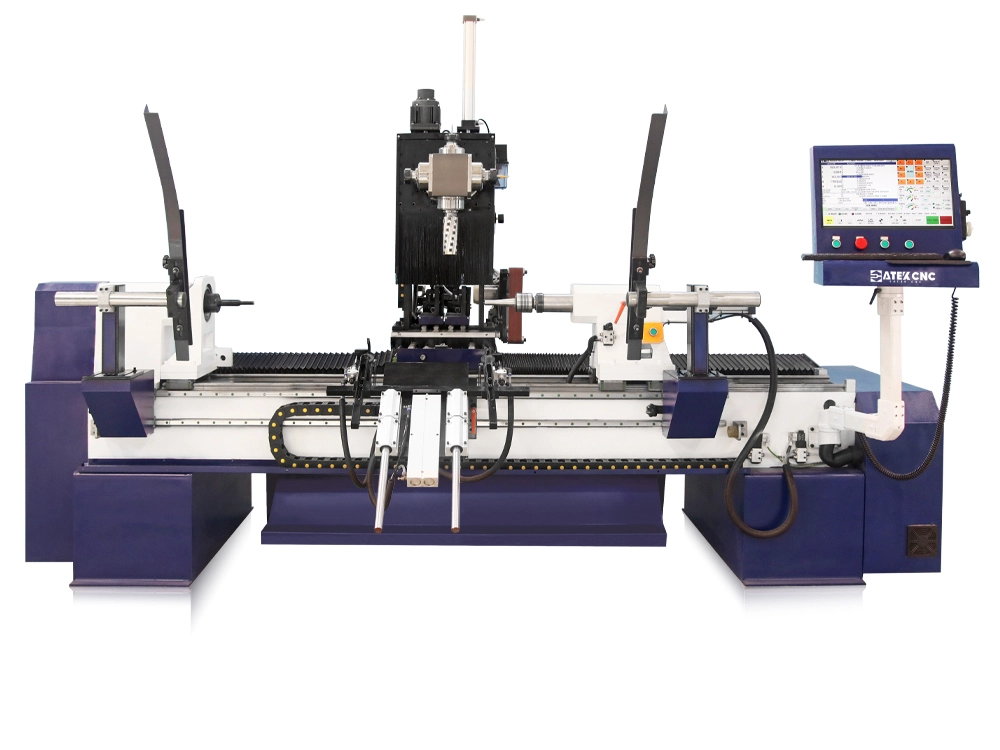

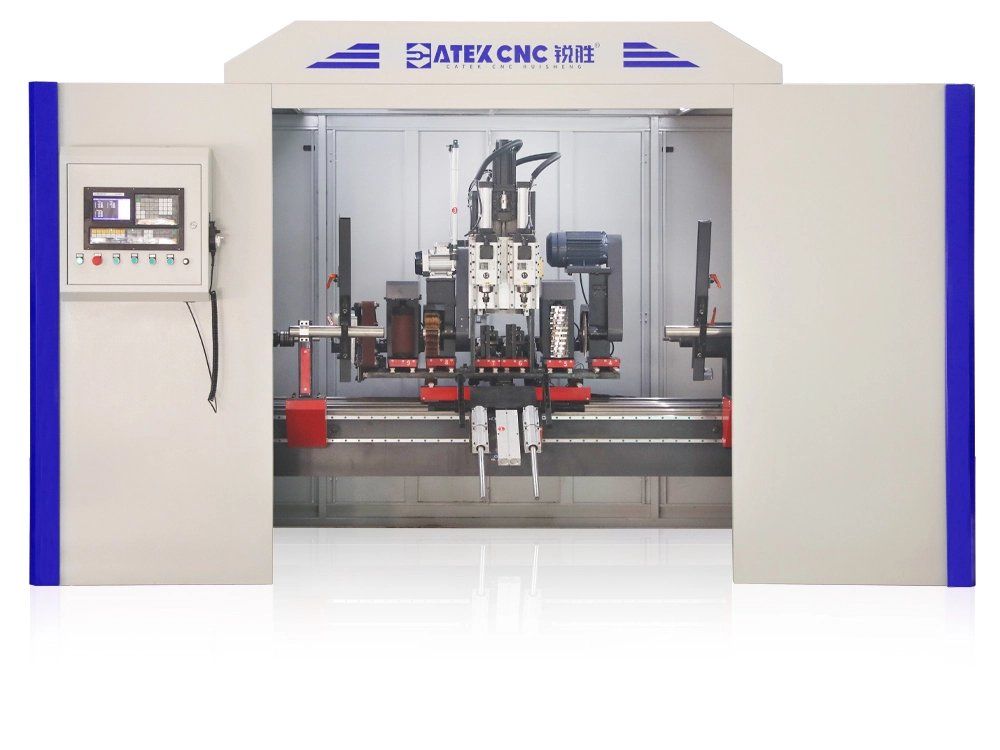

Four-Function Switching CNC Lathe for Wood Turning, Milling, Engraving and Grinding

The Most Popular 4-in-1 Turning, Milling and Carving CNC Wood Lathe

[Function Description]

The 4-in-1 multifunctional CNC woodworking lathe is a multi-tasking woodworking machine with comprehensive functions. It has four functional modules commonly used in wood processing, including turning tools, planing tools, spindles, and sanding wheels. It can perform multiple functional processing operations on the product at one time. It only needs to clamp the blank once to complete multiple processing procedures (such as automatic sanding after turning and drilling), which effectively reduces the number of transfers and clamping of workpieces between different machines, saves the labor required to operate multiple machines, and reduces the space occupied by other machines. The multifunctional CNC woodworking lathe is equipped with an automatic feeding function as standard. It can adapt to blanks of various sizes by adjusting the clamp. Whether the length is 1500mm or 150mm, it can be automatically loaded and unloaded with the help of an automatic feeding device.

The multifunctional CNC woodworking lathe machine reduces the number of clamping times between different machines, reduces error accumulation, and improves the stability of processing quality. For example, when processing stair columns, the traditional method requires a machine to turn the shape, a machine to groove, a machine to drill, and a machine to polish. The whole process requires multiple clamping of materials and position adjustment. The multi-function CNC woodworking lathe can complete all the processing steps at one time. Whether it is single-piece processing, small batch production or large batch production, the multi-function CNC woodworking lathe is very suitable. In recent years, it has been widely welcomed by American countries such as the United States, Canada, Brazil and EU countries.

Features of 4-in-1 Multifunctional CNC Wood Lathe with Automatic Feeding

The CNC wood lathe with automatic feeding system adopts a heavy-duty thickened bed of gray cast iron, which can work continuously for 24 hours without interruption. It is suitable for processing various complex wooden products, supports automatic feeding, and multi-functional all-in-one fully automatic processing.

Machine functions:

Turning, sanding, planing, drilling, slotting, four-axis 3D caving, automatic feeding, multiple functions are integrated into one, and products that require multiple processes can be processed at one time, saving time for manual loading and changing processes.

Processing method:

