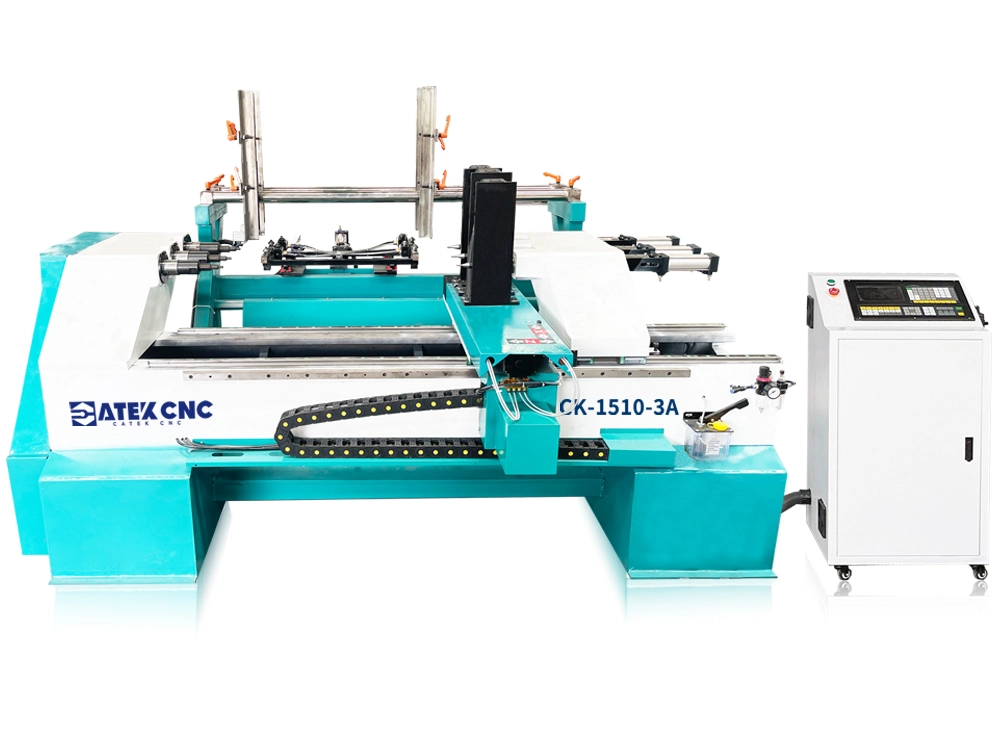

Billiard Cue CNC Milling Lathe with Automatic Loading and Unloading

Special Lathe for Milling Pool Cues with Automatic Loading and Unloading

[Function Description]

The 1510 cue lathe with automatic feeding kit adds an automatic feeding device and an automatic unloading collection tray on the basis of the CK-1510 model, which can realize automatic feeding, automated processing and automatic unloading of materials. The CNC wood lathe is equipped with a hopper and a pneumatic mechanical device, which can automatically transport the blanks in the hopper to the processing position through the pneumatic mechanical device. After processing, the workpiece is automatically unloaded using the cylinder that unloads the material. The whole process does not require manual intervention. Compared with traditional manual operation, it effectively reduces labor costs, and only requires simple settings to complete all operations of the machine. There is no need to worry about work-related accidents caused by manual operation. The workload completed by an automatic feeding CNC woodworking lathe is equivalent to more than 5 manual laborers, and one operator can easily operate more than 5 woodworking CNC lathes.

Advantages of a Pool Cue CNC Wood Lathe With Automatic Feeding System

- Automatic feeding kit, save the time of manual material clamping, improve the processing efficiency.

- 3.5kw air-cooled spindle, speed can be arbitrarily adjusted within 0-18000 rpm, according to different materials matching adaptable speed.

- 4KW three-phase asynchronous motor, high torque, stable speed, speed can be adjusted within 0-3000, according to different lengths and diameters of the parts to match the speed.

- Gray cast iron heavy-duty bed, using side oblique push automatic feeding structure, simple adjustment, stable structure.

- Using high-precision TBI screw drive, linear guide/linear bearing, machining accuracy can be controlled within 0.01mm.

- Processing adaptability, whether it is processing 1.5 m length of products, or processing 20 cm length of small products, automatic feeding system and processing length can be freely adjusted accordingly.

