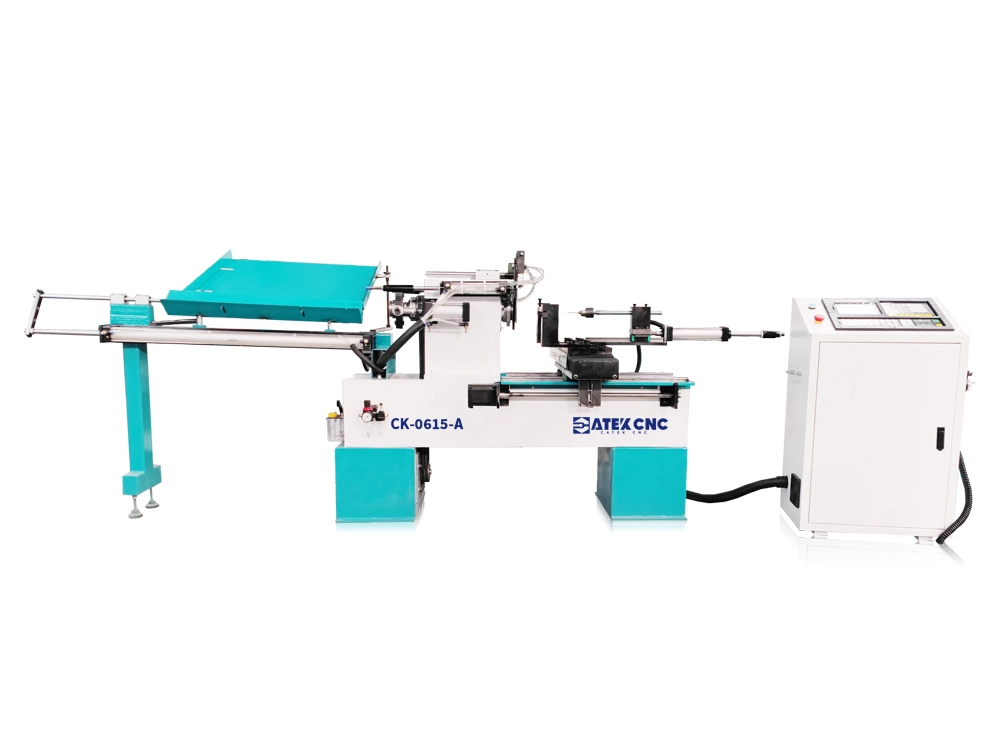

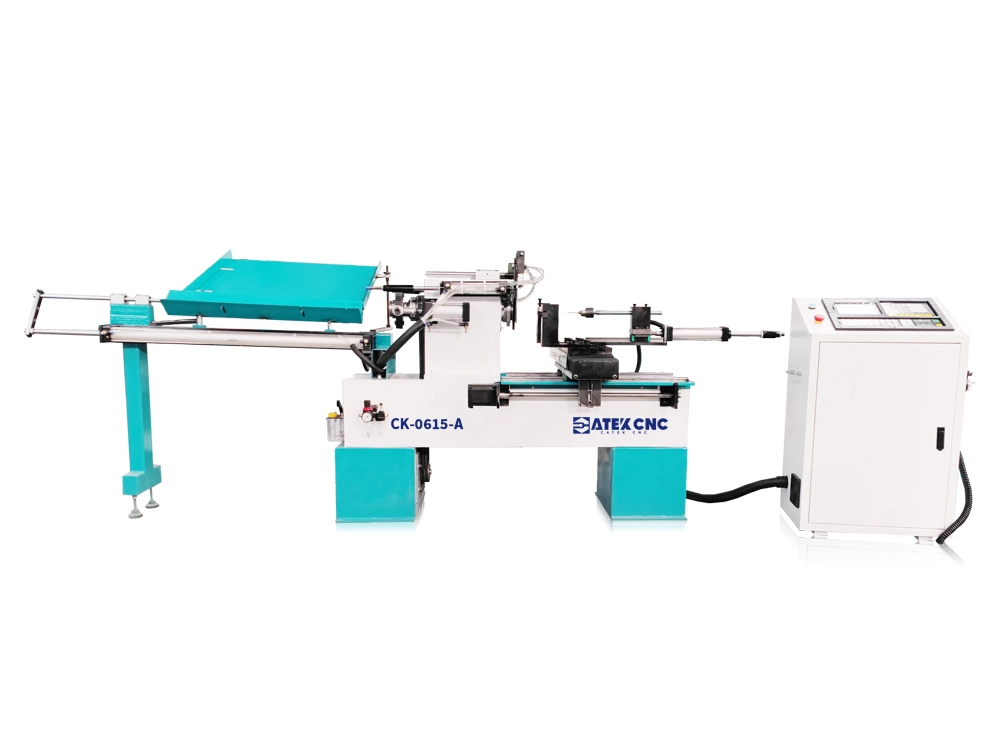

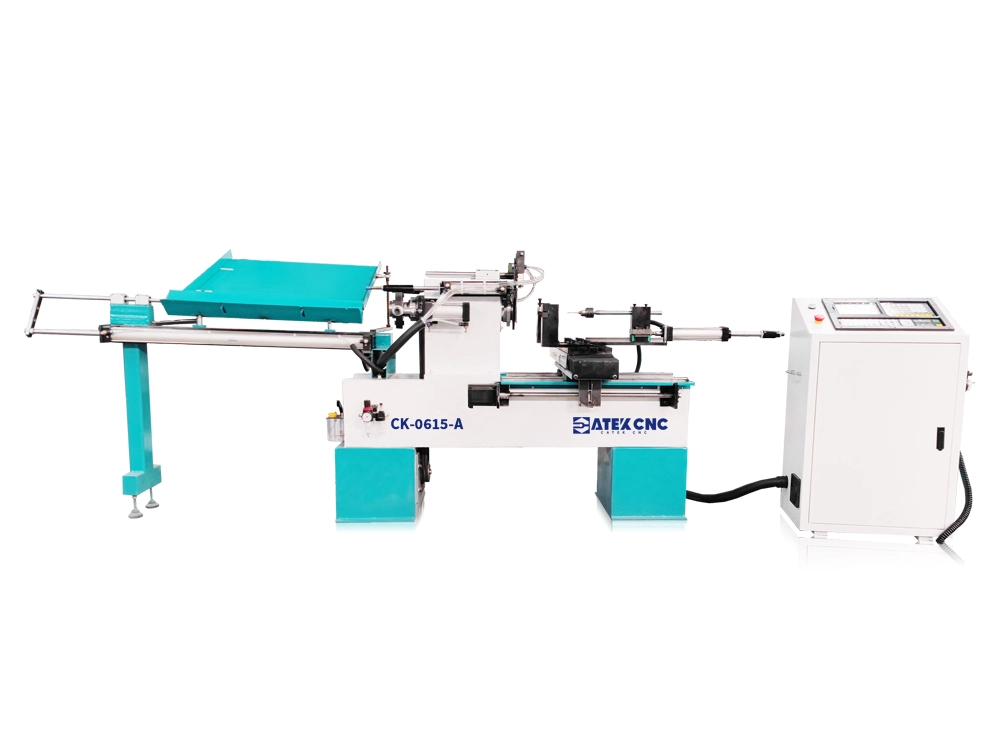

Super Cheap Small CNC Wood Lathe With Fully Automatic Feeding

Mini CNC Wood Lathe for Wood Crafts and Toys

[Function Description]

The mini CNC wood lathe with automatic feeding hopper is designed for processing small parts. The standard configuration is equipped with turning,facing, face grooving, cutting, turning inner hole etc functions. Sanding and polishing devices and multi-functional spindles can also be selected on this basis. After placing cylindrical blanks or square columnar blanks in the machine's silo, the machine can automatically pull the blanks for turning, cutting, etc., which is very suitable for processing small parts, such as wooden balls, wooden handles, handles and other parts. The machine can realize automatic loading and unloading of blanks, reduce manual intervention, and improve production efficiency. It adopts high-precision screw and linear guide transmission to effectively ensure processing accuracy. It is equipped with a 3KW three-phase asynchronous motor to continuously provide stable power output.

The mini automatic CNC woodworking lathe is flexible in use and can be applied to various production environments. The processing shape is simple to convert, the G code is set by computer and the control system can finish the processing by reading the G code. Simple operation, realizes the whole process of automatic operation from blank conveying, positioning to processing, saves labor cost, reduces the difficulty of operation, so that ordinary workers can be operated after simple training.

Characteristics of Small Crafts CNC Wood Lathe

- The machine is equipped with a turning tool, a cutting tool, an inner hole tool, and a drill bit, which can be adjusted and used at will according to the processed product, which is simple and convenient.