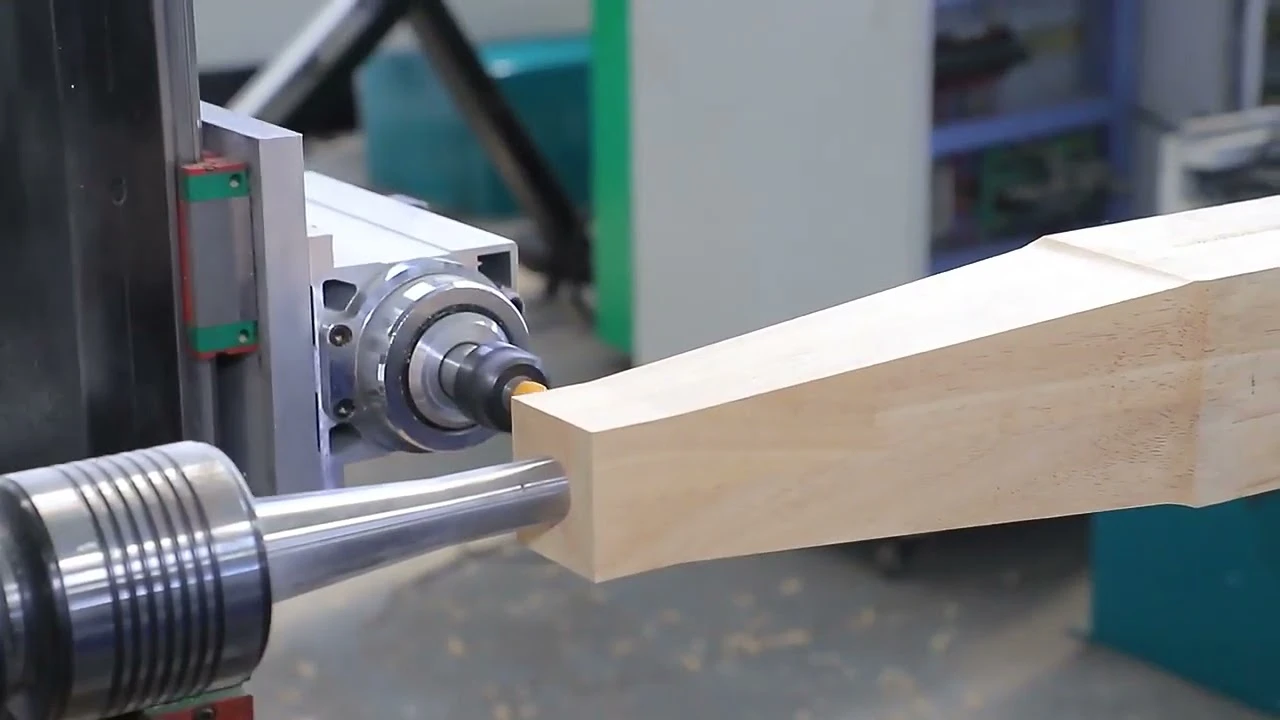

The large four-in-one CNC woodworking lathe uses automatic feeding device to fix the wood to be processed on the machine, and the four functions of the machine can be switched freely. Use the turning tool to turn the square wood, the planer to rough or mill the wood, the multi-functional spindle to punch, slot, pull the wire, four-axis 3D caving and other tasks, and use the sanding wheel to sand and polish the processed products to realize the multi-process fully automatic processing of wood.

Advantages of 4-in-1 CNC Wood Lathe with Automatic Feeding

The machine is driven by a full servo motor. The XYZ three-axis drivers are all connected by high-precision TBI ball screws. They are driven by servo drivers and run in conjunction with Hiwin guide rails/slides to achieve silent operation.