- Easy to operate, can be manually programmed or computer graphics, compatible with a variety of file formats, support a variety of cad/cam type software.

- The automatic feeding structure not only supports cylindrical materials, but also supports square column materials or materials with inconsistent dimensions at both ends, with a wide range of applications.

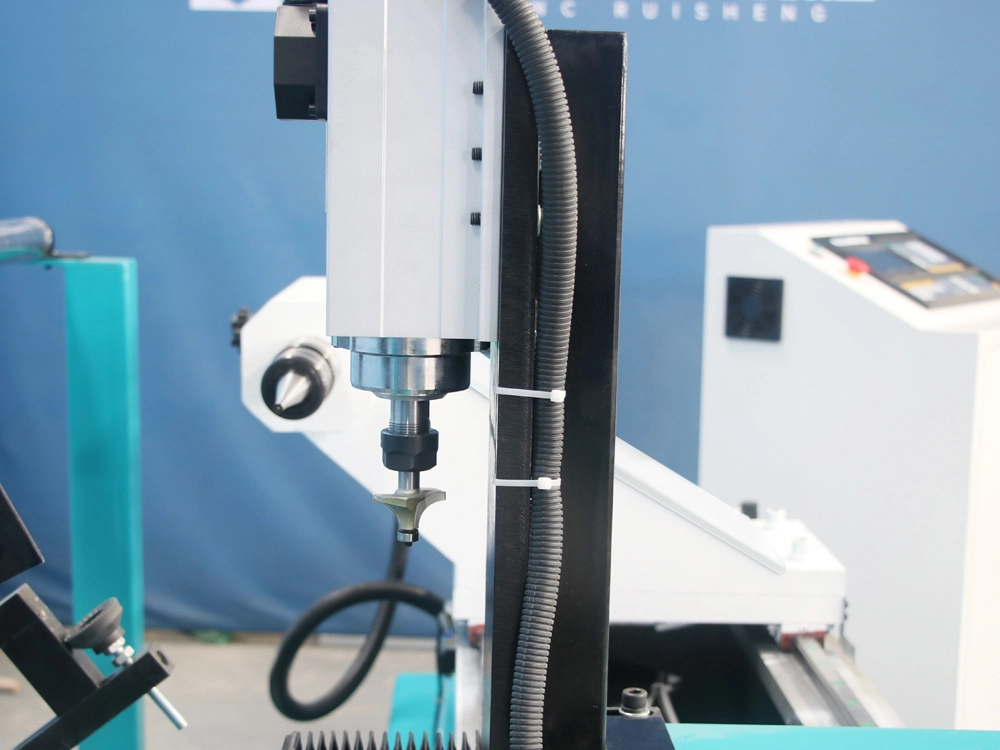

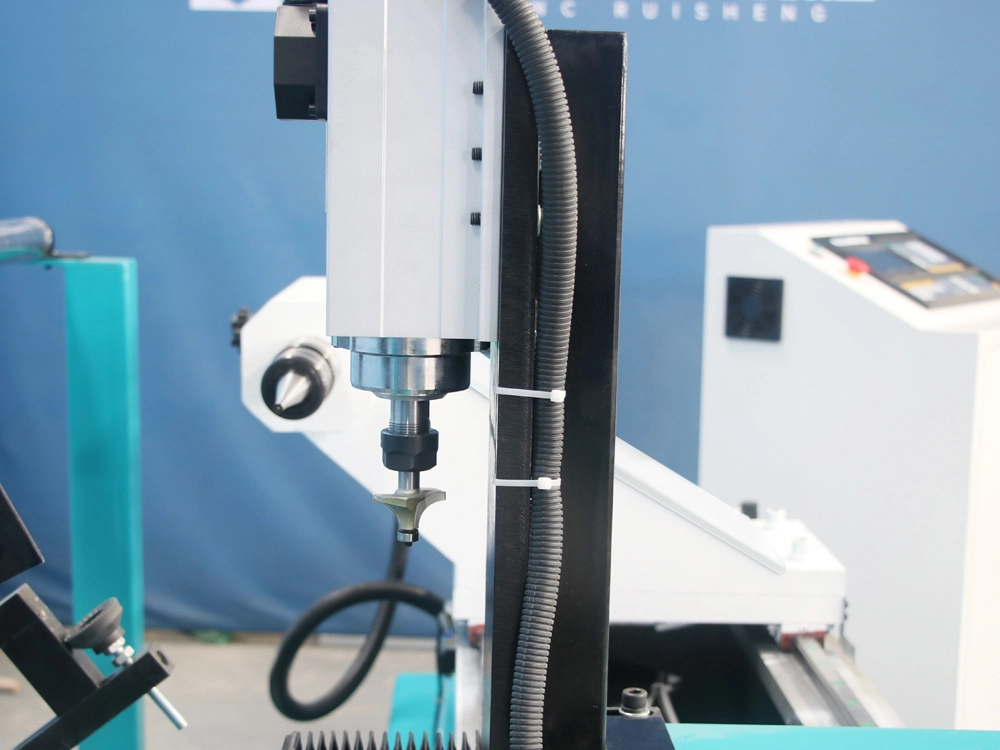

Details of CNC Wood Milling Lathes for Processing Rod Products

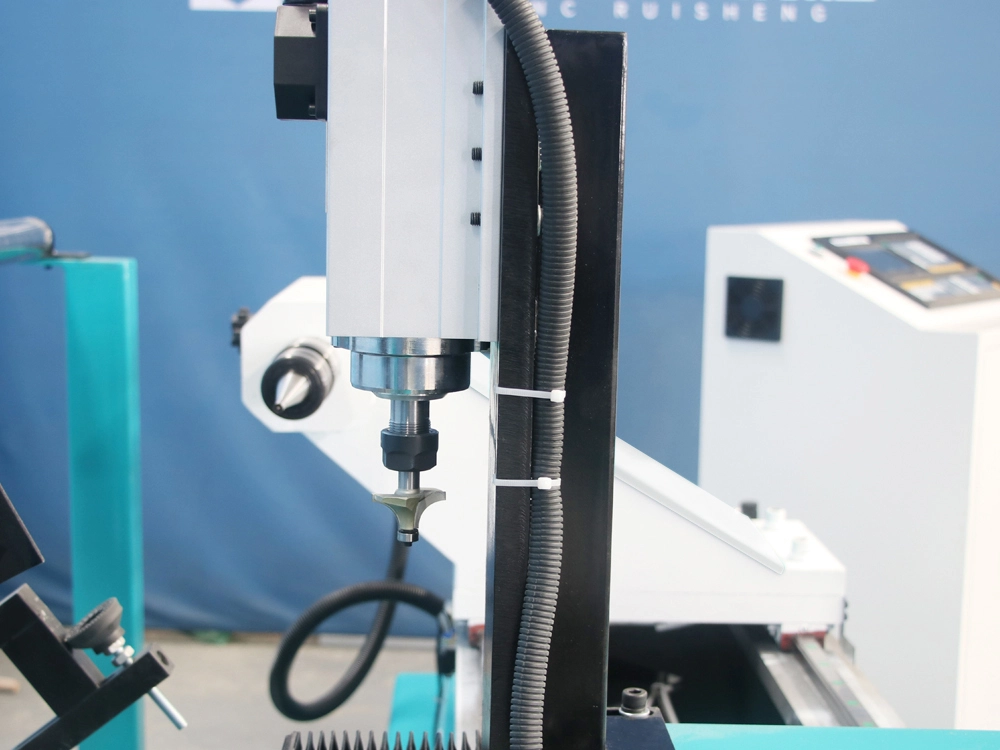

- Radius cutter

Can be used for milling wood. Can be replaced with various tools such as small saw blades, T-knife, etc.

