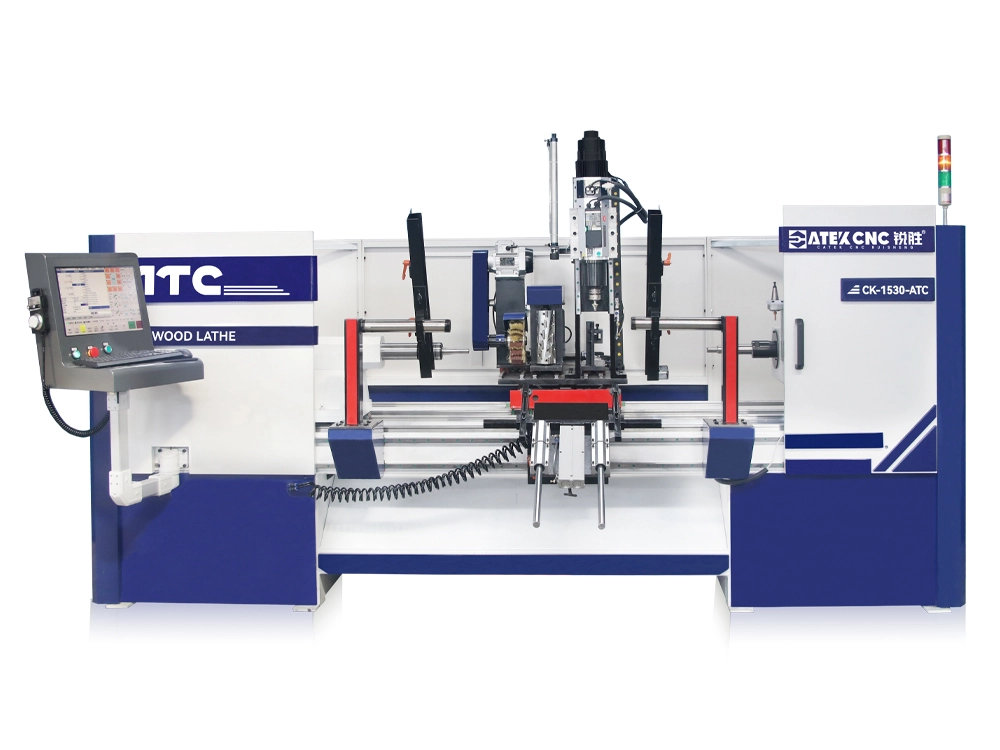

The Best ATC CNC Wood Lathe in 2025

Professional CNC Wood Lathe with Automatic Tool Changer

[Function Description]

