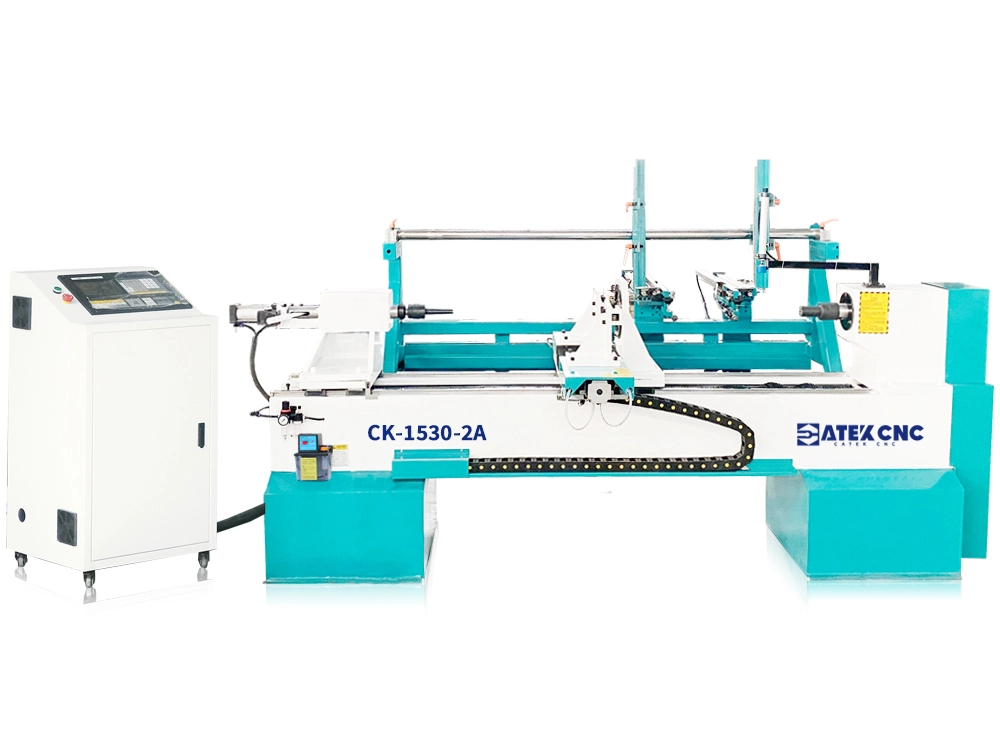

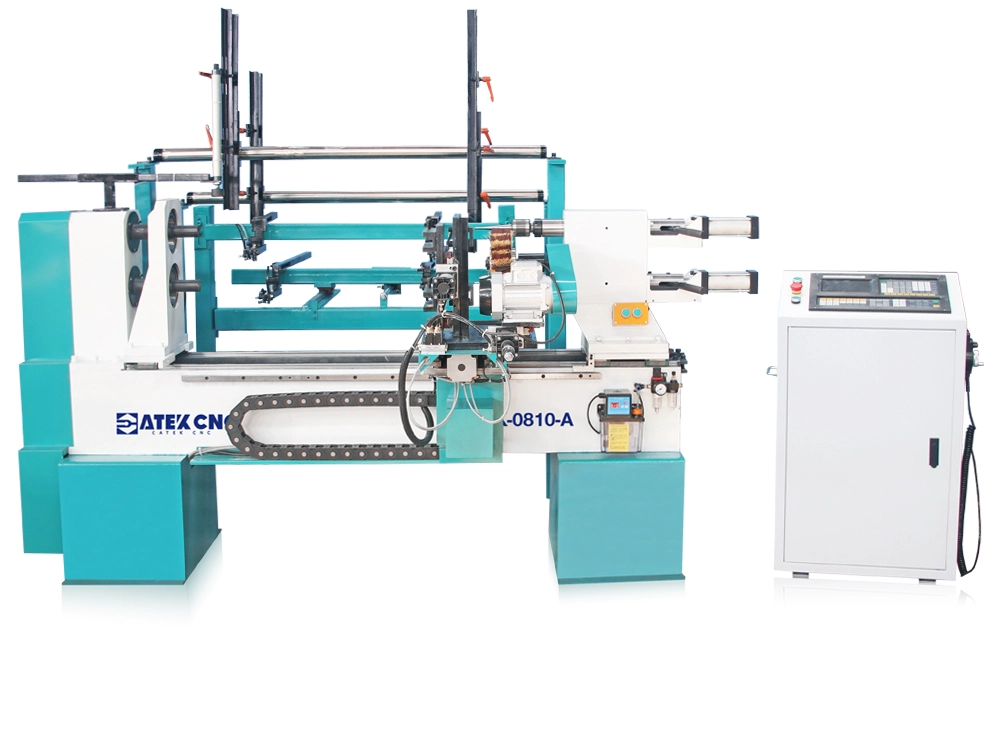

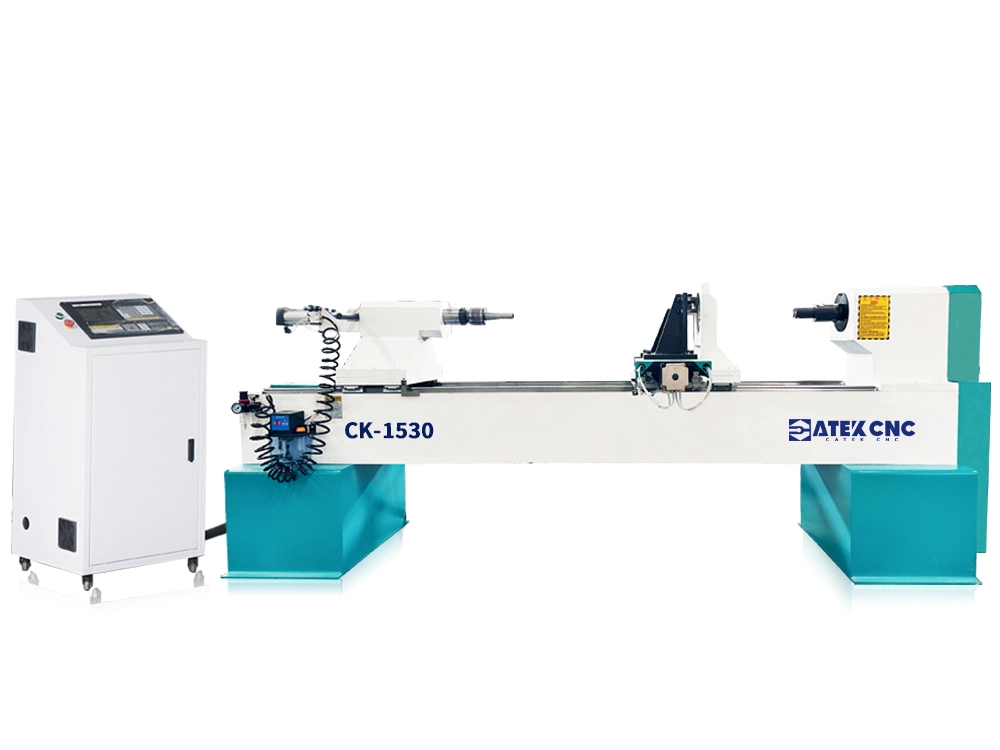

Two-Spindle CNC Wood Lathe, Machining Two Baseball Bats at Once

2-Station CNC Wood Lathe for Baseball Bat Making

[Function Description]

