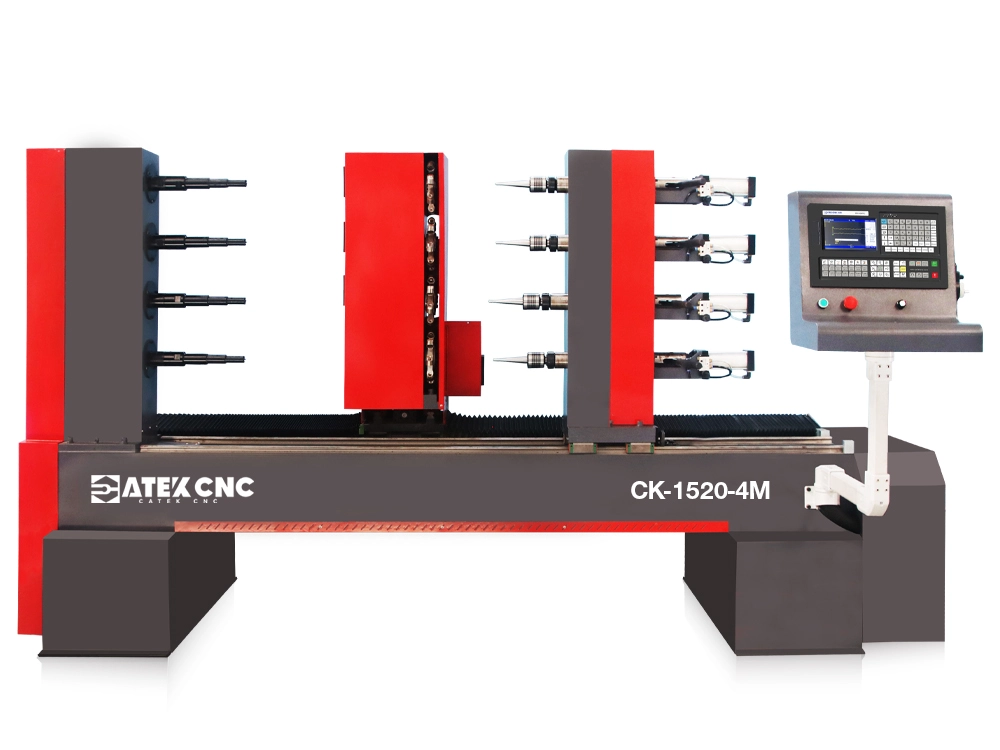

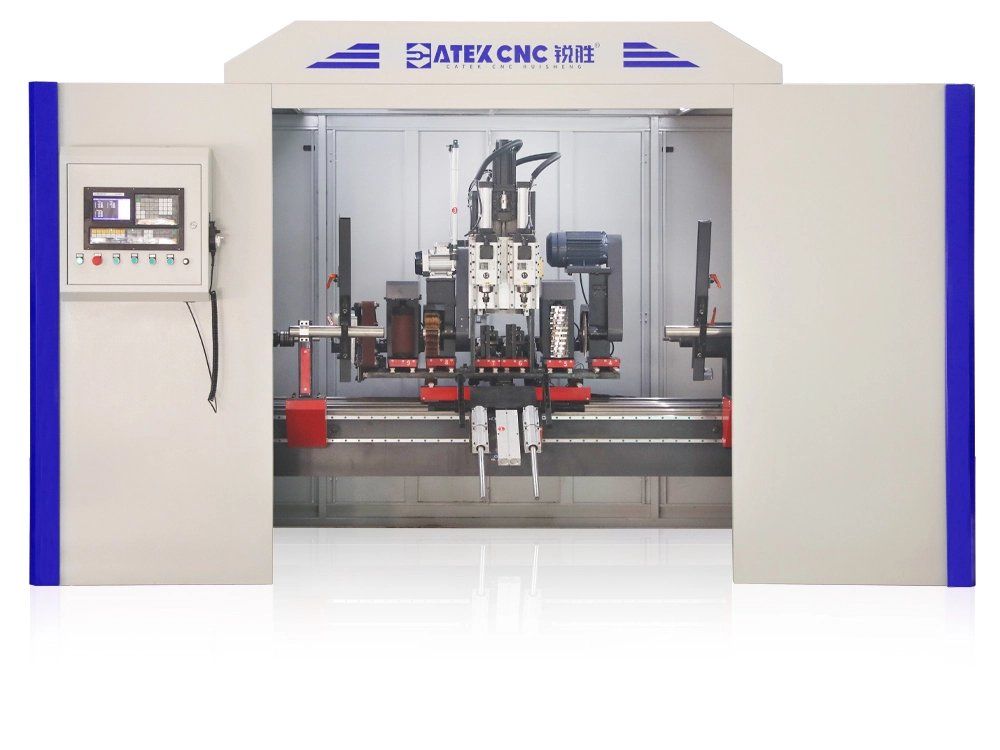

CNC Copy Lathe for Rapid Processing of Shaped Table and Chair Legs

2026 High-Efficiency 4-Station CNC Wood Copying Lathe

[Function Description]

