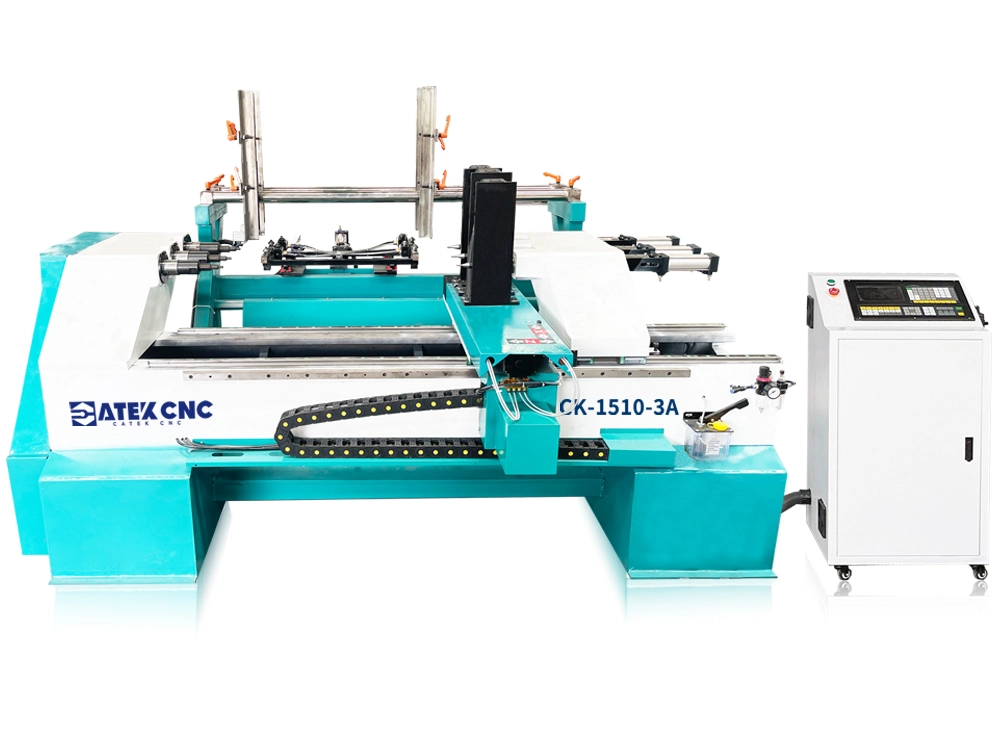

2-Station Pool Cue CNC Woodworking Lathe with Automatic Feeding

2-Station Pool Cue CNC Milling Machine with Automatic Loading and Unloading

[Function Description]

The fully automatic hopper fed CNC pool cue lathe with two processing stations is specially designed for the mass production of pool cues. It has a professional automatic feeding structure. The pneumatic feeding structure can automatically clamp two blanks at a time and automatically unload them after processing. It can achieve uninterrupted 24-hour continuous processing, avoiding the time waste caused by manual loading and unloading and the material waste caused by loading errors. At the same time, it can reduce dependence on manual operation and reduce labor costs. The 2-station pool cue automatic hopper fed CNC woodworking lathe adopts high-precision drive motors, linear guides, TBI ball screws and other precision components, combined with an automatic feeding system, which effectively ensures the stability and consistency of the processing process, and improves the processing accuracy and surface finish of the product.

How Does a Pool Cue Lathe Perform Milling Work?

The processing method of pool cues is quite special, and it cannot be processed using traditional turning methods. In traditional turning methods, the blank is rotated at high speed, and the processing tool uses a traditional fixed V-shaped tool. Since the blanks of pool cues are relatively slender, they are prone to vibration or flying out during high-speed rotation. For this reason, we have modified and upgraded the machine, using a motor to drive the blank to rotate at a low speed. The speed of pool cue products is only 200-300r/min, and the tool is driven by a high-speed air-cooled spindle, up to 18,000r per minute, which allows the tool to mill the raw materials at high speed. Since the workpiece rotates at a low speed, no vibration will occur during the processing, and because the tool rotates at a high speed, the surface finish of the processed products is very high.

Advantages of 2-Station Wood Lathe For Pool Cue With Automatic Loading & Unloadinge

- Two 3.5KW high-speed air-cooled spindles, 18000r/m, high-speed rotation for milling of workpieces.

- 4kw three-phase asynchronous motor, high-quality pure copper coil, stable speed.

- Two professional-grade pneumatic automatic feeding device, easy to adjust and use.

- Dedicated CNC system, English interface, friendly display, simple operation, even CNC novices without any basics can use it easily.