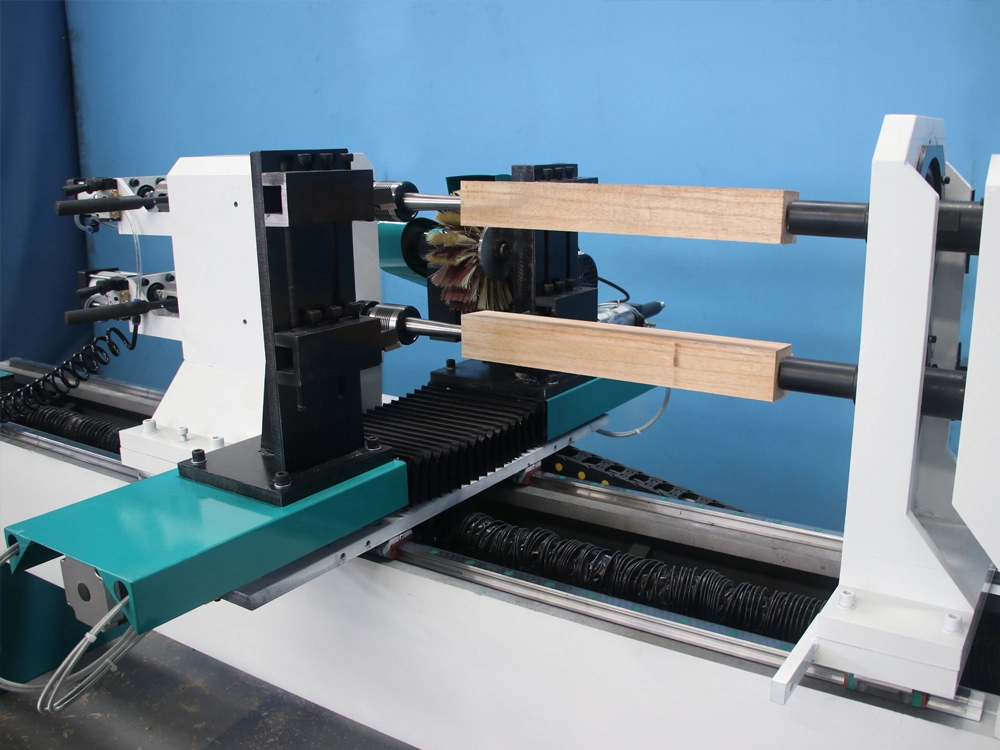

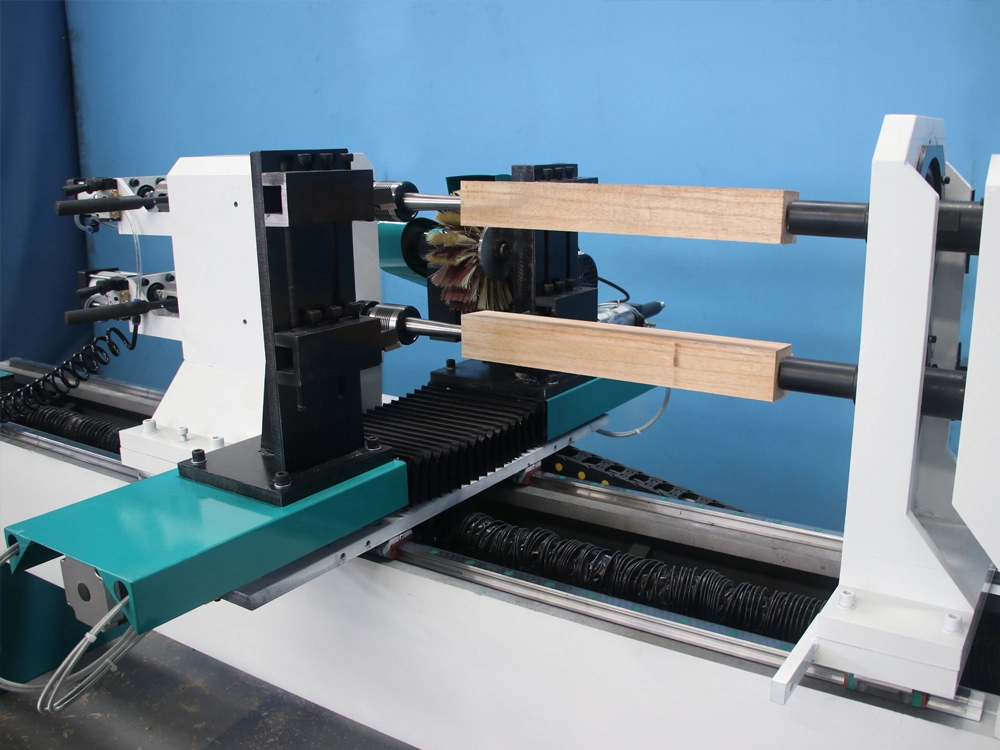

Overview of 1516 2-Spindle 4-Knife CNC Wood Lathe

The CK-1516-2 CNC woodworking lathe is a CNC processing machine that is more suitable for production factories. This machine is easy to operate, has a fast processing speed, and is cheap. You can get this lathe for only $5,000. It can realize four-knife feeding processing of two pieces of wood at the same time, which is very suitable for batch processing of the same products. It only takes about 80 seconds to process products with a length of 600mm and a diameter of 60mm. The processing efficiency is extremely high. It can easily process more than 500 parts every day, greatly saving labor and effectively reducing production costs.