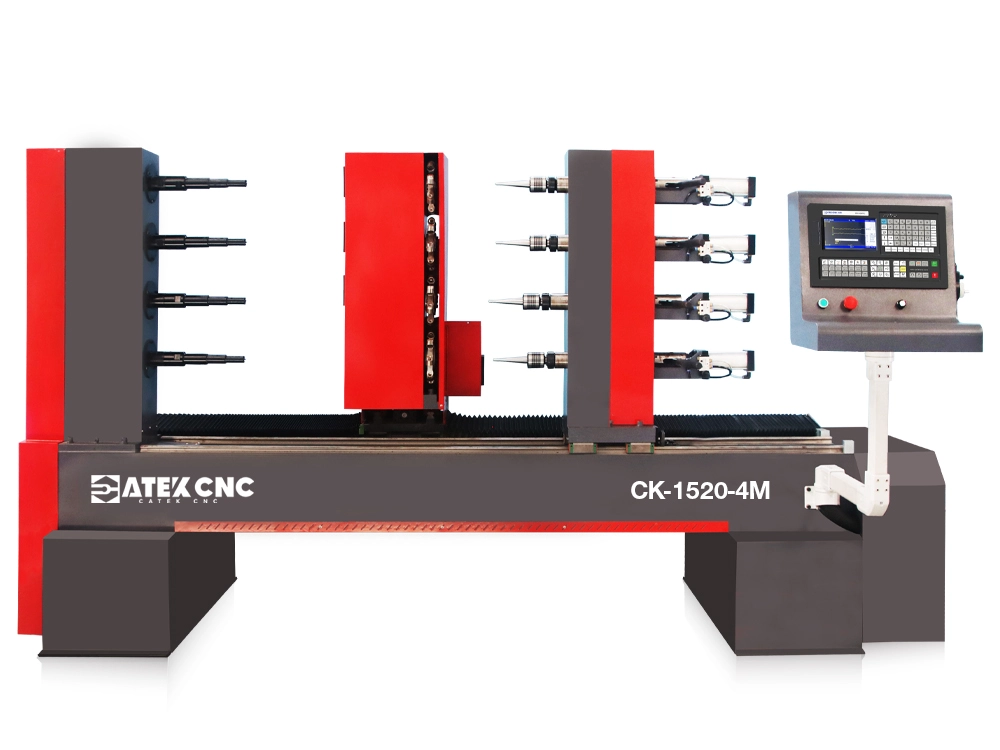

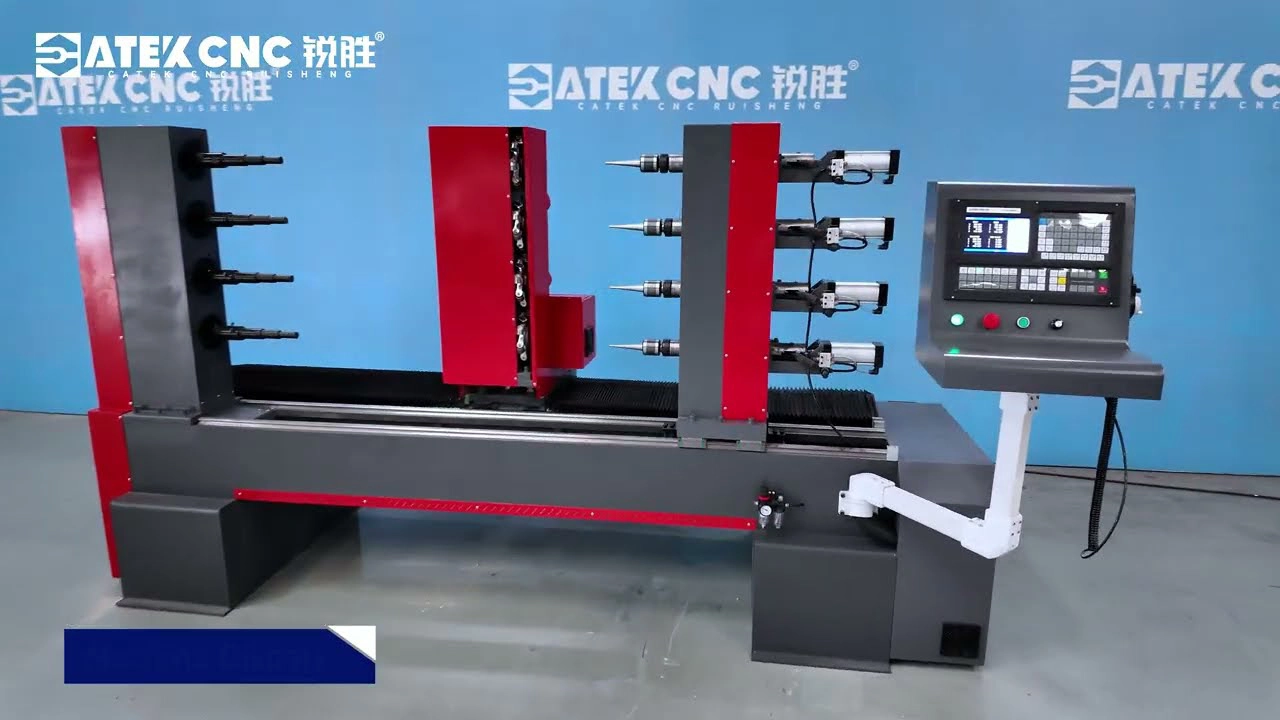

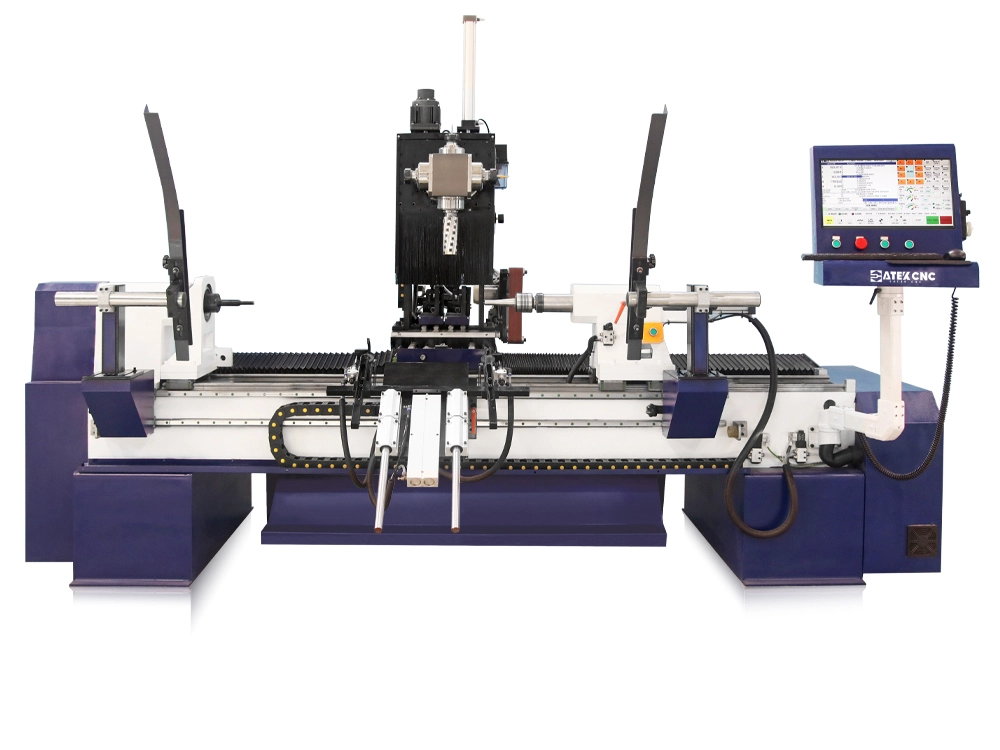

The CK-1520-4M is a 4-station CNC wood copying lathe equipped with disc milling cutters, developed by CATEKCNC for machining asymmetric revolving objects. It specializes in processing complex workpieces with intricate structural variations, intertwined curved surfaces, and irregular profiles that cannot be achieved by traditional lathes—such as oval or flat table/chair legs, curved chair backs, specially-shaped chair armrests, twisted hanger components, and hockey sticks. To meet the demands of large-scale batch production in factories, CATEKCNC has designed multiple processing stations for this "CNC Wood Copying Lathe for Special-Shaped Furniture Legs" Each station is equipped with an lathe drive center and processing tools, enabling simultaneous clamping and processing of multiple wood pieces, and directly multiplying production efficiency.

