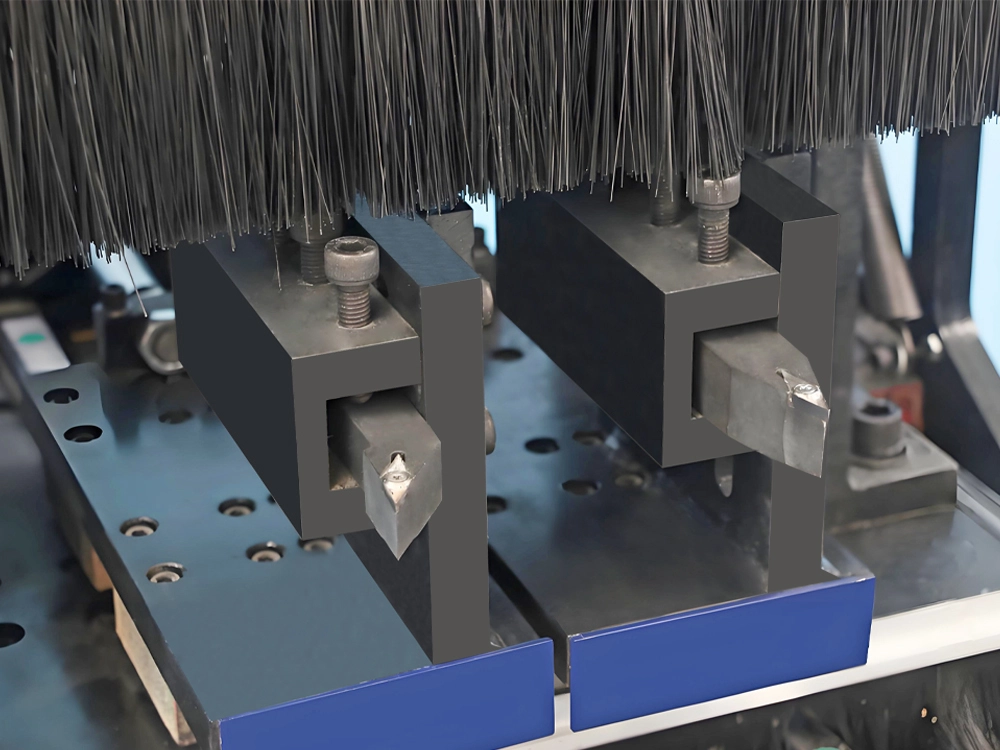

4. Comprehensive Functionality for Diverse Machining Needs

-

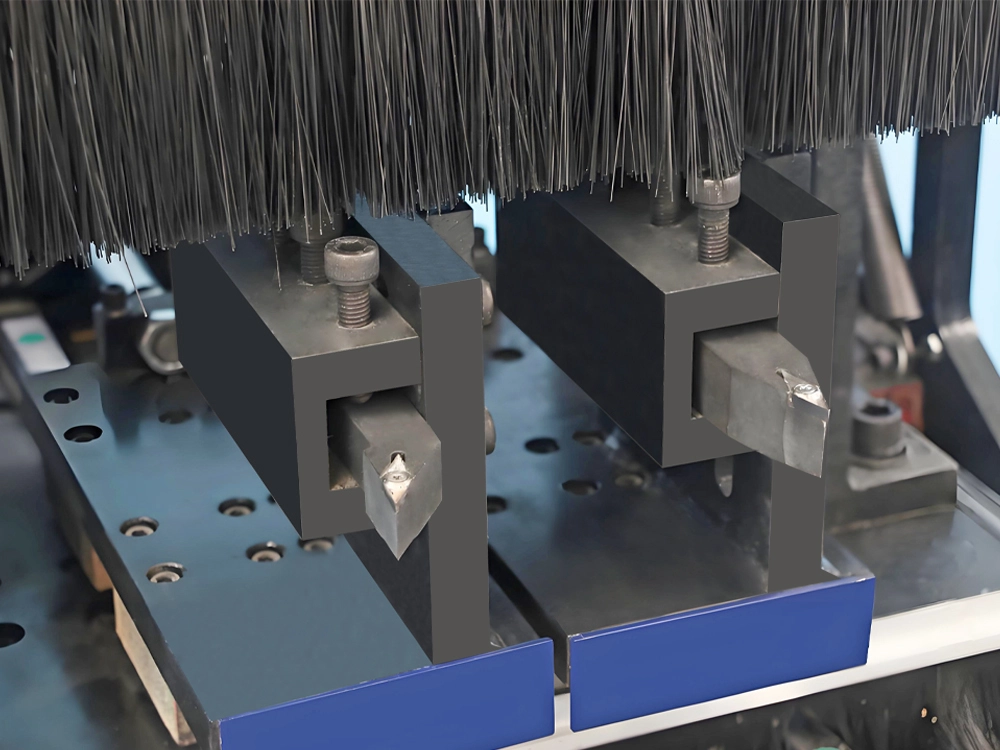

Turning Tools: Pre-configured with 2 tool stations, allowing for the simultaneous installation of 2 different tools (e.g., 1 V-groove tool, 1 U-groove roughing tool). This enables automatic tool changes during processing as needed, significantly improving machining efficiency.