- The machine uses multiple combined cylinder structures to operate in linkage to realize fully automatic feeding, one-button operation starts, the whole blank is automatically cut off, and the blank is automatically fed after processing.

- The pneumatic collet can be replaced at will according to the blank diameter, square blanks and round blanks can be selected at will, and the blank bin can be adjusted at will according to the length of the raw blank.

- It uses a 3KW brake motor with a speed of 6000rpm, millisecond-level braking, and high efficiency.

- It has complete functions and can perform turning, cutting, punching, hole-digging, grinding, drilling, grooving, engraving and other tasks, and the functions can be combined arbitrarily.

- Self-developed CNC special software, according to the raw blank size and product picture, the processing method can be set arbitrarily, which is simple and easy to use.

- Optional sanding device and spindle, after processing, the parts can be sand and polished and drilled and grooved, etc., eliminating the trouble of secondary processing.

Advantages of Mini CNC Woodworking Lathe with Automatic Feeding Hopper

- Improve processing efficiency. Using this small CNC woodworking lathe to process wooden handles, drawer handles and other products is more efficient. On average, 600-1500 can be produced every day. One person can take care of dozens of machines, with high processing efficiency, fast speed, and labor saving.

- Save wood. Traditional manual chuck lathes need to waste a section of wood used for clamping for each product processed. The new small CNC woodworking lathe does not need to waste wood in the clamping position, which can reduce waste and continue processing.

- Simple operation. The machine uses a CNC control system for fully automatic processing. Before processing, you only need to use the CNC system to calibrate the tool to start processing.

- Strong adaptability. It can handle the processing of various small products and is suitable for various production environments.