Advantages of High-Efficiency Multi-Station CNC Wood Copying Lathe

Machine Structure

The lathe bed adopts an integrated casting structure made of gray cast iron, with a cast iron thickness of up to 30mm, and has undergone professional annealing treatment to relieve internal stress. This design endows the machine with ultra-high rigidity, which can not only bear loads such as cutting force and workpiece gravity but also absorb vibrations generated during machining to the greatest extent, fundamentally ensuring the machining accuracy and surface quality of workpieces.

The lathe bed is designed with a double-row and four-guideway structure. The driving center and processing tools are placed on different guide rails respectively, which not only optimizes the weight distribution of the machine body but also further enhances the overall rigidity. Even when the machine body is equipped with four processing stations, it can still maintain ultra-stable operation.

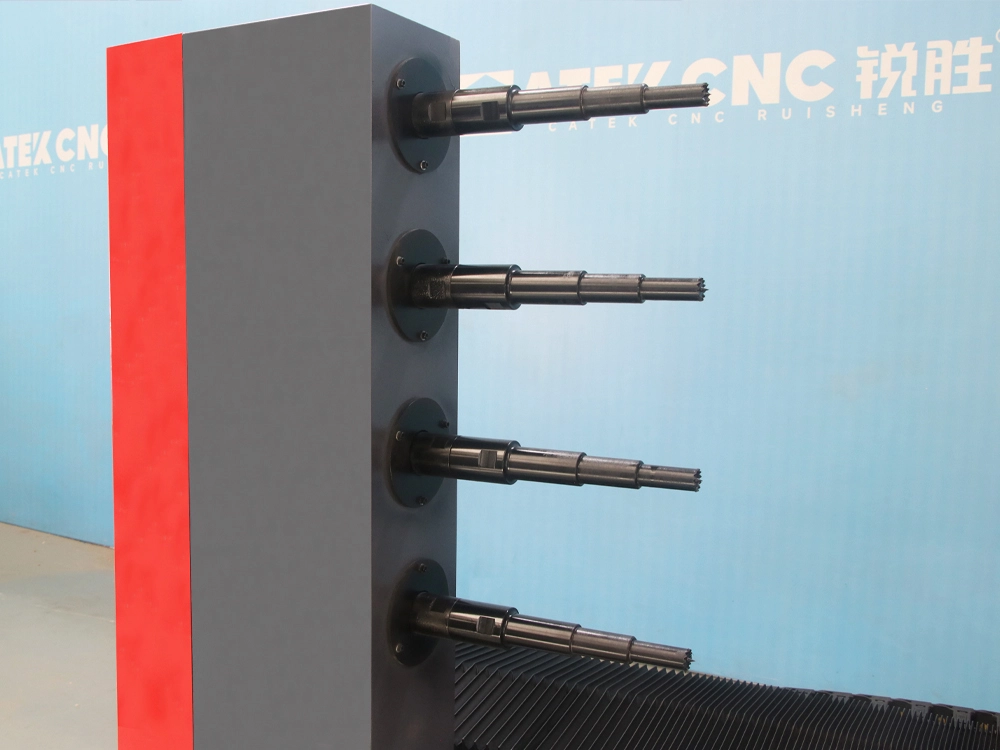

Four-Station Design

The CNC wood copying lathe incorporates a 4-station design, each equipped with a lathe center and corresponding disc-type milling tools. All stations can operate simultaneously for batch processing of identical products, increasing efficiency by four times compared to single-station lathes while ensuring high product consistency.

