Best-selling Multifunctional 7-in-1 CNC Wood Lathe in 2026

The Most Cost-Effective 7-in-1 Multifunctional CNC Wood Lathe in 2026

[Function Description]

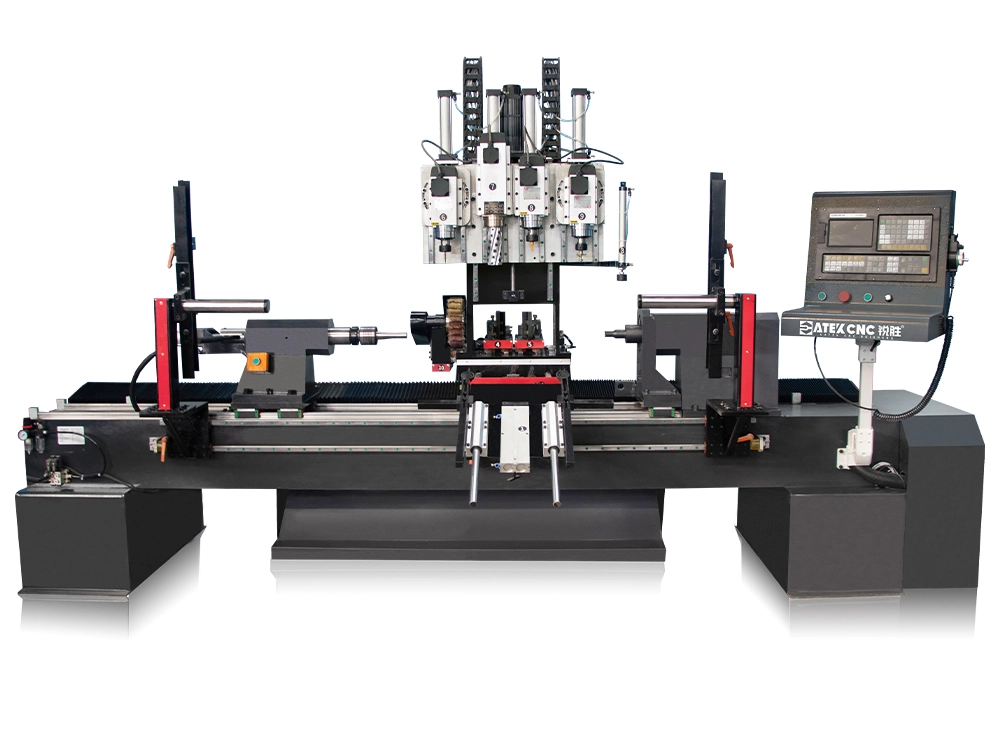

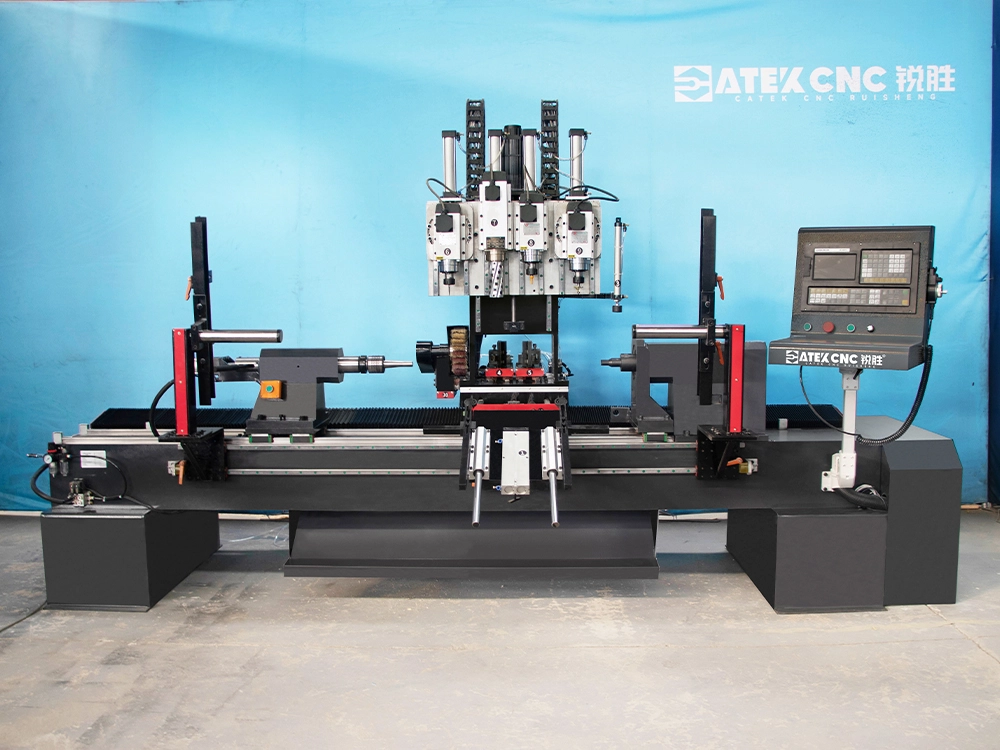

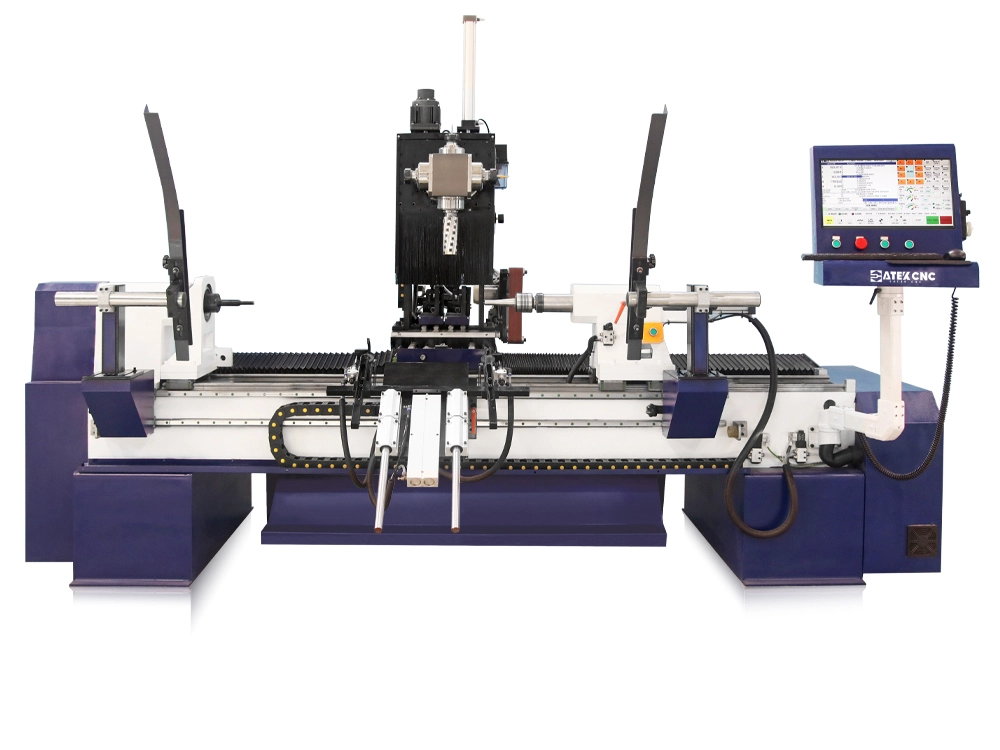

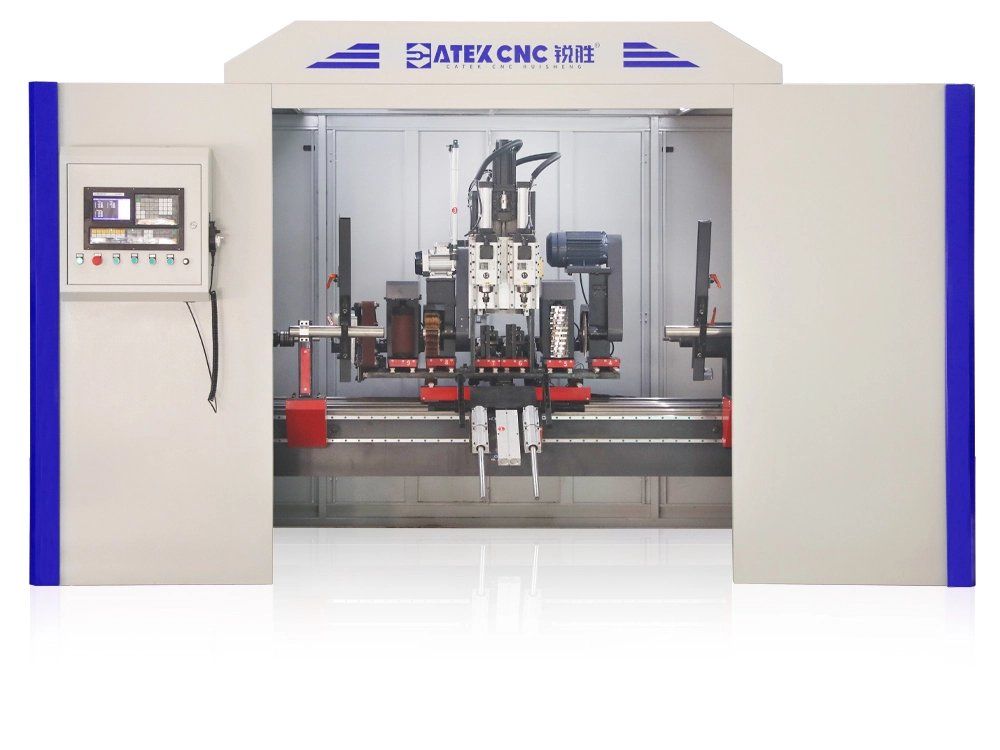

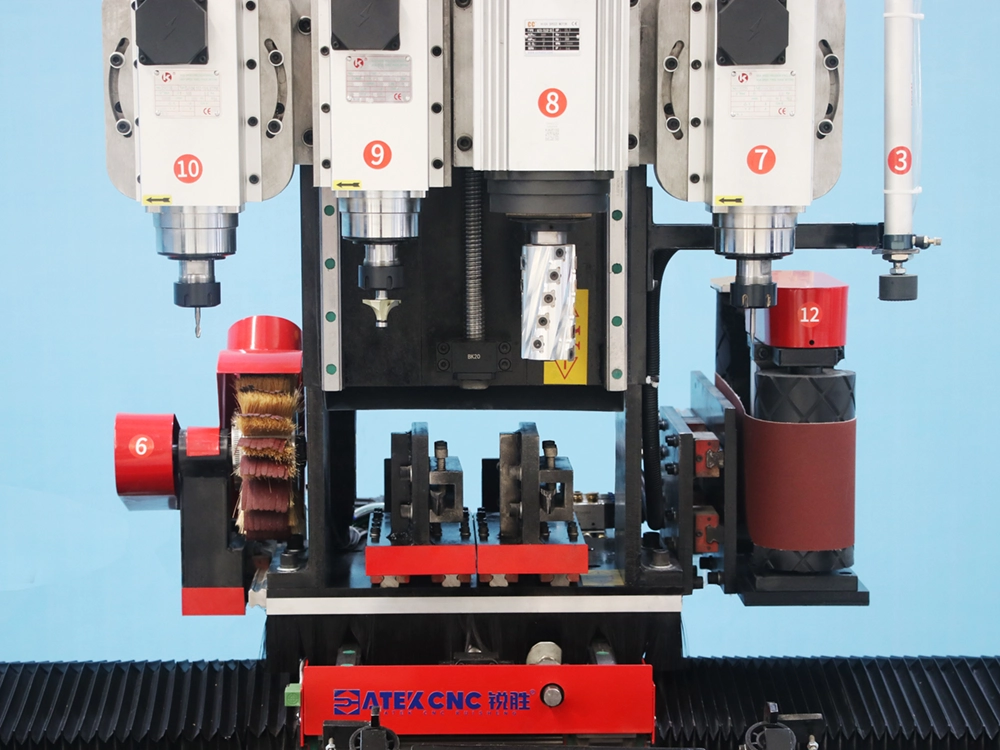

The CK-1530-7T is a multi-functional 7-in-1 CNC wood lathe, the latest cost-effective industrial-grade heavy-duty CNC wood lathe launched by CATEKCNC. Compared to competitors, this machine significantly outperforms in overall configuration and is meticulously designed for multi-process machining. It is equipped with seven machining tools, enabling continuous machining of workpieces with various techniques, including turning, drilling, grooving, milling, surfacing, chamfering, flat engraving, and 3D carving—all completed with a single workpiece clamping. Through