2026 Best Cheap Billiard Cue Milling CNC Wood Lathe

2026 Best Cheap Pool Cue Milling CNC Wood Lathe

[Function Description]

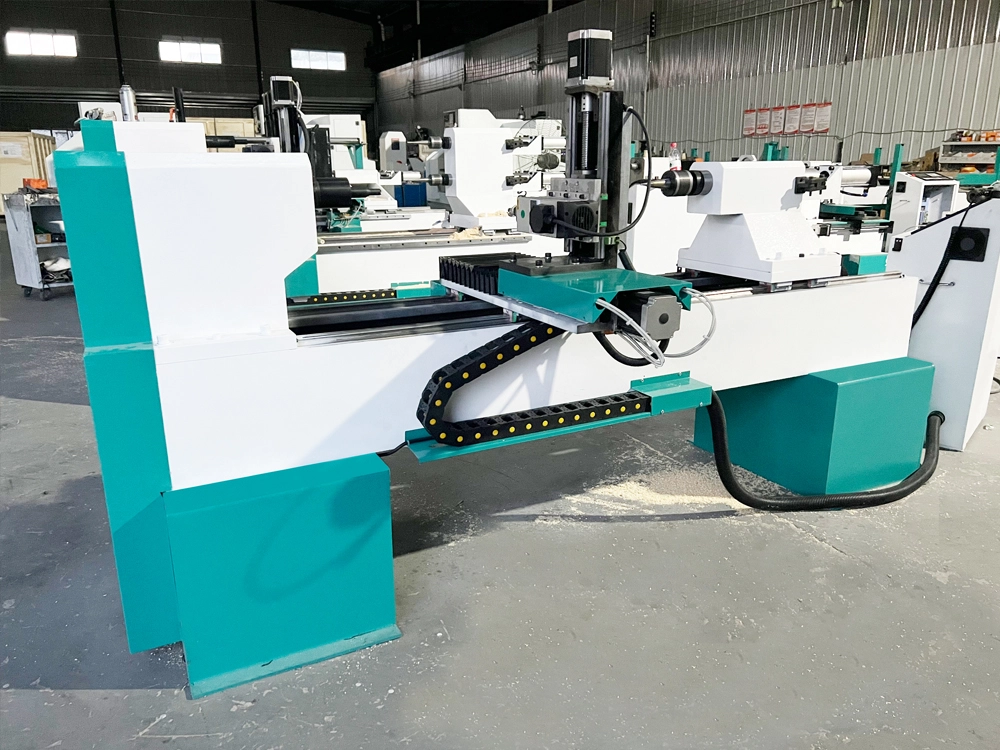

This is a very cheap CNC woodworking lathe for pool cue taper milling. It innovatively eliminates the turning tool in the lathe and is equipped with a high-speed frequency conversion spindle and it uses a radius cutter or saw blade to mill the pool cue. The finished product has a smooth and delicate surface, and even no secondary grinding is required. In addition to pool cues, this machine can also process any rod products with a small diameter. This is a basic pool cue taper machine, which only costs $4,000-5,000. If you have batch processing needs, you can choose our multi-station pool cue milling machine, or add an automatic loading and unloading system to achieve fully automated processing of the machine.

Features of CNC Wood Lathe Dedicated to Milling Pool Cues

- The standard processing length is 1500mm, the maximum processing diameter is 100mm, the processing length can be adjusted arbitrarily within 1500mm, and a longer processing length can be customized.

- The heavy gray cast iron bed is used, and the whole is processed by gantry milling. Even if it rotates at high speed, it will not cause jitter and affect the processing.

- The 3.5kw air-cooled spindle is used for milling, and the speed can reach 18000 per minute. With the use of radius cutter or saw blade, the processing finish is high.

- 4KW three-phase asynchronous motor, using inverter control, the speed can be adjusted arbitrarily within 0-3000 revolutions.

- CK-1000TC control system, full English interface, friendly operation, simple design to start processing.

- The system comes with a pulse handwheel, which makes it easier to calibrate the tool, and the tool can be adjusted with a precision range of 0.001mm.

- TBI ball screw, hiwin linear guide, linear bearing, the fastest processing speed can reach 2000mm/min

Advantages of CNC Wood Milling Machines

- 3.5kw air-cooled spindle (water-cooled optional).

- 4KW three-phase asynchronous motor.

- CATEKCNC dedicated high-torque servo motor for linear axes.

- Specialized CNC system.

- Pulse handwheel is attached.

- Rotation speed is transmitted by belt.

- Pneumatic control for clamping and unclamping.

- Replaceable chuck for clamping wood.

Details of Pool Cue CNC Wood Milling Lathe

- Radius cutter

It can directly process a surface with higher finish, which is more suitable for milling of rod products.

- Optional saw blade

Compared with radius cutters, the processing speed is faster.

- Optional chuck

An optional chuck is available to hold the workpiece for end face machining.

- Pulse handwheel

Equipped with a pulse handwheel, the accuracy can be manually controlled to 0.001mm.

- CNC system

Dedicated CNC system, you can set layers arbitrarily and view drawing thumbnails

Technical Parameters of CNC Wood Lathes Suitable for Processing Round Stick Products

| Model | CK-1510 |

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1100*1300mm |

Application Scope of The Cheapest Wood Lathe For Billiard Cue

The CNC wood lathes used for billiard cue production can process various types of pool cues, such as big-head cues, small-head cues, snooker cues, Chinese eight-ball cues, British nine-ball cues, American nine-ball cues, as well as billiard cue extension handles, crutches, trekking poles, round rods, shovel handles, civilized sticks, walking sticks, round table legs, tapered table legs, wooden sticks, wooden sticks and other types of rods and stick products.