- Automatic hopper feed loader

Simple operation, easy adjustment to suit the material being processed

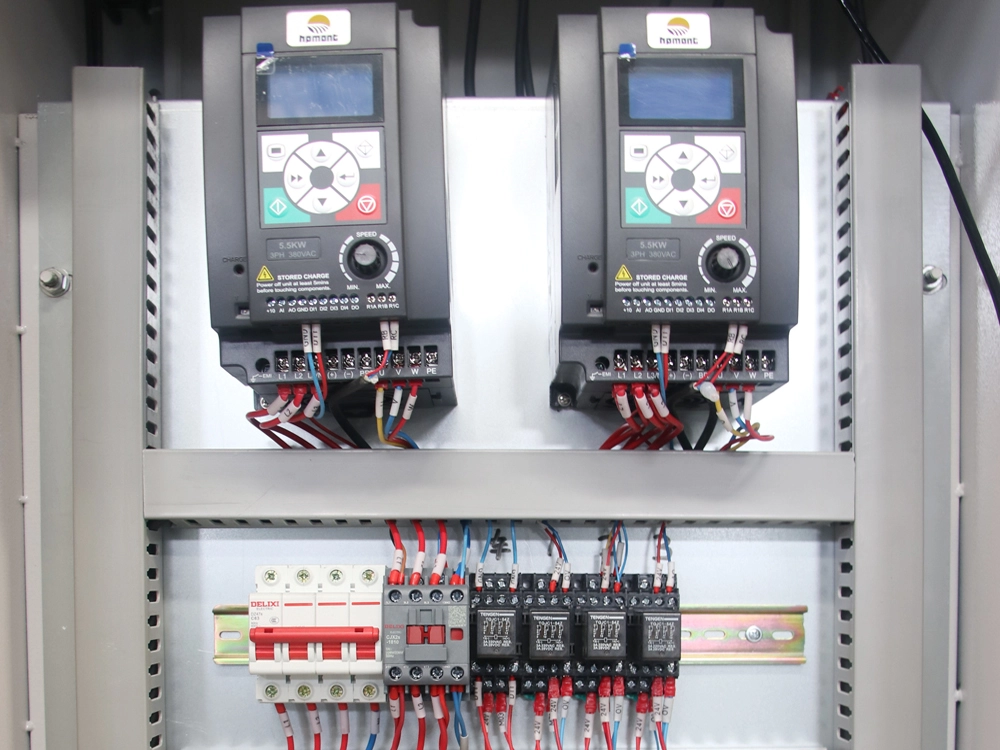

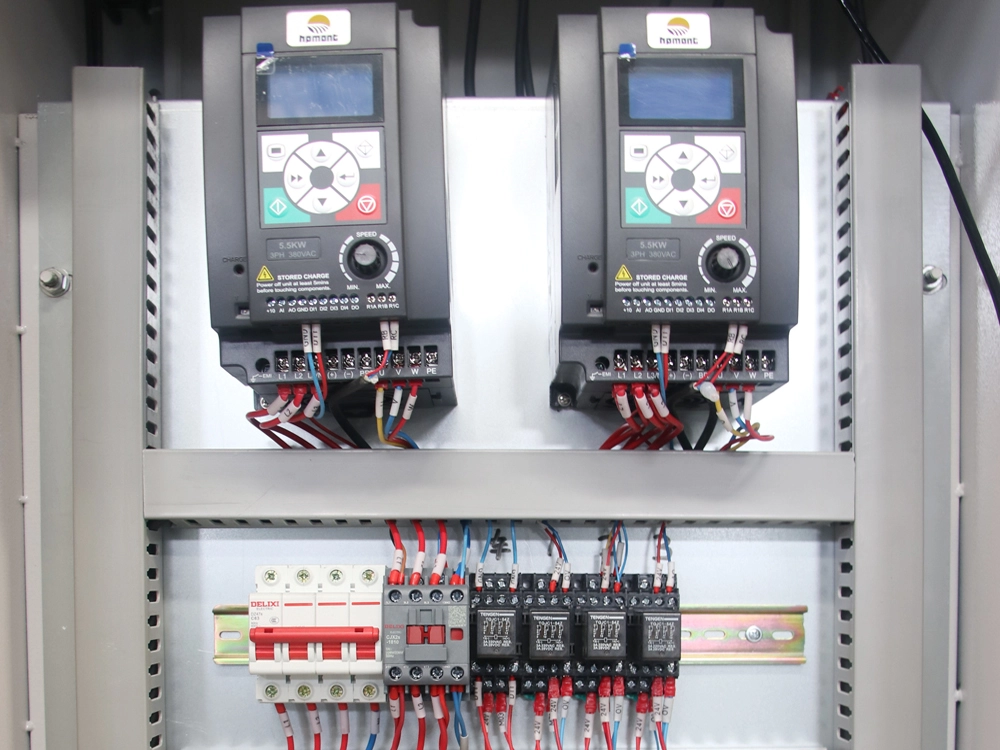