practical testing, the CK-1530-7T has proven capable of accurately handling over 95% of machining tasks for stair balusters, table/chair legs, and various furniture components. From diverse furniture parts to intricate artistic shapes, this CNC lathe can precisely replicate every product detail according to design drawings, making it a truly all-in-one machining powerhouse in modern woodworking.

Seven Core Configurations of the Multifunctional CNC Wood Lathe, Far Ahead of Its Peers

- Robust Construction for Ultra-High Stability

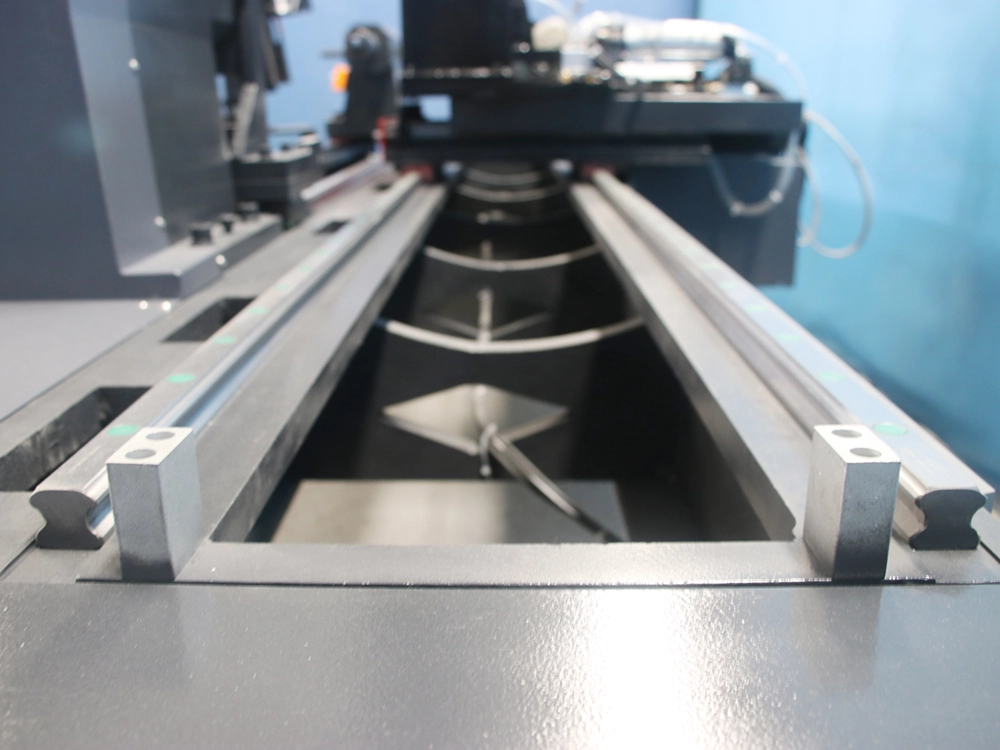

- The machine bed adopts a heavy-duty, double-row, four-track reinforced design made of gray cast iron, providing exceptional load-bearing capacity. It effectively withstands the weight of the machine, workpiece, and machining forces, allowing for the installation of more complex tools while ensuring superior stability during operation.