-

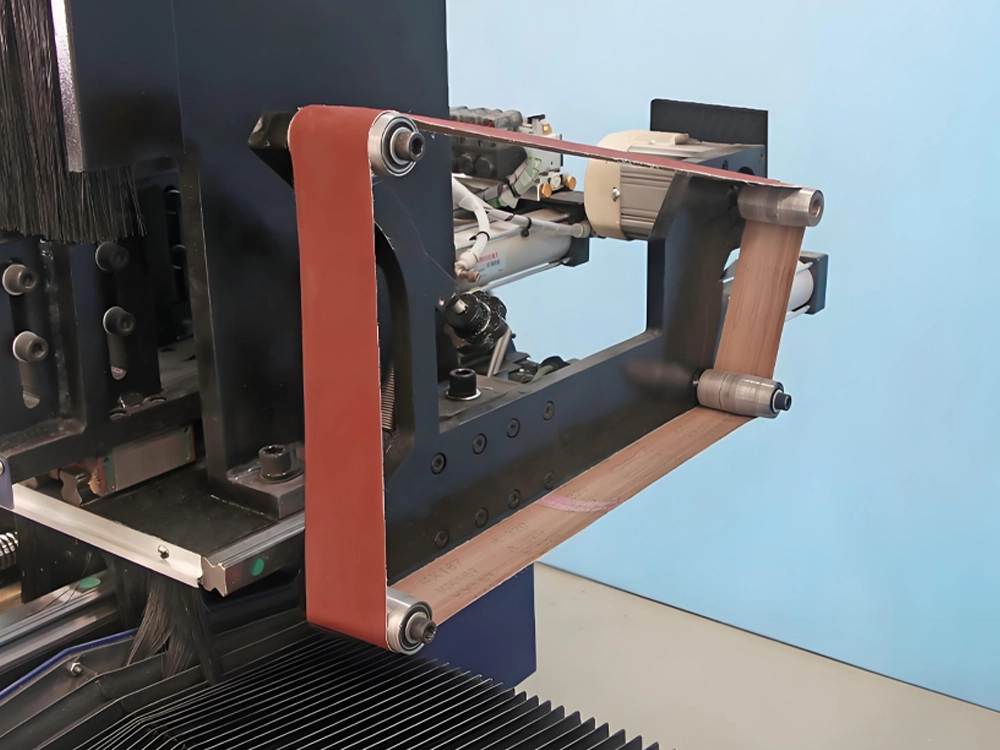

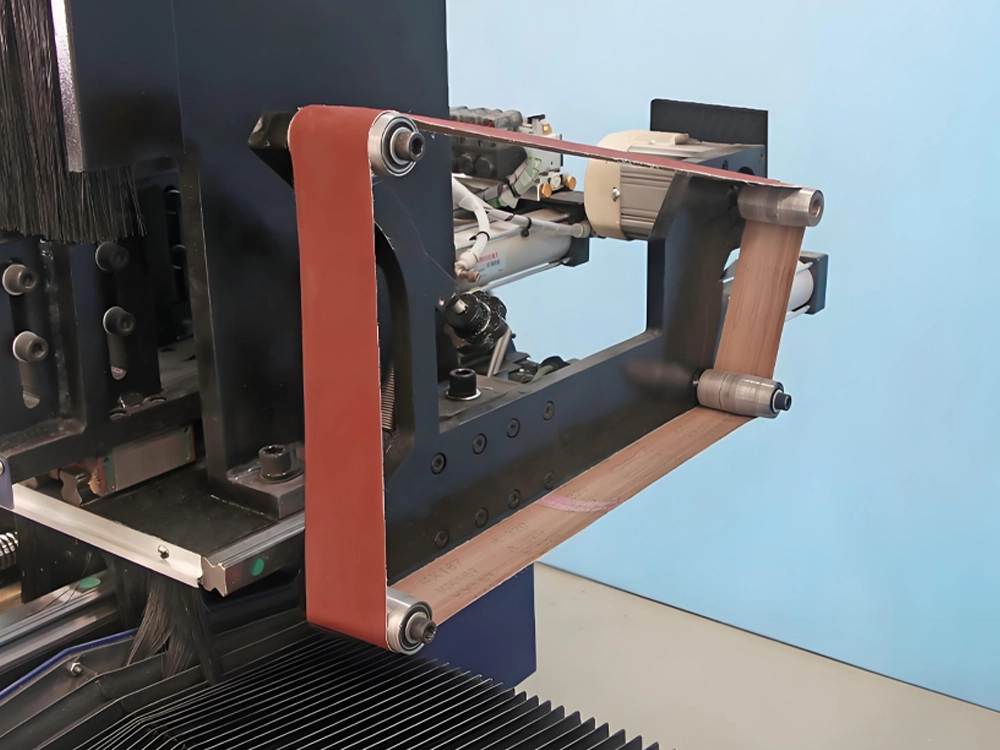

Sanding Belt: Driven by a 1100W servo motor with adjustable speed up to 6000 RPM.

Features a flexible, adjustable sanding belt for better conformity to the workpiece.

Suitable for sanding round rods and curved surfaces, effectively improving surface finish.

Supports changing sanding belts of different grits as needed. Optional sanding wheels and oscillating sanding devices are also available.

-

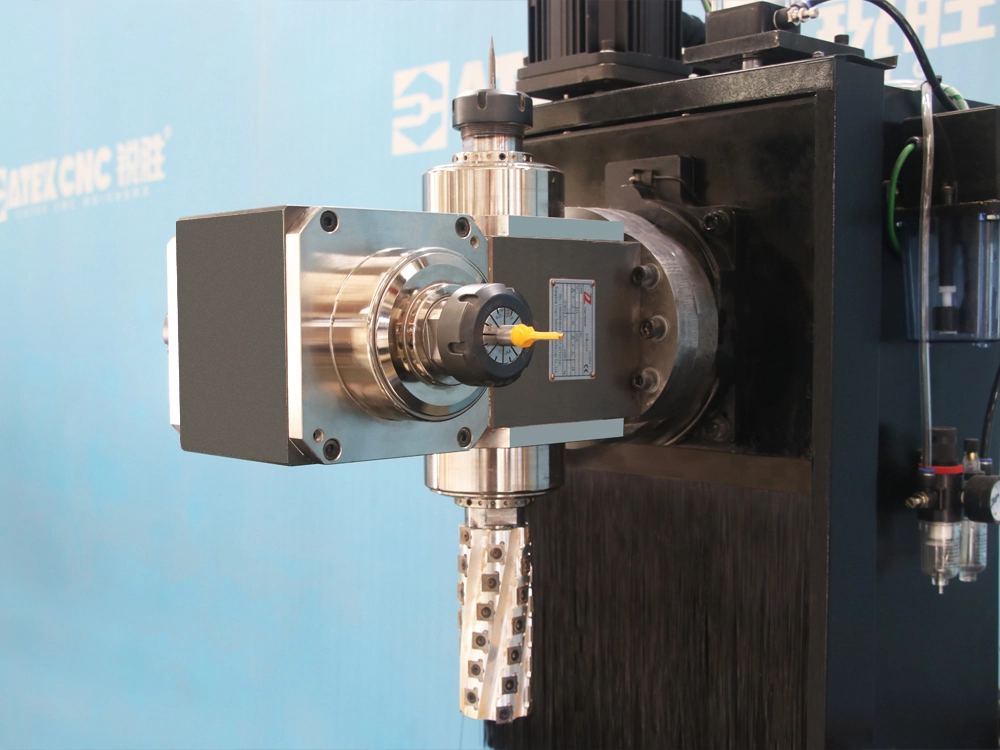

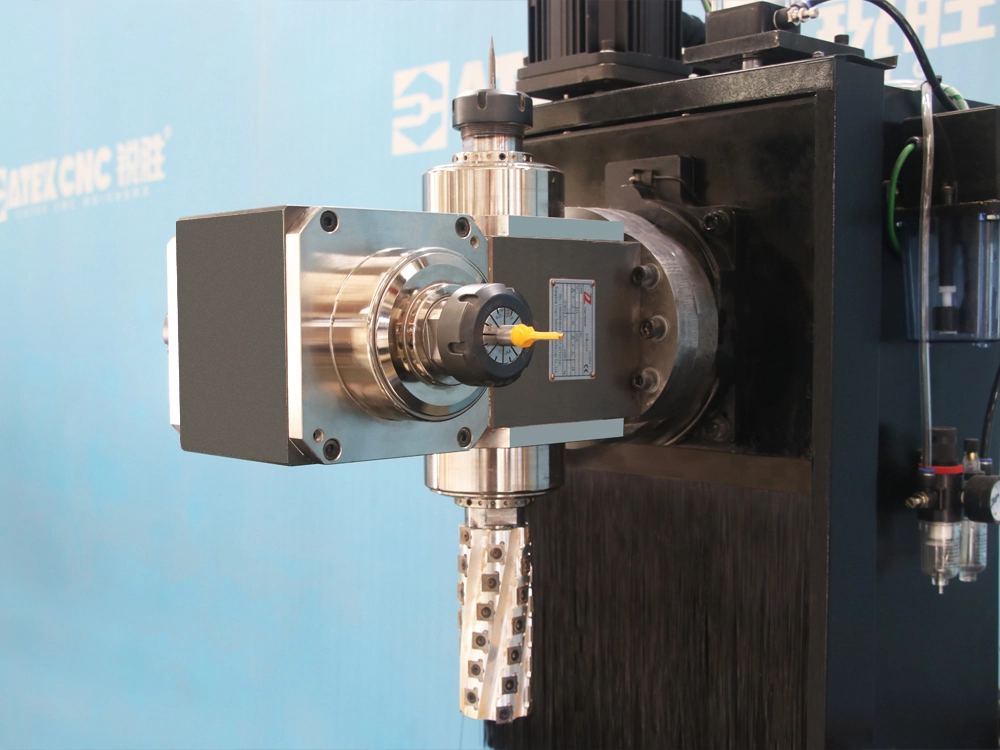

4-Head Spindle: Equipped with a 7.5KW integrated, air-cooled 4-head electric spindle specifically designed for 5-axis machining centers.

Maximum speed: 18,000 RPM.

Uses ER40 collets, capable of holding any tool with a shank diameter up to 26mm.