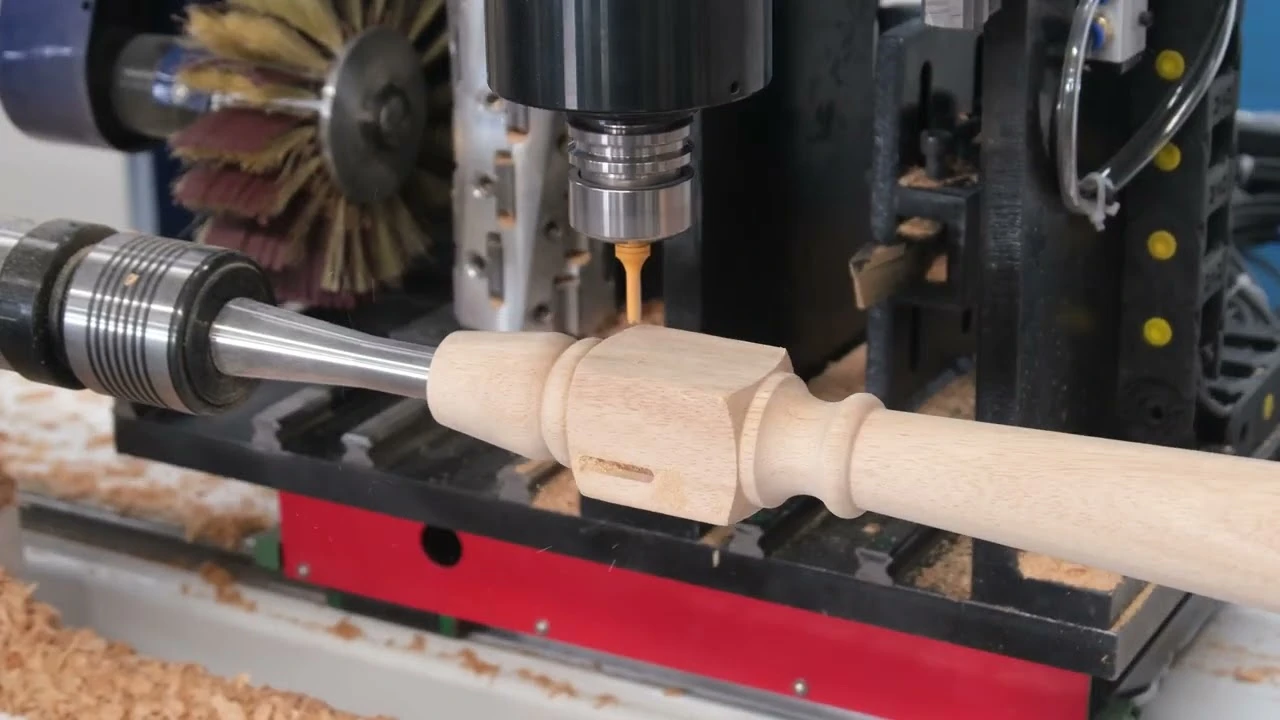

With the development of modern art and the improvement of people's aesthetic standards, the aesthetic requirements for various woodworking furniture and architectural components have increasingly risen, and the shapes and decorations of such products have become more complex. CATEKCNC's multi-functional wood lathe series integrates various processing functions into a single machine, capable of meeting the vast majority of processing needs. However, we have found that even when equipped with multiple multi-functional spindles, the number of tools required by users when machining extremely complex products can still exceed the upper limit of spindle capacity, forcing the machine to stop and change tools during the process. However, simply increasing the number of multi-functional spindles not only significantly raises machine costs but also poses new challenges to the overall structural design. To address this issue, we have introduced a new series of automatic tool-changing CNC wood lathes.

The core components enabling automatic tool changes in this series of CNC wood lathes are the ATC multi-functional spindle and the linear tool magazine. The tool magazine can hold six different types of tools, all of which must be coded before use. During machining, when a tool change is required, the multi-functional spindle moves to the tool magazine, removes the original tool at a designated position, then moves to the storage location of the new tool, precisely inserts the new tool into the spindle, and locks it in place. The ATC spindle then automatically returns to the processing position to continue the operation.

The ATC CNC wood lathe effectively solves the problem of frequent stops for tool changes in multi-process machining, achieving full automation of the machining workflow. It is suitable for scenarios requiring a variety of tools. By installing different tools, it can perform various operations such as turning, milling, planing, grooving, drilling, 2D engraving, 2.5D engraving, 3D carving, and polishing. Whether processing intricately patterned furniture legs—such as Queen Anne legs, Chippendale legs, Cabriole legs, or animal-shaped legs—or complex wood carvings like various Buddha statues, figurines, candlesticks, and more, the entire processing workflow can be completed automatically with just one clamping.

Features of the ATC CNC Wood Lathe

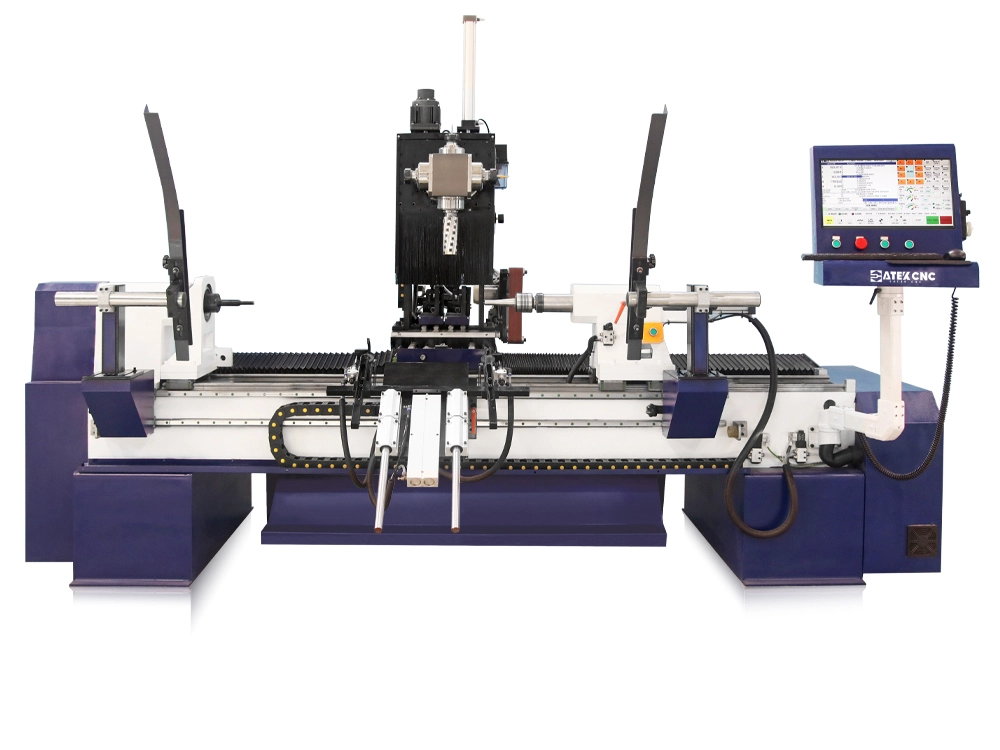

- The machine features a stress-relieved, heavy-duty double-row four-rail gray cast iron bed with a thickness of 30mm. The total machine weight reaches 3200kg, effectively supporting both the machine's own weight and the forces generated during machine. This ensures high stability, precision, and long service life during operation.