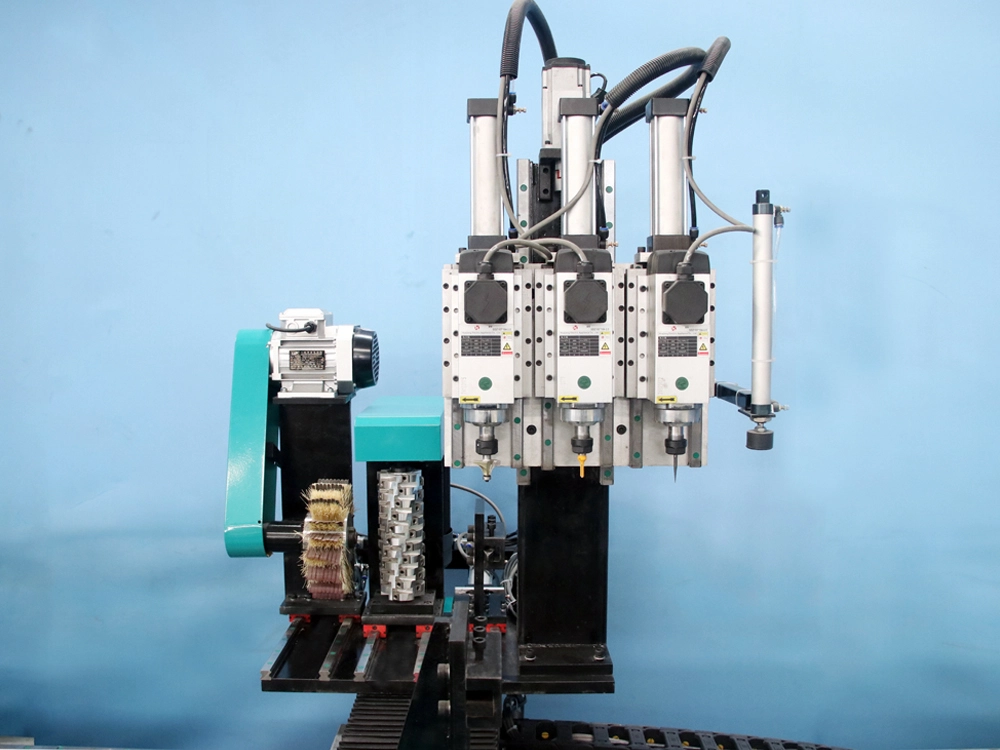

Each function is driven by an independent cylinder and can be switched at will. When processing, you only need to move the tool to the starting point of the material to start processing. The pulse handwheel operation makes tool setting more convenient.

The main motor uses a 4KW high-speed rotating servo motor, which can switch between speed mode and position mode at will, with a maximum speed of 6000r/min, and can switch the A-axis to rotate at any angle.

It uses a 3.5KW high-speed air-cooled rotary spindle, can clamp any shank diameter tool within 12.7, has a maximum speed of 18000r/min, can be equipped with a carving knife, runs a four-axis NC path, and realizes four-axis linkage operation, which is used to process various complex and special-shaped products.

It uses a 230mm high, 90mm large diameter independent heavy-cutting planer, driven by an independent high-torque motor, with a speed of up to 3000r/min, which can be used for rough processing and milling of materials.