This spindle can hold four different tools (e.g., planing tool, straight milling cutter, engraving tool, round-nose bottom cutter). Combined with the 5-axis control system, it can automatically rotate to switch tools or perform machining at tilted angles during operation.

5. Powerful 5-Axis RTCP Control System

Utilizes a LNC (Taiwan) control system supporting 5-axis (X/Y/Z/A/B) simultaneous control and the RTCP (Rotation Tool Center Point) function.

Capable of meeting various complex machining needs, including 5-axis turn-mill combination and 5-axis simultaneous engraving.

The system supports machining simulation, G-code editing, and includes a pulse handwheel.

It allows input of multiple program segments for continuous processing, supports multiple language switching, and is compatible with various CAD/CAM software. The interface is intuitive and user-friendly.

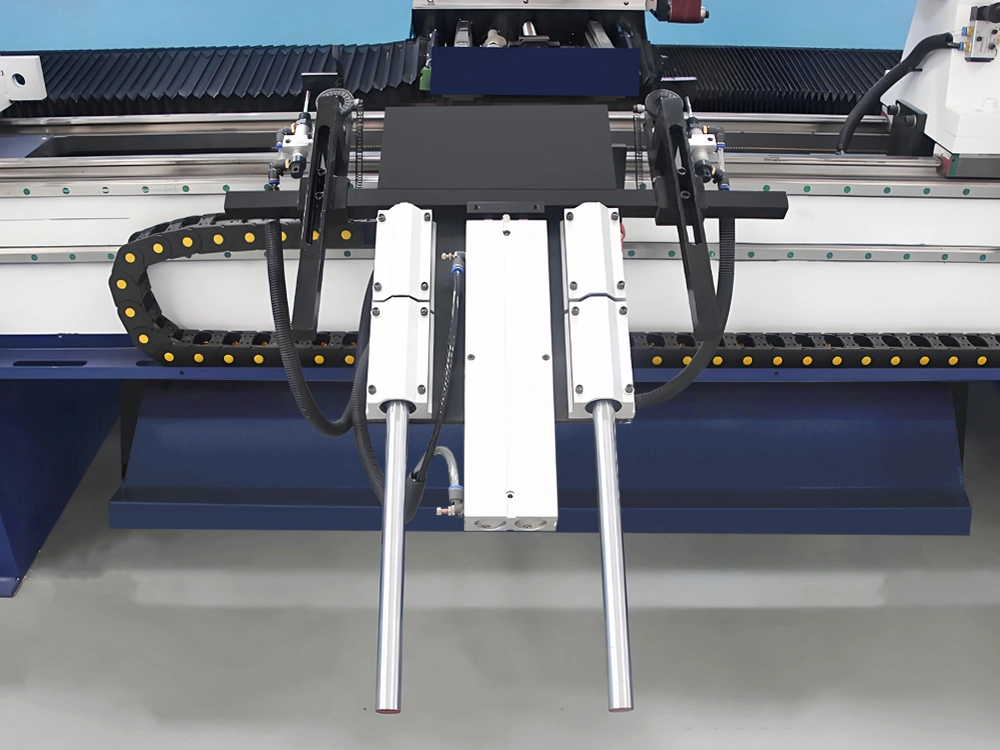

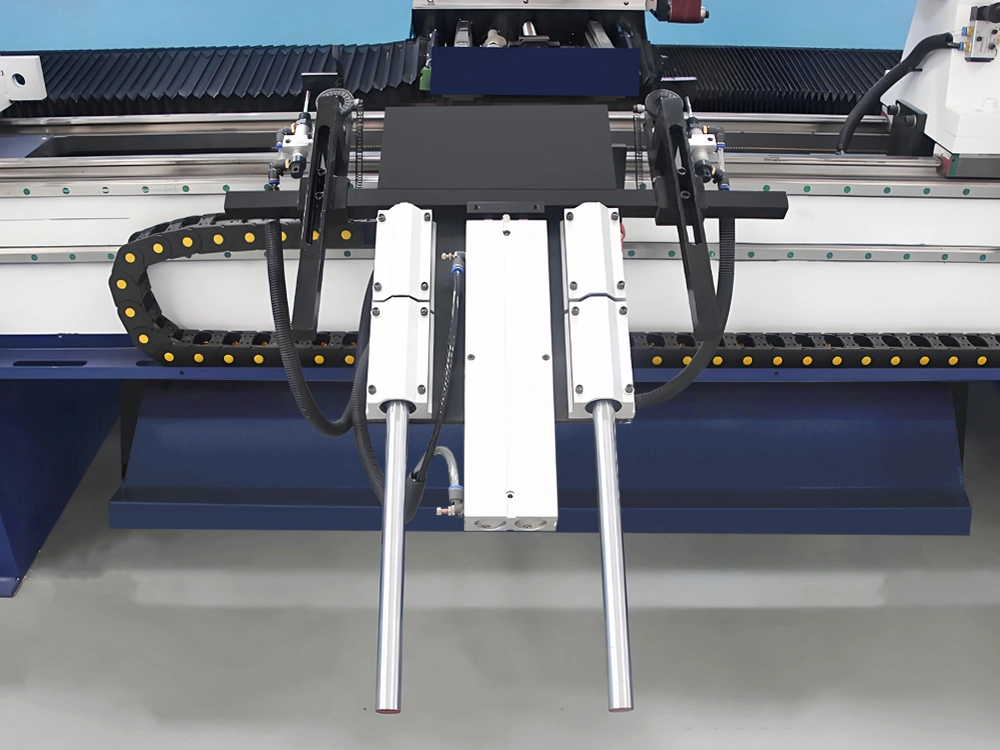

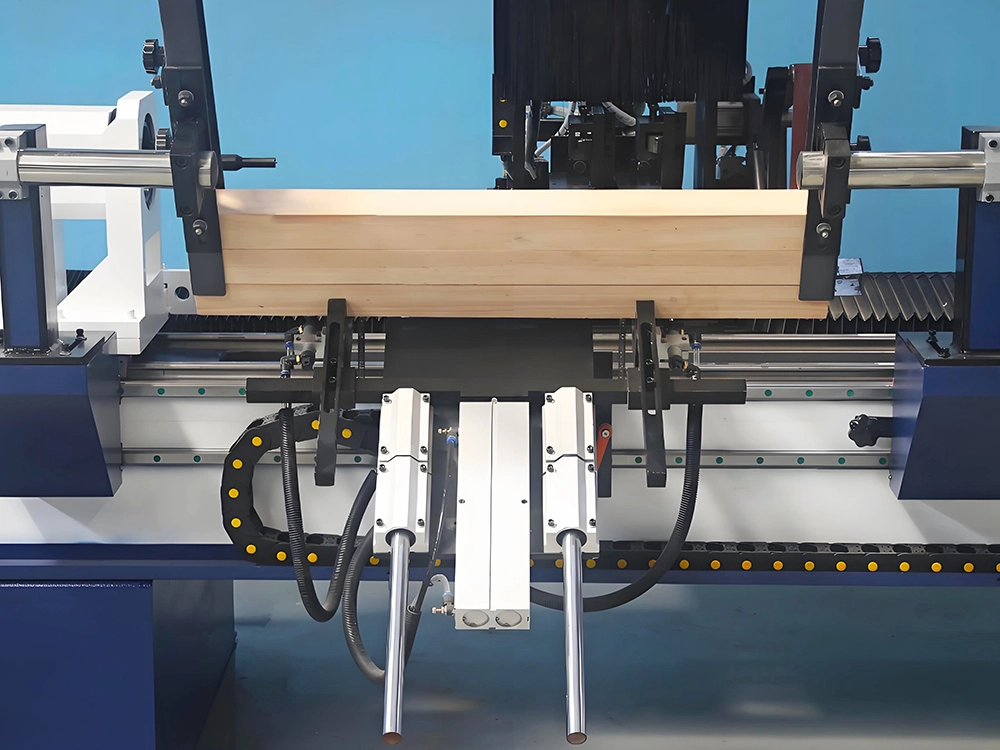

6. User-Friendly Automatic Feeding System

Equipped with a pneumatic heavy-duty four-bar linkage automatic feeding device, paired with a material bin that can hold multiple workpieces.

