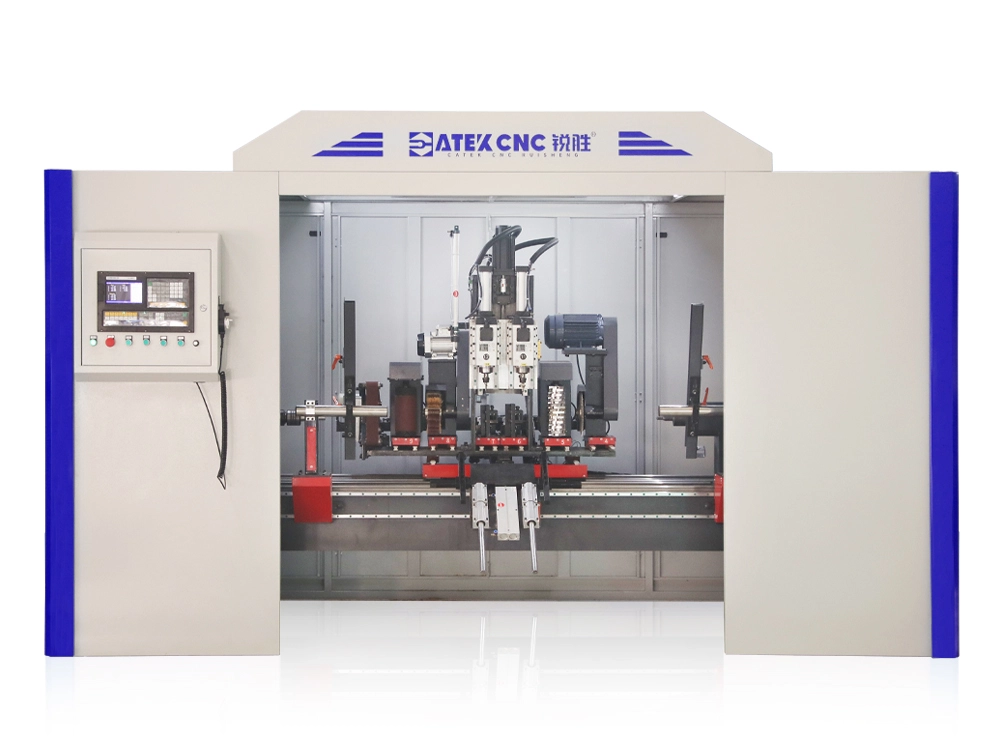

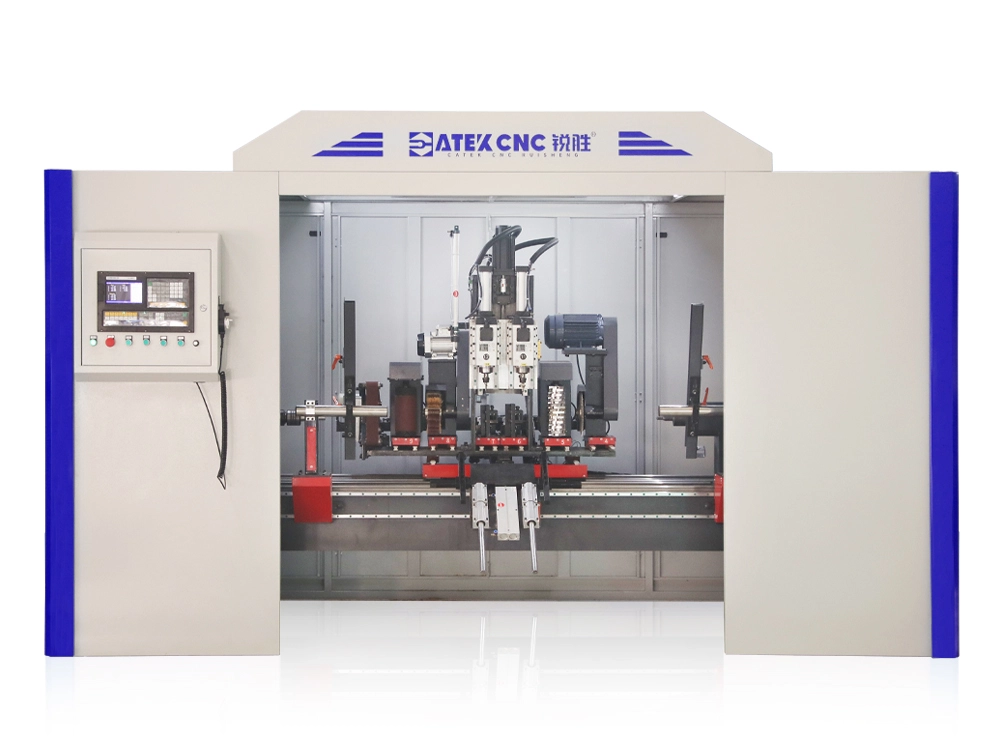

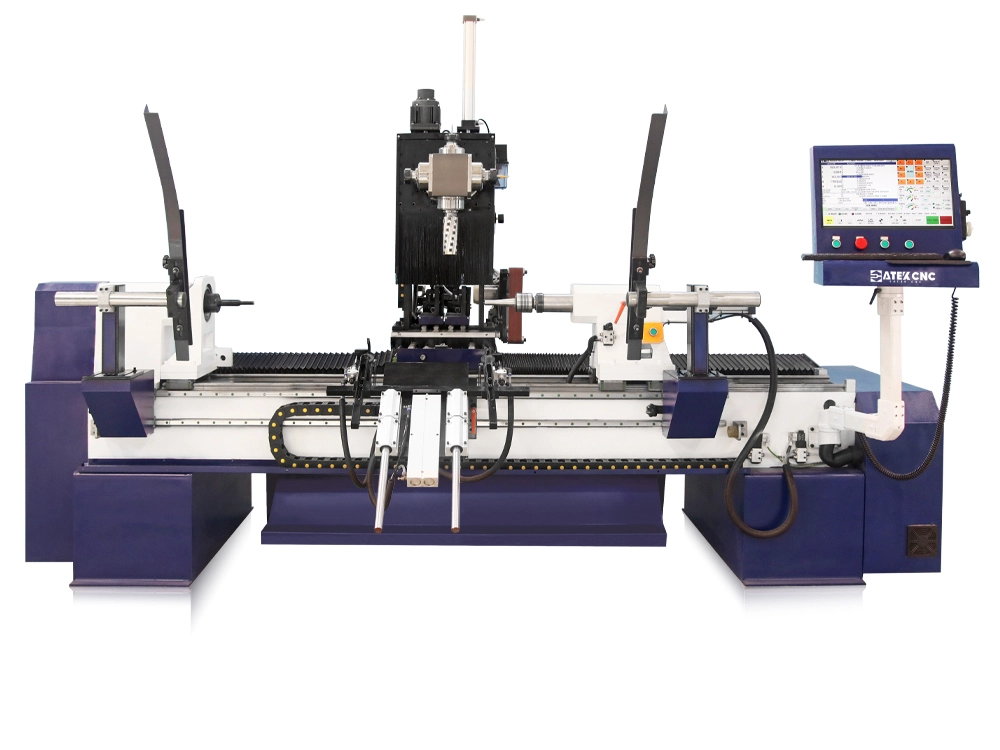

9-Function CNC Woodworking Lathe With Full Enclosure

Fully Automatic 9-in-1 CNC Wood Lathe with Safety Enclosure

[Function Description]

The 9-function CNC woodTurnning lathe with closed protective cover is equipped with nine functions at the same time, and is also equipped with an additional closed protective cover. The closed protective cover can effectively prevent damage caused by wood chips splashing, ensure that the operator cannot directly contact the high-speed rotating workpiece, effectively protect the operator's safety, and can also isolate dust and wood ash, and reduce the noise of machine operation. It is more environmentally friendly to use.