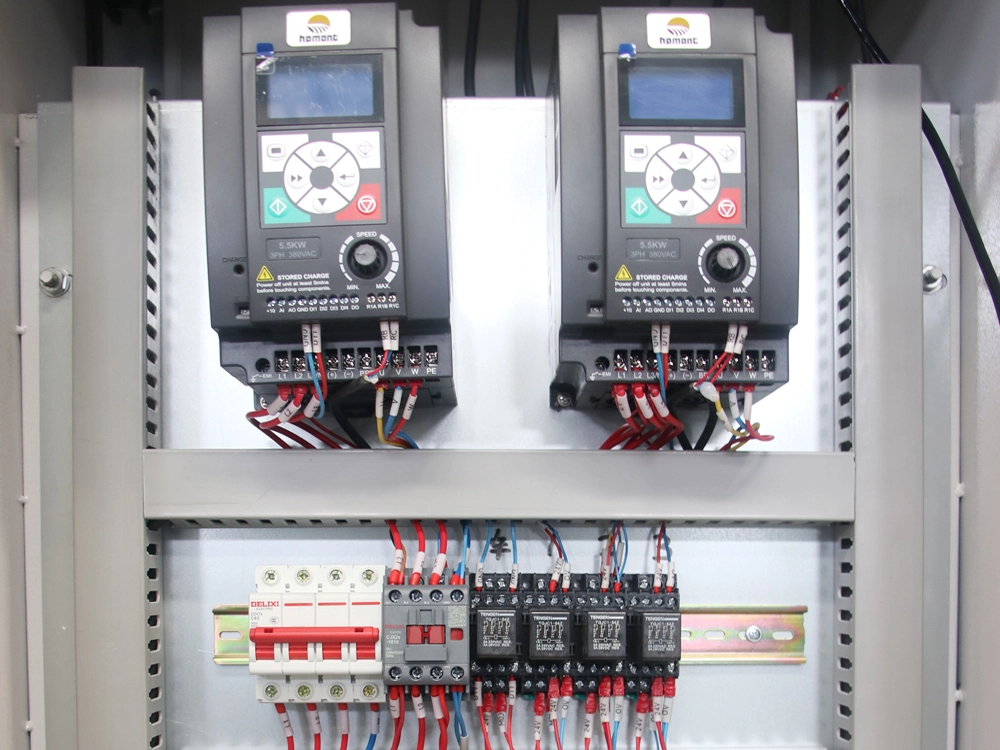

- Frequency converter

High-power inverter, three-phase asynchronous motor and high-speed air-cooled spindle are all controlled by inverter, and the speed can be adjusted arbitrarily.