- The automatic feeding structure can be used to realize automated processing, or can be fed manually with high flexibility.

- Precise precision control, processing accuracy can be accurate to 0.01mm, equipped with an external pulse handwheel, precision adjustment is more convenient.

- Heavy gray cast iron bed, thickened steel pipe welded automatic feeding structure frame, stable processing, effectively prevent wood from shaking.

- Automatic lubricating oil pot, can automatically lubricate and maintain the lubrication parts of the machine at regular intervals.

Details of a CNC Wood Lathe Used to Mill Pool Cues

- 2-station automatic feeding device

The 2-station automatic feeding device is equipped with two feeding cylinders for adjusting the length of the blank, two clamping cylinders for fixing the bin material, four positioning cylinders for fixing the center point of the wood, two top cylinders for clamping the material, and one lifting cylinder for lifting the feeding device. Each cylinder can be adjusted individually and is flexible to use.

- Two milling spindles

Two 3.5KW air-cooled spindles can clamp any tool holder within the 1/2 inch range and are easy to replace.

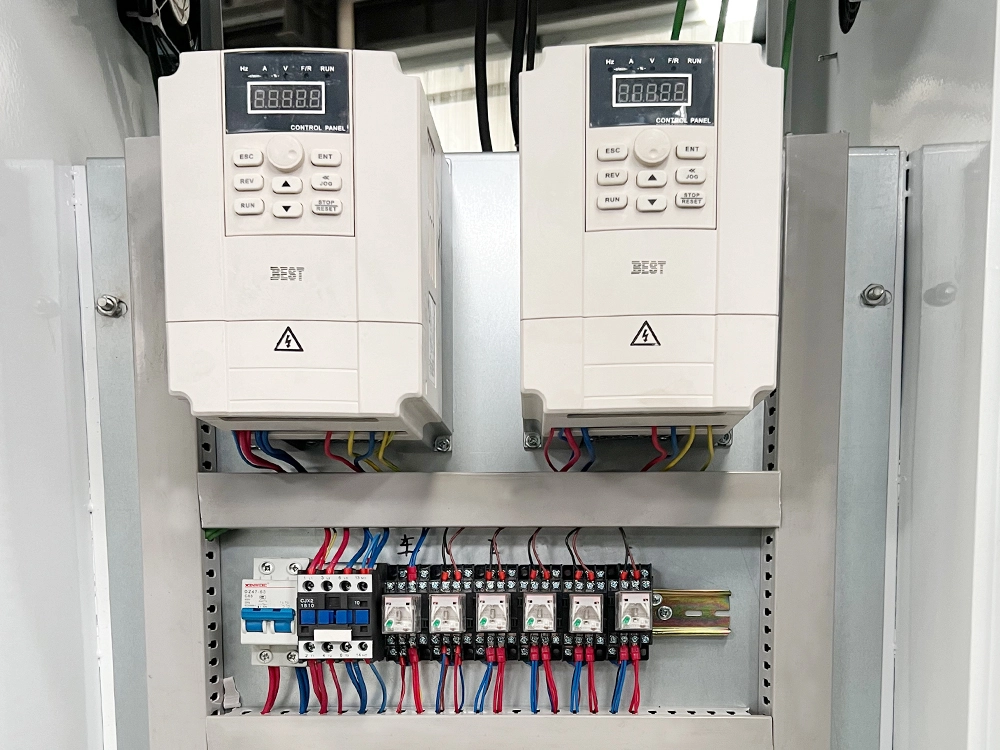

- Frequency converter

High power inverter, high quality Delixi electrical components.

Technical Parameters of 2-Station CNC Wood Lathe Machine With Automatic Feeding Kit

| Model | CK-1510-2A |

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm * 2 (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 2 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*2100*1600mm |

What Products Can Be Processed by the Automatic Feeding 2-Station Pool Cue CNC Lathe?

Automatic feeding pool cue CNC woodworking lathe can be applied to various materials, such as wood, plastic, pvc, acrylic, carbon fiber, fiberglass, etc., and can process various taper products, such as: pool cues, billiard cues, English cues, American cues, nine-ball cues, snooker cues, jump cues, carbon fiber pool cues, carbon pool cues, crutches, table legs, sofa legs, round table legs, chair legs, stool legs, wooden sticks, round sticks, tapered legs, canes, rolling pins, etc.

The Following Are the Processable Products of The Automatic Feeding 2-Station Pool Cue CNC Lathe

| Model | CK-1510-2A |

|---|---|

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm * 2 (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 2 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*2100*1600mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.