The CNC wood lathe with closed protective cover uses an external CNC system to control the operation of the machine, and is equipped with a fully automatic feeding device. After the operator adjusts the machine, he only needs to put enough wood in the silo, and the machine can run and process automatically. After all the wood in the silo is processed, the safety sensor installed on the silo senses that there is no wood in the silo, and the machine will stop automatically. The operator only needs to continue to put wood into the silo, and then click to continue running, and the machine can continue to run automatically. The entire processing process does not require manual intervention, and only needs to put wood into the silo regularly. That is, one person can operate more than 5 CNC wood lathes, which can effectively reduce labor costs and improve efficiency. At the same time, the machine is equipped with nine different functions, which has great advantages in processing complex wooden products and products that require multiple processes to complete. The wood only needs to be clamped once, and the machine can complete the workpiece's shape turning, milling, drilling, grooving, sawing, 3D carving, sanding, surface sanding and other processes. There is no need to transfer to other machines for secondary calibration processing, which effectively improves processing efficiency, and only needs to purchase one machine, saving the cost of purchasing other machines.

What Are the 9-in-1 of the Fully Automatic CNC Wood Lathe With Enclosure?

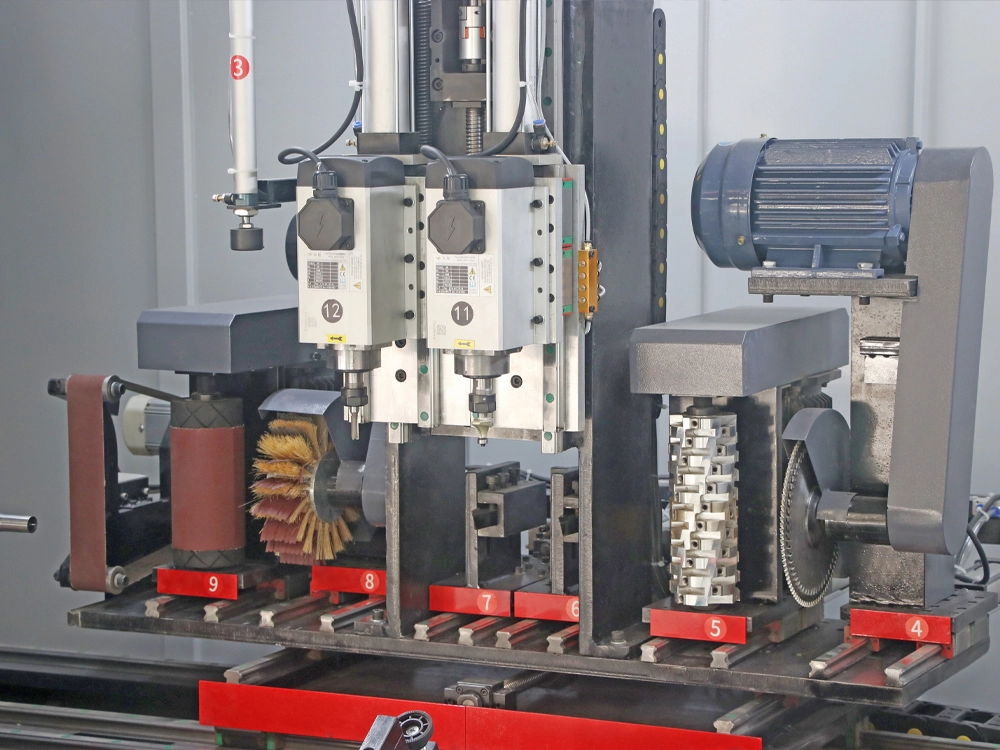

- Turning tools: It can be equipped with turning tools with any tool holder within 30mm. The standard configuration is a high-hardness alloy V-shaped turning tool with a service life of more than 180 days, which is durable.

- Functional turning tools: 90° right-angle turning tools, discarded V-type turning tools, U-type roughing tools, cup-shaped round bar tools and various other functional turning tools can be installed and can be freely replaced and installed.