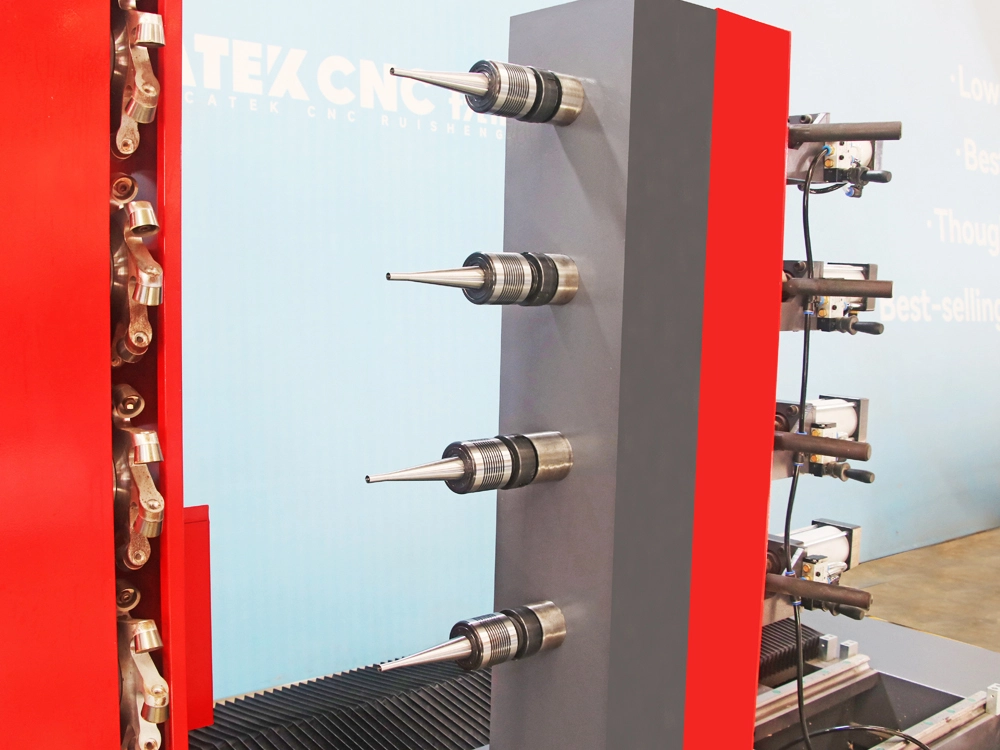

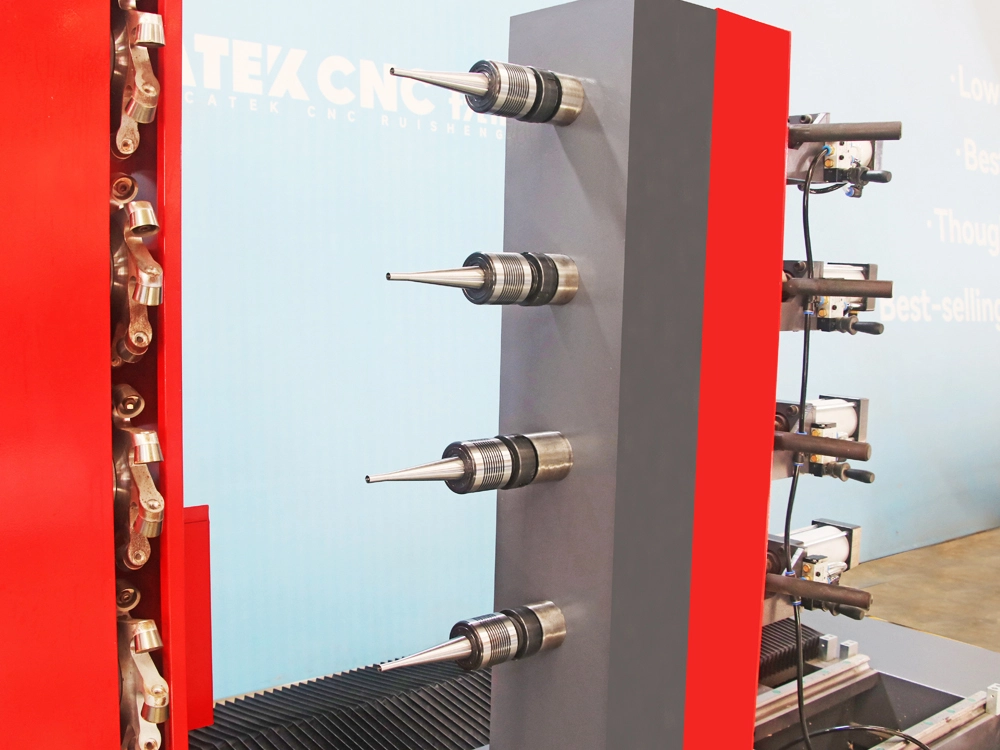

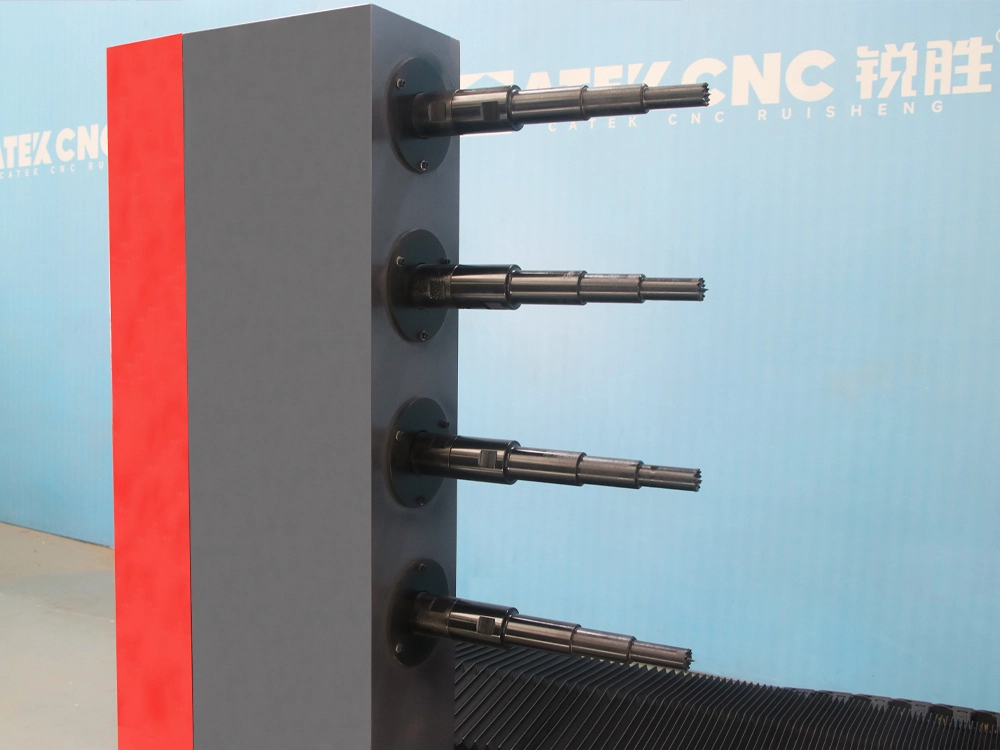

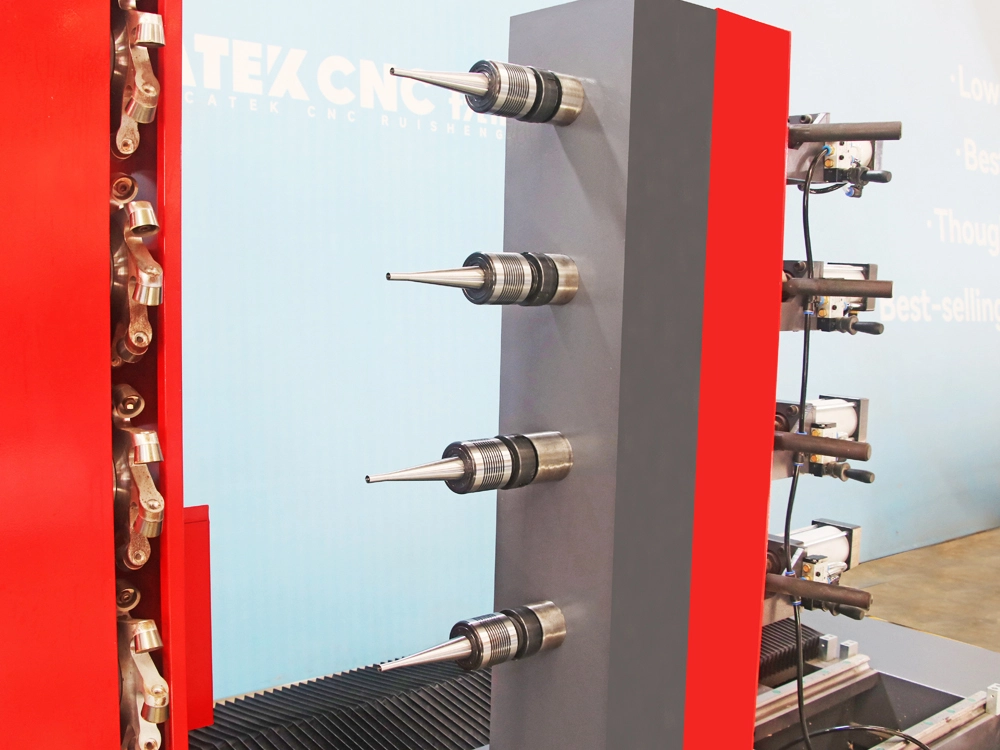

Lathe Drive Center

The lathe center consists of a headstock and tailstock, both cast from gray cast iron. Each drive spindle is supported by four bearings, providing high rigidity, smooth rotation, and minimal noise. The tailstock features a pneumatic locking mechanism for quick fixation before machining.

