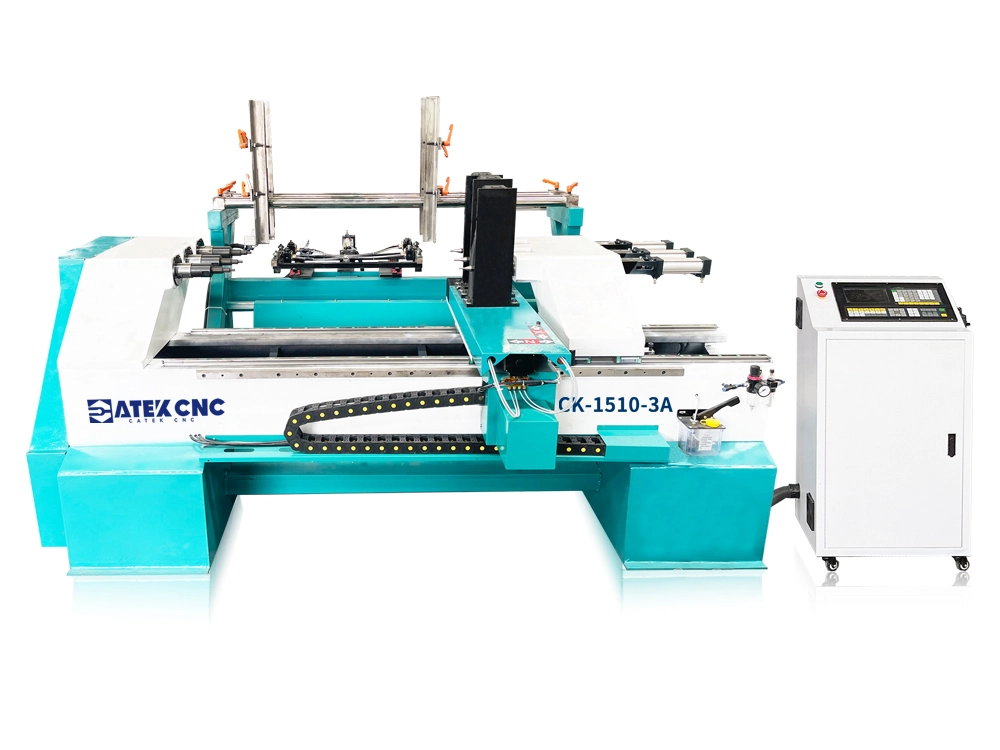

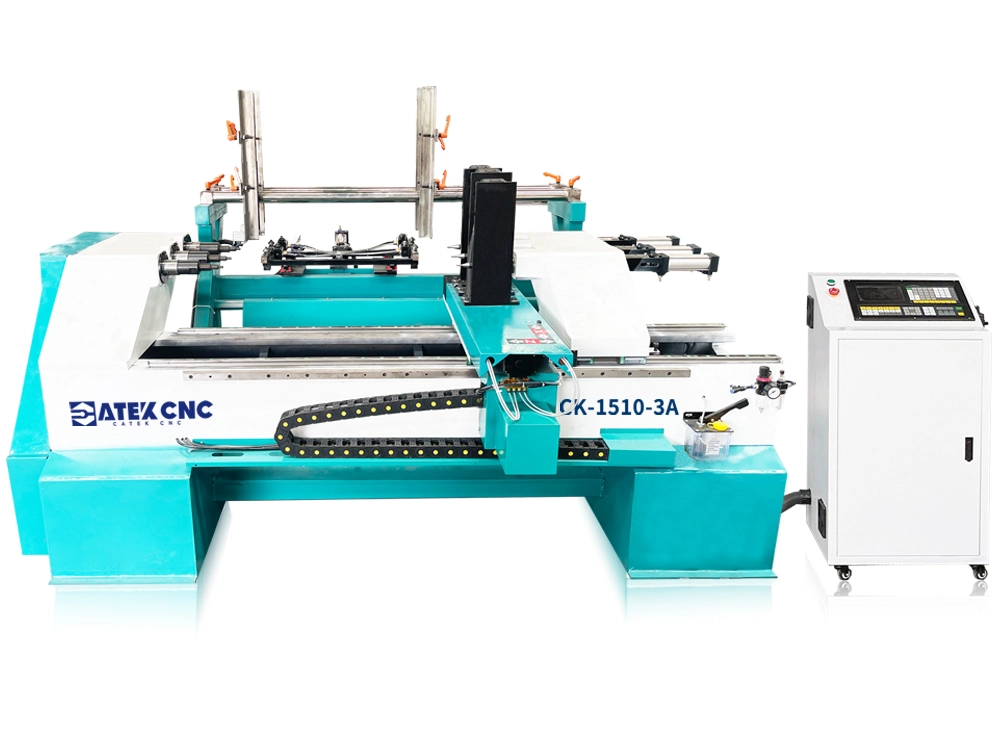

Most Popular 3-Station Pool Stick Building Lathe for Factory Batch Production

Automatic Loading and Unloading 3-Station Pool Cue CNC Milling Lathe

[Function Description]

The three-station automatic feeding pool stick CNC woodworking lathe is a pool stick processing machine that integrates CNC milling technology and automatic feeding technology. It can be used for processing various types of slender round rod products. The processing length can be adjusted arbitrarily within 1500mm. Three pieces can be processed at a time. The processing efficiency is three times that of the single-station CK-1510 CNC wood lathe, and it is equipped with a three-station automatic feeding device. It uses a full English CNC system control, supports visual processing drawings viewing and full monitoring of the operating status to ensure the stability and reliability of the processing process. The machine uses a 3.5KW air-cooled spindle for milling processing, and the processing speed is extremely fast. Even if processing 1000mm long wood, it can complete the processing task of three pool sticks in 90 seconds, and 120 pool sticks can be processed in one hour. One machine can replace the 6-8 traditional manual laborers. Only one person is needed to be on duty for more than 5 pool stick CNC woodworking lathes, effectively reducing labor costs. Moreover, this machine has high processing accuracy. Even if three pieces are processed at the same time, the processing accuracy can reach ±0.05mm, thus avoiding errors caused by human processing factors.

Advantages of CNC Wood Lathe With Three Processing Stations and Automatic Loading and Unloading Device

- TBI ball screw and linear guide/linear bearing, high positioning accuracy and fast moving speed.

- Gray cast iron bed, thickened square steel welded automatic feeding bin, stable operation, no shaking.

- High-speed air-cooled spindle, four ceramic bearing structure, speed 18000r/min.

- Visual English CNC system, friendly interface, simple operation.

- Widely compatible with software, manual programming can be used or CAD/CAM type software can be used to draw drawings.

- Automatic lubricating oil system, regular lubrication and maintenance of the machine, simple maintenance.

- Three-station automatic loading and unloading device, automatic feeding processing, no manual intervention required.

- Can be connected to the dust collection system, automatically collect wood chips during processing, more environmentally friendly.