- The machine has powerful machining capabilities. The drive spindle is equipped with a 4KW servo motor, enabling high-speed rotation or indexing. The standard configuration includes one turning station, one large planing knife, one ATC multi-functional spindle, and one sanding station, covering almost all machining needs.

- It is equipped with an automatic tool-changing device, with a tool magazine capacity of 6 tools. It is paired with a 9KW ATC multi-functional spindle, ISO30 tool holders, and ER32 collets.

- It is equipped with an automatic loading and unloading device, controlled by multiple cylinders in coordination, enabling automatic blank feeding and finished product unloading, effectively saving labor during batch machining, with only manual replenishment of wood into the hopper required.

- It is equipped with a Taiwan LNC controller, which is widely used, offers excellent cost-performance, supports keyboard and mouse control, and comes standard with a 19-inch LCD display for convenient use.

- The transmission system adopts Taiwan HIWIN 30 rails and flange sliders, TBI ball screws, and high-precision helical gear racks, powered by a 1.5KW servo motor, ensuring smooth and quiet movement, long-term stability, and extremely high reliability.

- It uses Delixi/Schneider electrical components, highly flexible and bend-resistant pure copper shielded cables, and thickened PU air hoses, ensuring equipment quality in every detail and providing solid support for the machine's long-term stable operation.

Details of ATC CNC Wood Lathe

- Protective enclosure

-

The machine is equipped with four-sided protective enclosures to effectively prevent waste chips from splashing during machining.