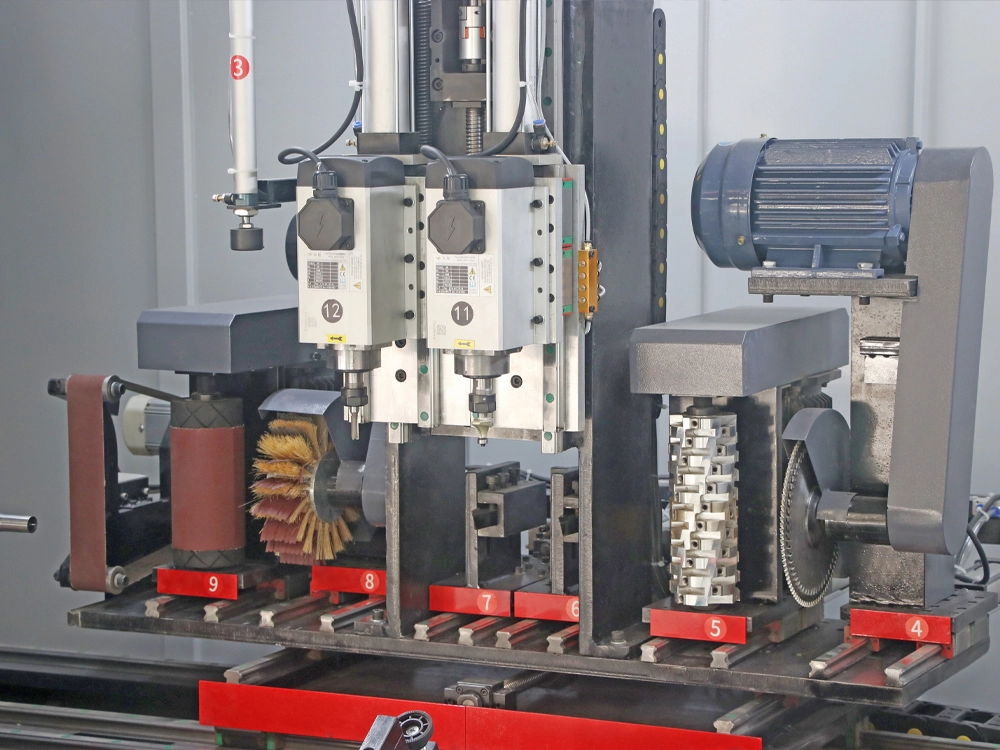

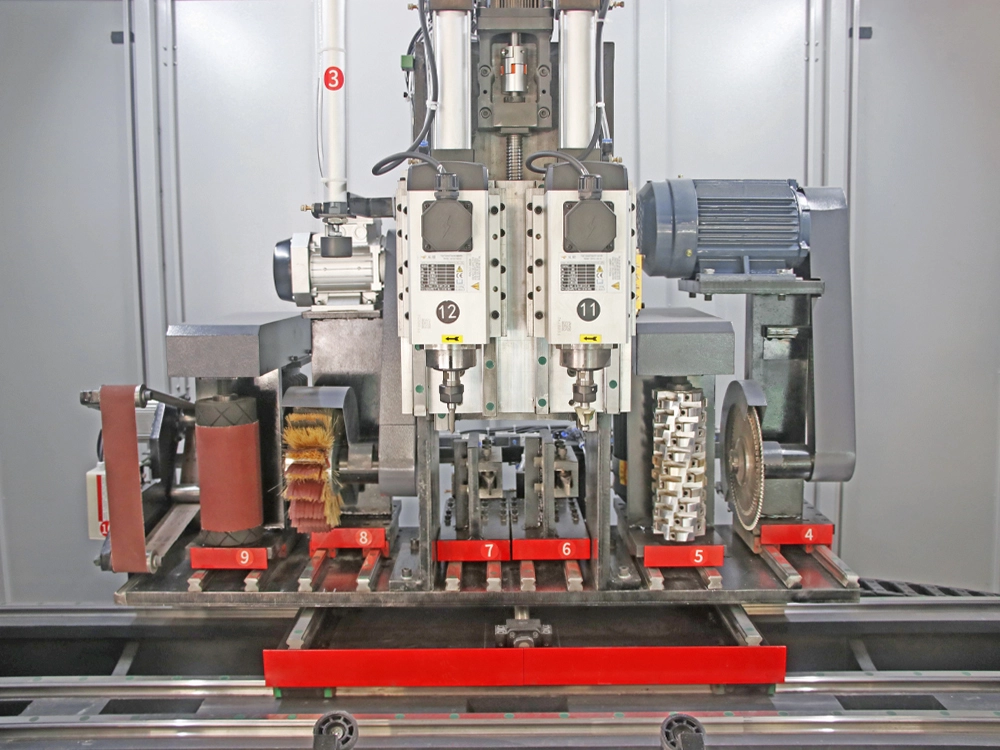

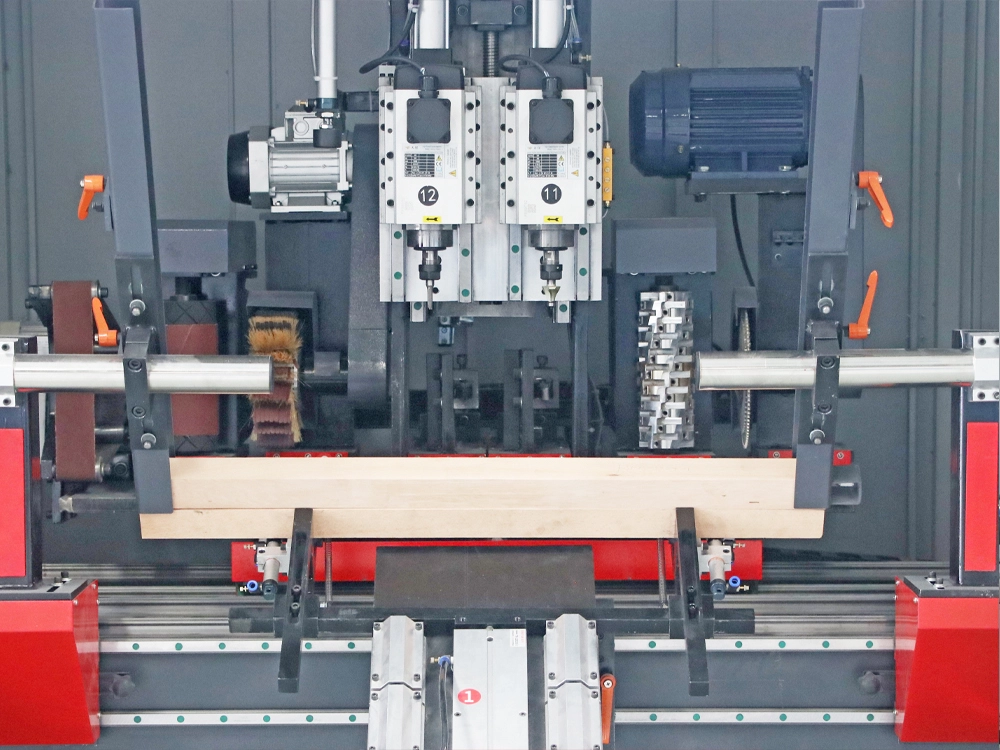

- Two 4.5KW high-speed air-cooled spindles: speed of 18000r/min, equipped with ER32 tool holders, can be installed with various tools within a shank diameter of 20mm. Two different types of tools can be installed at one time, including drills, milling cutters, forming milling cutters, ball-end milling cutters, etc., which can be replaced according to the processing requirements of the workpiece. Both spindles are four-axis linkage. In addition to drilling, grooving, milling and other functions, they can also be used for plane engraving, 3D rotary engraving, etc.