Details and Photos of CK-0615-A CNC Wood Lathe with Automatic Feeding Hopper

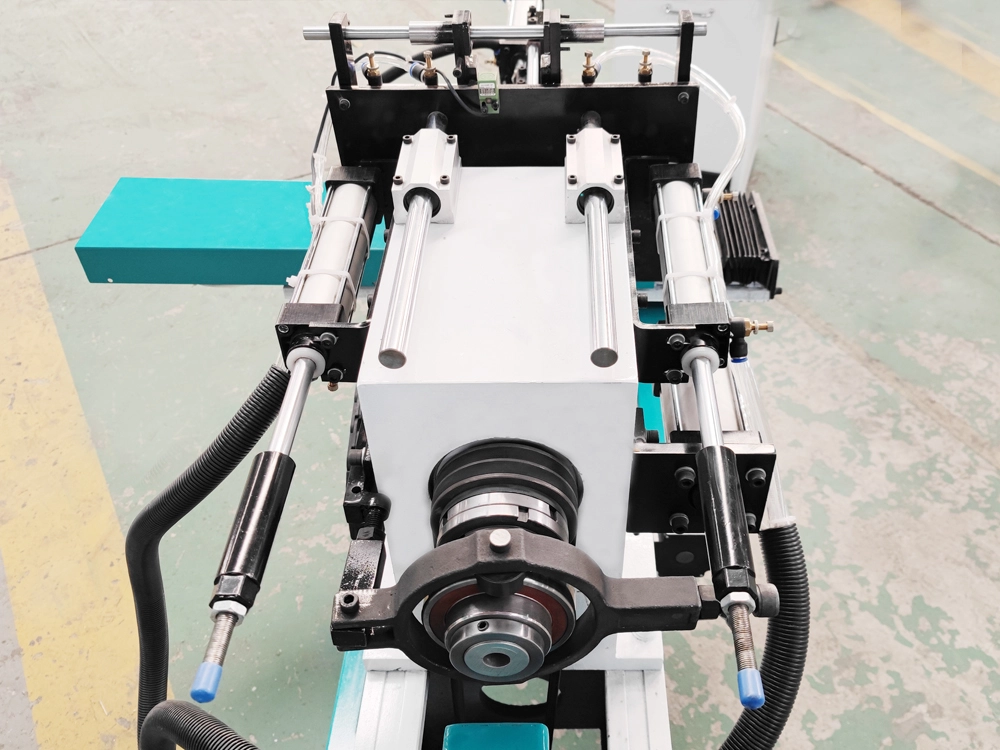

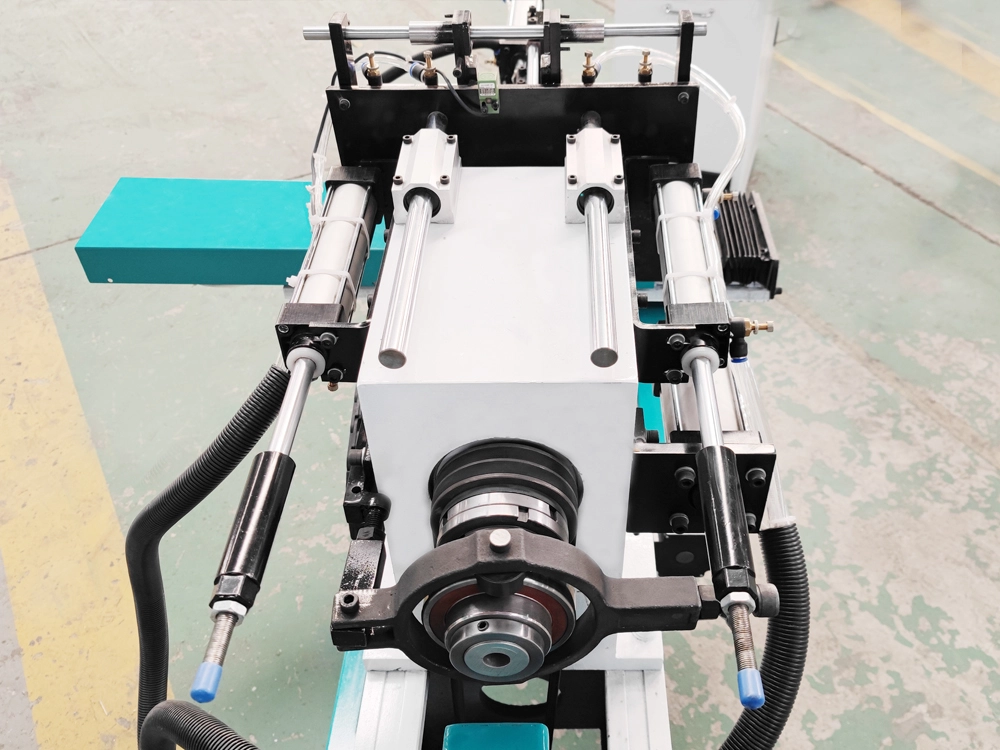

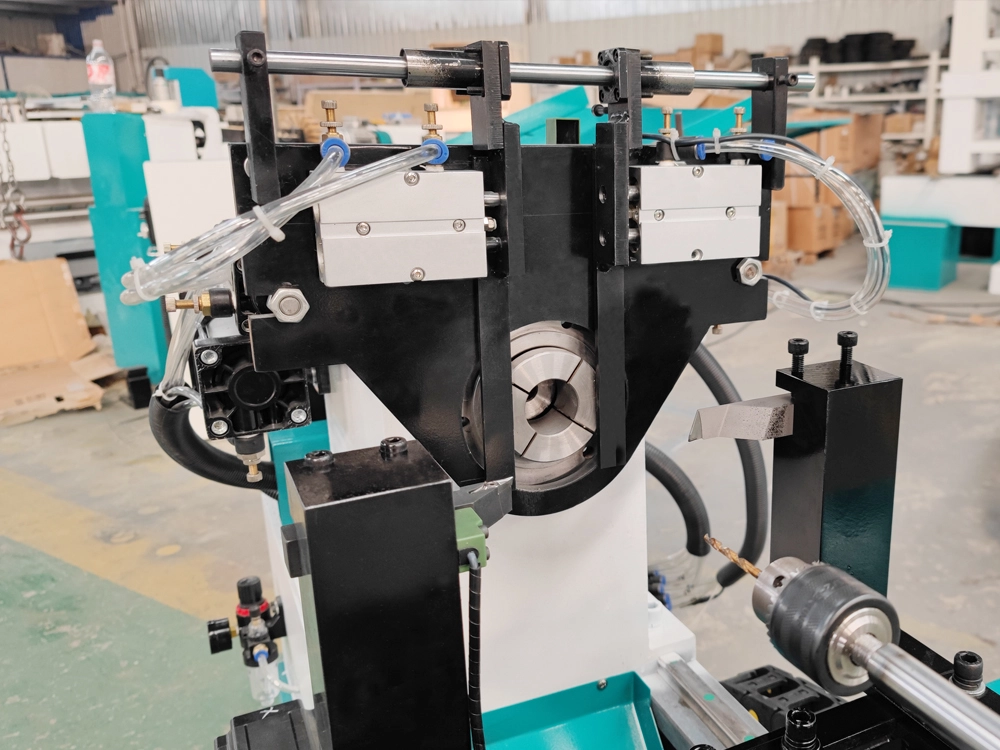

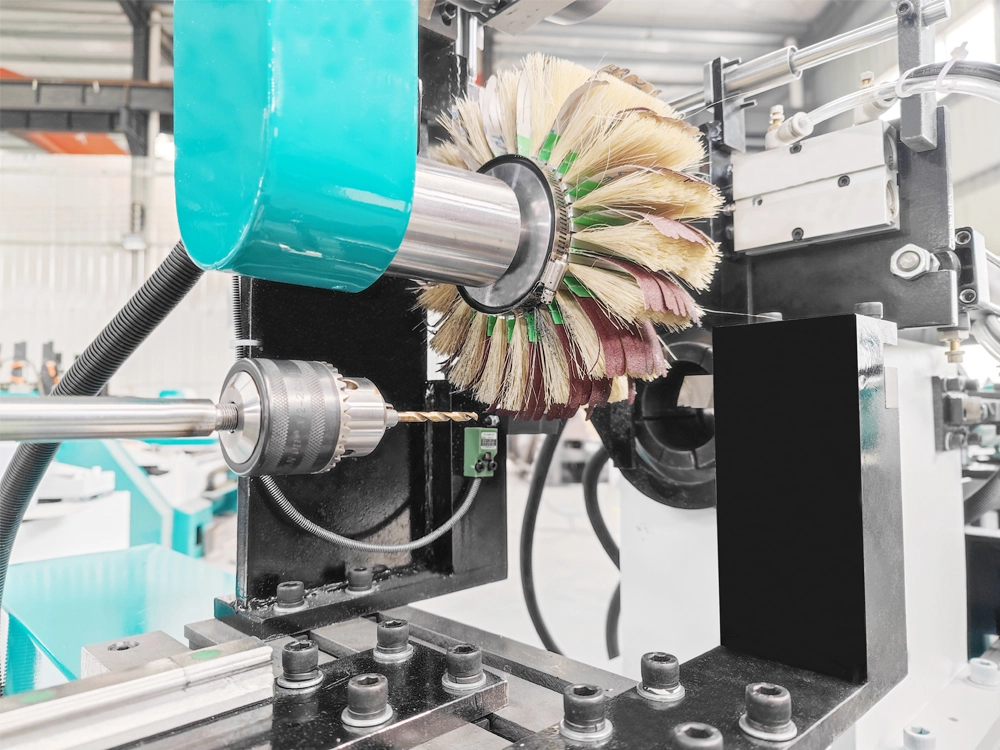

- Turning tools, cut-off tools, drill bits, combined use

Standard turning tool, cutting tool, drill bit, the shape of the blank can be automatically processed in layers, and the drilling depth can be automatically processed in batches. Compared with ordinary small CNC woodworking lathes, the processing efficiency is higher, and drilling work can be performed at the same time, eliminating the trouble of secondary drilling.