The drive spindle Driven by a 4KW servo spindle motor, it has an adjustable rotational speed ranging from 0 to 6000 r/min and offers two modes: speed mode and angle mode. In speed mode, it can clamp the workpiece for high-speed rotation; in angle mode, it can clamp the workpiece to rotate to a specified angle. With indexing rotation, the lathe center can rotate the workpiece, exposing the area to be machined in front of the processing tool and facilitating the machining of different parts of the workpiece.

Processing Tools

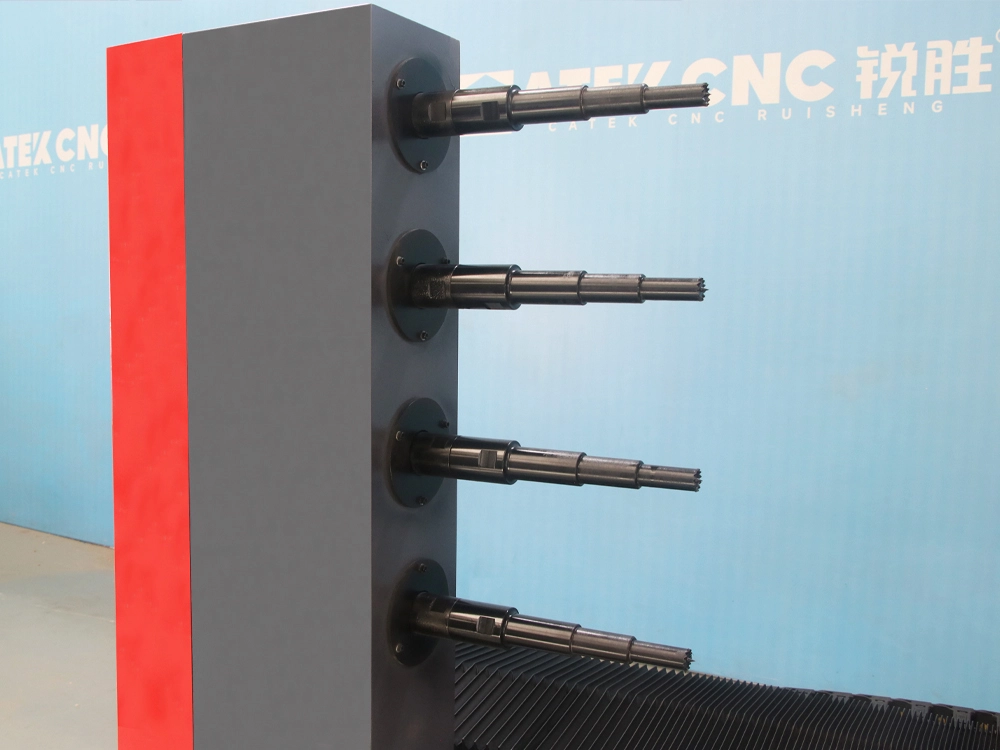

A combined solution of "milling cutter disc + cup-type turning tool" is adopted, with 8 cup-type turning tools evenly mounted on the radial tail end of the milling cutter head. During machining, the milling cutter head rotates at high speed, driving the cup-type turning tools to perform vertical turning of the workpiece.

The cup-type turning tool is a special-shaped turning tool, with its cutter head in a hollow cup shape (formed by annular cutting edges enclosing a cup-shaped contour, its rotation axis is perpendicular to the rotation axis of the workpiece). In the machining process, this tool can not only achieve a large depth of cut but also ensure the smoothness of the workpiece's surface, making it especially suitable for the machining of curved surfaces and special-shaped contours of rod-shaped products.

The cup-type turning tool supports easy disassembly and replacement. When they worn, there is no need to replace the entire cutter head, which greatly reduces maintenance costs and equipment downtime. The solution is equipped with a 4KW high-torque servo motor drive, with a speed range of 0-12000r/min, allowing adjustment of the tool speed according to different material properties of the workpiece.

Transmission System

Guide Rails and Sliders: 30mm linear guide rails and flange sliders from Taiwan HIWIN are used. They have an extremely low friction coefficient, while providing super strong rigidity and load-bearing capacity, easily handling heavy-load machining scenarios and ensuring long-term operation accuracy.

Ball Screws: TBI ground-level ball screws are used, featuring extremely high transmission efficiency. The required driving torque is only 1/3 of that of ACME screws, and the axial clearance is almost zero, enabling precise micro-feeding at the 0.1-micron level, which is the core guarantee for high-precision machining.

Helical Gear Racks: High-precision ground helical gear racks are used. The helical teeth designed with a specific angle ensure continuous and smooth transition of the contact line during the meshing of gears and racks, effectively avoiding sudden changes in impact load caused by straight-tooth structures and significantly improving transmission stability and load-bearing capacity.