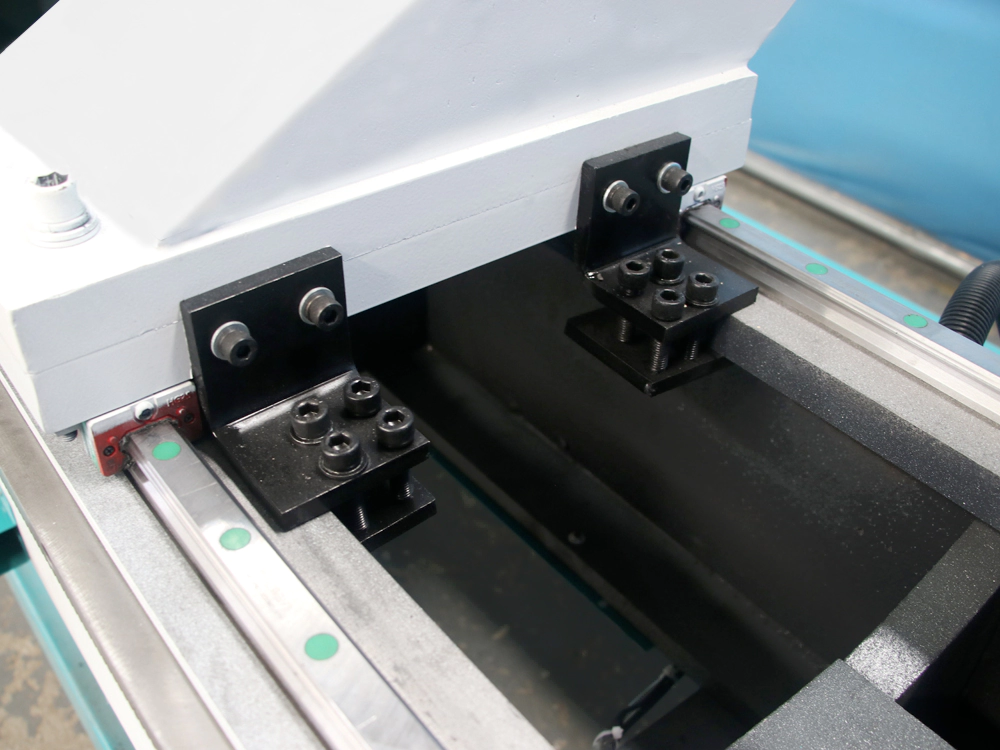

- Tailstock locking device

Before clamping the workpiece, this device needs to be tightened to prevent the tailstock from moving during machining.

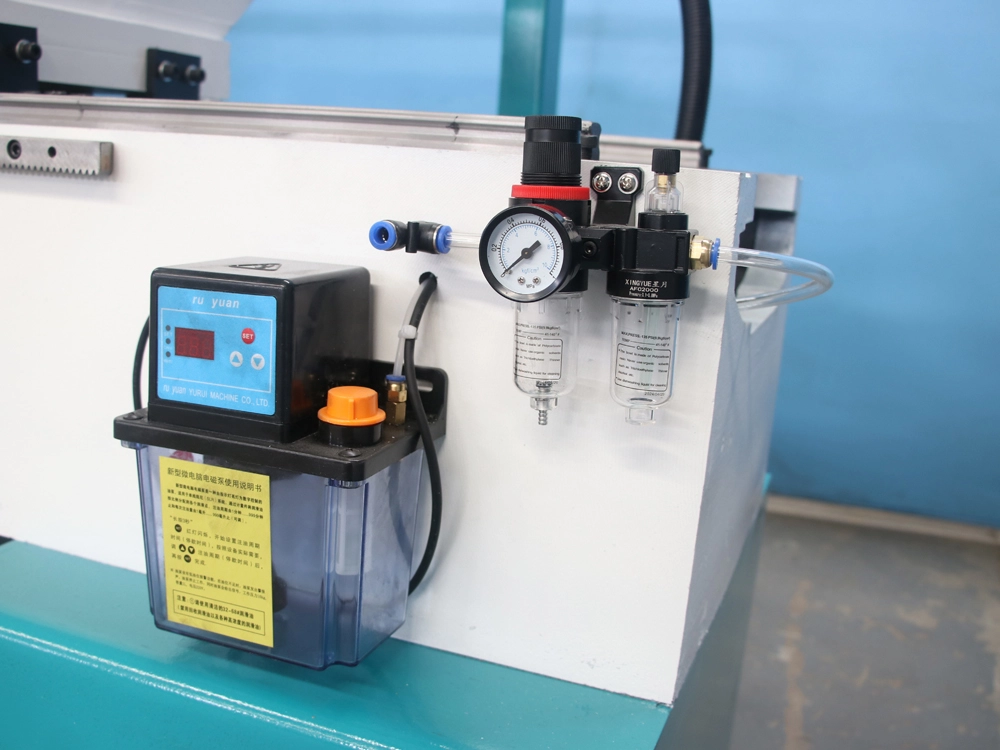

- Lubricating oil pot

The lubrication interval and lubrication duration can be set, and the oiler will automatically lubricate all transmission parts.

Technical Parameters of Wood Lathe For Pool Cue with Automatic Loading & Unloading

| Model | CK-1510-A |

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1500mm |

What Kind of Work Can the Pool Cue CNC Wood Lathe Machine With Automatic Feeding Be Used for?

It can be used to process billiard cues, English cues, American cues, big head cues, small head cues, nine-ball cues, snooker cues, jumping cues, various billiard cues, crutches, wooden sticks, wooden sticks, wooden sticks, round table legs, tapered round sticks, coat racks, rolling pins, walking sticks, trekking poles and other stick-shaped products.

Suitable for Pool Cue CNC Woodworking Lathe Processing Projects

| Model | CK-1510-A |

|---|---|

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1500mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.