Operation is simple, just adjust the feeding device according to the raw material size, place a batch of materials into the bin, and start automatic batch processing.

Once started, the control system automatically secures the material and begins machining. After completion, the finished product is automatically unloaded to the receiving device below via an unloading cylinder.

The entire process is fully automated, requires no manual intervention, allowing one operator to manage multiple machines, saving labor costs.

Details of The Most Powerful 5-Axis CNC Wood Lathe

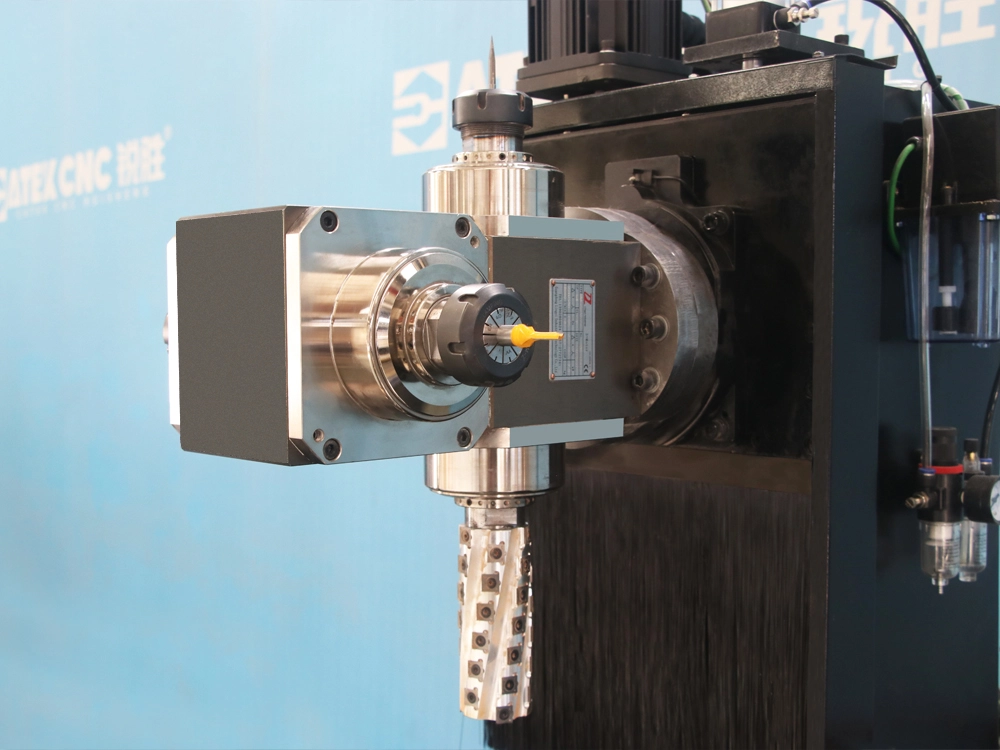

- Special four-head electric spindle for 5-axis CNC machining center

-

Adopts an integrated structural design, using compressed air as the cooling medium; compared to ordinary air cooling, the cooling efficiency is significantly improved, effectively controlling temperature rise during high-speed operation.

The maximum speed of the electric spindle reaches 18,000 rpm, equipped with an ER40 tool holder, capable of assembling four different types of tools at once.

During the machining process, it can both automatically rotate and switch tools according to the drawings and achieve ±90-degree tilt adjustment, easily completing complex processes such as drilling, grooving, and carving on inclined and vertical surfaces of the workpiece.