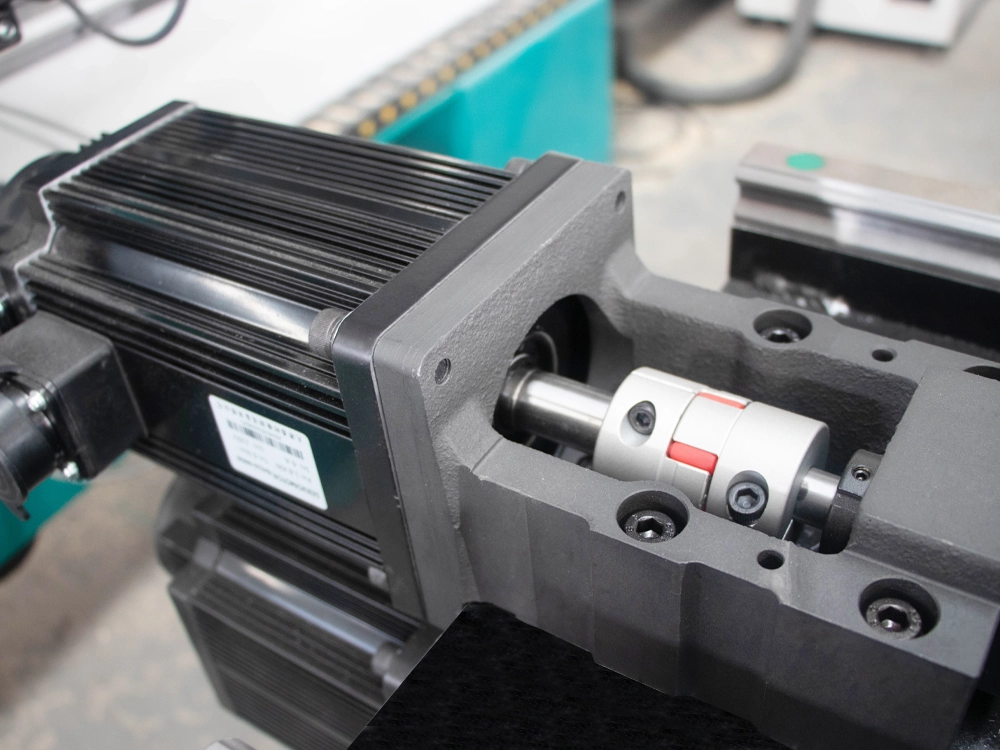

- Premium Materials for Precision Transmission

-

This CNC wood lathe has three linear axes: X, Y, and Z. The Z axis is driven by rack + linear guide, and the X and Y axes are driven by ball screw + linear guide.

-

Guideway: Taiwan-made HIWIN 30 linear guide rails with flange sliders provide a large contact surface to handle multi-directional loads, enhancing stability and preventing deformation under heavy long-term use.

-

Ball screws: TBI ball screws offer high transmission efficiency, requiring only 1/3 the driving torque of ACME screws, with positioning accuracy up to 0.01mm.

-

Rack: 1.5-module high-precision helical rack ensures smooth meshing, higher torque capacity, and quieter operation.

All three axes are powered by 1500W pure servo motors, with the Z-axis additionally equipped with a Japanese Shimpo planetary reducer. The traversing speed can reach 60 m/min, with a wide speed control range, smooth speed regulation, stable torque output, and high positioning accuracy.

-

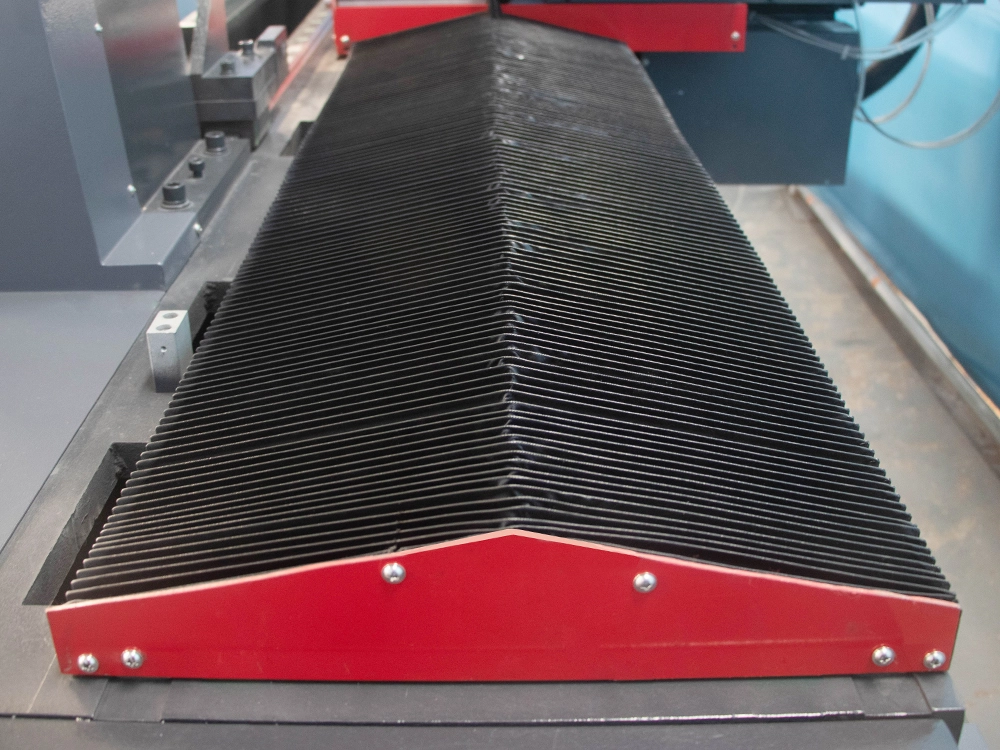

- Meticulous Details, Reflecting Premium Quality

-

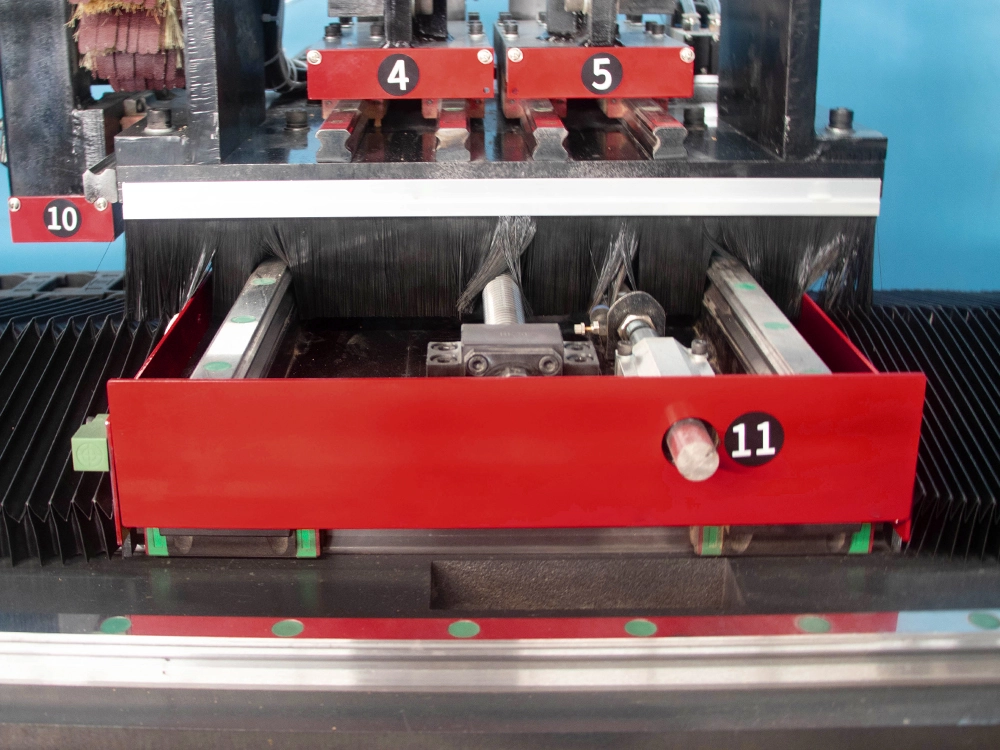

In order to meet the dust prevention needs during the machining, this CNC wood lathe has also done a lot of dust prevention or dust removal. The Z axis is equipped with a closed dust cover, and the X axis is equipped with a dust scraper and brush for sweeping away machining waste. It effectively prevents material debris from entering the transmission system, improves the reliability of the machine and reduces maintenance costs.

- Large-Scale Machining with Versatile Engraving & Milling

-

Machining size: It can process blanks with a maximum length of 1500mm and a maximum diameter of 300mm.