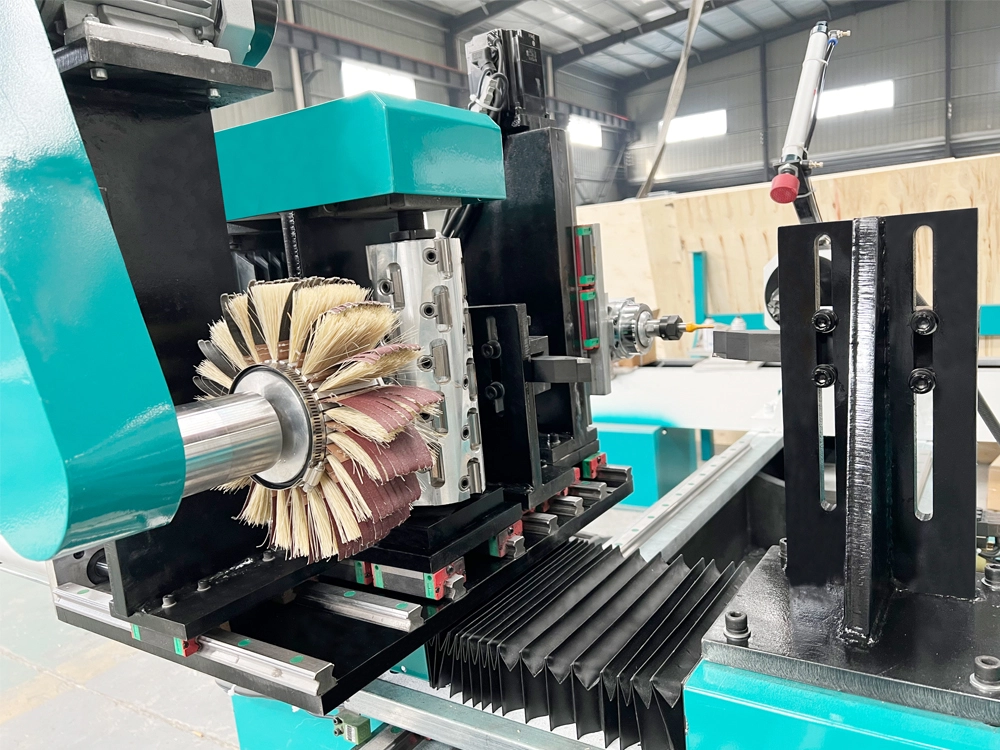

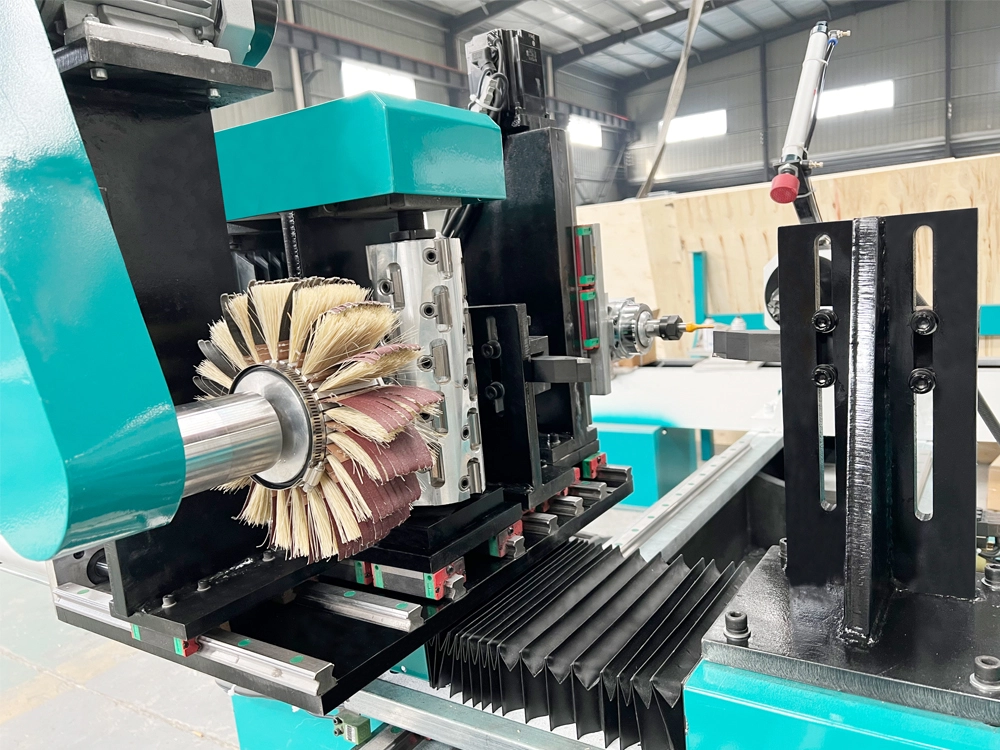

Use independent cylinder to control the grinding wheel to run grinding and polishing. A single product can be polished multiple times or partially polished. Grinding belts or grinding rollers can be selected for different products.

Using professional industrial CNC system, each function is equipped with independent button control. The machine uses international standard G code, and each function has a corresponding G code control switch, which is easy to operate.

It uses a multi-cylinder linkage fully automatic loading and unloading structure. The loading length and diameter can be adjusted arbitrarily. The hopper can hold multiple materials at a time, saving manual center positioning time. After the settings are completed, it can be started with one button. One person can watch over multiple machines, saving labor.