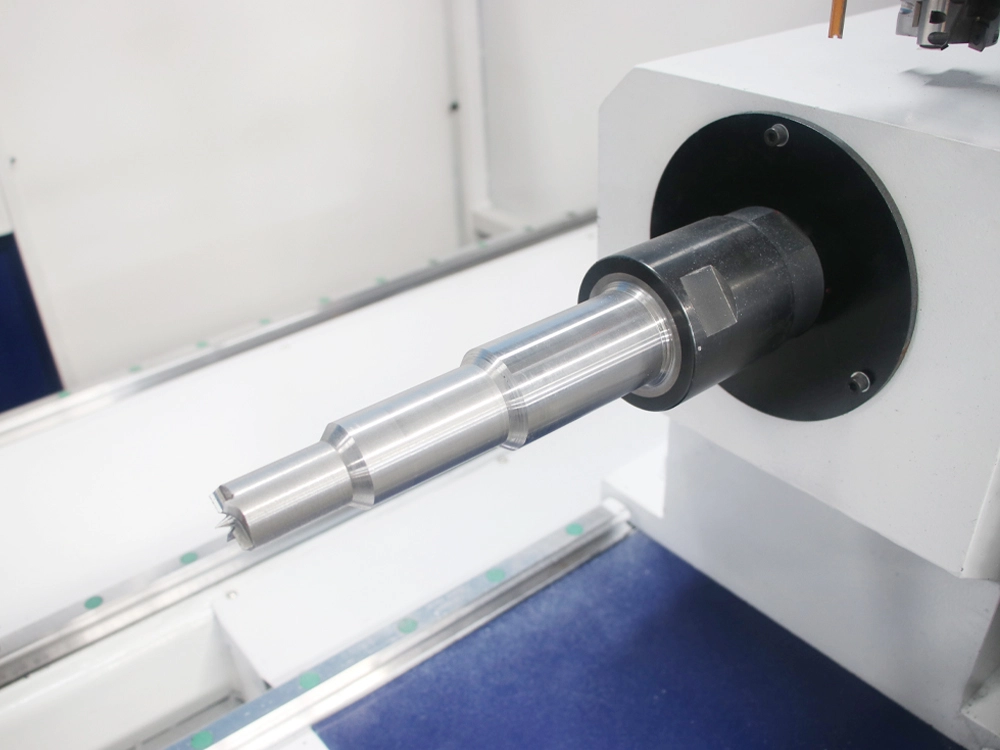

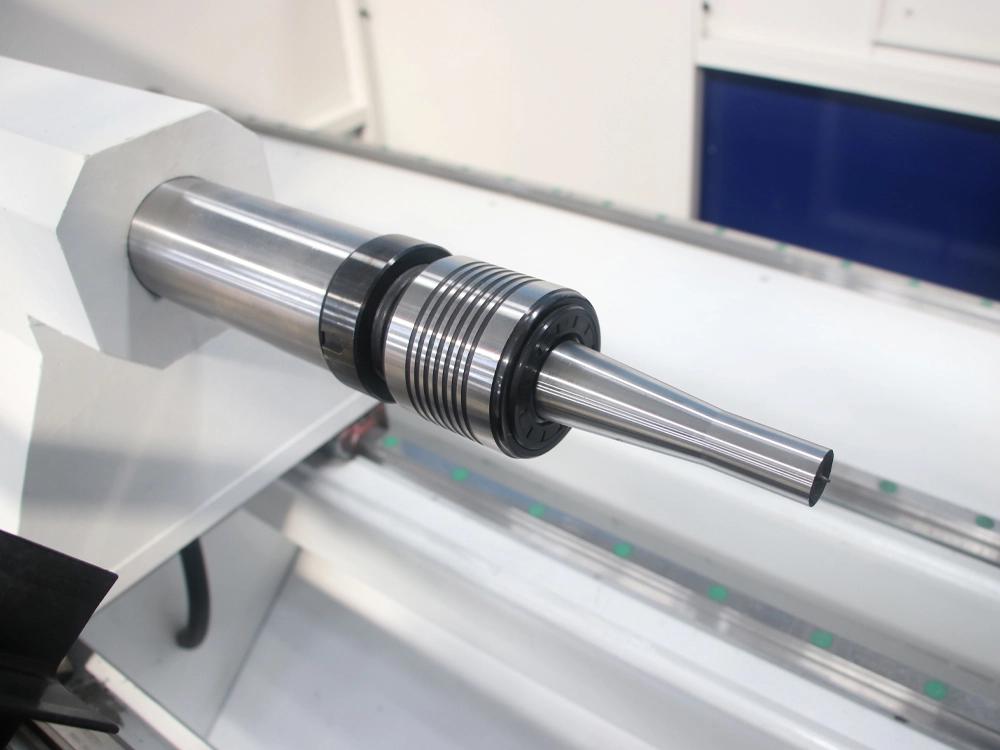

- Lathe center

-

The headstock is made of gray cast iron and is equipped with a four-bearing drive spindle, which makes the rotation more stable and the machining more powerful.

The cast tailstock is equipped with a Morse No. 5 taper and a standard stroke cylinder for fast clamping of wood.