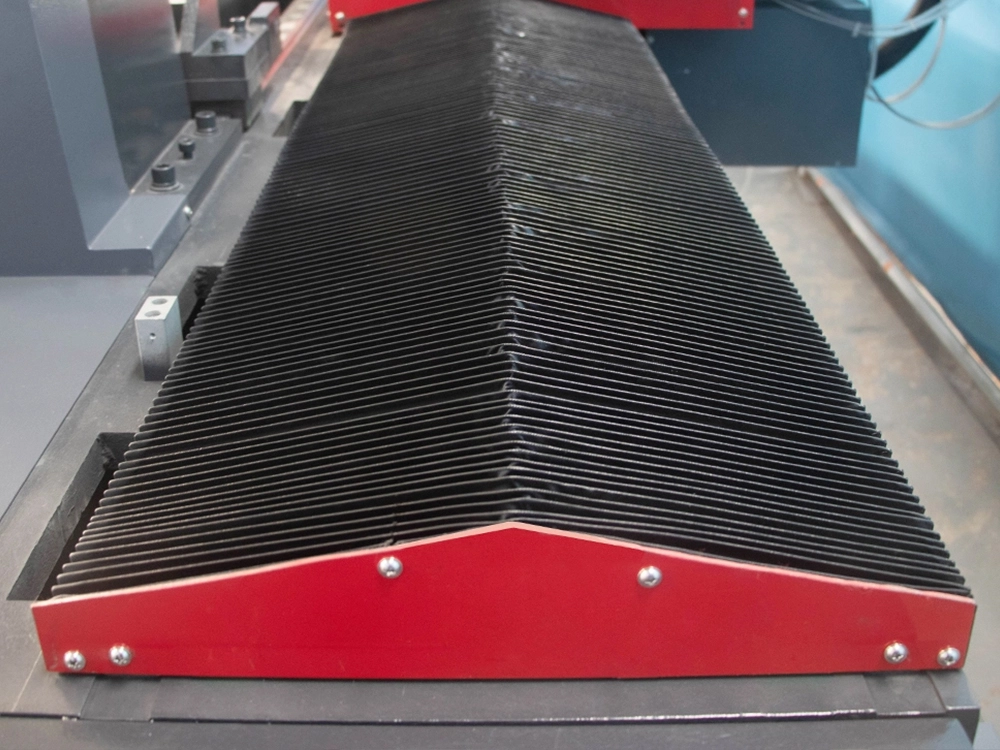

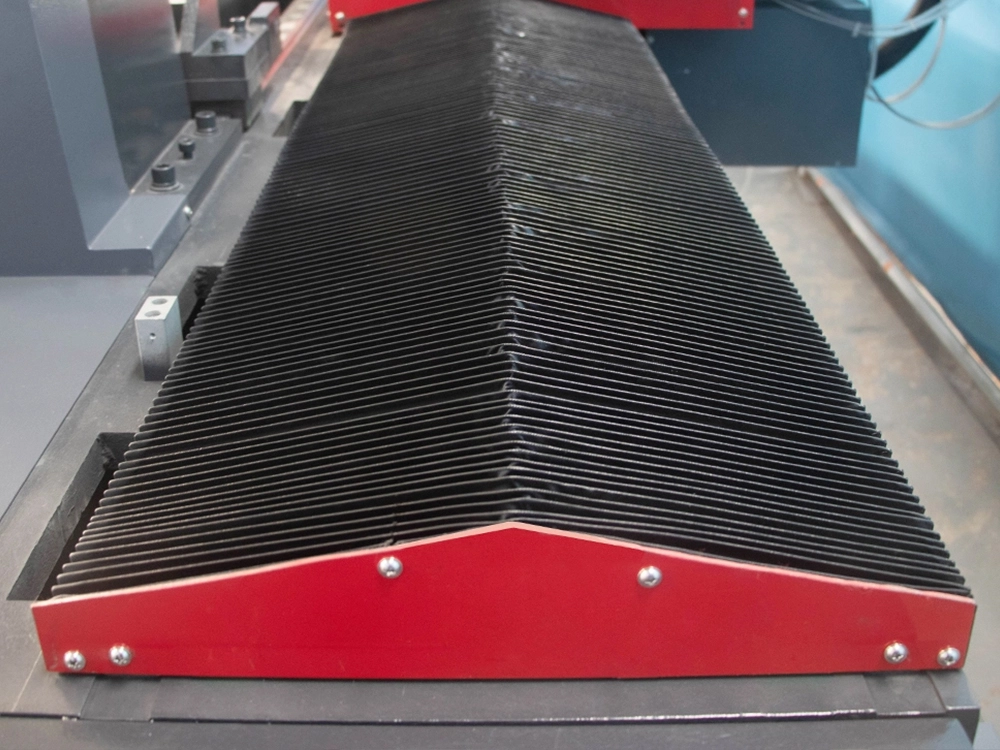

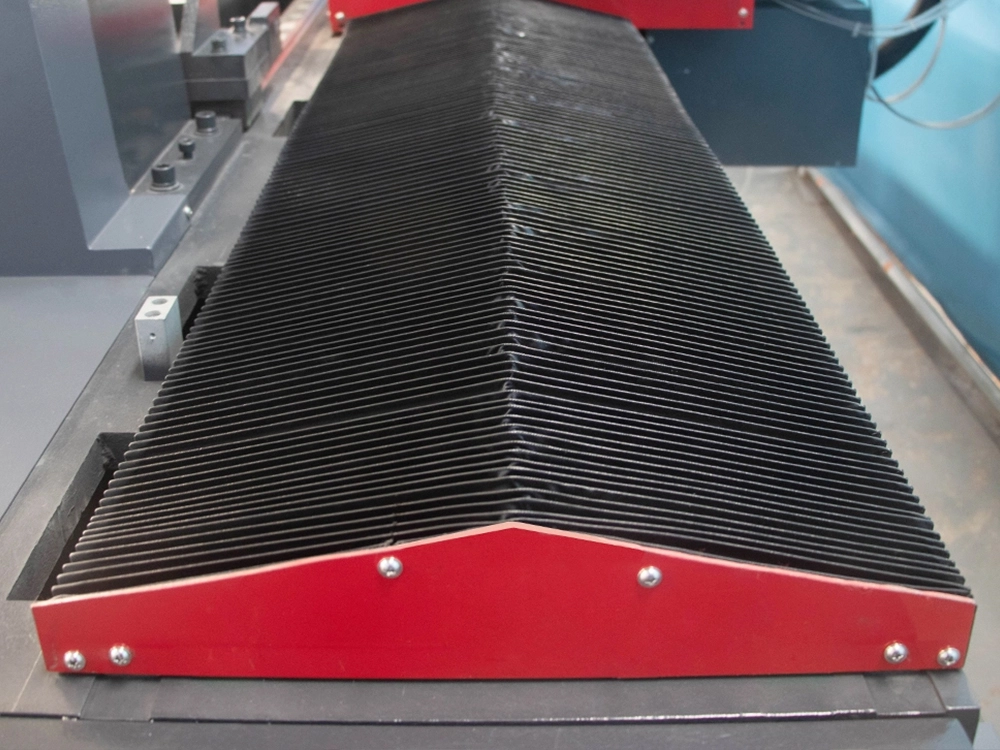

Dust Protection: The Z-axis is equipped with a bellows telescopic dust cover, which can effectively isolate machining chips and dust from entering the transmission system, reducing the occurrence of transmission system failures and lowering maintenance frequency.