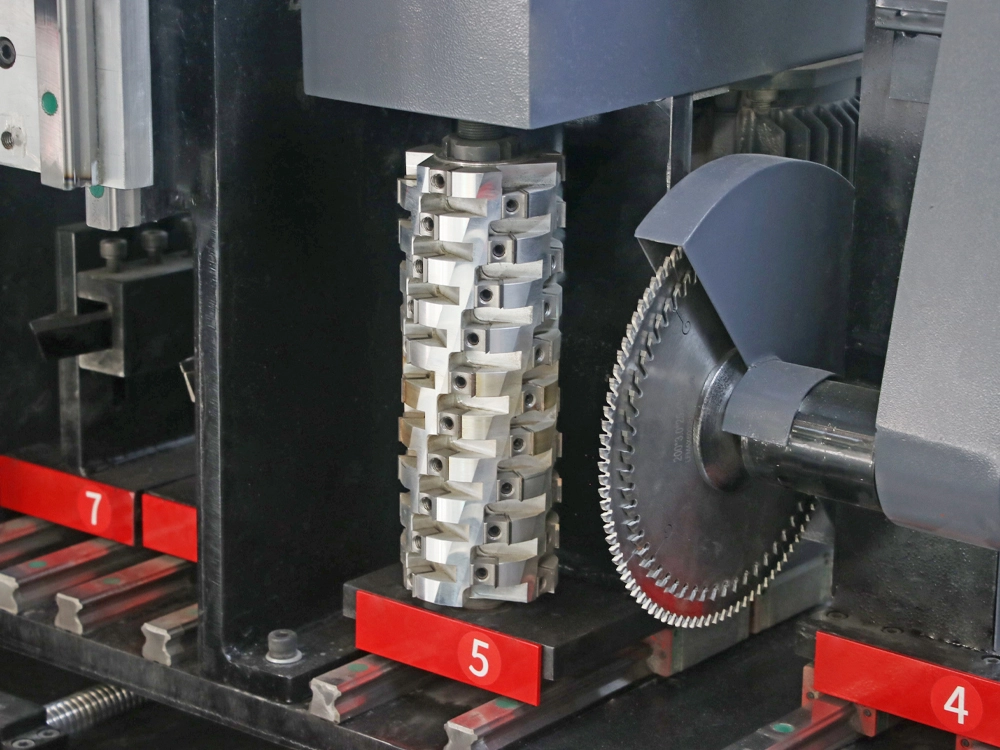

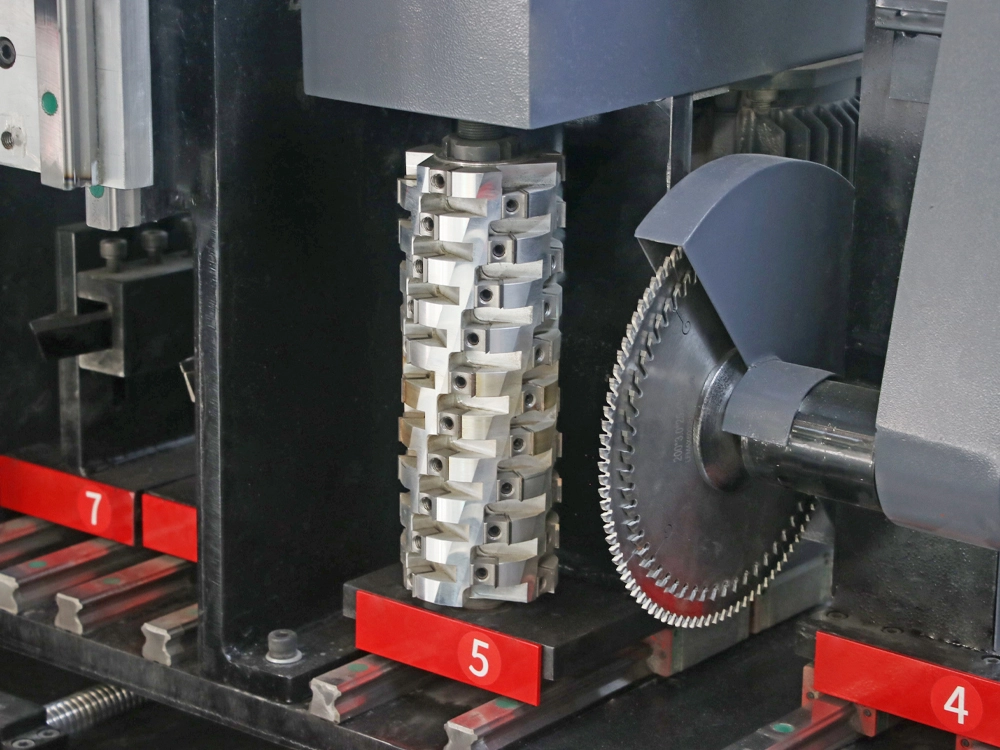

- Planer: The large-size planer with a height of 240mm and a diameter of 90mm uses 60 blades and is driven by a 2200w high-torque three-phase asynchronous motor. It can quickly plan wood and can be used for rough processing of wood. It can also be used for plane planing or cooperate with the A-axis to process twisted plane milling.

- Combination saw blade: Multi-piece combination saw blade, diameter 230mm, using multiple saw blades combined, with 1100W high-speed motor drive, can quickly saw and rough various woods, can also be used as an ordinary turning tool for milling type processing.

- Sanding wheel: Use a sanding wheel with a diameter of 230mm and a thickness of 50mm, driven by a 370W high-speed motor. The number of sandpaper meshes can be customized, and sanding brushes are installed interspersed, which can be used to sand various cylindrical products.