Lathe center: The drive-spindle adopts a 4KW pure servo high-speed rotary motor, which can rotate at high speed during turning (the maximum speed can reach 6000rpm), and can be indexed when milling, engraving, and drilling are required.

- Comprehensive Functions for Diverse Machining Needs

-

- Two turning stations on the same side are standard, which can be used with a variety of tools.

- A 7.5KW air-cooled spindle for planers, with a speed of up to 18,000rpm, and a planer with a length of 15 cm and a diameter of 6 cm is standard.

- Three 6KW high-speed air-cooled variable frequency spindles, supporting ER32 shank diameter. Two of the spindles located on the outside can be manually rotated to achieve tilting machining of the workpiece.

- A sanding station. Three options are available: sanding wheel, sanding belt, and sanding roller. 150-mesh sandpaper is standard, and 80-300-mesh sandpaper is optional. The sanding device is driven by an independent brushless servo motor, and the speed can be adjusted as needed within 0-6000 rpm.

- Fully Automatic Loading/Unloading, Reducing Labor Costs

-

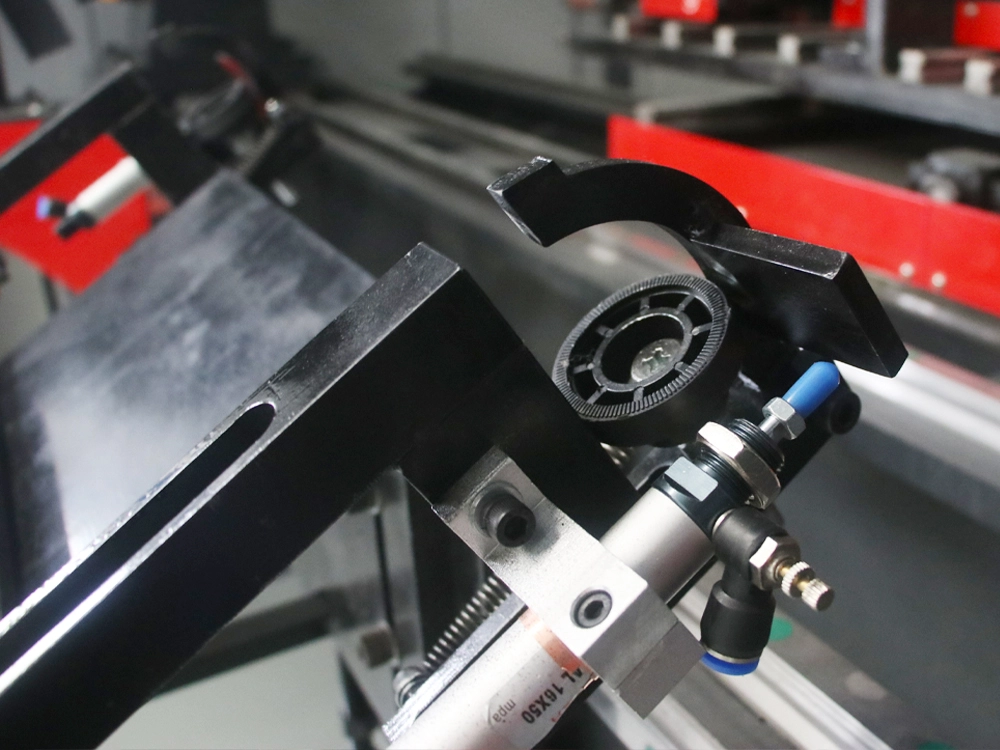

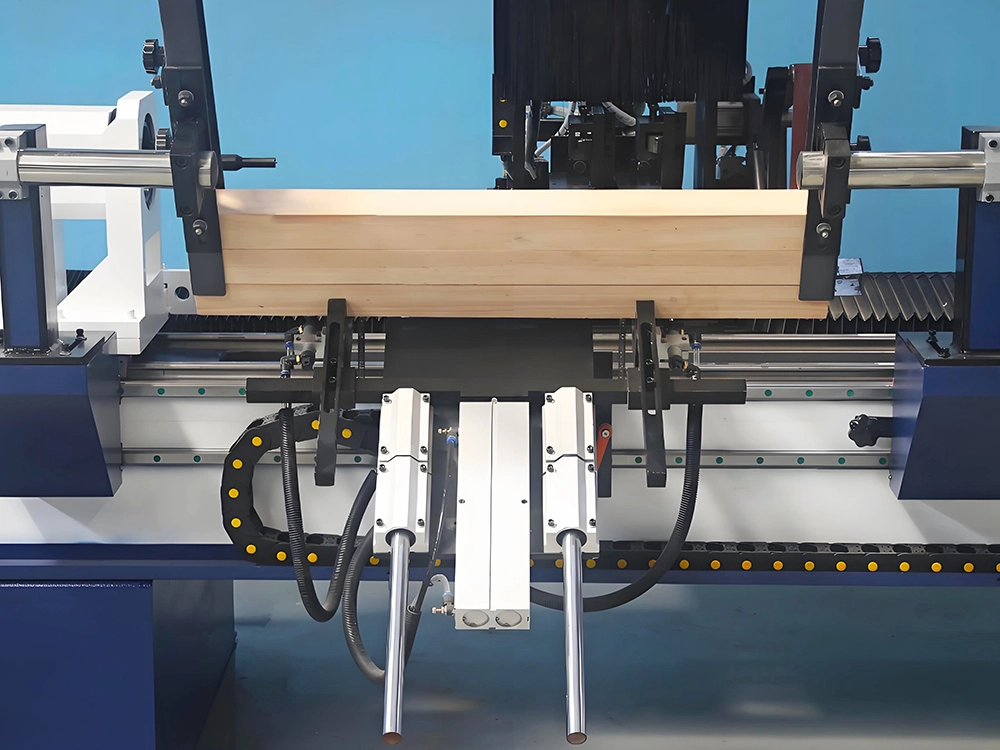

This CNC wood lathe is equipped with an automatic loading and unloading device.

- Before machining, the loading and unloading device needs to be adjusted according to the length and diameter of the material to be processed, and then the blanks are filled into the hopper.

- After machining begins, the loading cylinder accurately sends the blank from the hopper to the center of the workstation, and then the lathe center automatically clamps the workpiece and starts machining.

- After machining is completed, the unloading cylinder ejects the finished product from the workstation, causing it to fall into the receiving slide below. Then, the loading cylinder continues to feed in wood to start the next round of machining.

The hopper is equipped with a limit switch. When the wood in the hopper is exhausted, the limit switch will send a signal to the control system to automatically stop machining.

- Top-tier electrical components, where quality makes all the difference.

-

All electrical components of the CNC wood lathe are purchased from Schneider, Delixi and other top-tier upstream suppliers to ensure the reliability and stability of the electrical system.

High-flexibility pure copper shielded cable is used, which has good conductivity, strong anti-interference ability, high flexibility, bending resistance and not easy to damage.

The air hoses is made of thickened PU material, with high resilience and high pressure resistance, and does not harden at low temperature and does not soften at high temperature.

The control cabinet adopts separate layout for high/low voltage, preventing electromagnetic interference.

Display of the Best 7-In-1 CNC Wood Lathe in 2026

- Bed

-

The CNC wood lathe adopts a double-row four-track bed, which is cast in gray cast iron with a thickness of up to 30mm. It can effectively bear the heavy deadweight of a heavy-duty multifunctional lathe and ensure higher stability when machining large workpieces.