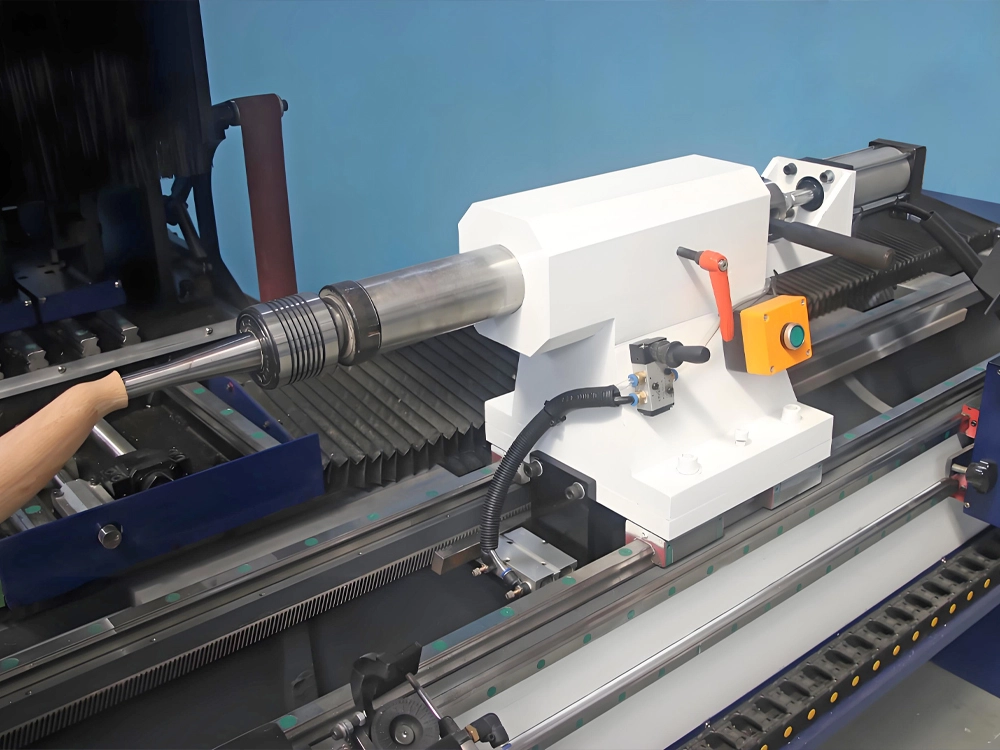

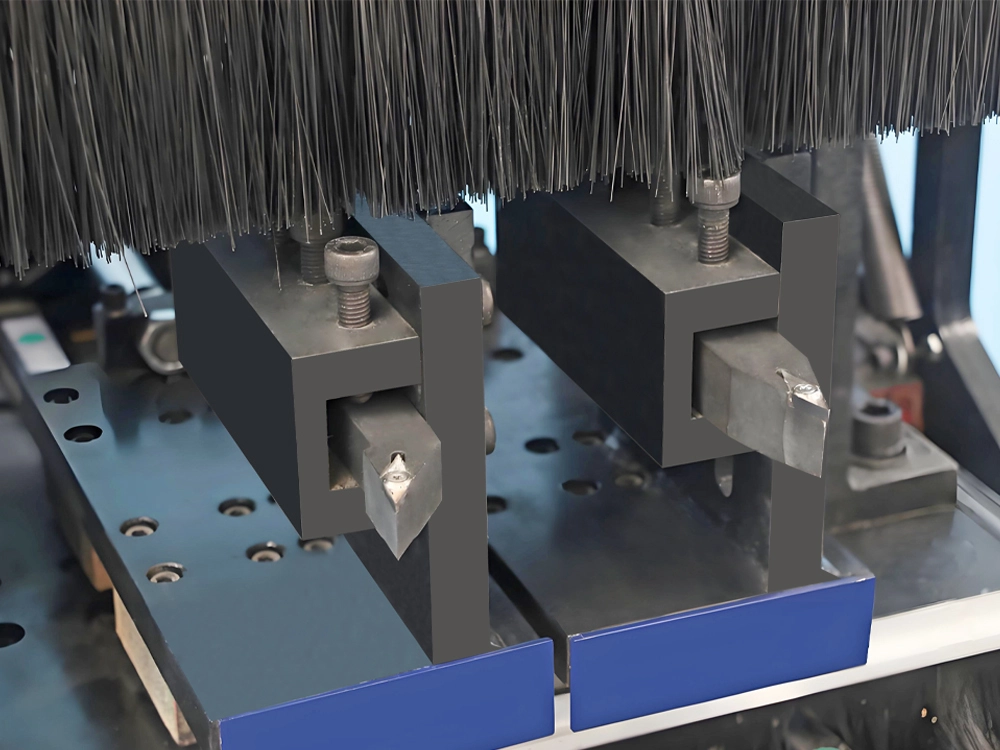

- Turning tools

-

Equipped with two turning tool installation positions, switching control is achieved by cylinders. The two installation positions can accommodate various functional tools such as V-type turning tools, U-type turning tools, O-type turning tools, and cut-off tools. During processing, they can automatic switching is performed according to workpiece requirements, meeting diverse turning processing needs.

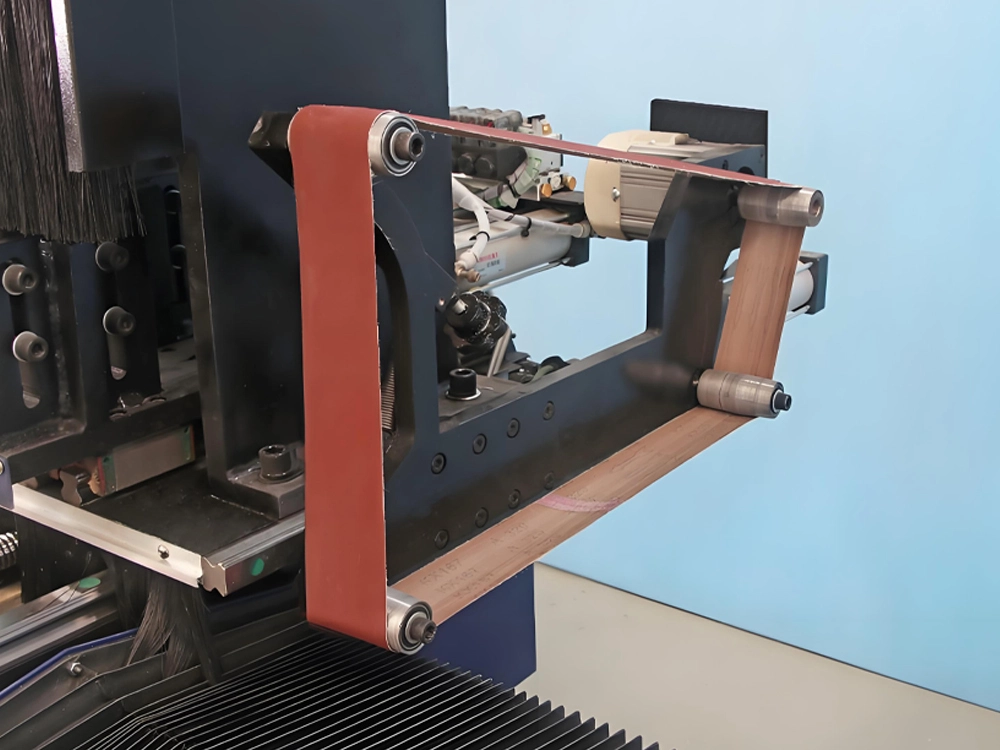

- Sanding device

-

Equipped with a sanding belt device for polishing, driven by a 1100W brushless servo motor, the maximum speed can reach 6,000 r/min, and the speed can be arbitrarily adjusted according to polishing requirements. Polishing grinding wheels and reciprocating sanding devices are provided as optional accessories, and sandpaper grit size can also be selected as needed.

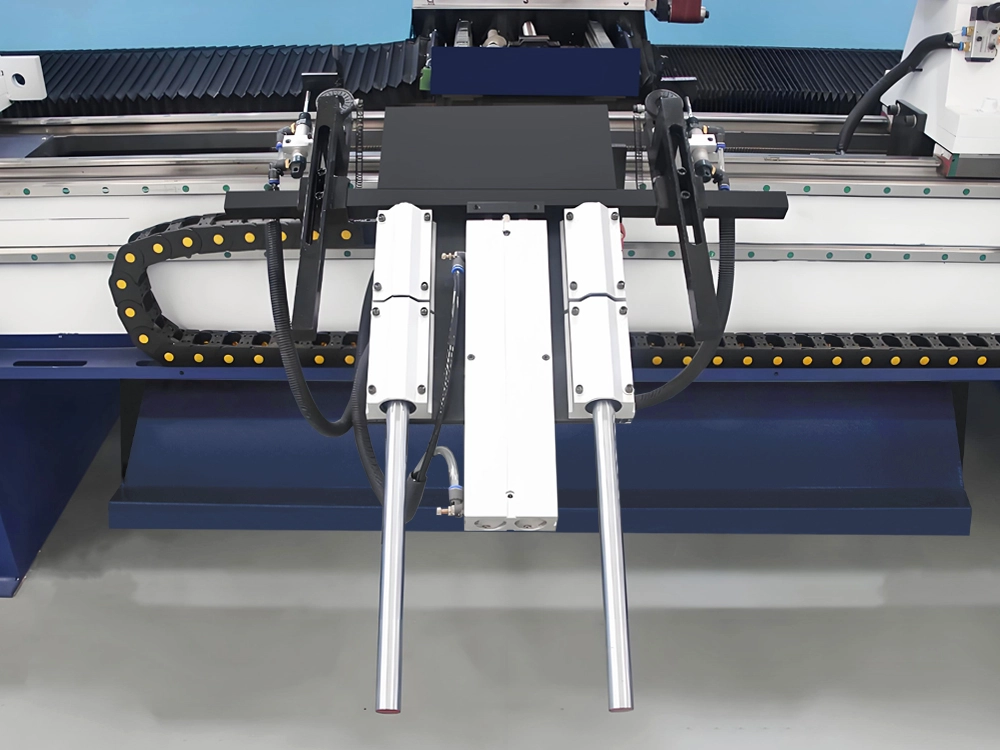

- Automatic feeding system

-

Utilizes a heavy-duty pneumatic four-bar linkage feeding structure, realizing the feeding function through multi-cylinder linkage, and relevant parameters can be self-adjusted according to the different sizes of raw materials, the adjustment operation is simple and convenient, and the operation process is stable and reliable.

The large-sized hopper is made by hot bending forming process, and its good structural integrity makes it more durable.

- 1500W bus-type absolute servo motor

-

The entire machine adopts 1500W bus-type absolute servo motors for drive; compared to ordinary pulse-type servo motors, it possesses higher operational stability and anti-interference capability, better adapting to the high requirements of the 5-axis CNC wood lathe for machining precision and multi-axis synchronization.