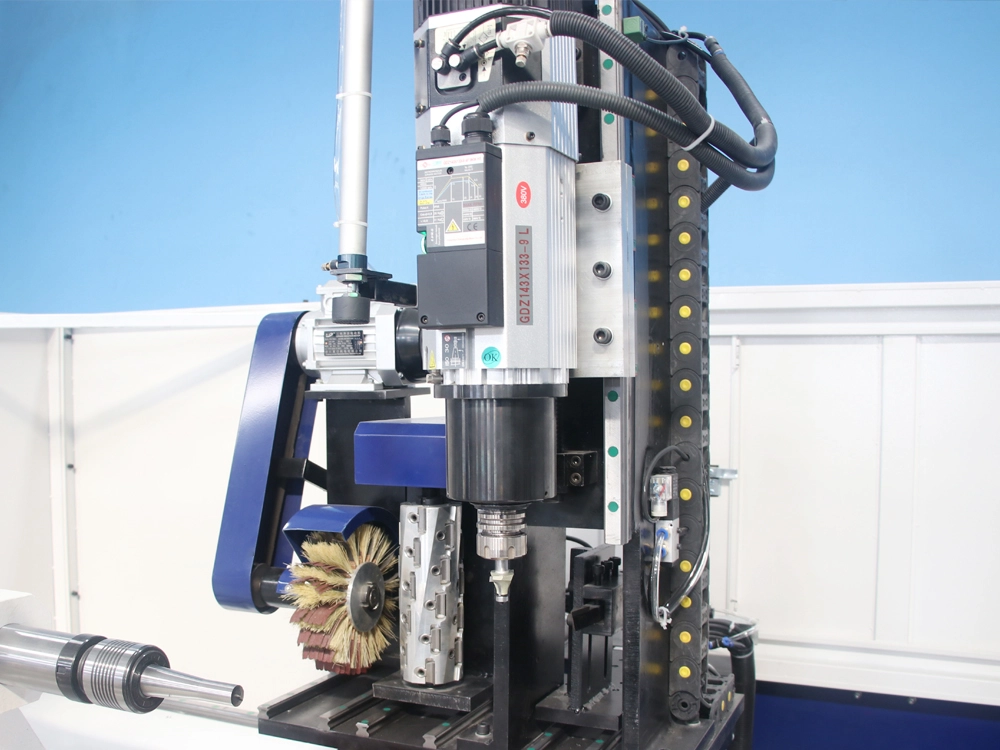

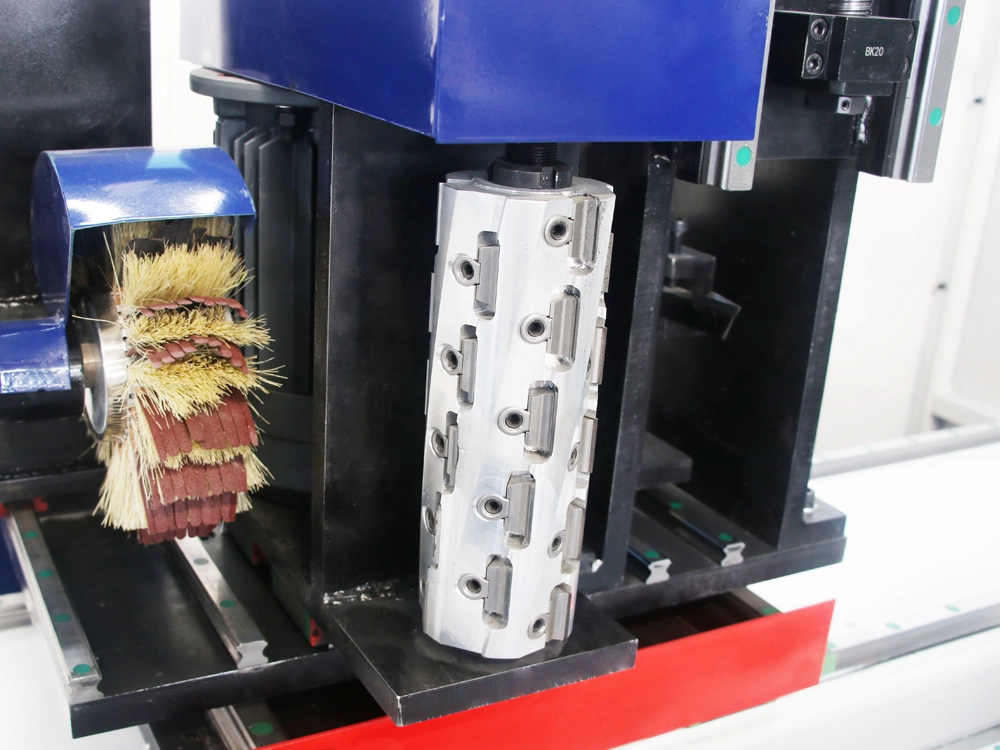

- ATC spindle

-

It uses a 9KW air-cooled ATC spindle with a maximum speed of 18,000rpm, it can be adapted to ISO30 tool holders and ER32 collets, and can stably clamp various types of tools with a shank diameter of up to 20mm. During the machining, the tool can be automatically replaced according to needs, which significantly improves production efficiency.

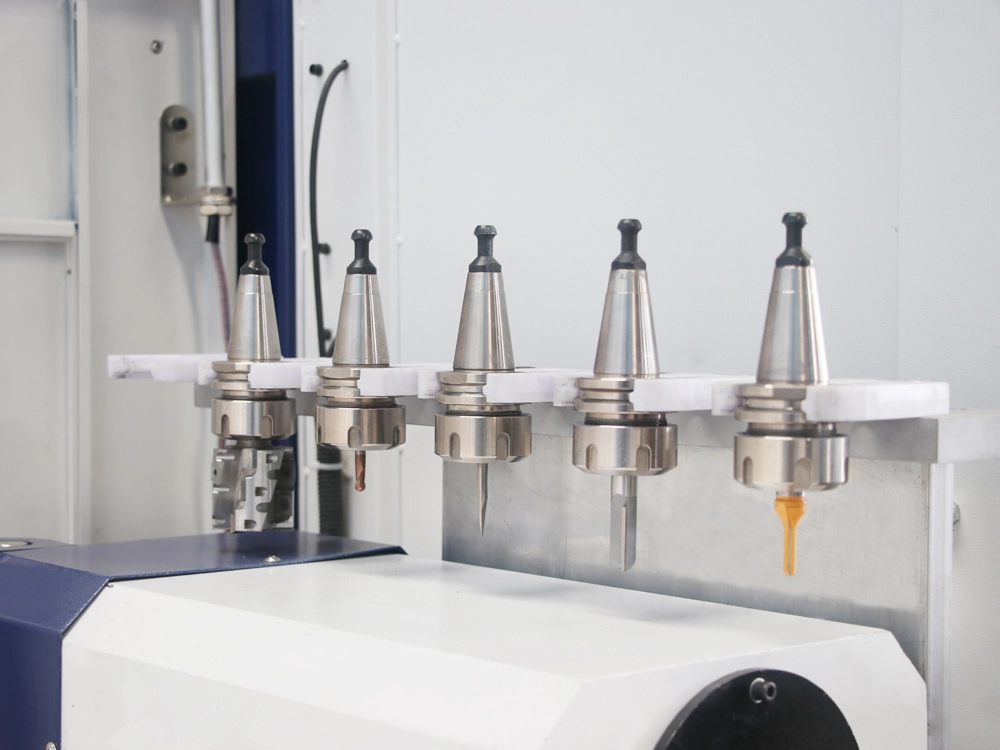

- Linear tool magazine

-

Equipped with a linear tool magazine that can accommodate 6 tools and can clamp ISO30 tool holders.