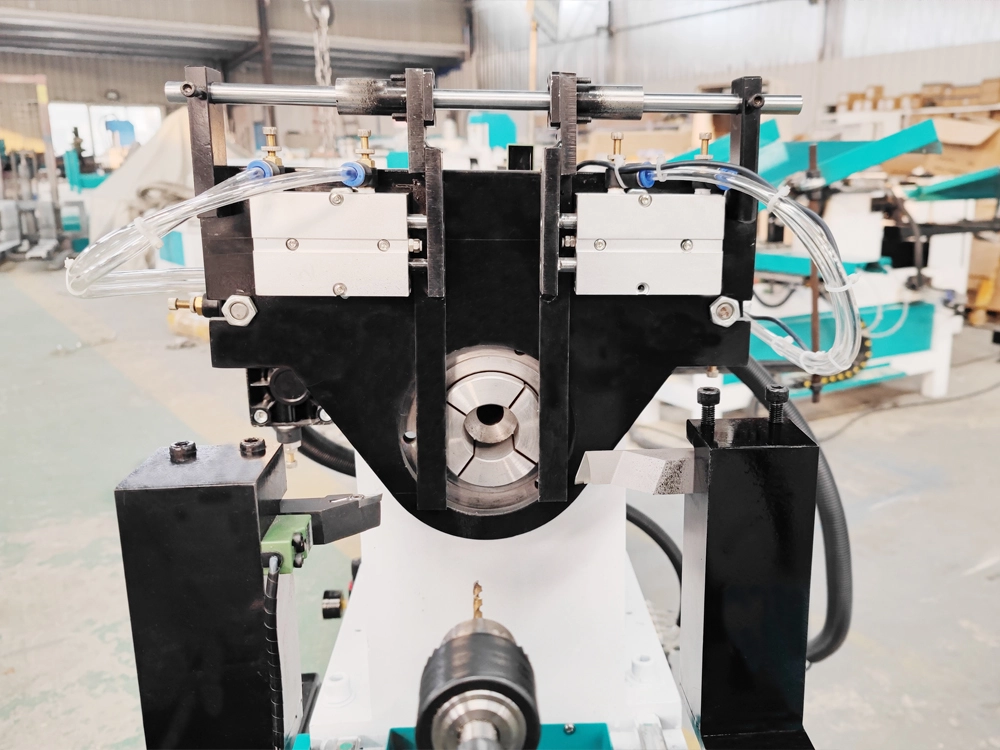

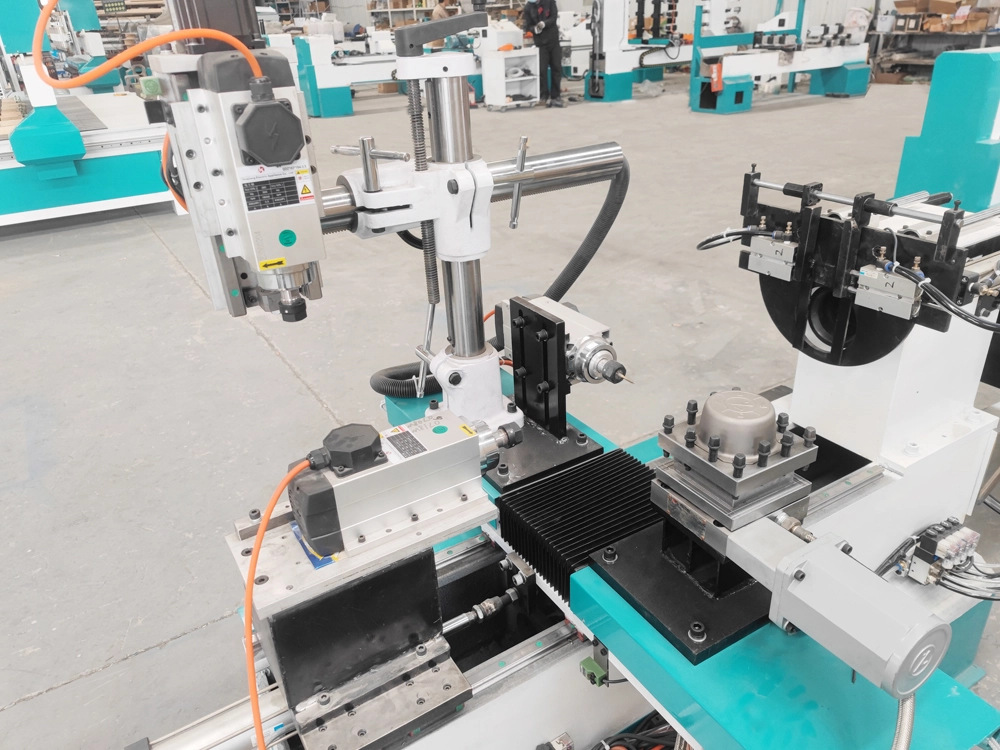

- Pneumatic collet can be replaced according to different processing materials, easy to use

A fully automatic pneumatic spring collet is used to clamp the material, which will not deform during high-frequency use. A cylinder push ring bearing is used at the tail to drive the collet to tighten and loosen. A three-layer metal pulling tube structure is used inside, which can work 24 hours a day, greatly improving the processing efficiency.