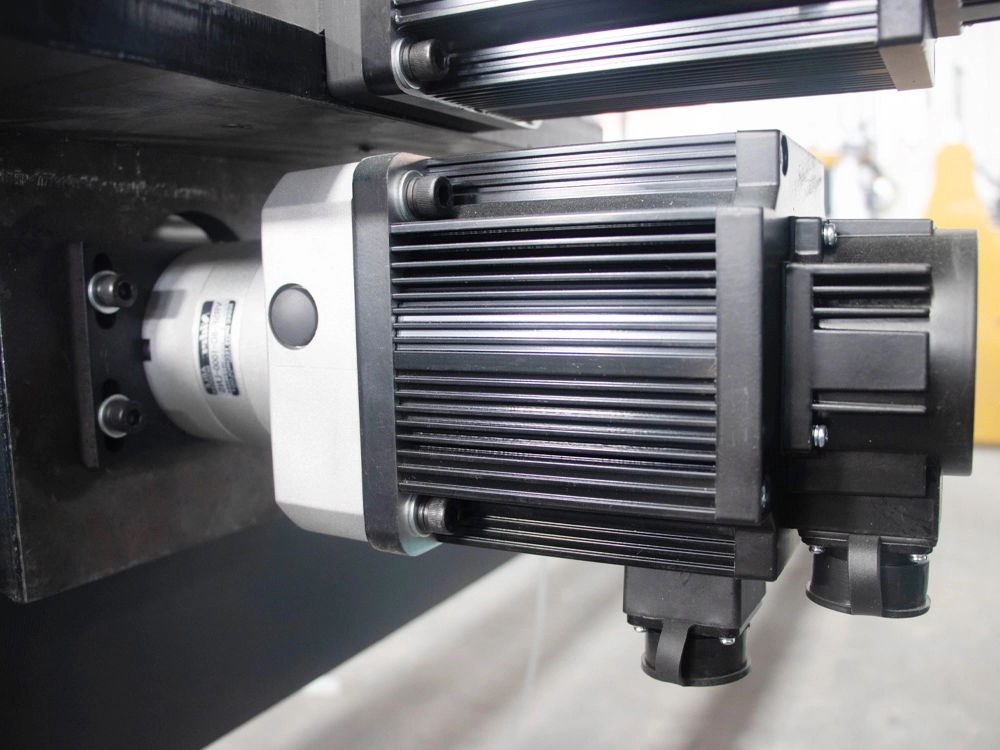

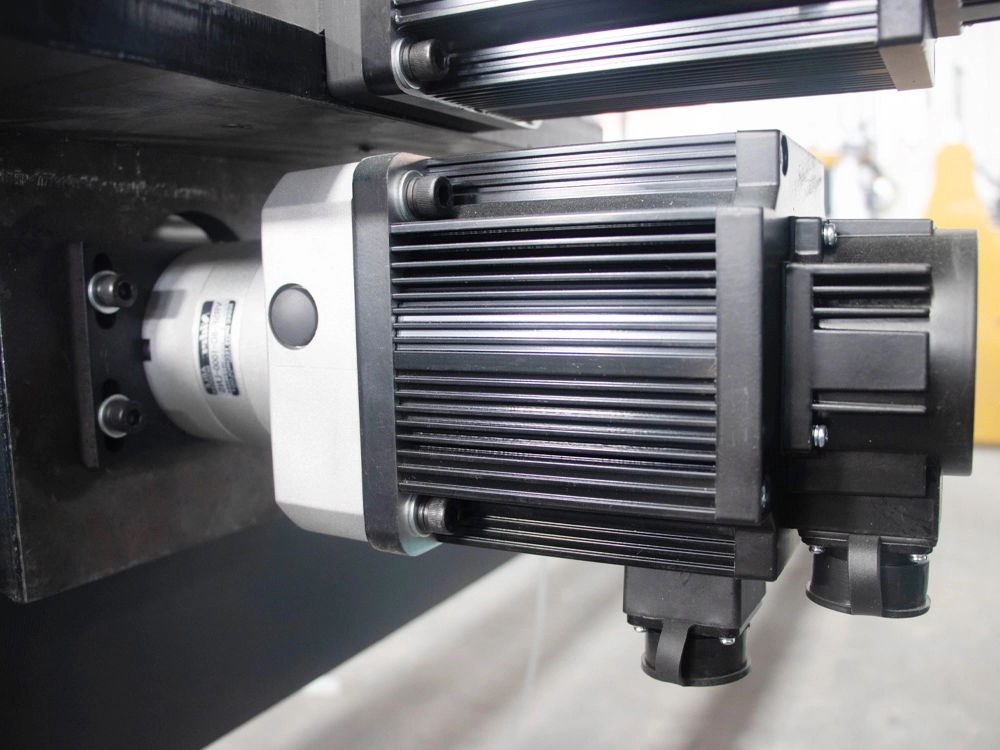

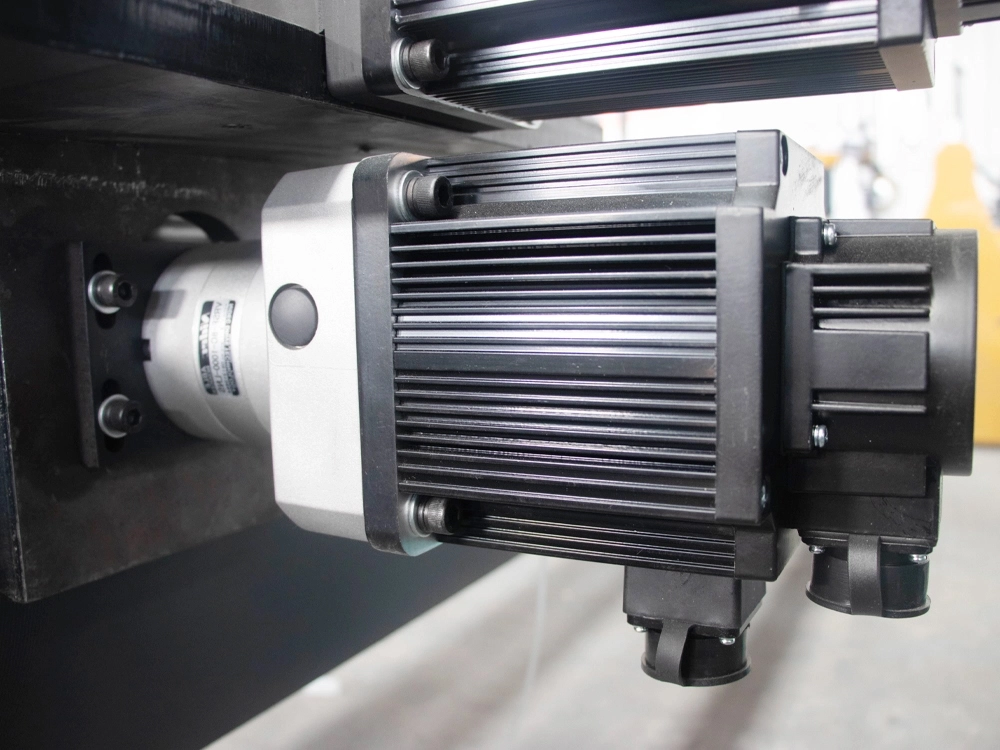

Servo Drive System

The linear axes are driven by 1500W high-power servo motors independently developed by CATEKCNC. The Z-axis is equipped with a Shimpo (Japan) planetary gear reducer. The machine can operate at a speed of over 60,000mm/min, with more stable torque input and higher positioning accuracy.

Control System

It adopts a self-developed 4-axis control system by CATEKCNC, supporting Chinese-English interface switching and advanced functions such as handwheel simulation and fault alarm. It is compatible with various types of CAD/CAM software, operates with standard G-code, and has an optimized operation interface. The operation is simple, allowing even CNC beginners to quickly get started.

Other Configurations

Electrical System: All electrical components are sourced from first-tier upstream suppliers, ensuring reliable quality. The interior of the control cabinet adopts a layout that separates strong and weak currents, effectively isolating electromagnetic interference.