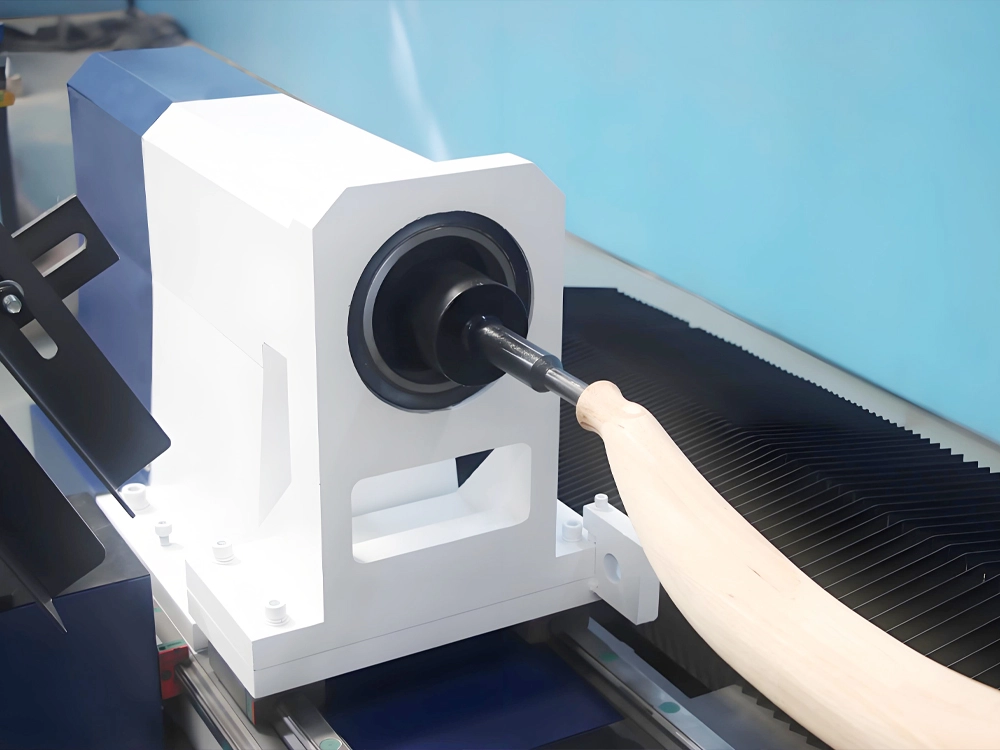

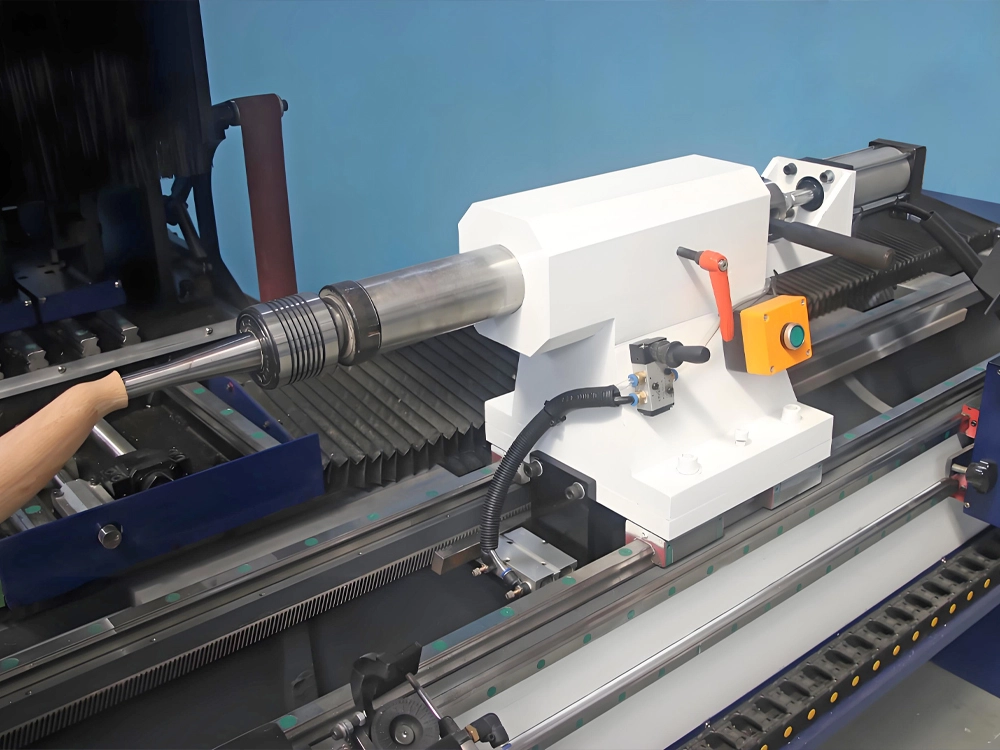

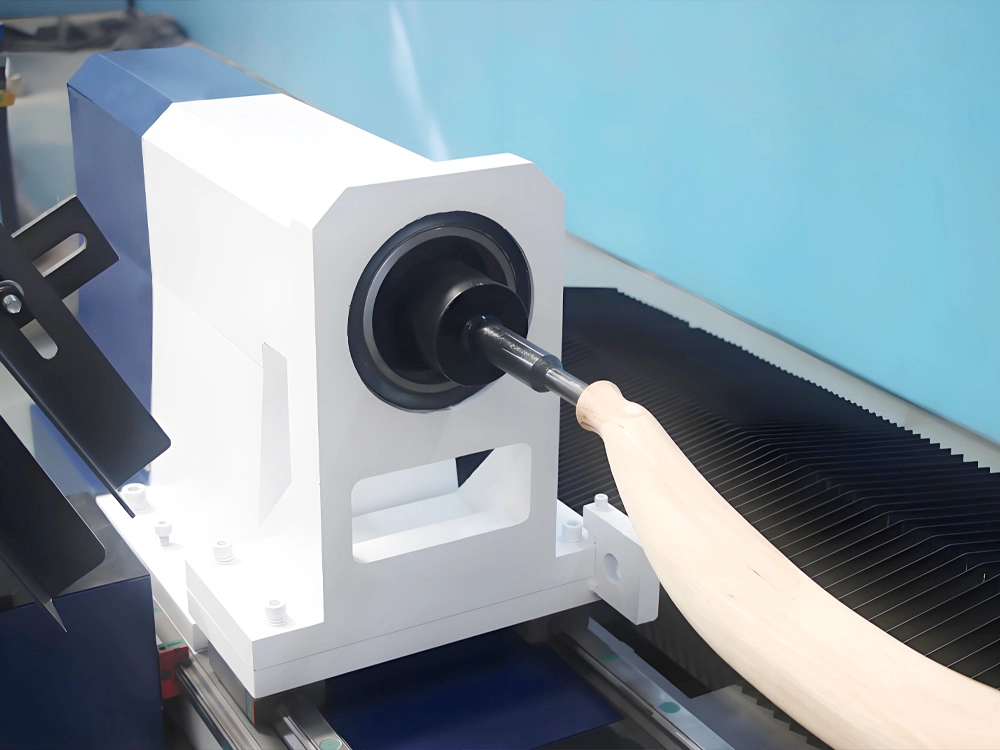

- Headstock

-

The entire unit is cast from gray cast iron, housing four high-strength bearings inside, which can better distribute load forces, effectively reduce rotational friction, provide higher rotational accuracy, and more stable speeds.