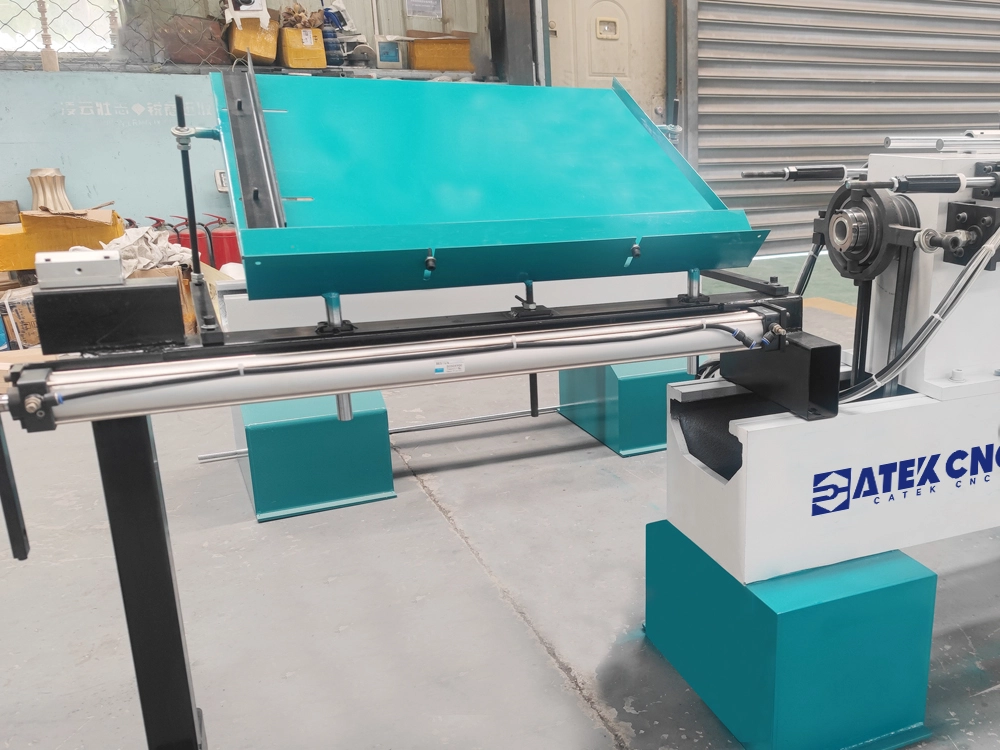

- Pneumatic hopper feed loader, adjustable according to different processing lengths

Multiple cylinders operate in conjunction, and the loading tray is adjustable. Multiple cylindrical or square column blanks with a maximum length of 800mm can be placed at a time and cut off automatically. Simply adjusting the machine settings can achieve fully automatic loading and unloading, avoiding the trouble of manually placing blanks. The operator only needs to put the blanks in on time and then focus on other work, greatly improving the efficiency of processing and production.

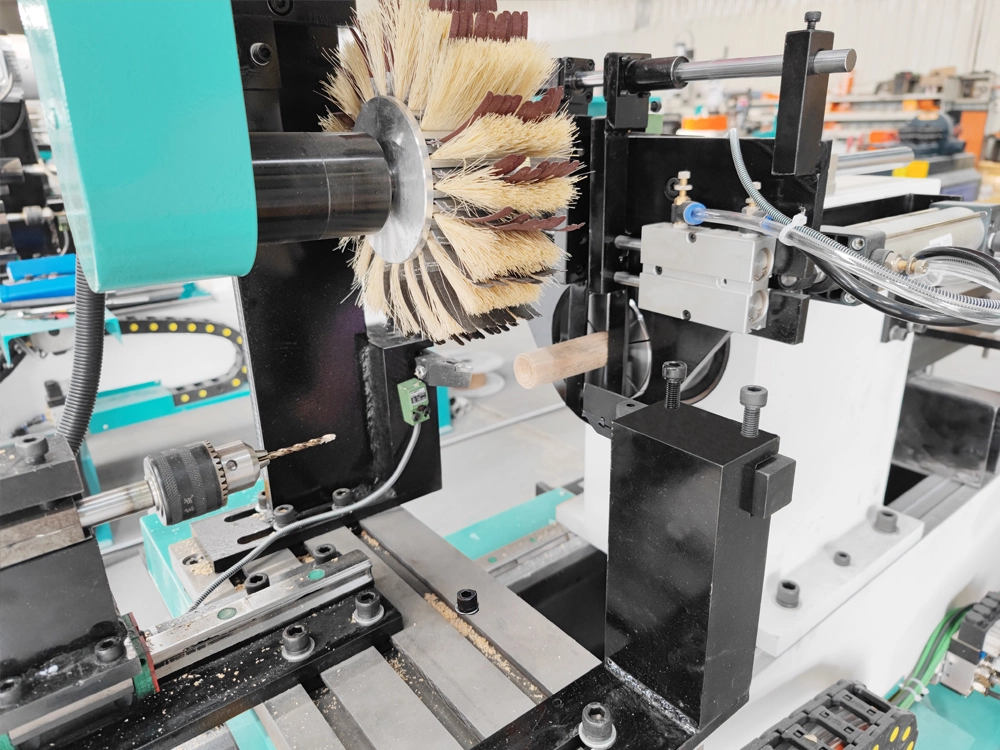

- Optional sanding wheels

Optional sanding wheel, automatic sanding after workpiece processing.

- Optional multifunctional spindle

An optional multi-function spindle can be installed to add engraving, grooving, drilling side hole and other functions to the machine.