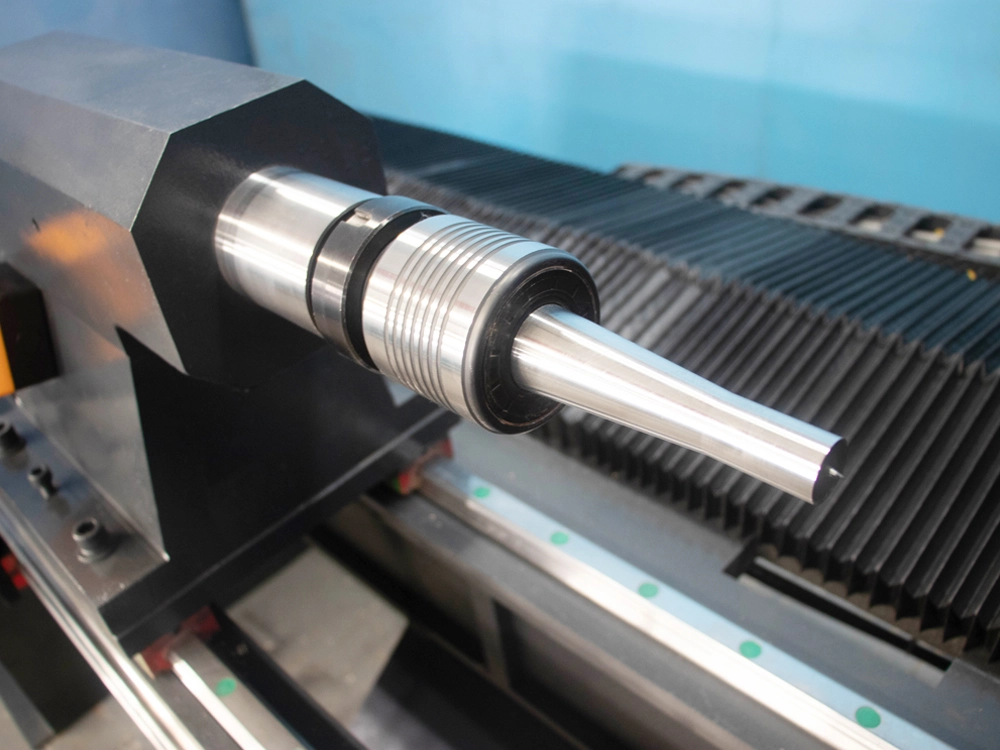

- Lathe center

-

The headstock is made of gray cast iron and is equipped with a four-bearing drive spindle, which makes the rotation more stable and the machining more powerful.

The cast tailstock is equipped with a Morse No. 5 taper and a standard stroke cylinder for fast clamping of wood.

After the workpiece is in place, the tailstock can be fixed by the tailstock locking device so that the tailstock and the headstock can clamp the workpiece.

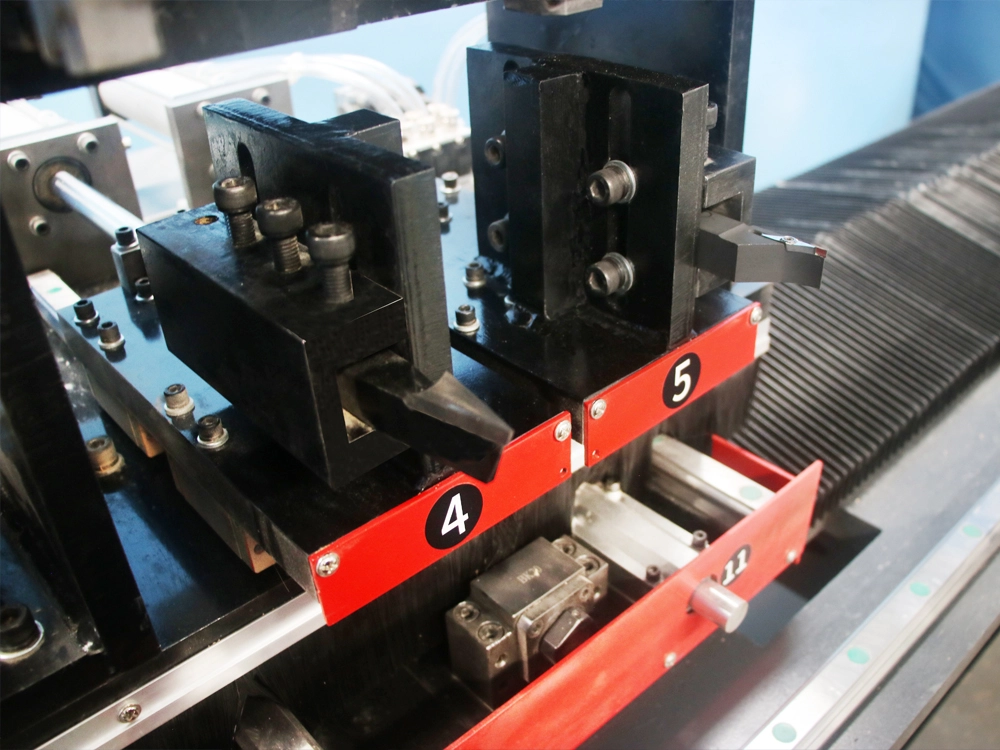

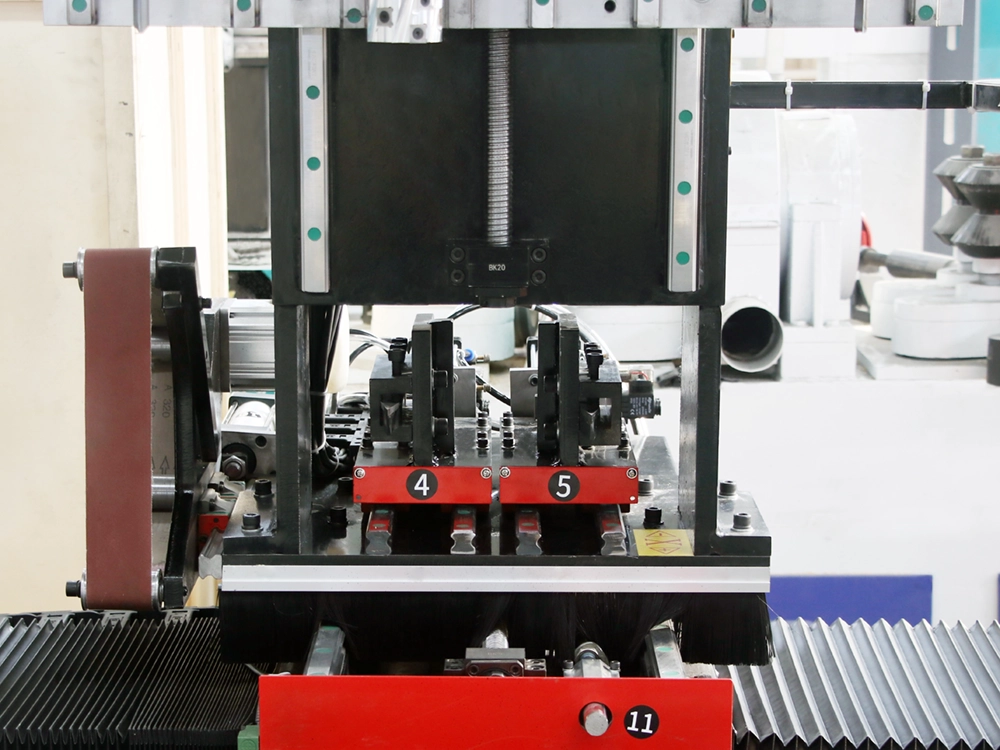

- Turning tool

-

Equipped with two turning tool stations, different tools can be installed for switching, meeting the product's multi-turning tool machining needs, without stopping to switch tools.

