2026 Top Rated Highest Specification CNC Wood Lathe

2026 Best Multi-Function 8-in-1 CNC Wood Lathe for Sale

[Function Description]

What Is a Heavy Duty 8-in-1 Multifunctional CNC Woodworking Machine?

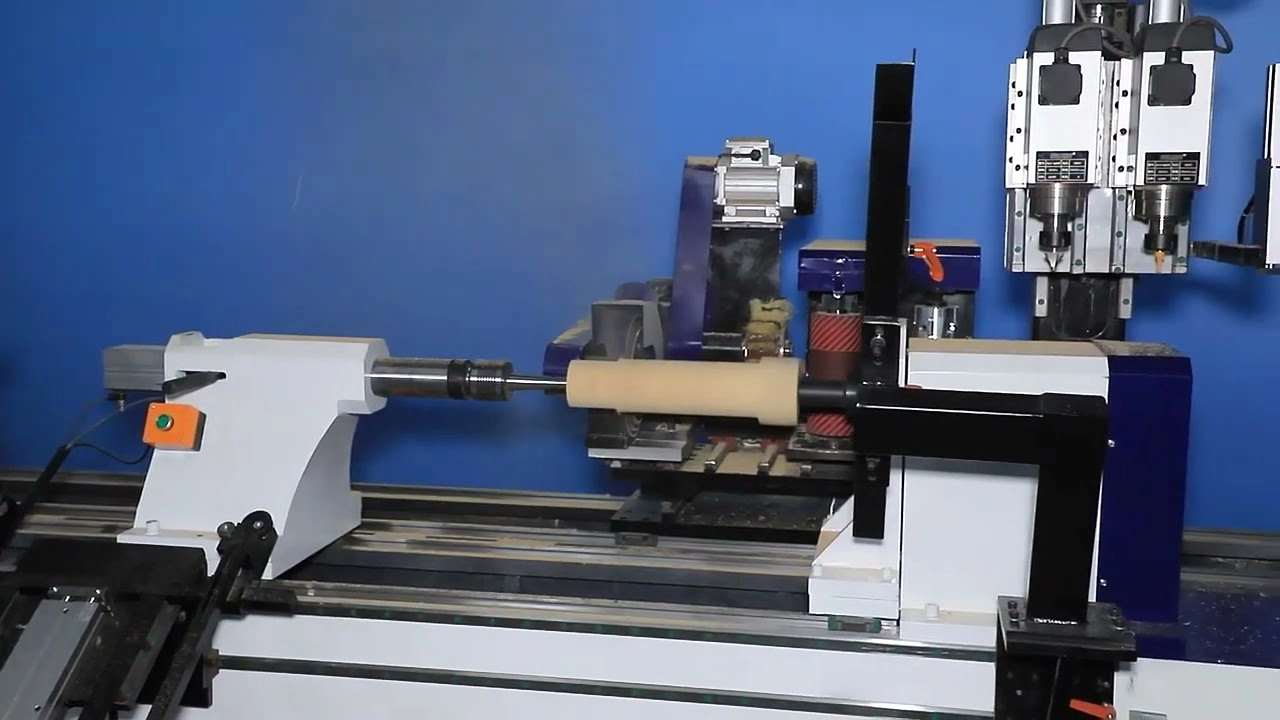

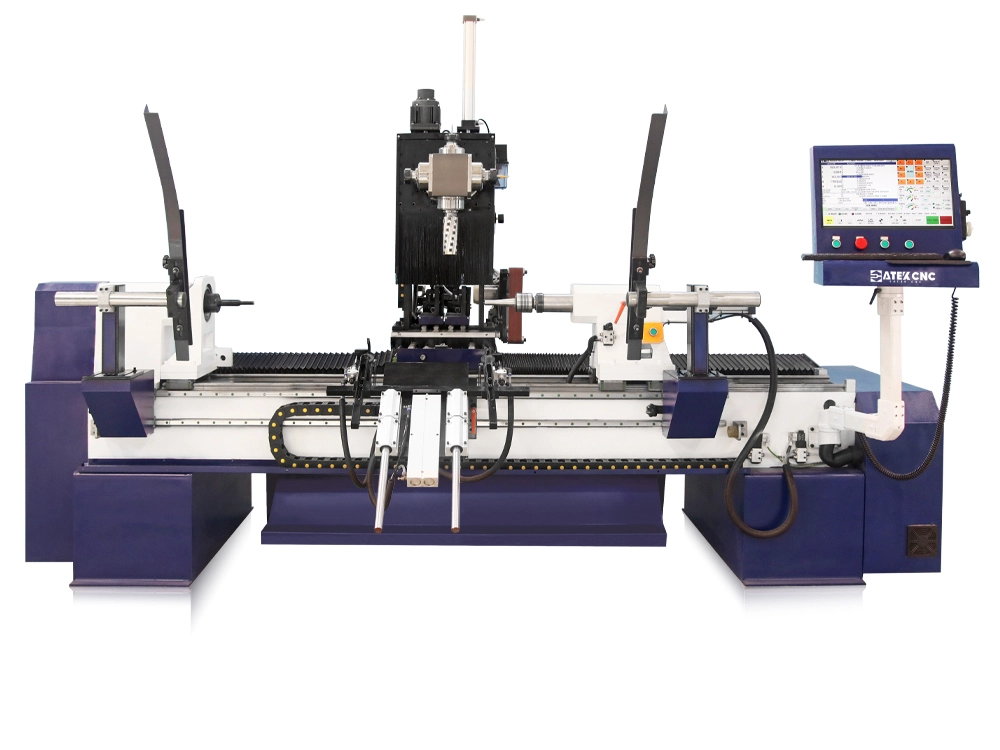

CK-1530-8T is the most advanced super CNC woodworking machine that combines multiple functional kits such as turning tools, multi-function spindles, planers, sanding and polishing devices, saw blades, automatic feeding systems, etc. It is mainly used for the processing of complex wooden products. By combining other functions such as turning and milling, a multi-process composite processing method is realized. In modern society, labor costs continue to increase, and people's appreciation of the appearance of wooden products continues to improve. The modern wood processing industry has put forward higher requirements for the processing efficiency, processing accuracy, versatility and degree of automation of machines. The multi-function CNC wood lathe does not simply merge turning and other processing functions into one machine tool, but uses an intelligent CNC system to control all functions of the machine tool. After the workpiece is clamped once, all processes can be completed automatically, realizing the processing concept without manual secondary intervention.

The multi-function CNC wood lathe can complete all or most of the processing procedures by clamping the material once, effectively shortening the product manufacturing process chain, reducing the trouble caused by subsequent processing, and significantly improving production efficiency. And because the number of clamping times is reduced, the error caused by multiple clamping of materials is avoided, the processing accuracy of the product is improved, and the qualified rate of the finished product is guaranteed. A multiple functional 8-in-1 woodworking CNC lathe can complete the work of more than 5 single-function woodworking machines at a time, and can complete the turning, drilling, milling, pattern carving, sanding and polishing of a complex product at one time, effectively saving labor, reducing the floor space occupied by other machines, and reducing investment costs as well as production operation and management costs.