Cables and Air Hoses: High-flexibility, anti-bending pure copper shielded cables are used, featuring excellent conductivity, strong anti-interference ability, high flexibility, and resistance to repeated bending. The air hoses are made of thickened PU material, with high resilience and pressure resistance; they do not become brittle in winter or soft in summer, adapting to different temperature environments.

Cable Protection Cable Carriers (Drag Chains): All cables are housed in high-strength cable carriers made of flame-retardant material, preventing direct contact between cables and machine guide rails/frames, reducing the risk of outer sheath wear and tangling. They also isolate the impact of harsh environments such as oil stains and chips, and facilitate quick cable identification during maintenance.

Automatic Lubrication System: It is equipped with a fully automatic timed lubrication system. Only by presetting the lubrication interval and duration, the system can automatically inject lubricant into each transmission part, eliminating the need for frequent manual lubrication, simplifying the maintenance process, and extending the service life of transmission components.

Details of 4-Station CNC Wood Copying Lathe

- 4-station with disc milling cutters

Each station is equipped with a milling cutter head made of high-strength alloy, and each milling cutter head is fitted with 8 cup-type turning tools. When the tools are worn, the inserts can be directly disassembled and replaced without replacing the entire tool, resulting in low usage costs.enabling simple maintenance.

- Servo drive motor for linear axes

It uses a 1500W servo motor independently developed by CATEKCNC. The Z-axis is equipped with a planetary reducer, which can achieve stable torque output at low speeds, buffer load impacts, improve positioning accuracy, and extend the machine's service life.

- Servo spindle motor

Both the drive spindle and machining spindle are driven by 4KW high-power, high-torque servo spindle motors, and the rotational speed can be adjusted according to the machining conditions.

- Full-enclosure cover for Z-axis

A full-enclosure bellows cover is equipped, which effectively prevents wood chips and waste residues generated during machining from falling into the transmission system.

- Integral cast headstock

The headstock is cast from gray cast iron, with the outer surface processed by gantry milling and the inner holes processed by a high-precision boring machine. Each drive spindle is equipped with four built-in high-strength bearings, ensuring stable rotation and low operating noise.

- Integral cast tailstock

The tailstock body is cast from gray cast iron. It equipped with a Morse No. 5 live center and a standard-stroke air cylinder, and each live center can be controlled independently, making workpiece fixing simpler and more convenient to use.

- Lubrication System

A automatic electric timed lubrication device is equipped. The lubrication duration and interval can be set independently according to the machine's usage frequency. It automatically lubricates the machine's transmission system without manual lubrication, preventing the situation of untimely manual lubrication.

- Self-Developed Control System by CATEKCNC

It adopts a 4-axis control system independently developed by CATEKCNC, featuring a full English operation interface and automatic operation. Equipped with a pulse handwheel, it supports handwheel simulation operation, allowing even CNC beginners to operate it easily. It is compatible with various types of CAD/CAM software, operates with G-code, and supports multiple formats such as DXF/NC/TXT.

A pulse control handwheel is provided, which can control the manual operation and positioning of the X, Z, and A axes. It allows free adjustment of the moving position, making tool calibration more convenient.

Technical Parameters of the 4-Station CNC Wood Copying Lathe for Special-Shaped Table and Chair Legs

| Model | CK-1520-4M |

|---|---|

| Machining Capacity | 1500 * 200mm * 4 (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | CATEKCNC dedicated high-torque 1500W servo motor * 2 |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Reducer | Shimpo (Japan) planetary gear reducer |

| Variable Frequency Drive | High torque servo frequency converter * 2 |

| Drive-Spindle Motor | 4KW pure servo high torque high speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Tool Motor | 4KW pure servo high torque high speed motor |

| Tool Speed | 0-12000r/min |

| Tool | High-strength alloy disc milling cutter * 4 |

| Control System | CATEKCNC self-developed control system - CK-1000TC |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactors, relays, circuit breakers |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, Type3, AutoCAD, CDR, Carving, Powermill, UG, Mastercam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2400kg |

| Dimensions | 3750*1950*1950mm |

What Products Can the 4-Station CNC Wood Copying Lathe Machine?

With CNC automatic control and complex curved surface machining capabilities, the CNC wood copying lathe can cover the machining of various products, ranging from practical furniture components to wooden crafts.

It can machine a variety of symmetric/asymmetric curved workpieces, such as table legs, chair legs, bed legs, sofa legs, European-style furniture components, sofa armrests, chair armrests, wooden hangers, chair backs, Queen Anne legs, and other complex curved wooden furniture parts, as well as axe handles, hammer handles, agricultural tool wooden handles, wooden crafts, and other products.

Advantages of CATEKCNC Wood Copying Lathe with Disc Milling Cutter in Curved Surface Machining

The CATEKCNC Multi-station CNC Wood Copying Lathe With Disc Milling Cutter is equipped with an indexable rotating lathe drive center, which can stably clamp the workpiece and drive it to rotate. Fitted with a high-speed rotating milling cutter disc for machining, and a cup-shaped tool is mounted on the disc. Specifically designed for the machining of curved surfaces or special contours, these cutters enable efficient milling. They not only offer a larger depth of cut and extremely high machining efficiency but also ensure the surface finish of the machined workpiece, resulting in smooth and natural curve transitions of the workpiece.

In terms of actual machining efficiency, for a standard oval chair leg with a length of 1 meter, this CNC wood copying lathe takes only about 10 minutes on average to machine a single leg. Moreover, it supports simultaneous machining of 4 legs at a time, significantly improving the efficiency of mass production.

Comparison with traditional machining equipment:

When using a standard 4-axis lathe to machine chair legs of the same specification, it takes approximately 1 hour to process one leg, with an efficiency only 1/6 of this equipment.

Even if planing cutters are used to reduce the machining time of a single leg to around 20 minutes, subsequent replacement of tools such as ball-end mills is still required for secondary finishing of details and special-shaped contours. Furthermore, the higher the complexity of the product shape, the more the overall machining time will increase, making it impossible to achieve efficient "one-time forming" machining.

| Model | CK-1520-4M |

|---|---|

| Machining Capacity | 1500 * 200mm * 4 (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | CATEKCNC dedicated high-torque 1500W servo motor * 2 |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Reducer | Shimpo (Japan) planetary gear reducer |

| Variable Frequency Drive | High torque servo frequency converter * 2 |

| Drive-Spindle Motor | 4KW pure servo high torque high speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Tool Motor | 4KW pure servo high torque high speed motor |

| Tool Speed | 0-12000r/min |

| Tool | High-strength alloy disc milling cutter * 4 |

| Control System | CATEKCNC self-developed control system - CK-1000TC |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactors, relays, circuit breakers |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, Type3, AutoCAD, CDR, Carving, Powermill, UG, Mastercam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2400kg |

| Dimensions | 3750*1950*1950mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.