- Oscillating Spindle Sanding roller: Driven by a 2200W motor, the Oscillating Spindle Sanding roller device can not only rotate at high speed, but also "move up and down" in the axial direction, which can effectively avoid local wear of the sanding belt and improve the uniformity and efficiency of sanding. It is very suitable for sanding the surface of flat or cylindrical products.

- Sanding belt: driven by 1100w high-speed servo motor, the speed can be adjusted arbitrarily from 0 to 6000 rpm, and the mesh size of the sandpaper can be selected arbitrarily, suitable for surface sanding of various cylindrical products.

Advantages of Fully Automatic CNC Woodworking Lathe With Closed Protective Cover

- Use CATEKCNC's self-developed CNC wood system for CNC wood lathes, with built-in macro programs, supporting various types of files such as NC/DXF/DBF/TXT. DXF/DBF, a flat 2D line file, can be automatically converted into G code through the system's built-in macro program. It does not require complex G code conversion, is simple to operate, and is easier to use.

- Equipped with 4KW high-speed rotating servo spindle motor, the maximum speed is 6000r/m, the speed can be adjusted arbitrarily, and the A-axis can be switched using the position mode to control the angle rotation. The angle can be accurately controlled to 0.01°, which is easy to use.

- It uses a double-row thickened casting bed. The entire bed is cast from gray cast iron. The machine weight is over 2500kg. Even when processing large-diameter workpieces, there will be no shaking.

- Using four 30mm Taiwan Hiwin linear guides, Taiwan Hiwin 30mm flange sliders, TBI ball screws, the machine runs at extremely fast speed, low noise and high positioning accuracy.

- XYZ axes all use 1500w servo motors, the Z axis is equipped with a new planetary reducer imported from Japan, and the Y axis uses a brake servo motor. The operating speed can reach 60000mm/m, which is more efficient.

- Equipped with a four-link pneumatic automatic feeding device, which is easy to adjust and can realize automatic clamping and unloading of materials. There is no need for manual clamping of wood, which effectively improves processing efficiency.

- Equipped with a closed fully enclosed protective cover, it can effectively isolate the noise, wood chips and dust generated by processing, making it more environmentally friendly and effectively protecting the safety of operators.

- A CNC wood lathe is equipped with 9 functions. The 9 functions are automatically switched according to the drawings during the processing. No manual operation is required. Products that require multiple functions can be processed in one clamping, which improves efficiency and saves costs.

- Compatible with various CAD/CAM type software, such as commonly used autucad, artcam, powermill, mastercam, etc., compatible with various G code files.

- The machining accuracy can be controlled within ± 0.05mm, with extremely high precision, effectively ensuring smooth assembly between workpieces.

Details of Fully Automatic CNC Woodworking Lathe Machine With Enclosure

- Fully enclosed safety protection enclosure

-

The whole machine is fully surrounded and protected, effectively isolating noise, dust, and wood chips. It is environmentally friendly and can be connected to a vacuum cleaner to automatically vacuum the dust generated during the processing process.

- Nine functions in one

-

Turning, milling, planing, drilling, grooving, wire drawing, milling, chamfering, 3D engraving, sanding, automatic feeding, all kinds of functions are available.

- CNC system

-

It uses self-developed CNC system with intuitive interface, simple operation, equipped with various advanced functions such as handwheel simulation, processing status monitoring, abnormal alarm, etc. The precision control can be within ±0.01mm.

- Automatic feeding device

-

Four-link pneumatic automatic feeding device, simple adjustment, can be freely adjusted according to different raw material sizes, easy to use.

- Automatic lubrication device

-

The electric fully automatic lubrication oil pot can automatically lubricate and maintain the transmission parts of the machine without manual lubrication, thus preventing untimely manual lubrication.

- Pulse handwheel

-

Equipped with an external pulse handwheel, it can accurately control the moving distance of the XYZA axis and the moving speed, making calibration more convenient.

- Automatic material receiving device

-

The processed wood automatically falls to the material receiving platform to prevent it from falling to the ground and damaging the workpiece.