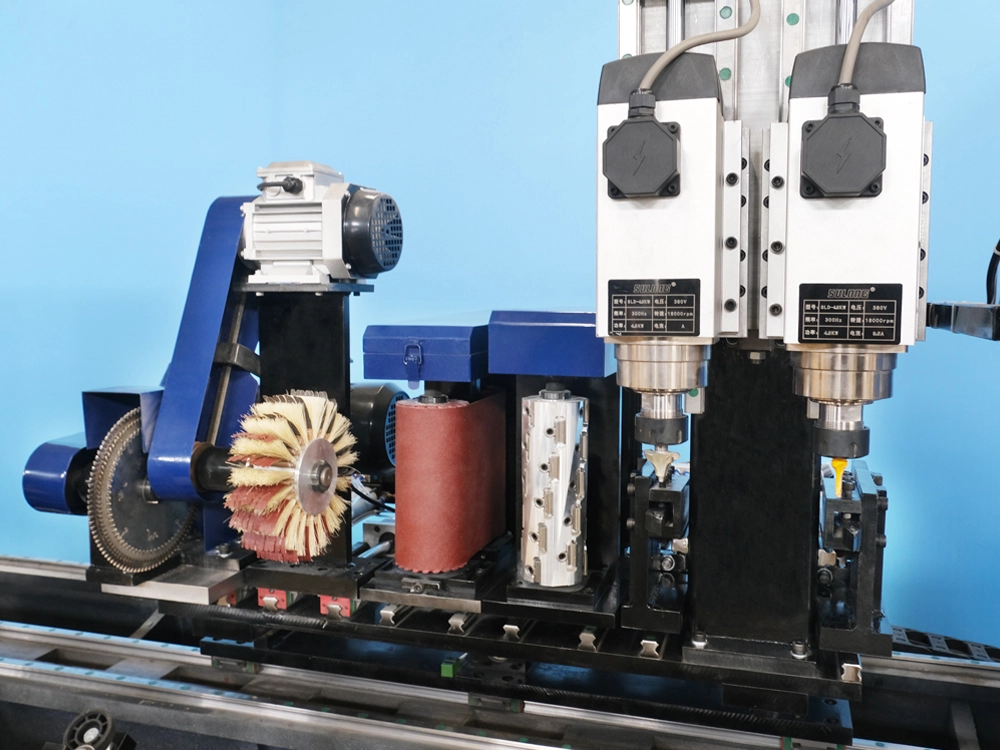

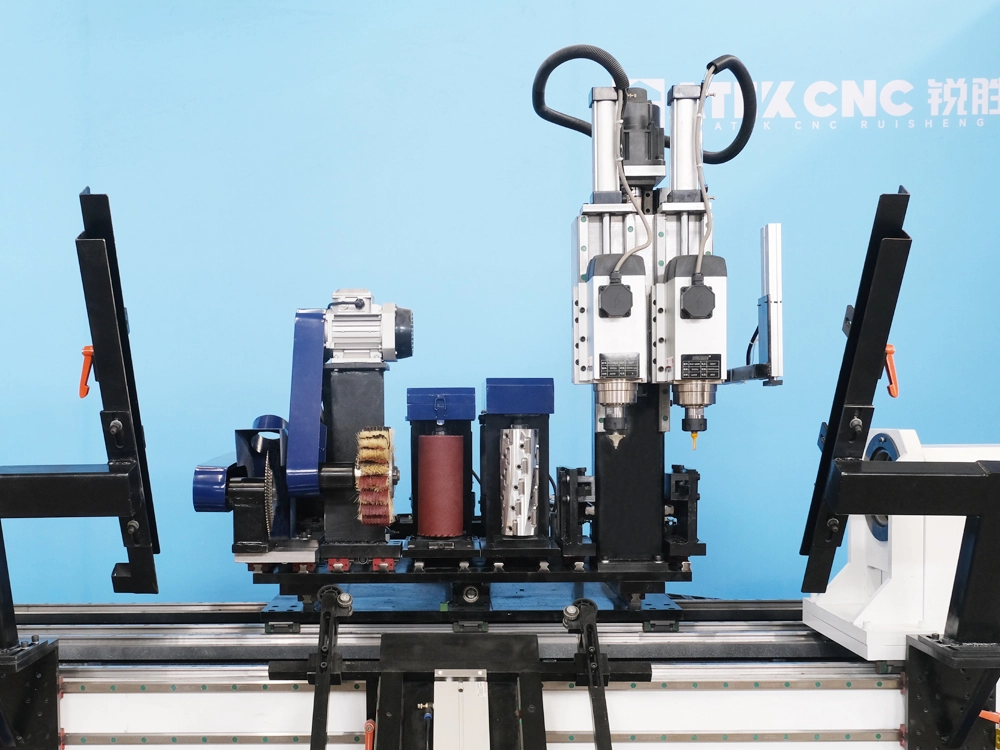

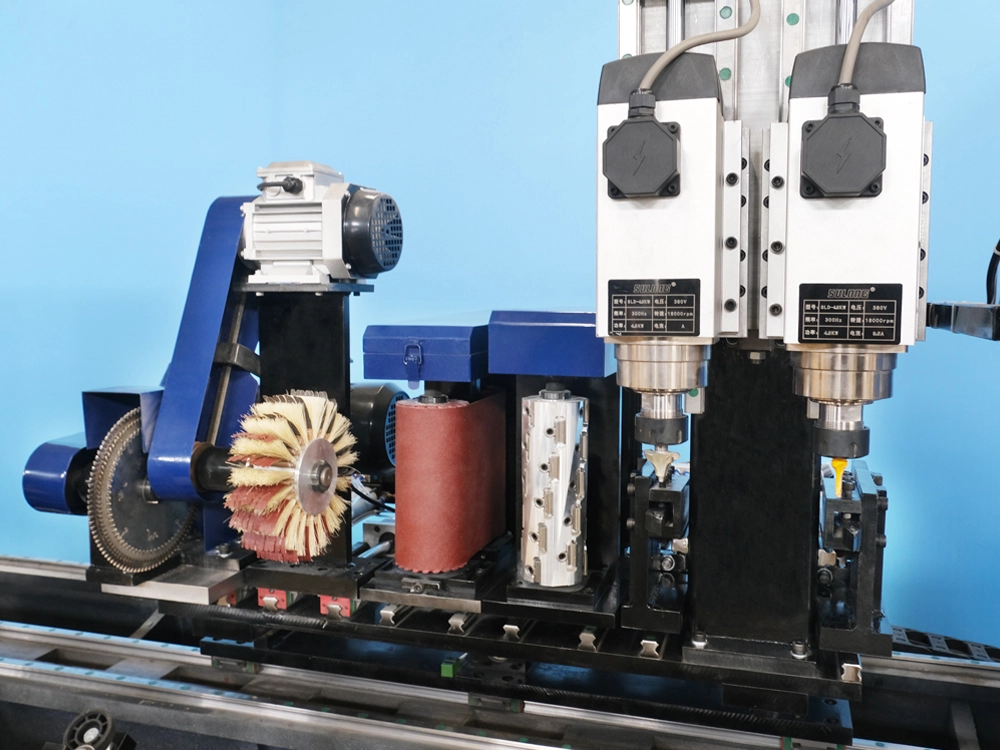

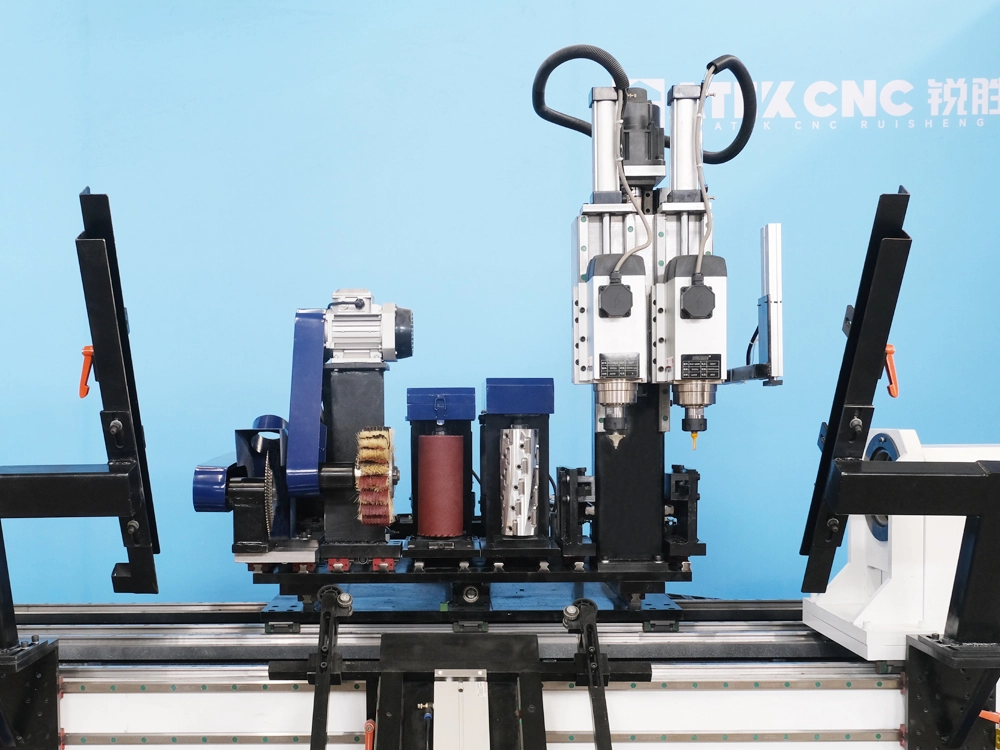

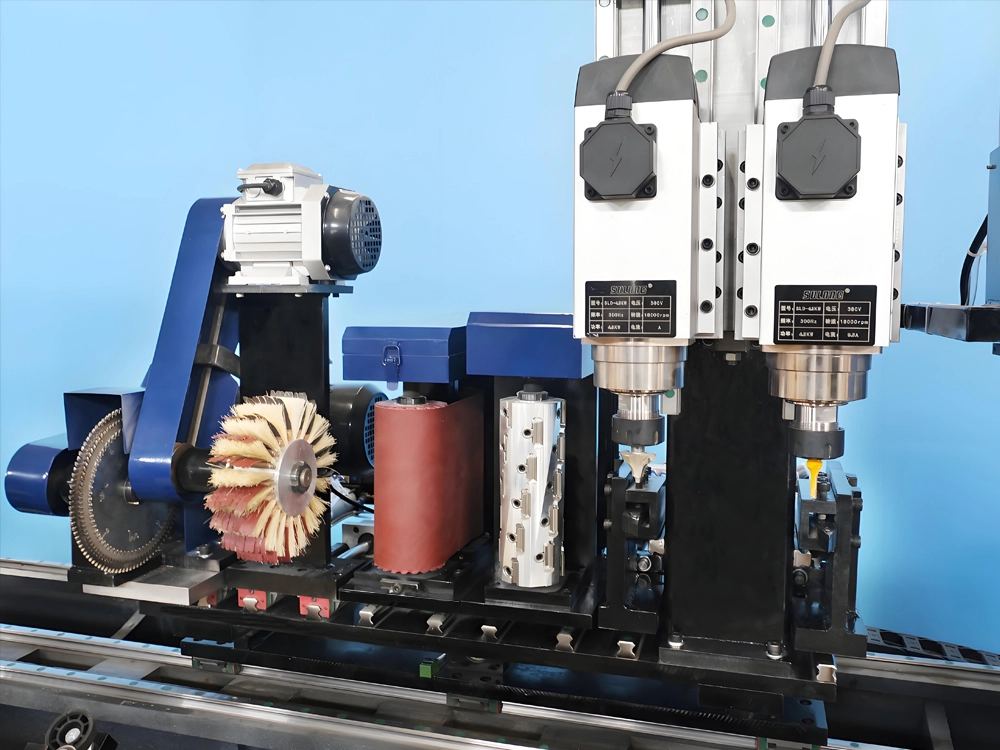

Functional Package of Top Heavy-Duty 8-in-1 CNC Woodworking Processing Center

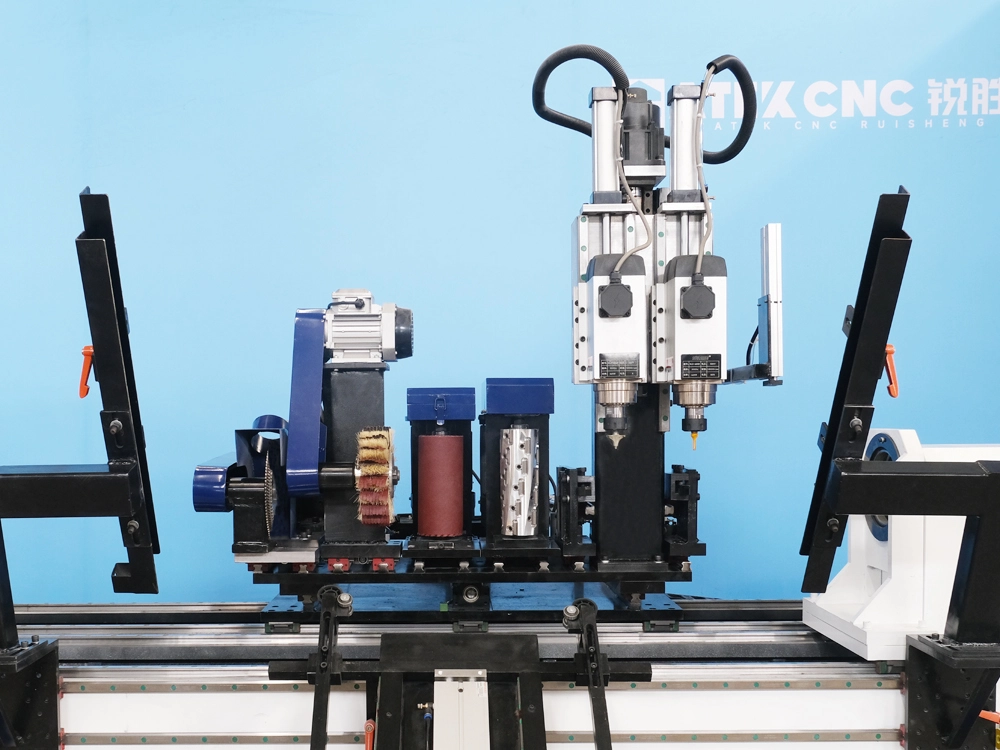

- V-type alloy turning tool: Use double-edged V-type alloy turning tool with large cutting capacity, which can turn more than 50mm of wood at a time.