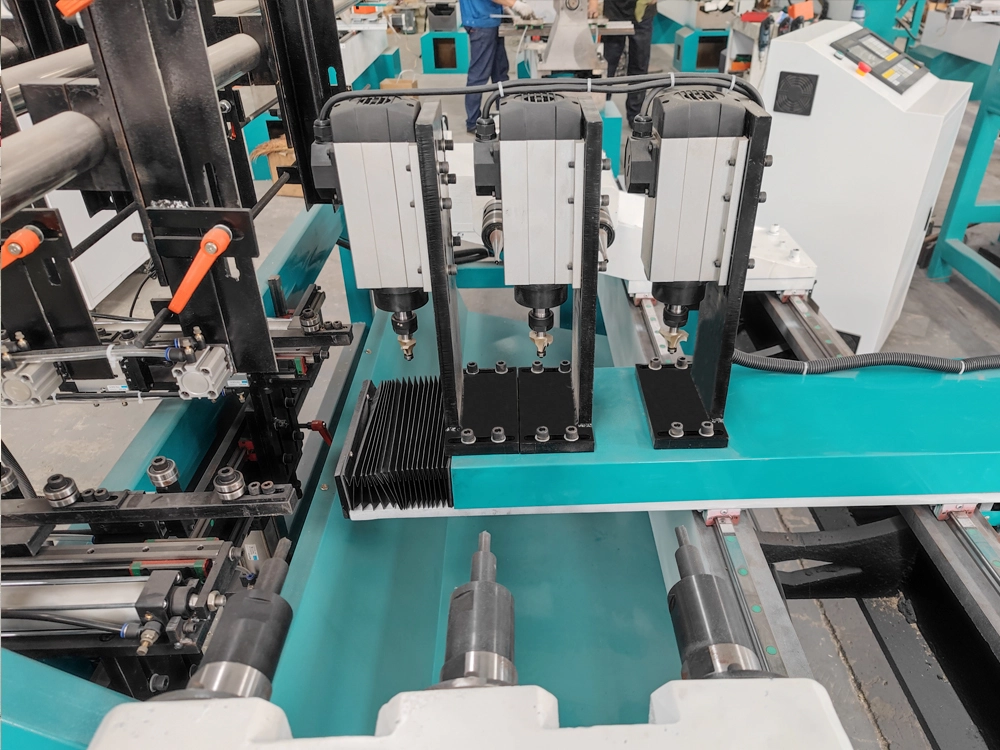

Details of 3-Station Pool Cue CNC Wood Lathe With Automatic Loading and Unloading

- 3-station automatic feeding device

Each pneumatic device can be adjusted independently, and each feeding device is equipped with independent control buttons for easy use.

- Three milling spindles

Three 3.5kw high-speed air-cooled spindles (water-cooled spindles are optional), with a maximum speed of 18000r/min, stable speed and high quality processed products.

- Frequency converter

High-quality inverter, the spindle speed can be adjusted arbitrarily through the inverter, the speed control is stable and the output torque is large.

- Accessories

Before shipment, the lathe center and processing tool need to be disassembled and shipped together with other accessories.

Technical Parameters of 3-Station CNC Lathe For Pool Stick With Automatic Feeding

| Model | CK-1510-3A |

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm * 3 (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 3 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1950kg |

| Dimensions | 3100*2400*1600mm |

Application Scope of 3-Station Wood Lathe For Pool Cue with Automatic Loading & Unloading

pool cues, big head cues, small head cues, English nine-ball cues, snooker cues, carbon fiber pool cues, fiberglass, carbon cues, pool cue shaft, pool cue extension handles, jumping cues, crutches, walking sticks, wooden sticks, wooden sticks, wooden handles, agricultural tool handles, lifting handles, axe handles, mop handles, broom handles as well as furniture legs, table legs, round legs, stool legs, sofa legs and other products.

Processing Project Case of 3-Station Wood Lathe with Automatic Loading & Unloading

How to Choose the Most Suitable CNC Woodworking Lathe for Pool Cues?

- Clear processing requirements: Choose the appropriate machine's size and station according to your processing requirements. The processing stations of the lathe are 1-station, 2-station, 3-station or 4-station types. The standard processing length is 1500mm. If you need a longer processing size, you can choose to customize a lathe with a maximum processing length of 2000mm or 2500mm. If you think the processing size of 1500mm is too large, you can also customize a lathe with a maximum processing length of 1000mm or 800mm. The choice of processing station depends on your production needs, and you need to consider the output. If your daily production demand is within 500 pieces, a single-station lathe can meet your needs; if your product demand is large, you can choose a three-station or four-station lathe.

- Consider processing accuracy: The accuracy of the CNC woodworking lathe directly affects the processing quality, and the error is generally within 0.1mm. When choosing, you need to pay attention to the spindle speed, ball screw, linear guide, and bed accuracy. Since the machine processing length and diameter can be adjusted, you also need to pay attention to whether the speed can be adjusted arbitrarily.

- Pay attention to after-sales service: Choose a brand that provides good after-sales service, such as CATEKCNC. Make sure that the supplier can provide free training services and respond in time when there is a problem with the machine to help you use the machine smoothly.

- Make a good budget plan: Consider factors such as machine performance, brand, and after-sales service, and select products with high cost performance. Different models correspond to different budgets. When considering the budget, you should take the machine price, freight, and maintenance costs into consideration. Do not blindly choose the lowest-priced machine, because the machine price often reflects the quality and after-sales service level of the machine.

- Consider maintenance: Choose a brand that is easy to maintain and provides a detailed maintenance manual. Good maintenance can effectively extend the service life of the machine, while easy maintenance can effectively reduce the cost of use.

| Model | CK-1510-3A |

|---|---|

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm * 3 (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle * 3 |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1950kg |

| Dimensions | 3100*2400*1600mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.