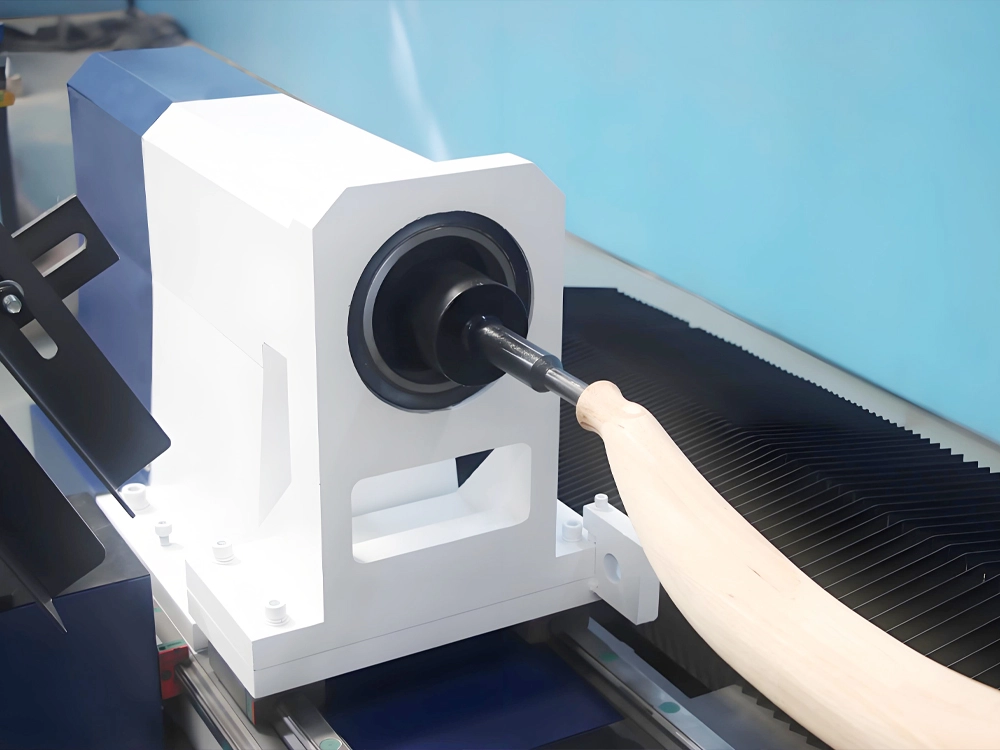

- Tailstock

-

The entire unit is cast from gray cast iron, the center shaft uses a Morse Taper #5 live center, and is equipped with a pneumatic locking device, making it convenient to use.

- Taiwan HIWIN guideways

-

Z-axis equipped with four Taiwan HIWIN 30mm linear guideways / linear bearings, providing better high-speed stability. Coordinating with the servo motors, the movement speed can reach over 60,000 mm/min, and noise is lower.

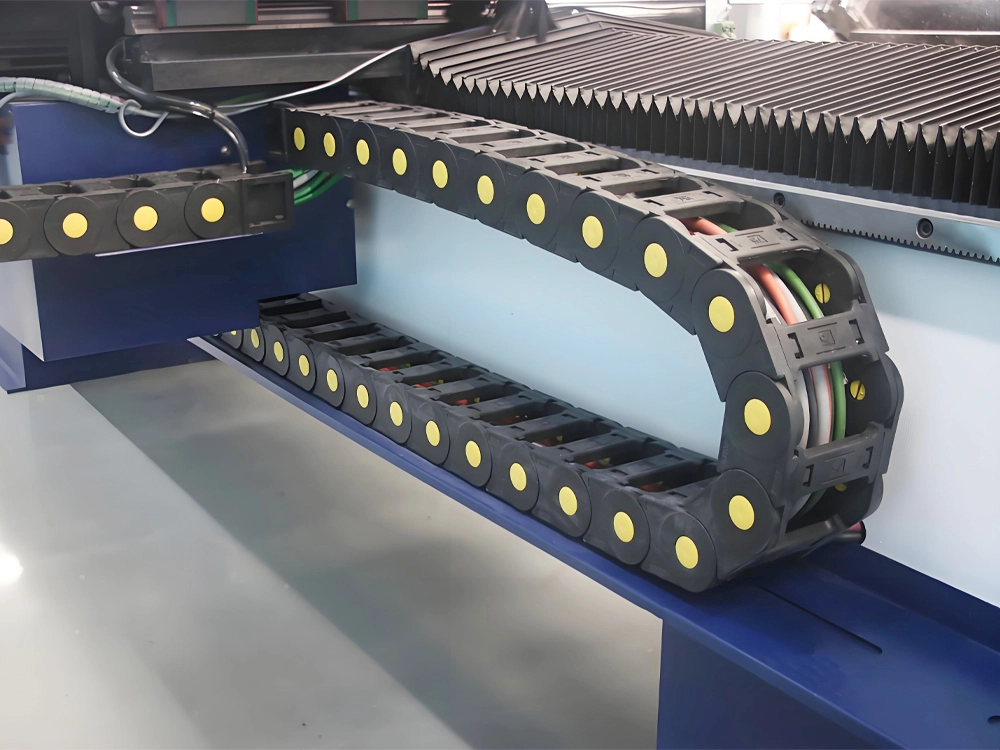

- High-strength cable carriers (drag chains):

-

Uses high-strength, impact-resistant cable protection carriers, featuring high structural strength, effectively protecting cables from damage, and avoiding cable breakage caused by friction, stretching, or dust intrusion.

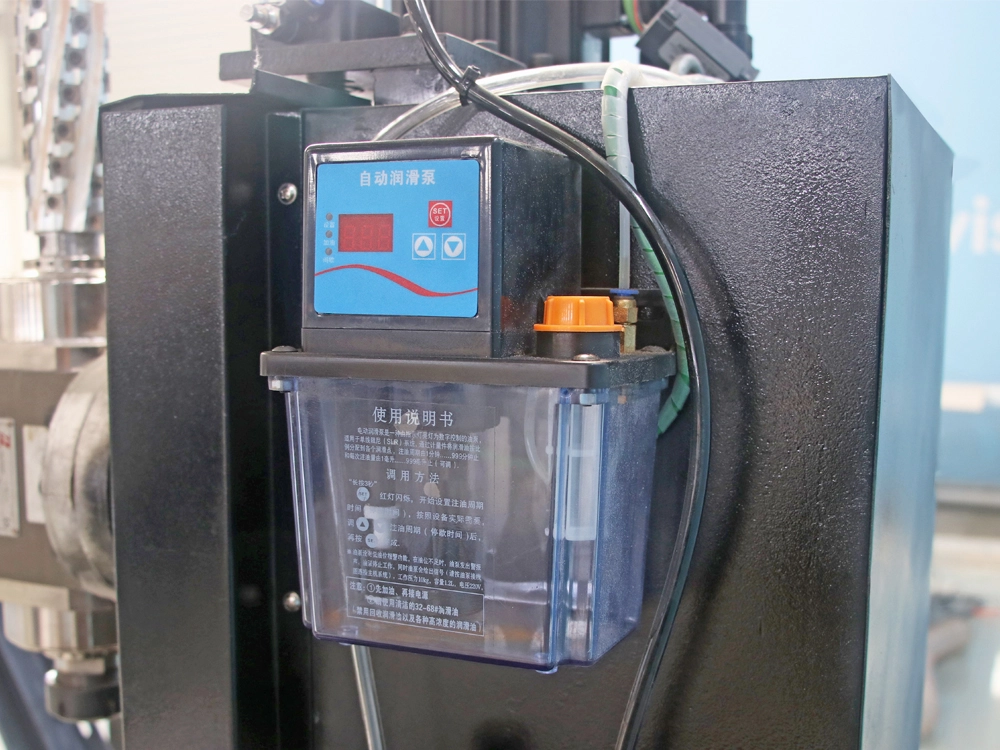

- Electric timed lubrication system

-

Equipped with a fully automatic electric timed lubrication maintenance system, the lubrication interval can be set according to the machine's usage frequency, automatically providing timed, quantitative, and precise lubrication for the machine's transmission system, completely avoiding situations where manual lubrication is untimely.

- Taiwan LNC control system

-

Equipped with a specialized Taiwan LNC control system for 5-axis lathes, supporting advanced functions such as 5-axis RTCP and handwheel simulation operation processing; supports multiple language switching, features a friendly interface; paired with a 5-axis pulse handwheel, operation is convenient and easier to master.