Details of 4-in-1 Multifunctional CNC Wood Lathe

- Demonstration of four independent processing functions

Turning tools, planing tools, grinding wheels, multi-function spindles.

- Demonstration of five independent processing functions

Turning tools, planing tools, grinding wheels, two multifunctional spindles.

- Demonstration of six independent processing functions

Turning tools, planing tools, grinding wheels, three multifunctional spindles.

- Automatic hopper feeding function

Standard automatic feeding hopper, which can realize automatic loading and unloading.

- Optional electric tool holder

An electric tool holder is available as an option, which can hold up to four tools and switch tools by rotating during processing, saving manual tool changing time.

- CK-1000TC control system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

Fully Automatic 4-in-1 CNC Wood Lathe Technical Parameters

| Model | CK-1530-4T |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed motor |

| Driving Mode | The XY axis uses a 750W CATEKCNC high-torque servo motor, and the Z-axis uses a 1.5KW CATEKCNC high-torque servo motor |

| Frequency Converter | BEST/Hpmont frequency converter / pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230 * 50mm, independently controlled sanding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack / TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Multi cylinder linkage automatic feeding system |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1850kg |

| Dimensions | 3550*2300*1750mm |

| Functions | Automatic hopper feeding, turning, planing, milling, 3D caving, slotting, drilling, sanding, polishing |

Application Scope of Professional-Grade 4-in-1 Multifunctional 1530 CNC Lathe

Applicable Materials:

Suitable for use on various materials such as wood, PVC, plastic, nylon, acrylic, carbon fiber, bamboo, density board, etc.

Applicable Industries:

- Furniture: tables, chairs, sofas, beds, stair railings, pool tables, etc.

- Musical instruments: drumsticks, flute, suona, cucurbit flute, bassoon, piano, etc.

- Sports equipment: pool cues, baseball bats, wooden balls, etc.

- Crafts: wooden bowls, vases, cups, pen holders, nesting dolls, wooden guns, candlesticks, etc.

- Sculptures: figure sculptures, animal sculptures, totem sculptures, text sculptures, etc.

It can be used to process various difficult special-shaped products such as solid wood stair columns, solid wood sofa legs, solid wood table and chair legs, billiard table legs, tiger legs, horse legs, bed legs, special-shaped curved legs, sports equipment, musical instruments, solid wood handicrafts, carving products, various furniture accessories, etc.

What Types of Products Can Be Processed Using an Automatic Feeding 4-in-1 CNC Wood Lathe?

How to Choose a CNC Wood Lathe That Is More Suitable for You?

CNC wood lathes have many functions, and there are also large differences in functions between different models.Understanding the following tools will help you choose the right machine.

- Turning tool: There are many types of turning tools available, including right-angle tools, U-shaped tools, V-shaped tools, cutting tools, inner hole tools and other tools. You can choose according to your processing needs.

- Planer: The planer can be used to plan the wood, such as processing it into a twist shape, a polyhedron, a 6-sided column, an 8-sided column, etc. It can also be used for roughing wood.

- Spindle: The spindle can clamp various tools to process the material.

- Engraving knife: Mainly used for pattern carving and handicraft production.

- Milling cutter: Milling the shape of some special-shaped products.

- Straight knife: Cut, slot and punch the product.

- Saw blade: A combination of multi-piece saw blades or a single saw blade can be used to complete the turning or cutting of the material.

- Other special-shaped tools: For example, a pointed milling cutter, a V-shaped milling cutter, etc., can be used for wire drawing of wood.

- Sanding tools: Three sanding methods are provided, namely sanding wheel, sanding roller and sanding belt, for sanding and polishing wood. Among them, sanding wheels are more suitable for sanding various types of products; sanding rollers are more suitable for sanding square or polyhedral surfaces; and sanding belts are suitable for sanding round bars, cones and other products.