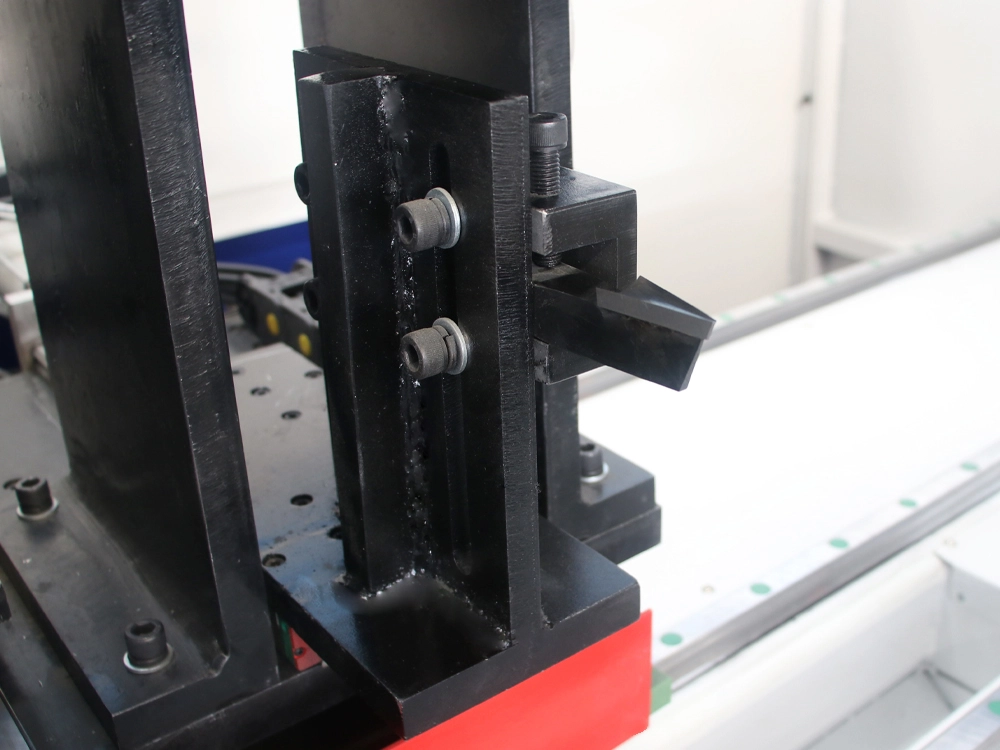

- Turning tool

-

A turning station is standard and can accommodate a variety of tool types (including U-shaped, V-shaped and 90-degree right-angle tools), tool changes simple and convenient.

- Planing tool

-

Independent planer position, you can use the planer to improve the efficiency of rough machining or plane planing. It is driven by a 2.2KW independent motor with a speed of up to 3000rpm. The standard large planer with a height of 230mm and a diameter of 90mm can be equipped with 30 large blades or 60 small blades.

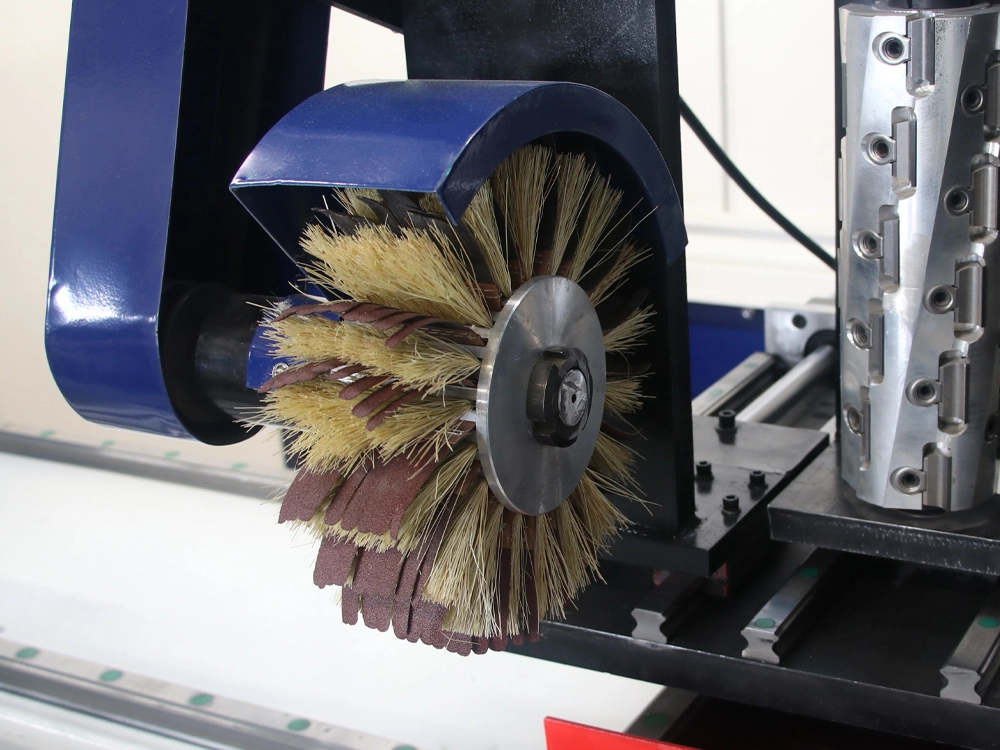

- Sanding device

-

Equipped with a sanding wheel with a diameter of 230 mm and a width of 50 mm, it is driven by an independent 370W three-phase asynchronous motor. The number of sandpapers is optional.