- Right-angle turning tool: 90-degree right-angle turning tool, specially used for processing some vertical steps.

- Planer: High-speed helical planer with 230 mm height and 90 mm diameter for surfacing, milling, planing and other work.

- Sanding wheel: 230mm diameter, 50mm thickness sisal sanding wheel, good sanding effect, high finish, suitable for most sanding scenarios.

- Sanding roller: using a 230mm height oscillating sandpaper, it can be used for sanding flat surfaces, round rods, and other types of products.

- Saw blade: 230mm diameter multi-blade V-shaped saw blade is used, controlled by three-phase asynchronous motor, which can be used for wood roughing, milling and other processing.

- Spindle: using two 4.5KW high-speed air-cooled spindles, driven by servo motors, it can realize four-axis, four-linkage machining, and the two spindles can clamp different knives for milling grooves, engraving, punching holes in the material, and so on.

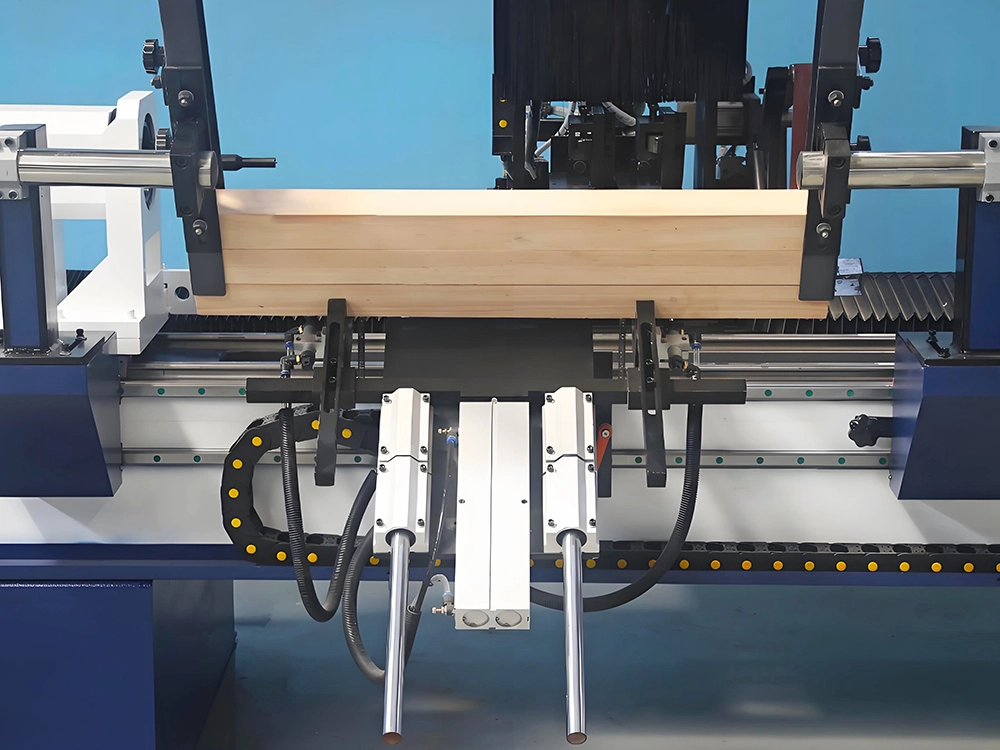

- Automatic feeding: Multi-cylinder linkage automatic loading and unloading, you can adjust the size of loading material, automatic unloading after processing is completed.

Advantages of 8-in-1 Multifunctional CNC Wood Lathe

Complete functions: It has various functions: turning, grinding, planing, milling, slotting, drilling, 3D engraving, automatic feeding, etc.

Simple operation: It adopts advanced fully automatic CNC system control, equipped with high-precision screw and grinding grade helical rack and Taiwan Hiwin guide rail/slide, and each axis is driven by servo motor, which runs fast and smoothly.