Small Crafts CNC Wood Lathe Technical Parameters

| Model | CK-0615-A | CK-0715-A | CK-0820-A |

| Processing Dimensions | 60mm diameter * 150mm length (customizable) | 70mm diameter * 150mm length (customizable) | 80mm diameter * 200mm length (customizable) |

| Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet | ||

| Motor | 3KW brake motor | ||

| Motor Speed | 3000rpm | ||

| Driving Mode | CATEKCNC dedicated high-torque servo motor | ||

| Transmission Mode | XY axis 25 TBI ball screw | ||

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider | ||

| Equipment Cable | Pure copper anti bending cable | ||

| Control System | Dedicated control system panel, CK-1000TC (matching pulse handwheel) | ||

| Lubrication System | Electric lubrication oil injection maintenance system | ||

| Operating Voltage | AC380V/50/60Hz OR AC220V/50/60Hz (customizable) | ||

| Compatible Software | Artcam, AutoCAD, CDR, Illustrator, etc. (including self-developed simple drawing software) | ||

| Engraving Instruction | Standard G code, u00,mmg,plt | ||

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) | ||

| Security System | XYZ three-axis all photoelectric limit | ||

| Repeat Positioning Accuracy | ±0.02mm | ||

| Weight | 750kg | 800kg | 850kg |

| Dimensions | 4100*1100*1350mm | ||

Application of Mini Automatic CNC Woodworking Lathe

- Handles: wooden handles, drawer handles, skipping rope handles, pot handles, door handles and other handles.

- Crafts: Crafts: vases, pen holders, cups, jars, bracelets, wooden boxes, wooden lids, small bottles, matryoshka dolls, etc.

- Other products: chess, checkers, wooden toys, wooden figures, dolls, wooden balls, small crafts, wooden accessories, etc.

The Following Are the Processable Products of Mini Crafts CNC Wood Lathe

| Model | CK-0615-A | CK-0715-A | CK-0820-A |

|---|---|---|---|

| Processing Dimensions | 60mm diameter * 150mm length (customizable) | 70mm diameter * 150mm length (customizable) | 80mm diameter * 200mm length (customizable) |

| Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet | ||

| Motor | 3KW brake motor | ||

| Motor Speed | 3000rpm | ||

| Driving Mode | CATEKCNC dedicated high-torque servo motor | ||

| Transmission Mode | XY axis 25 TBI ball screw | ||

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider | ||

| Equipment Cable | Pure copper anti bending cable | ||

| Control System | Dedicated control system panel, CK-1000TC (matching pulse handwheel) | ||

| Lubrication System | Electric lubrication oil injection maintenance system | ||

| Operating Voltage | AC380V/50/60Hz OR AC220V/50/60Hz (customizable) | ||

| Compatible Software | Artcam, AutoCAD, CDR, Illustrator, etc. (including self-developed simple drawing software) | ||