Technical Parameters of 9-in-1 Multifunctional Wood CNC Lathe

| Model | CK-1530-9TE |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mechanism | CATEKCNC dedicated high-torque servo motor |

| Variable Frequency Drive | BEST/Hpmont inverter/pure servo inverter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 4.5KW high-speed air-cooled spindle * 2 (supports four-axis linkage) |

| Spindle Speed | 0-18000r/min |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Turning Tool | V-type alloy turning tool (large turning capacity) |

| Right Angle Knife | 90 degree V-shaped discard right angle knife |

| Planer | 90*240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230*50mm, independently controlled sanding wheel, 370w three-phase asynchronous motor |

| Oscillating Sanding Shaft | 240mm high oscillating sanding shaft, 2.2KW three-phase asynchronous motor |

| Sanding Belt | Driven by a servo motor, the speed can be adjusted within 0-6000 rpm |

| Saw Blades | 230mm diameter multi-piece saw blade, 1.5kw three-phase asynchronous motor |

| Transmission Mechanism | XY axis 25 TBI ball screw transmission, Z-axis uses high-precision helical gear rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper high-flexible bending-resistant cable |

| Automatic Loading & Unloading | Multi-cylinder 4-linkage fully automatic loading and unloading (simple and easy to use) |

| Control System | Taiwan LNC lathe dedicated control system |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2700kg |

| Dimensions | 3900*2150*2250mm |

| Toolbox | Turning tool, wrench, collet, handwheel, center, chuck, oil pot, oil-water separator, relay, photoelectric limit. |

Application Scope of Fully Automatic CNC Woodworking Lathe Machine With Closed Protective Cover

- Furniture parts: table and chair legs, sofa legs, bed legs, furniture columns, support rods, coat racks, Queen Anne legs, complex curved legs, furniture armrests, table and chair backrests, European carved legs, horse legs, etc.

- Architecture and decoration: stair columns, railings, antique building support columns, Roman columns, wall wood decorations, door handles, candlesticks, table lamps, etc.

- Crafts and daily wooden products: wooden cups, wooden bowls, vases, wooden plates, wooden jars, wooden balls, wood carvings, figure statues, Buddha statues, Buddhist shrines, aromatherapy utensils, drumsticks, piano legs, tool handles, axe handles, walking sticks, agricultural tool handles, etc.

- Industrial and sports equipment: baseball bats, trekking poles, rowing oars, cricket bats, pool cues, pool table legs, etc.

| Model | CK-1530-9TE |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Motor | 4KW pure servo high torque high-speed rotating motor |

| Driving Mechanism | CATEKCNC dedicated high-torque servo motor |

| Variable Frequency Drive | BEST/Hpmont inverter/pure servo inverter |

| Spindle Servo Motor Speed | 0-6000r/min |

| Spindle Power | CATEKCNC dedicated 4.5KW high-speed air-cooled spindle * 2 (supports four-axis linkage) |

| Spindle Speed | 0-18000r/min |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Turning Tool | V-type alloy turning tool (large turning capacity) |

| Right Angle Knife | 90 degree V-shaped discard right angle knife |

| Planer | 90*240mm, large diameter independent planer, 2.2KW three-phase asynchronous motor drive |

| Sanding Wheel | 230*50mm, independently controlled sanding wheel, 370w three-phase asynchronous motor |

| Oscillating Sanding Shaft | 240mm high oscillating sanding shaft, 2.2KW three-phase asynchronous motor |

| Sanding Belt | Driven by a servo motor, the speed can be adjusted within 0-6000 rpm |

| Saw Blades | 230mm diameter multi-piece saw blade, 1.5kw three-phase asynchronous motor |

| Transmission Mechanism | XY axis 25 TBI ball screw transmission, Z-axis uses high-precision helical gear rack/TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 30 linear square rail/30 flange slider |

| Equipment Cable | Pure copper high-flexible bending-resistant cable |

| Automatic Loading & Unloading | Multi-cylinder 4-linkage fully automatic loading and unloading (simple and easy to use) |

| Control System | Taiwan LNC lathe dedicated control system |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instruction | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2700kg |

| Dimensions | 3900*2150*2250mm |

| Toolbox | Turning tool, wrench, collet, handwheel, thimble, chuck, oil pot, oil-water separator, relay, photoelectric limit. |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.