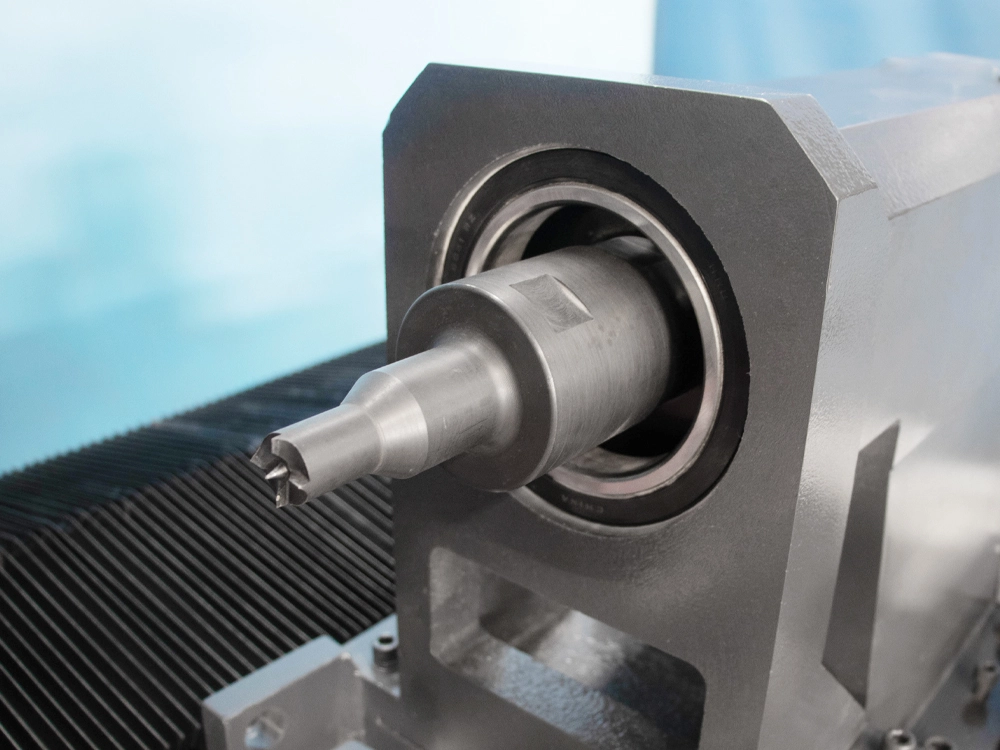

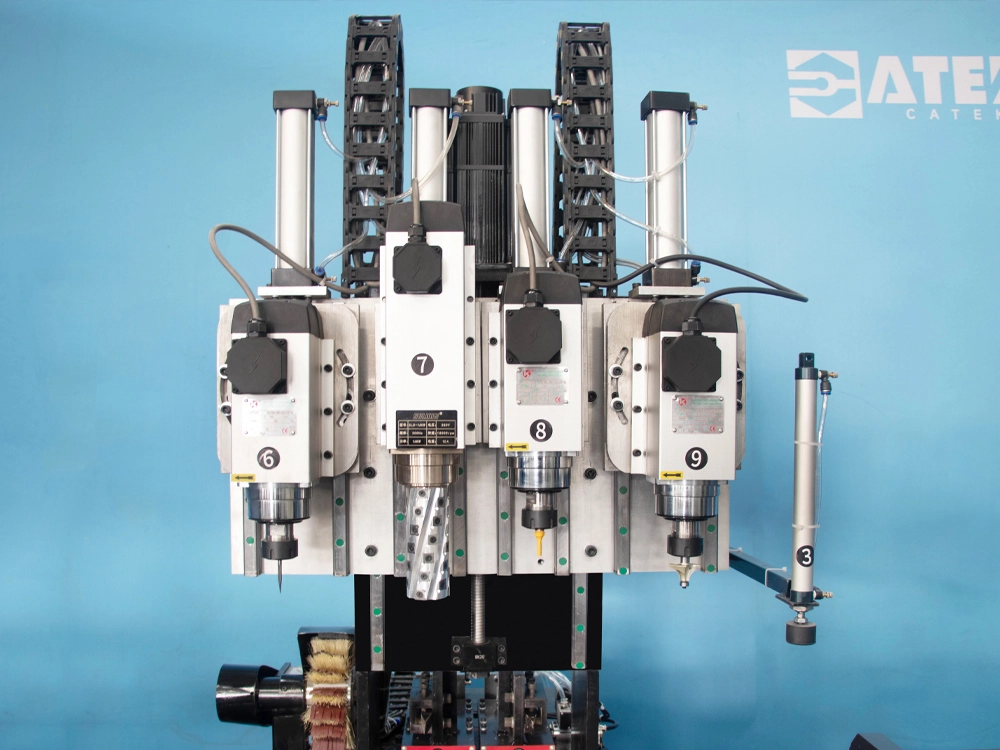

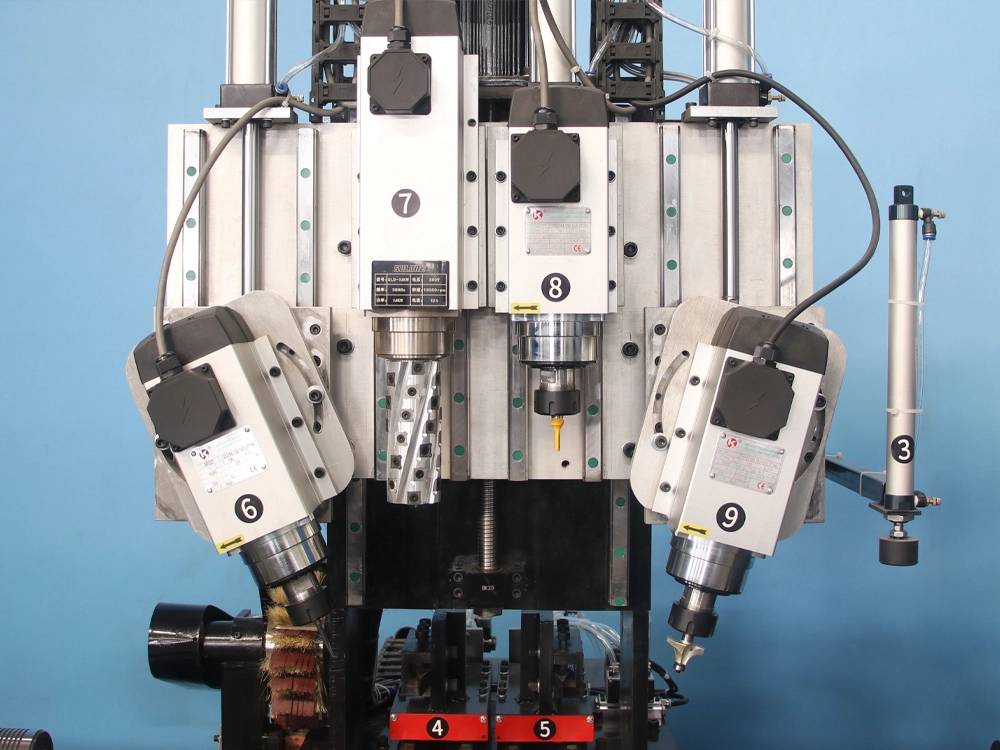

- Planer spindle

-

Equipped with a 7.5KW planer-specific air-cooled spindle (second from left), with a speed of up to 18,000rpm, and a standard planer with a length of 15 cm (customizable).

- Milling/carving/drilling spindle

-

Equipped with three 6KW high-speed air-cooled variable frequency spindles, which can be installed with different tools such as milling cutters, carving cutters, drill bits, etc. The two outer spindles can be rotated manually to perform tilting machining on the workpiece, such as carving the bevel or step surface of the workpiece, drilling side holes, etc.

- Sanding device

-

The sanding device is driven by an independent brushless servo motor, and the speed can be adjusted arbitrarily within 0-6000 rpm. Sanding wheels, sanding belts, and sanding rollers are optional. 150-mesh sandpaper is standard, and 80-300 mesh is optional.