| Engraving Instruction | Standard G code, u00,mmg,plt | ||

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) | ||

| Security System | XYZ three-axis all photoelectric limit | ||

| Repeat Positioning Accuracy | ±0.02mm | ||

| Weight | 750kg | 800kg | 850kg |

| Dimensions | 4100*1100*1350mm | ||

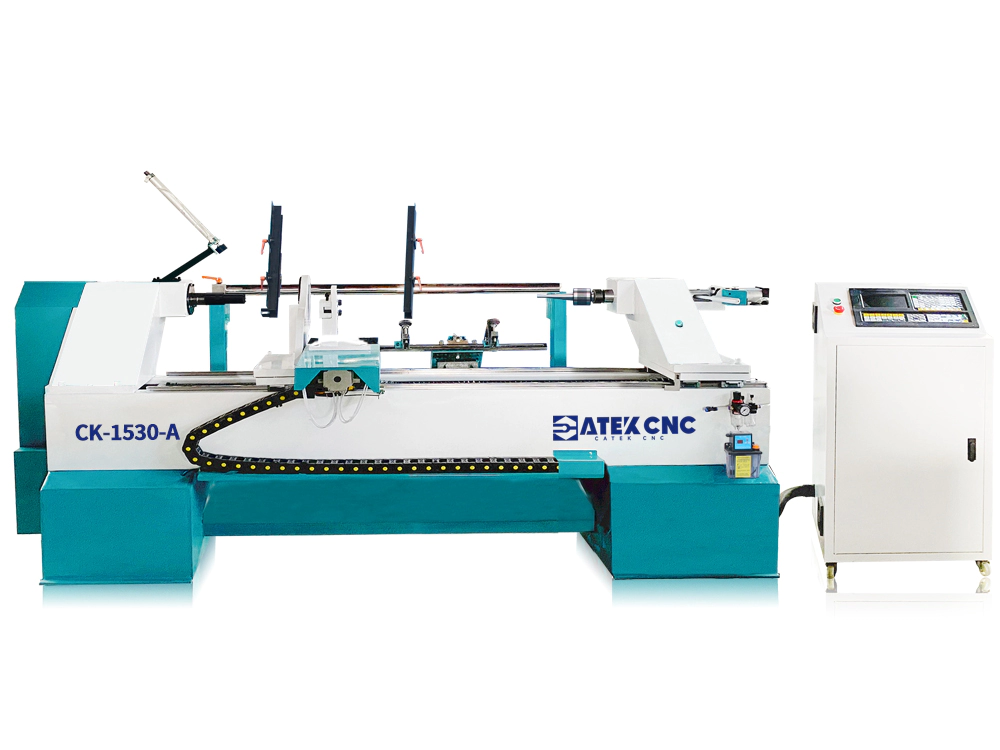

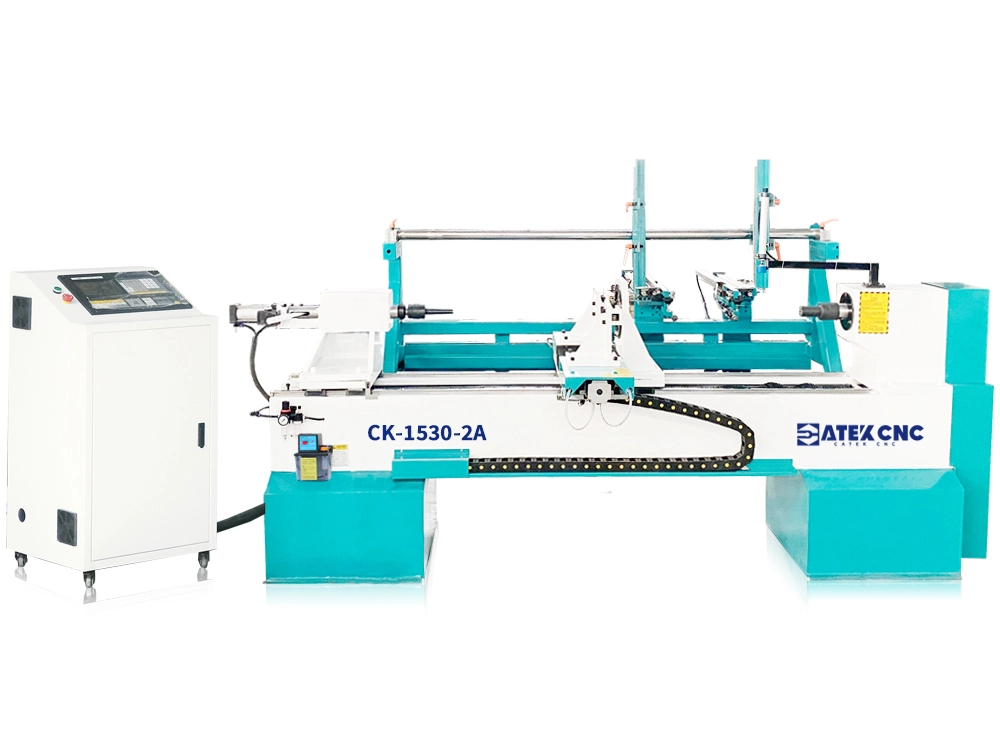

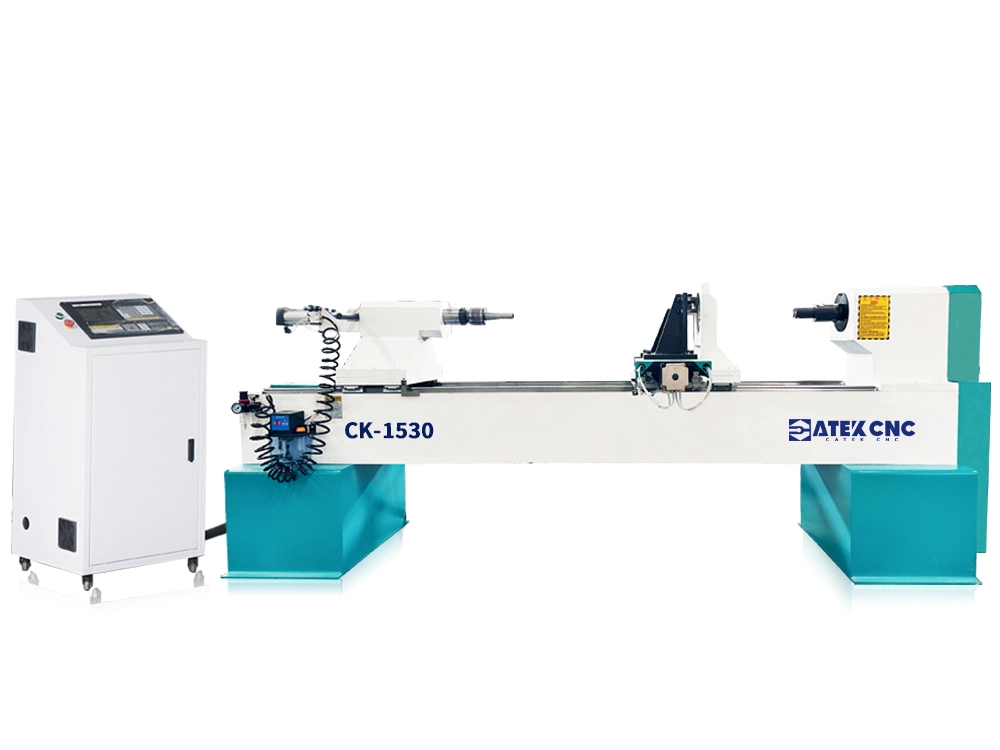

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.