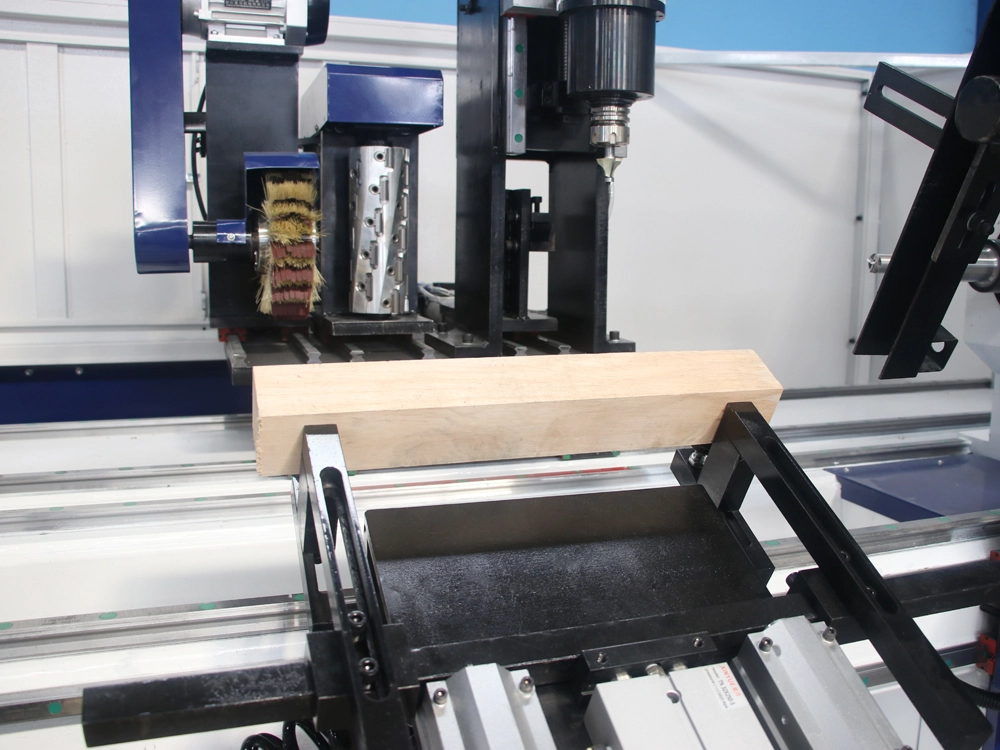

- Automatic loading and unloading device

-

The automatic loading and unloading device is equipped with multiple combined cylinders, which can realize automatic feeding of blanks and unloading of finished products, effectively simplifying the production process, reducing labor costs and improving processing efficiency. The large-sized hopper is made by hot bending forming process, and its good structural integrity makes it more durable.

- Lubrication system

-

Equipped with a fully automatic lubricating oil pot, the lubrication time and lubrication interval can be set, and the lubricating oil can be diverted to various transmission parts of the machine by the oil splitter.

- Control System

-

Taiwan LNC controller, user-friendly interface, complete functions, compatible with all kinds of CAD/CAM software. The control panel is operated by keyboard and mouse, equipped with a 19-inch LCD display.

Technical Parameters of ATC CNC Wood Lathe

| Model | CK-1530-ATC |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | CATEKCNC dedicated high-torque 1500W servo motor * 3 |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X, Y axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Variable Frequency Drive | BEST/Hpmont Inverter |

| Drive-Spindle Motor | 4KW pure servo high-torque and high-speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Turning Tool | One mounting position for turning tools |

| Milling/Carving/Drilling Spindle | 9KW high-speed air-cooled ATC spindle (supports four-axis linkage) |

| Milling/Carving/Drilling Spindle Speed | 0-18000r/min |

| Tool Magazine | 6-capacity linear-row tool magazine |

| Planer Motor | 2.2KW three-phase asynchronous motor |

| Planer Motor Speed | 3000r/min |

| Planer Dimensions | 230mm length * 90mm diameter (customizable without extra charge) |

| Sanding Device | Independent 370W three-phase asynchronous motor control Standard sanding wheel with 230mm diameter * 50mm width (customizable) |

| Sanding Device Speed | 3000r/min |

| Automatic Loading and Unloading | Multi-linked cylinder loading and unloading device (simple and easy to use) |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 3200kg |

| Dimensions | 3850*2000*2550mm |

Application Scope of ATC CNC Wood Lathe

ATC CNC wood lathes are equipped with turning tools (turning), large planers (planing), large-capacity tool magazines and high-power ATC spindles (milling, drilling, grooving, carving), and sanding devices (sanding), which can process various types of complex woodworking products.

Applicable Materials:

Suitable for various materials such as wood, bamboo, PVC, plastic, nylon, acrylic, carbon fiber, density board, etc.

Applicable Products:

-

Furniture: various special-shaped table and chair legs, handrails, such as tiger legs, horse legs, Queen Anne legs, Chippendale legs, Flemish Scroll legs, Cabriole legs, Sabre leg, Spiral legs, etc.