Reducing production costs: The high efficiency and high degree of automation of CNC woodworking lathes can greatly reduce production costs, and can improve the quality and fineness of products, making products more competitive.

Simplifying production process: It effectively reduces many auxiliary molds and fixtures used in the production process and simplifies the production process. At the same time, due to the cheap price of CNC tools, the production cost is further reduced.

Strong adaptability: It has excellent adaptability to the processing object, and only needs to reprogram to realize the processing of new products. There is no need to prepare in advance, nor to replace various tools, fixtures and gauges during the processing process. You only need to recalibrate the tool and import the drawing. It is highly flexible and is particularly suitable for mass production of small and medium-sized wood enterprises. It can flexibly set the shape at any time, quickly change the processing style, and improve production efficiency.

High processing accuracy: The CNC system controls the tool to process according to the preset program, which can achieve an extremely high processing accuracy of 0.01mm and save more labor.

Environmental protection: A double-barrel bag dust collector can be optionally equipped to achieve dust removal while processing, making the processing process healthier and more environmentally friendly.

Energy saving: Only electric drive is required during the processing, and no other energy is required. The machine has a built-in transformer and inverter to convert the voltage, which saves more power during processing.

Detailed Introduction of 8-in-1 Composite CNC Wood Lathe

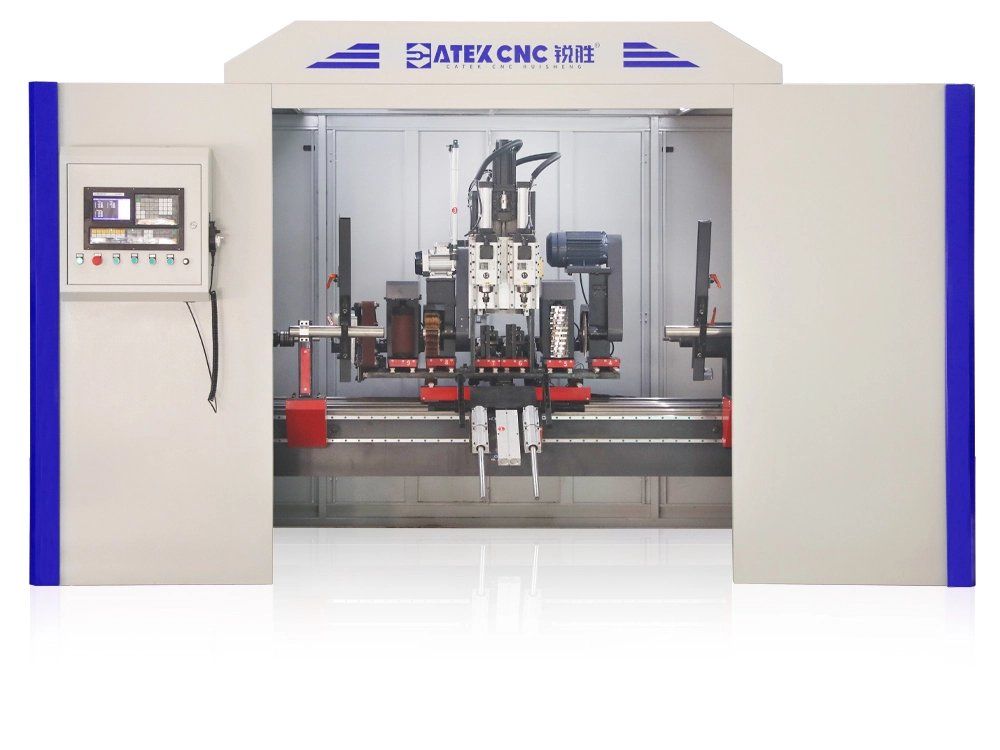

- Bed

The whole machine adopts super strong full casting side by side heavy double bed, the machine weight is close to 2500kg, and the processing and use are more stable.

- Functional package

V-type turning tools, right-angle tools, saw blades, sandng wheels, sandng rollers, planers, milling spindles, hopper automatic feed.

The large-sized hopper is made by hot bending forming process, and its good structural integrity makes it more durable.