Technical Parameters of The Most Powerful 5-Axis CNC Wood Lathe

| Model | CK-1530-7T-5AXIS |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | Bus-type absolute 1500W servo motor |

| Fifth Rotary Axis Drive Motor | Bus-type absolute 750W servo motor |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X, Y axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Reducer | Shimpo (Japan) planetary gear reducer |

| Variable Frequency Drive | Hpmont frequency converter/servo frequency converter |

| Drive-Spindle Motor | 4KW pure servo high-torque and high-speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Turning Tool | Two mounting positions for turning tools |

| Multi-functional Spindle | 7.5KW high-speed air-cooled four-head spindle (supports 5-axis RTCP) |

| Multi-functional Spindle Speed | 0-18000r/min |

| Multi-functional Spindle Collet | ER40 φ26mm |

| Sanding Device | Independent 1100W variable frequency servo motor control, replaceable sanding belt, selectable sandpaper grit |

| Sanding Device Speed | 0-6000r/min |

| Automatic Loading and Unloading | Four-bar linkage cylinder loading/unloading device (simple and easy to use) |

| Control System | Taiwan LNC control system |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactors, relays, circuit breakers |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, Type3, AutoCAD, CDR, Carving, Powermill, UG, Mastercam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | XYZB four-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2300kg |

| Dimensions | 3750*2150*2150mm |

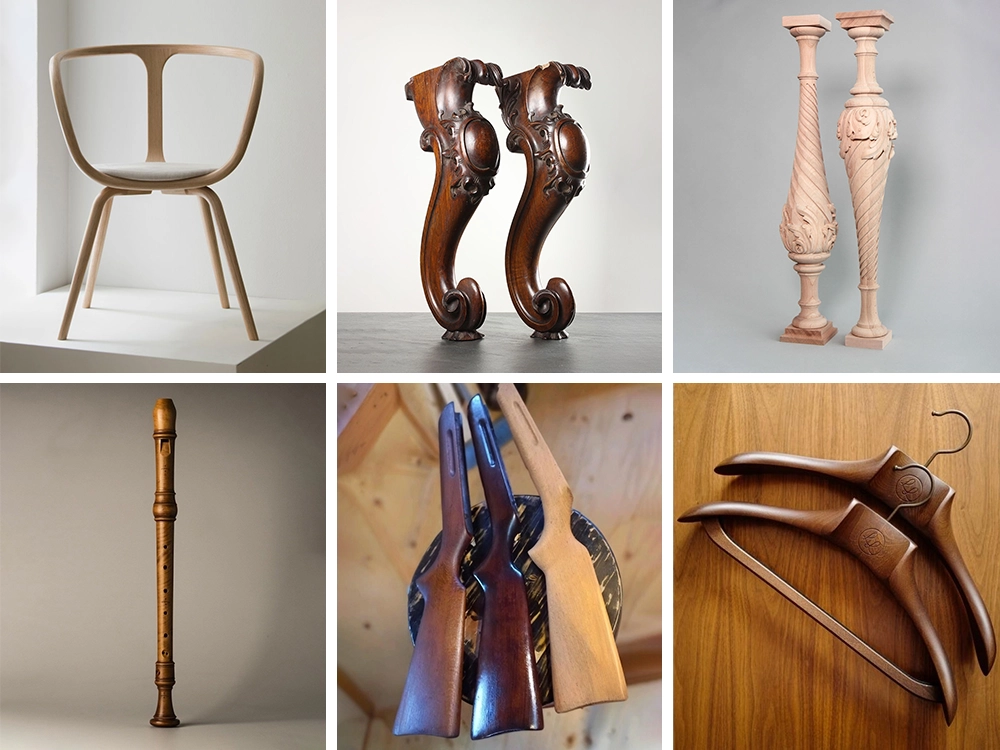

Application Scope of The Multi-functional 5-axis CNC Wood Lathe

With capabilities such as 5-axis RTCP linkage, high-precision control, and multi-functional automatic switching, the 5-axis multi-functional CNC wood lathe meets the full-scenario processing needs from ordinary wooden products to complex special-shaped crafts. Its application scope covers various industries, including furniture manufacturing, musical instrument production, custom crafts, architectural decoration, and more.

-

Furniture manufacturing industry: Special-shaped surfaces, curved and wave-shaped table legs, chair legs, sofa legs, bedposts, headboards, chair backs, chair tops, sofa armrests, chair armrests, European-style relief patterns, multi-faceted chamfering, S-shaped curves, diagonal grooves, angled drilling, and various types of furniture legs and components.

-

Architectural decoration industry: Stair balusters, Roman columns, wall decoration carvings, special-shaped carving accessories for doors and windows, wooden hangers, etc.

-

Musical instrument manufacturing: Various types of string instrument components, guitar necks, violin fingerboards, flutes, bassoon parts, and other musical instrument accessories.

-

Craft Manufacturing: Rifle stocks, character sculptures, animal sculptures, vases, antique furniture, artistic ornaments, etc.

Frequently Asked Questions

- 1. What voltage does the 5-axis CNC wood lathe support?

- The machine standardly supports 380V. If you have special voltage requirements, such as 220V/230V/415V/440V, etc., we can also provide customized voltage services.

- 2. What is the maximum processing length and diameter of the 5-axis CNC wood lathe, and can it be customized?

- The standard configuration supports a processing length of 1500mm and a processing diameter of 300mm. If you require other processing dimensions, we can customize it for you.

- 3. Can additional functions be installed on the 5-axis CNC wood lathe?

- We provide comprehensive customization services. You can select additional functions based on your needs. We offer various configurations such as saw-milling units, sanding wheels, traversing sanding units, chucks, and fully enclosed protective covers. If you would like more detailed information, please contact us.

- 4. How is the lathe delivered?

- After the machine is manufactured, we conduct thorough debugging and package it once everything is confirmed to be in order. We use three-layer packaging—waterproof film, anti-impact foam, and export-grade fumigation-free wooden crates, and transport it via land or sea freight to ensure the machine arrives intact at its destination.

- 5. How long is the production cycle?

- The production cycle for the 5-axis CNC wood lathe typically takes around 20 working days. However, we can also prioritize your order for faster delivery.

- 6. How difficult is it to learn to use the five-axis CNC wood lathe for beginners?

- Whether you are new to CNC or an experienced expert, you can easily operate this CNC wood lathe. We provide 7*24 after-sales service, and our team of professional engineers offers comprehensive technical support—from machine programming and operation training to daily maintenance guidanc, assisting you in mastering the equipment and ensuring a smooth and worry-free production process.

- 7. What should I do if the machine breaks down?

- CATEKCNC provides a three-year free warranty and lifelong free maintenance. If the machine encounters any issues, you can contact our engineers for troubleshooting. Once the problem is confirmed, we will ship new replacement parts to you via express delivery for your replacement.

| Model | CK-1530-7T-5AXIS |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | Bus-type absolute 1500W servo motor |

| Fifth Rotary Axis Drive Motor | Bus-type absolute 750W servo motor |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X, Y axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Reducer | Shimpo (Japan) planetary gear reducer |

| Variable Frequency Drive | Hpmont frequency converter/servo frequency converter |

| Drive-Spindle Motor | 4KW pure servo high-torque and high-speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Turning Tool | Two mounting positions for turning tools |

| Multi-functional Spindle | 7.5KW high-speed air-cooled four-head spindle (supports 5-axis RTCP) |

| Multi-functional Spindle Speed | 0-18000r/min |

| Multi-functional Spindle Collet | ER40 φ26mm |

| Sanding Device | Independent 1100W variable frequency servo motor control, replaceable sanding belt, selectable sandpaper grit |

| Sanding Device Speed | 0-6000r/min |

| Automatic Loading and Unloading | Four-bar linkage cylinder loading/unloading device (simple and easy to use) |

| Control System | Taiwan LNC control system |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactors, relays, circuit breakers |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, Type3, AutoCAD, CDR, Carving, Powermill, UG, Mastercam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | XYZB four-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2300kg |

| Dimensions | 3750*2150*2150mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.