-

Musical instruments: drumsticks, flutes, suona, Plum Zurna, Hulusi, bassoon, etc.

-

Sports equipment: pool cues, baseball bats, wooden balls, etc.

-

Crafts: wooden bowls, vases, cups, pen holders, Matryoshka dolls, wooden guns, candlesticks, etc.

-

Sculptures: figure sculptures, animal sculptures, Buddha statues, etc.

-

Building components: stair columns, stair newel post, building decorative panels, etc.

Available Tools for ATC Spindle

- Straight milling cutter

-

Features: The cutting edge is perpendicular to the tool axis and is straight. The cutting force is directly downward and the lateral force is small. Common ones are single-edged, double-edged, and triple-edged.

Application: Large cutting volume, often used for rough processing of high-density materials, high-speed grooving, plane trimming, and relief bottom surface processing.

- Spiral milling cutter

-

Features: The cutting edge is spiral, and the common helix angle is 30°-45°. The cutting force is decomposed along the helix angle, reducing vertical impact, smooth cutting, and strong chip removal ability.

Application: Produces a high-quality surface finish, suitable for applications requiring high precision, such as deep slotting, contour milling, and hollowing.

- Replaceable spiral milling cutter

-

Features: The cutter body is designed in a spiral shape, with a common helix angle of 15°-45°. It is equipped with multiple replaceable blades. The blades are usually designed with multiple blades, which can be used in an indexable manner and can be directly replaced after wear without regrinding.

Application: Ideal for large-scale machining where tool wear is a concern, such as rapid roughing or machining difficult-to-cut materials like oak or beech.

- Round-over milling cutter

-

Features: The blade is arc-shaped (R angle), which can process fillets or chamfers of different radii to avoid sharp edges.

Application: Used for rounding edges of wooden parts (e.g., chair armrest edge edges), relief carving, or 3D surfaces to prevent stress concentration at sharp corners.

- Ball-nose milling cutter

-

Features: The tip is hemispherical, designed for 3D surface machining.

Application: Wood carving, artistic engraving, complex surfaces (e.g., European-style furniture patterns), or fine machining of recessed areas.

- Engraving sharp knife

-

Features: The tip is sharply angled (typically 30°–60°) with a keen edge, enabling detailed engraving.

Application: Engraving text, decorative lines, V-grooves, or sharp-edged detailing.

Maintenance for ATC CNC Wood Lathe Tools

- Keep tools clean. Use standard industrial solvents or compressed air to remove resin, wood chips, and other debris from the tool surface. Ensure no residue remains on the tool body, and thoroughly clean the shank contact area to prevent slippage due to contamination. Increase cleaning frequency when machining composite wood materials containing organic solvents or adhesives.

- Apply a thin, even layer of machine oil to the tool surface to prevent oxidation and rust. After machining damp wood, immediately spray the tool body with a rust inhibitor (water-based WD-40 is recommended).

- Maintain storage humidity at 50–60% RH. For long-term storage, protect the CNC wood lathe or remove the tools and store them in a suitable environment. Tools should be hung vertically or laid flat in dedicated racks to prevent deformation or edge damage.

- It is strictly forbidden to re-grind or modify the tool privately. Any cutting edge treatment must be performed by professional equipment and technicians. Improper operation may cause the cutting edge to crack and cause safety accidents.

- Ensure the tool holder and collet match the tool specifications to avoid damage to the tool or fixture. Regularly inspect holders (e.g., ER collets, chucks) for debris to prevent poor clamping or eccentricity during tool changes.

- Adjust machining parameters based on tool characteristics and wood hardness to avoid overheating or overloading.

- It is recommended to establish a tool life management table to record the processing time of each tool (it is recommended that carbide tools ≤ 200 hours). Replacing unqualified tools in time can ensure good processing accuracy.

| Model | CK-1530-ATC |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | CATEKCNC dedicated high-torque 1500W servo motor * 3 |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X, Y axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Variable Frequency Drive | BEST/Hpmont Inverter |

| Drive-Spindle Motor | 4KW pure servo high-torque and high-speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Turning Tool | One mounting position for turning tools |

| Milling/Carving/Drilling Spindle | 9KW high-speed air-cooled ATC spindle (supports four-axis linkage) |

| Milling/Carving/Drilling Spindle Speed | 0-18000r/min |

| Tool Magazine | 6-capacity linear-row tool magazine |

| Planer Motor | 2.2KW three-phase asynchronous motor |

| Planer Motor Speed | 3000r/min |

| Planer Dimensions | 230mm length * 90mm diameter (customizable without extra charge) |

| Sanding Device | Independent 370W three-phase asynchronous motor control Standard sanding wheel with 230mm diameter * 50mm width (customizable) |

| Sanding Device Speed | 3000r/min |

| Automatic Loading and Unloading | Multi-linked cylinder loading and unloading device (simple and easy to use) |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 3200kg |

| Dimensions | 3850*2000*2550mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.