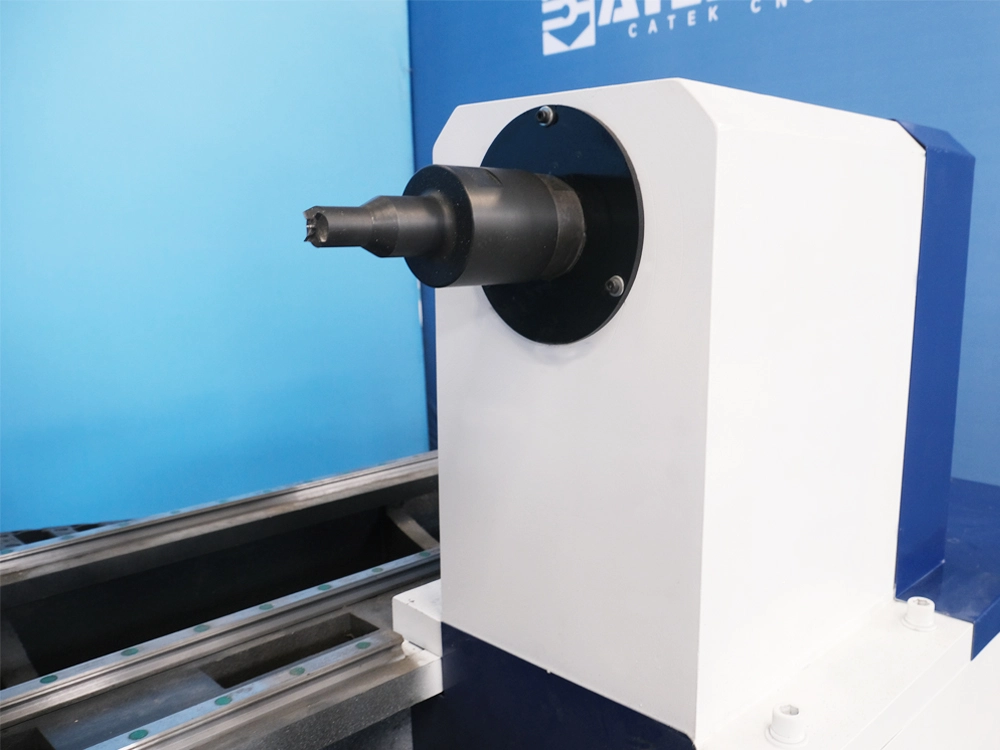

- Headstock and tailstock

- Control cabinet

Use an independent control cabinet to connect and control the machine, which has strong anti-interference ability and can cope with various complex environments.

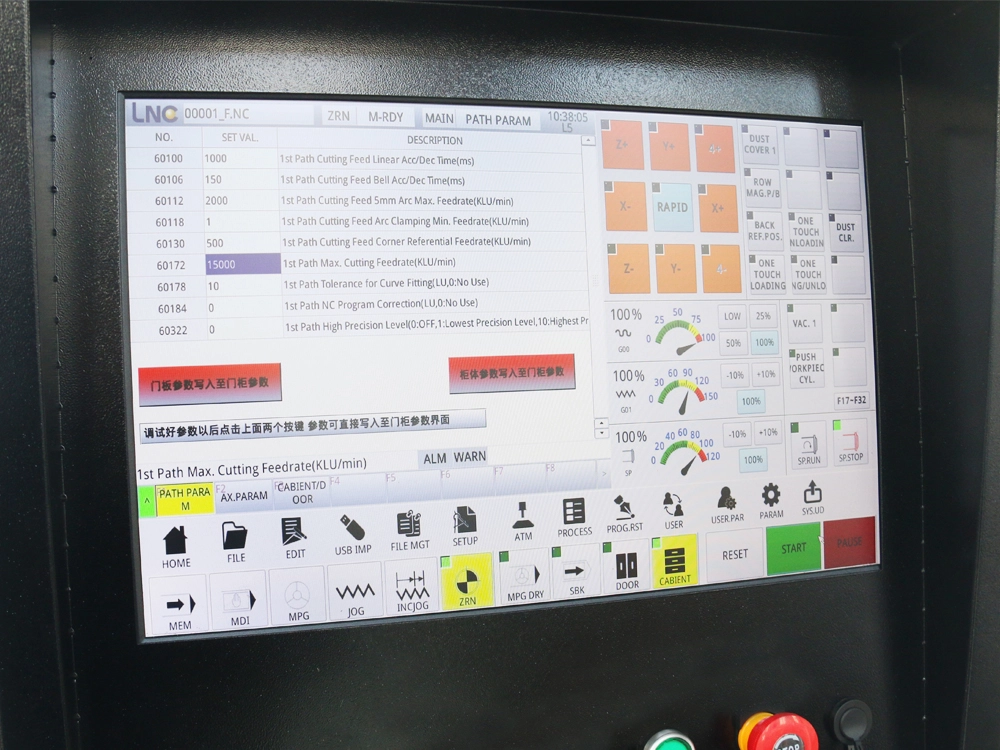

- Control system

Taiwan LNC numerical control system, full English operation interface, user-friendly interface display and automated operation, novices can also easily operate it, compatible with various CAD/CAM type software, runs using G code, and supports various formats such as DXF/NC/TXT.

The headstock is made of gray cast iron & equipped with a four-bearing spindle, which makes the rotation more stable and the processing more powerful.

The fully cast tailstock is equipped with a Morse rotary center and a standard stroke cylinder, making it easier to fix the wood and more convenient to use.