Different models of woodworking lathes have different features and functions. How to choose a suitable CNC machine according to your budget and needs is a difficult problem. catekcnc has CNC woodworking lathes with various functions and features for you to choose from. Whether you use it for commercial purposes, studio use, or personal DIY, we can provide you with the most cost-effective choice. Moreover, we provide a three-year free warranty service for all models of products. During this period, you can use it with confidence. Once there is any problem with the machine, we will arrange professional engineers to provide you with a full range of after-sales services. If you encounter difficulties in choosing CNC machinery, please contact catekcnc's sales experts, who will provide you with professional advice.

Why Choose CATEKCNC's CNC Wood Lathe?

CATEKCNC by virtue of excellent technical research and development, design and manufacturing capabilities, to provide customers with comprehensive automation CNC solutions, the company adheres to the “quality first” principle, with integrity, quality, professionalism, timeliness, innovation for the purpose of dedication to customer service.

Quality Control

At CATEKCNC, each machine is born after careful design, rigorous assembly and precise debugging to ensure the accuracy and stability of each machine. After the debugging of the equipment is completed, the professional team will first carry out internal acceptance, and only after the acceptance is qualified will the customer be notified of the acceptance, to strictly ensure that each piece of equipment can meet the customer's requirements.

We welcome you to participate in the final acceptance of the machine on site or through live broadcast.

Delivery time

We will start producing the machine for you as soon as we receive your order. It will take about 7 days, and we will notify you to inspect the machine.

When sending the machine, we will provide you with the following documents for free:

- The machines operation video and operating instructions.

- The machines drawing software and software operation video.

- The machines basic maintenance and machine maintenance manual.

- Spare parts and spare wearing parts of the machine.

The assembly of the machine usually takes 7-15 days. If you have urgent needs, we will expedite production for you.

After-sales service

The warranty period of the machine is 3 years. During the warranty period, if the accessories are damaged due to the machine itself, the accessories will be replaced free of charge (except for wearing parts).

The machine has free maintenance and free software updates for life.

After receiving the fault report, we will respond within 10 minutes in the form of online chat, telephone, fax, and email, and find the cause of the fault within 60 minutes.

We provide you with free technical support, machine installation, drawing programming, machine operation, machine maintenance, and provide lifelong after-sales problem solving for the machine.

Things You Need to Consider When Ordering a Machine

- Trial processing:

If you need, we can provide you with sample processing before you buy, so that you can ensure that the machine can process the products you need.

- Voltage:

We need to customize your machine according to your voltage. If the voltage in your country is special, we can provide you with a specially customized transformer to ensure that the machine can operate normally.

- Control system:

In addition to using our standard control system, we also provide other systems for you to choose, such as: DSP control system, Weihong control system and other systems, you can choose according to your usage habits.

- Drive system:

Machine has stepper motors and servo motors for you to choose. Stepper motors use semi-closed loop operation and are low in price. Servo motors use closed loop operation and have collision protection. The price is higher. You can choose according to your budget.

- Transportation method:

Machine can choose sea, land, air and other transportation methods. Among them, sea transportation is cheap and takes a long time, while air and land transportation are more expensive.

| Model | CK-1530-4T |

|---|---|

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed motor |

| Driving Mode | The XY axis uses a 750W CATEKCNC high-torque servo motor, and the Z-axis uses a 1.5KW CATEKCNC high-torque servo motor |

| Frequency Converter | BEST/Hpmont frequency converter / pure servo frequency converter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Planer | 90 * 240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230 * 50mm, independently controlled sanding wheel, driven by 370w three-phase asynchronous motor |

| Transmission Mode | XY axis 25 TBI ball screw, Z-axis uses high-precision helical gear rack / TBI 32 ball screw |

| Turning Tool | V-shaped alloy cutting tool (large cutting capacity) |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Automatic Loading & Unloading | Multi cylinder linkage automatic feeding system |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1850kg |

| Dimensions | 3550*2300*1750mm |

| Functions | Automatic hopper feeding, turning, planing, milling, 3D caving, slotting, drilling, sanding, polishing |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.