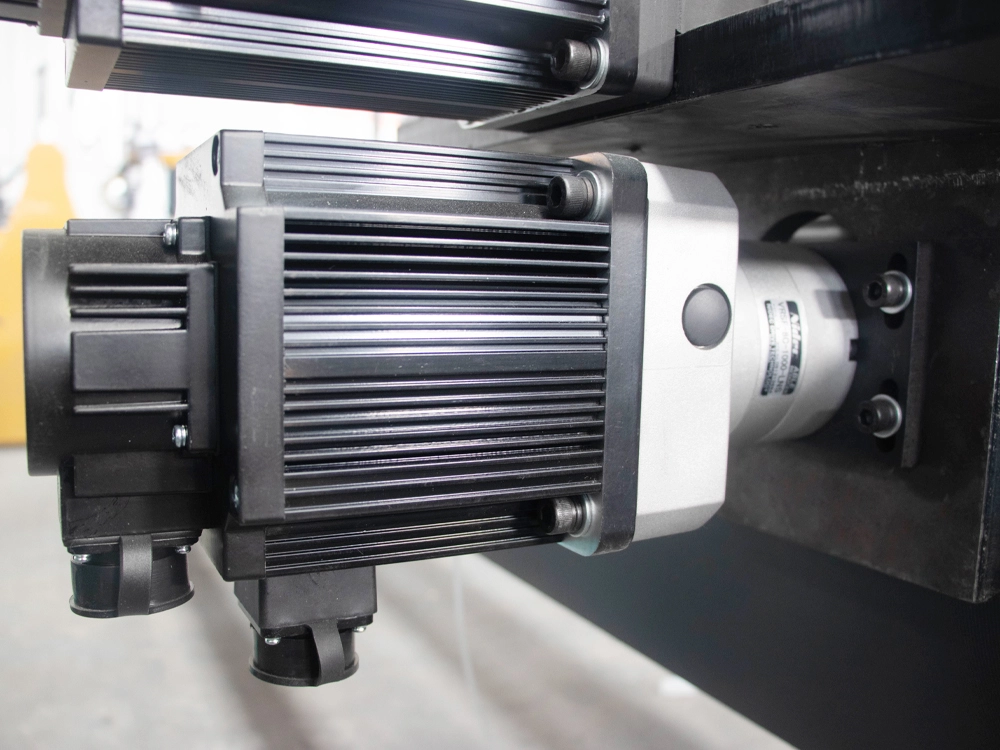

- Drive-spindle motor

-

A 4KW high-speed servo motor that provides power for the drive-spindle. The maximum speed can reach 6000rpm, and high-speed rotation can be performed to turn the workpiece. The workpiece can also be rotated at an angle by indexing to mill, carve, and drill the workpiece.

- Linear axis servo motor

-

1.5KW servo motors power the three linear axes.

- Transmission system

-

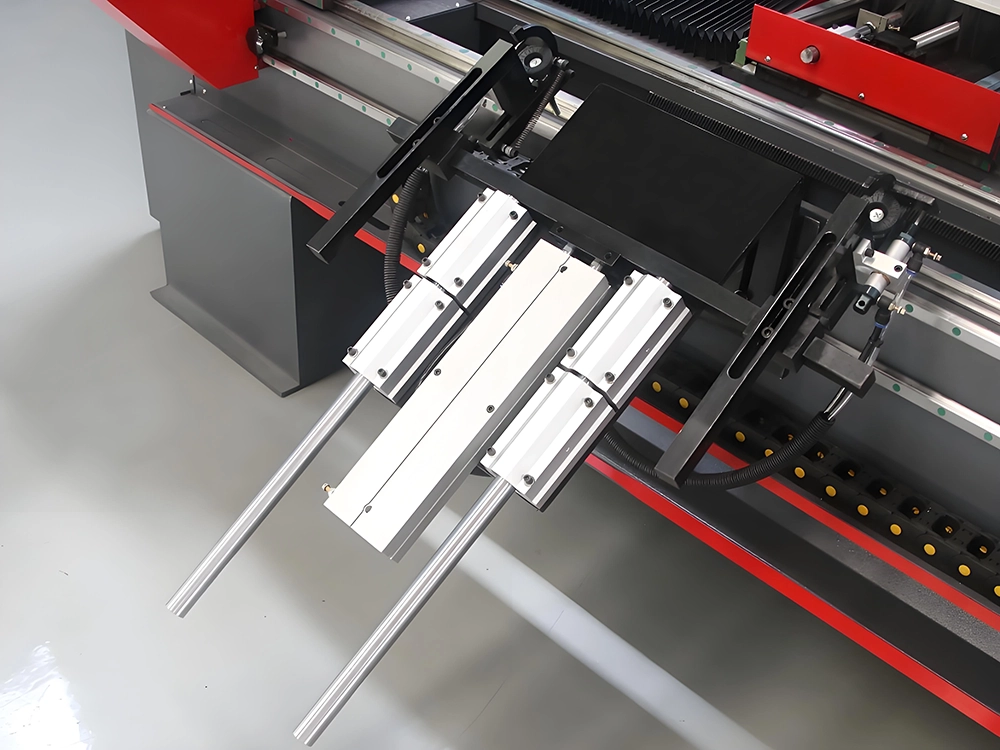

The guideway components of the transmission system are all Taiwan Hiwin 30 slide rails and flange sliders. The Z axis is driven by a high-precision helical rack (fast running speed, improved machining efficiency), and the X and Y axes are driven by TBI ball screws.

The Z axis is equipped with a closed dust cover to ensure reliable and stable transmission conditions.

The X axis is equipped with a dust scraper and brush to remove scraps that fall into the guideway or screw during machining.

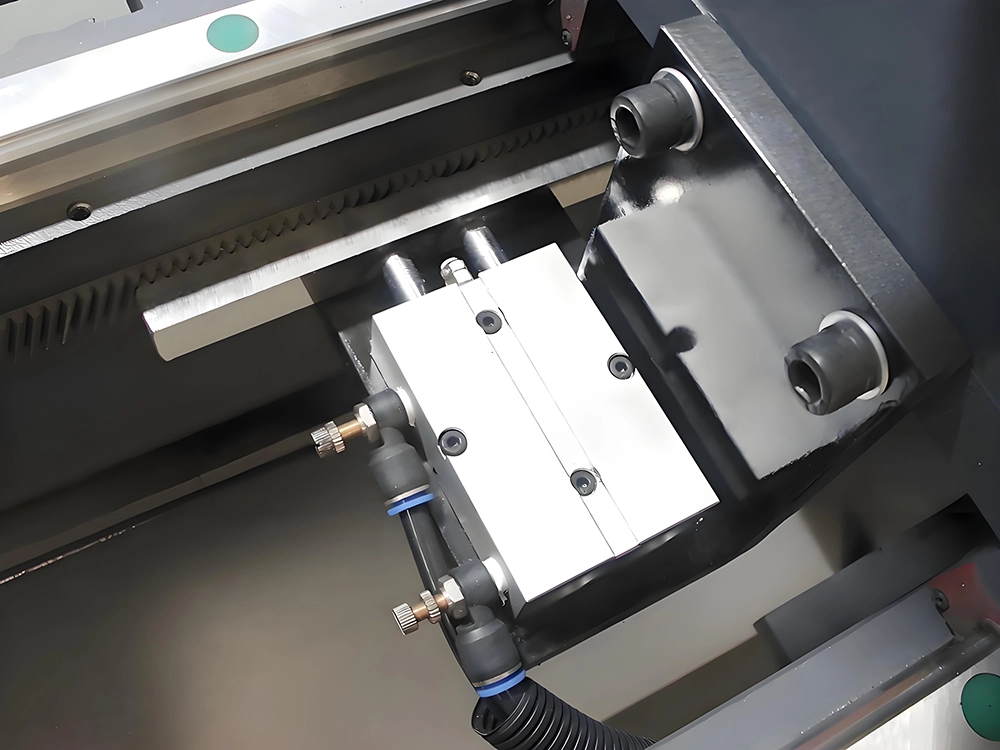

- Lubrication system

-

The central lubrication maintenance system is used to automatically lubricate the transmission parts according to the preset lubrication interval and lubrication duration.

- Automatic loading and unloading system

-

The standard four-link pneumatic automatic loading and unloading system effectively ensures stability and heavy load capacity.

The large-sized hopper is made by hot bending forming process, and its good structural integrity makes it more durable.

After machining is completed, the pneumatic unloading device can assist in ejecting the finished product to prevent material jamming.

The finished product slides out via the discharge chute, preventing damage caused by direct falling. Additionally, it facilitates the operator's collection of the finished products.

- Control system

-

The self-developed CK-1000TC multi-function CNC system is adopted. It has been tested in the market for a long time, is extremely friendly to novice users, is compatible with various CAD/CAM software, and supports formats such as DXF/NC/TXT/DBF.