The Following Are the Processable Products of the Cheapest CNC Wood Lathe for Pool Cue

- One-piece cue

- Two-piece cue

- Three-quarter two-piece cue

- Pool break cue

Other Machines

In addition to this inexpensive basic single station billiard cue CNC woodturning machine, we have a number of other machines that can be used in the production of manufacturing billiard cues.

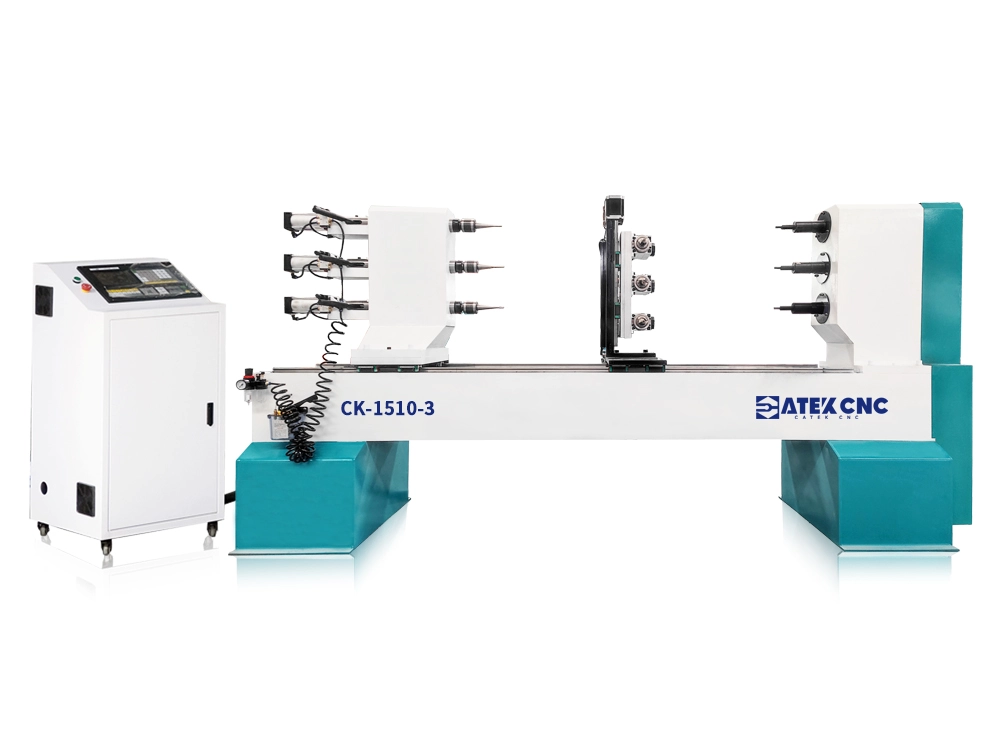

- CK-1510-3

The lathe has three identical processing stations and can process three identical billiard cues at one time.

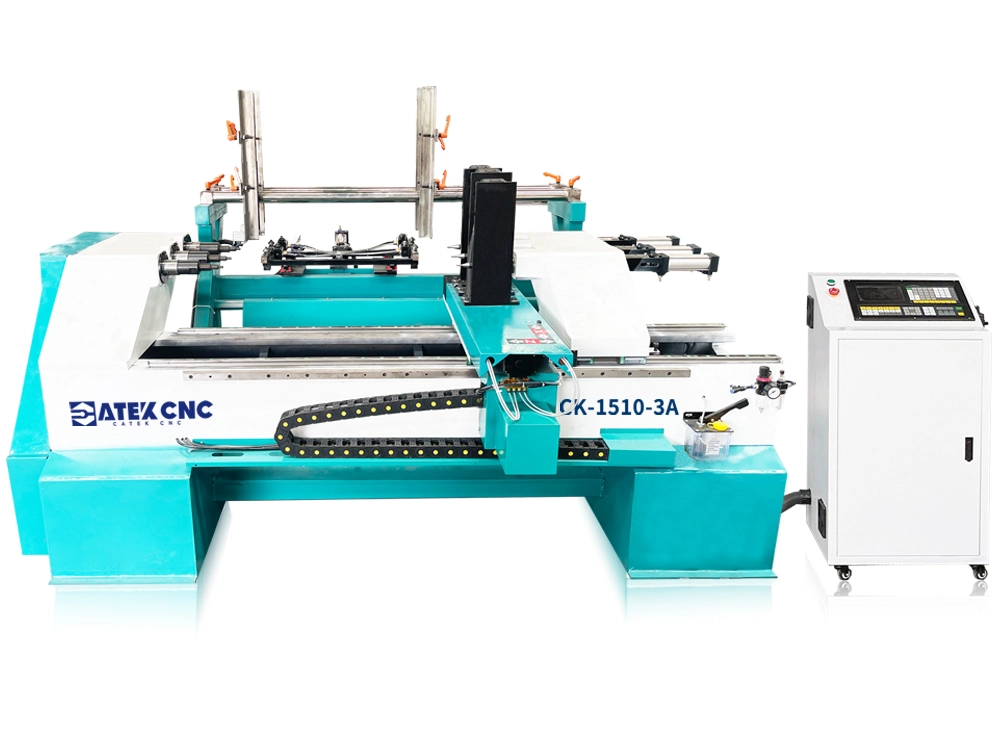

- CK-1510-3A

The lathe has three identical processing stations, can process three identical billiard cues at a time, and is equipped with an automatic feeding hopper.

| Model | CK-1510 |

|---|---|

| Processing Dimensions | Maximum length 1500mm * maximum diameter 100mm (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-3000r/min |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | X axis uses 25 TBI ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XZ two-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1100*1300mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.