Technical Parameters of 8-in-1 Multifunctional Wood CNC Lathe

| Model | CK-1530-8T |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter / pure servo inverter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 4.5KW high-speed air-cooled spindle * 2 (supports four-axis linkage) |

| Spindle Speed | 0-18000r/min |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Turning Tool | V-type alloy turning tool (large cutting capacity) |

| Right Angle Knife | 90 degree V-shaped discard right angle knife |

| Planer | 90*240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230*50mm, independently controlled sanding wheel, 370w three-phase asynchronous motor |

| Sanding Roller | 240mm high movable sanding roller, 2.2KW three-phase asynchronous motor |

| Saw Blades | 230mm diameter multi-piece saw blade, 1.5kw three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 30 straight square rail / 30 flange slider |

| Equipment Cable | Pure copper high-flexible bending-resistant cable |

| Automatic Loading & Unloading | Multi-cylinder 4-linkage fully automatic loading and unloading (simple and easy to use) |

| Control System | Taiwan LNC lathe dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2500kg |

| Dimensions | 3750*2500*1850mm |

| Toolbox | Turning tool, wrench, collet, handwheel, center, chuck, oil pot, oil-water separator, relay, photoelectric limit. |

Application Scope of 8-in-1 Multifunctional CNC Woodworking Machine

Applicable Materials:

Wood: beech, oak, Chinese toon, birch, teak, sapele, ash, bologna, sandalwood, rosewood and other hardwood, softwood and adhesive wood.

Fiber materials: such as medium density fiberboard (MDF), high density fiberboard (HDF), glass fiber, carbon fiber, synthetic fiber, etc.

Composite materials: such as thermosetting and thermoplastic plastics, acrylic, PVC, PCB, resin, etc.

Other materials: including gypsum, asbestos, foam materials, etc.

Applicable Industries:

Furniture manufacturing: It is widely used in furniture manufacturing, mainly used to process various furniture parts, such as chair legs, table legs, bed rails, etc. In addition, the CNC wood lathes can also be used for complex furniture carving, making furniture decorative details and various furniture decorative accessories.

Staircase manufacturing: It can be used for the processing of symmetrical cylindrical products such as stair handrails and stair support feet, and can also be used to process some complex stair Roman columns with grooves and carved with various patterns.

Crafts production: It is also widely used in the crafts industry, such as making beads, cups, bowls, scroll painting heads, various wooden craft toys, etc.

Wood product turning: It can process various types of cylindrical, cone, curved surface, sphere or other complex shaped wooden products.

Complex product milling: Complex special-shaped curved legs such as Queen Anne legs and Chippendale legs, various square, oval, trapezoidal, diamond and other special-shaped products.

The Following Are the Processable Products of 8-in-1 Multifunctional CNC Woodworking Machine

Precautions for the Use of 8-in-1 Multifunctional CNC Woodworking Machine

Preparation before operation: Before operating the CNC wood lathe, you must ensure that all safety measures are in place, including wearing appropriate labor protection supplies, such as work clothes, safety shoes and protective glasses, etc. In addition, the machine's tool fastening and tool wear should be checked to ensure the stability of the equipment.

Programming and debugging: The processed product needs to be programmed before use. If this is the first time to process this type of product, it is recommended to run it first to confirm that the machine tool is working normally and the processed shape is correct before batch processing.

Operation steps: During the operation, the correct operation steps should be followed. For example, when moving the position of each axis, you need to see the signs of the X and Z axes of the machine tool clearly. During the movement, you need to move slowly first, and then speed up after observing that it is correct. In addition, when using handwheels or other quick movement methods, you must also pay attention to the direction of movement of the machine tool.

Maintenance: In order to ensure the long-term and stable operation of the machine tool, regular maintenance is essential, including cleaning the surface of the machine, regularly checking the tightness of the machine belt, and adding lubricating oil. In addition, the lubrication system needs to be inspected and maintained regularly.

Safety precautions:During operation, the cutting tool must be kept sharp to ensure the processing effect. The processing speed should match the material rotation speed, processing volume and material hardness.

Continuous running time: It is recommended that the continuous running time should not exceed 24 hours. Too long continuous operation time will affect the life of the electrical system and some mechanical components.

The bed design and structure of CNC woodworking machine tools are crucial to their performance and stability. The CK-1530-8T uses cast iron to make the bed to improve its wear resistance and stability. The bed design is cast in one go and aging treated to reduce process deformation, thereby greatly improving the stability of the equipment.

The structure of the bed will also affect the layout and performance of the machine. The bed design of CNC machine tools produced by CATEKCNC focuses on material selection, structural optimization and process treatment to ensure the stability and processing accuracy of the machine.

| Model | CK-1530-8T |

|---|---|

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter / pure servo inverter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 4.5KW high-speed air-cooled spindle * 2 (supports four-axis linkage) |

| Spindle Speed | 0-18000r/min |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Turning Tool | V-type alloy turning tool (large cutting capacity) |

| Right Angle Knife | 90 degree V-shaped discard right angle knife |

| Planer | 90*240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230*50mm, independently controlled sanding wheel, 370w three-phase asynchronous motor |

| Sanding Roller | 240mm high movable sanding roller, 2.2KW three-phase asynchronous motor |

| Saw Blades | 230mm diameter multi-piece saw blade, 1.5kw three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 30 straight square rail / 30 flange slider |

| Equipment Cable | Pure copper high-flexible bending-resistant cable |

| Automatic Loading & Unloading | Multi-cylinder 4-linkage fully automatic loading and unloading (simple and easy to use) |

| Control System | Taiwan LNC lathe dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2500kg |

| Dimensions | 3750*2500*1850mm |

| Toolbox | Turning tool, wrench, collet, handwheel, thimble, chuck, oil pot, oil-water separator, relay, photoelectric limit. |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.