Comparison Between the 7-In-1 Multifunctional CNC Wood Lathe and Competing Products

| CK-1530-7T | Competing Products | |

|---|---|---|

| Frame | The double-row four-track bed is made of grey cast iron with a thickness of 30mm and a total weight of 2300kg. It will not deform after prolonged use, and has extremely high stability and precision. The surface of the finished product by it is fine and has no chatter marks. | They commonly uses a square tube welded bed, with only the headstock and tailstock made of cast iron, resulting in low cost and light weight—just over one ton. However, prolonged use can easily lead to deformation, affecting the machine's precision and machining quality. |

| Drive System | X, Y, and Z axes all use 1.5KW pure servo motors (Y axis is a brake type motor). | Most are 750W or 1KW servo motors or stepper motors. |

| Processing Dimension | The maximum length is 1500mm and the maximum diameter is 300mm. | Most are 1200mm*200mm or even smaller. |

| Turning Function | It comes standard with two turning tools on the same side, allowing for the installation of different types of cutters for switching use. | There is only one turning tool with a single function, and the tool needs to be changed when there are different machining requirements. |

| Planing Function | It comes standard with a 7.5KW planer spindle and a planer with a length of 150mm and a diameter of 60mm (customizable), with a maximum speed of 18,000rpm. | Most of them are 4.5KW or 6KW planer spindles, and the maximum speed is only 6000rpm. |

| Carving/Milling/Drilling Functions | Three 6KW high-speed air-cooled variable frequency spindles are standard. It can hold ER32 standard toolholders with a maximum clamping handle diameter of 20mm. The two outer spindles can rotate to perform angled processing on the workpiece. | Most of them are 3.5KW air-cooled spindles, the standard tool holder diameter is ER20, and the maximum holder diameter is only 12.7mm. And usually only vertical feed machining is possible. |

| Sanding Function | The standard brushless servo motor sanding wheel can adjust the speed within 0-6000 rpm. | Most of them are fixed speed motors and the speed cannot be adjusted according to demand. |

| Loading and Unloading Function | Four-link thickened cylinder. The hopper is thickened and formed in one step by hot bending process. | Ordinary small diameter cylinder. Steel pipe welded hopper. |

| Transmission System | Taiwan Hiwin 30 guideway + TBI ball screw / high-precision helical rack. The Z axis is equipped with a dust cover, and the X axis is equipped with a dust scraper and brush to minimize the impact of machined waste on the transmission system | Most of them use fake or counterfeit guideways, racks, and screws, which have no guarantee of accuracy and a worrying service life. |

| Electrical Components | All are purchased from top-tier brands such as Schneider and Delixi. Highly flexible shielded bending-resistant cable. Thickened PU material air hose. | Non-branded electrical components. Copper-clad aluminum cables. Low-quality air hoses, prone to cracking in winter. |

| Pre-Sales Service of CATEKCNC | Our professional pre-sales team, with extensive experience, can recommend the most cost-effective machine based on your processing needs, helping you save on procurement costs and accurately identify the model best suited for you. We offer personalized services such as factory visits, certificate presentations, and free sample production. | |

| After-Sales Service of CATEKCNC | The entire machine comes with a free three-year extended warranty and lifetime professional after-sales service available 24/7. | |

Technical Parameters of Multifunctional 7-In-1 CNC Wood Lathe

| Model | CK-1530-7T |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | CATEKCNC dedicated high-torque 1500W servo motor * 3 |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X, Y axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Variable Frequency Drive | BEST/Hpmont inverter |

| Drive-Spindle Motor | 4KW pure servo high-torque and high-speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Turning Tool | Two mounting positions for turning tools |

| Milling/Carving/Drilling Spindle | CATEKCNC dedicated 6KW high-speed air-cooled spindle * 3 (supports four-axis linkage) |

| Milling/Carving/Drilling Spindle Speed | 0-18000r/min |

| Planer Spindle | 7.5KW high-speed air-cooled spindle (special for planer) |

| Planer Spindle Speed | 0-18000r/min |

| Planer Dimensions | 150mm length * 60mm diameter (customizable without extra charge) |

| Sanding Device | Independent variable frequency servo motor control Standard sanding wheel with 230mm diameter * 50mm width (customizable) |

| Sanding Device Speed | 0-6000r/min |

| Automatic Loading and Unloading | Multi-linked cylinder loading and unloading device (simple and easy to use) |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2300kg |

| Dimensions | 3750*2350*1950mm |

Application Scope of Multifunctional 7-In-1 CNC Wood Lathe

The multifunctional 7-in-1 CNC wood lathe is equipped with turning tools and multiple multifunctional spindles, which enables it to machine most wooden rotating bodies, and perform pattern carving, shape planing and milling, drilling, etc.

- Furniture manufacturing: It can process various furniture parts, such as various special-shaped table and chair legs with carved patterns, chair armrests, bed headposts, bed footposts, etc.

- Crafts production: It can process various wooden crafts, such as wood carvings, vases, wooden bowls, etc. that require complex 3D carving.

- Musical instrument production: It can process various orchestral instruments that require milling and drilling, such as flutes, Hulusi, bassoons, guitar necks, violin heads, necks, etc.

- Construction industry: It can process various Roman columns, stair newel post, architectural decorative brackets, etc. with complex carved patterns.

How to Buy a CNC Wood Lathe?

-

Clarify the processing requirements

CNC wood lathes have rich and diverse appearances and configurations, and there are many models designed for different process requirements. Before purchasing a machine, you must first clarify your own processing requirements. For example, if you only need to process simple stair railings or table and chair legs, and the product is a standard rotating body without complex engraving patterns, and only needs to be processed with a turning tool, then you can choose our turning CNC wood lathe. If you have simple drilling, non-planar engraving, grooving along the rotating curve of the workpiece, etc., you can choose from our carving and turning CNC wood lathes. If your process requirements are extremely complex, such as processing special-shaped table and chair legs or architectural decorative brackets with complex engraving patterns, it is recommended to consider our multi-functional CNC wood lathe. If you are not sure about the processing technology required for the product, please contact our sales staff, who have many years of experience in recommending CNC machines to users.

-

Communicate with sales staff

Explain your processing needs to the sales staff, or directly tell the machine model you want to know or buy, and they will provide you with detailed information. If you have the intention to buy, they will select the machine configuration with you, calculate the machine price, transportation and customs clearance fees for you, and plan a suitable transportation plan.

-

Order production

To prevent malicious orders, you need to pay a certain deposit to buy our machines. After paying the deposit, if it is a standard model of spot machine, we will arrange the delivery directly; if it is a customized machine, it is necessary to arrange the production in the order sequence. The production cycle is affected by the factory order volume and the complexity of customization. It is recommended that you inform the sales staff of the urgency of the order. We will do our best to speed up the production progress and ship as soon as possible.

-

Pick up goods

After delivery, we will send you a delivery note, and you can pick up the goods by yourself with this document. If you are not familiar with the delivery process, you can contact our sales staff at any time. They will assist you in connecting with local freight forwarders and deliver the machine directly to your designated location.

| Model | CK-1530-7T |

|---|---|

| Machining Capacity | 1500 * 300mm (customizable according to processing requirements) |

| Lathe Bed | Heavy-duty integrally cast parallel twin beds, independent anti-interference control cabinet |

| Linear Axis Drive Motor | CATEKCNC dedicated high-torque 1500W servo motor * 3 |

| Linear Axis Transmission Mechanism | Z axis: high-precision helical rack + Taiwan Hiwin 30 guide rail/flange slider X, Y axis: TBI ball screw + Taiwan Hiwin 30 guide rail/flange slider |

| Variable Frequency Drive | BEST/Hpmont inverter |

| Drive-Spindle Motor | 4KW pure servo high-torque and high-speed motor |

| Drive-Spindle Speed | 0-6000r/min |

| Turning Tool | Two mounting positions for turning tools |

| Milling/Carving/Drilling Spindle | CATEKCNC dedicated 6KW high-speed air-cooled spindle * 3 (supports four-axis linkage) |

| Milling/Carving/Drilling Spindle Speed | 0-18000r/min |

| Planer Spindle | 7.5KW high-speed air-cooled spindle (special for planer) |

| Planer Spindle Speed | 0-18000r/min |

| Planer Dimensions | 150mm length * 60mm diameter (customizable without extra charge) |

| Sanding Device | Independent variable frequency servo motor control Standard sanding wheel with 230mm diameter * 50mm width (customizable) |

| Sanding Device Speed | 0-6000r/min |

| Automatic Loading and Unloading | Multi-linked cylinder loading and unloading device (simple and easy to use) |

| Lubrication System | Centralized electric oil-lubrication system |

| Electrical Components | Delixi/Schneider AC contactor, relay |

| Operating Voltage | AC 380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, artcam, etc. |

| Engraving Instructions | Sandard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 2300kg |

| Dimensions | 3750*2350*1950mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.