This two-station CNC woodworking lathe is equipped with a 5.5KW high-torque three-phase asynchronous large motor. It is controlled by a frequency converter and the speed can be adjusted arbitrarily. The maximum processing length is 1.5m. When two materials are processed at the same time, the maximum processing diameter is 160mm; if only one is processed at a time, the maximum processing diameter is 300mm, and the machine has a wider range of applications. The processing size can also be customized for you, and the processing length and processing diameter can be customized as needed.

The Advantages and Uses of a 2-Station CNC Woodworking Lathe

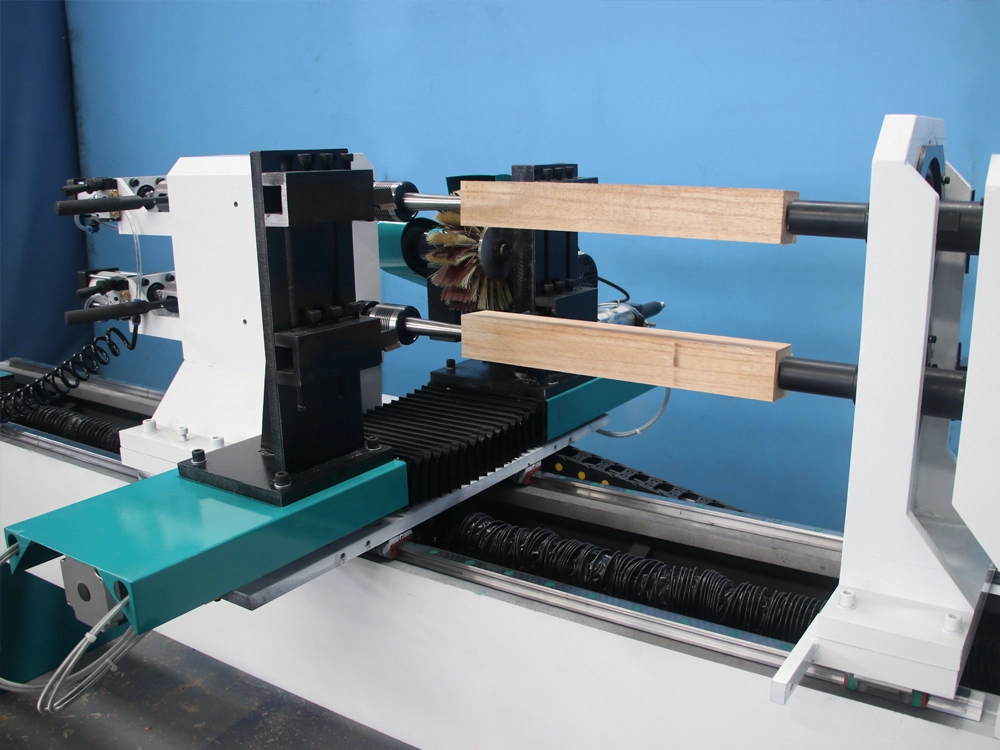

- 2-station design, each station is equipped with a drive spindle and two turning tools. Two pieces of wood can be processed at one time, two knives are fed simultaneously, two tools on the X axis are roughed, and two tools on the Y axis are finely processed, which makes the turning efficiency higher.

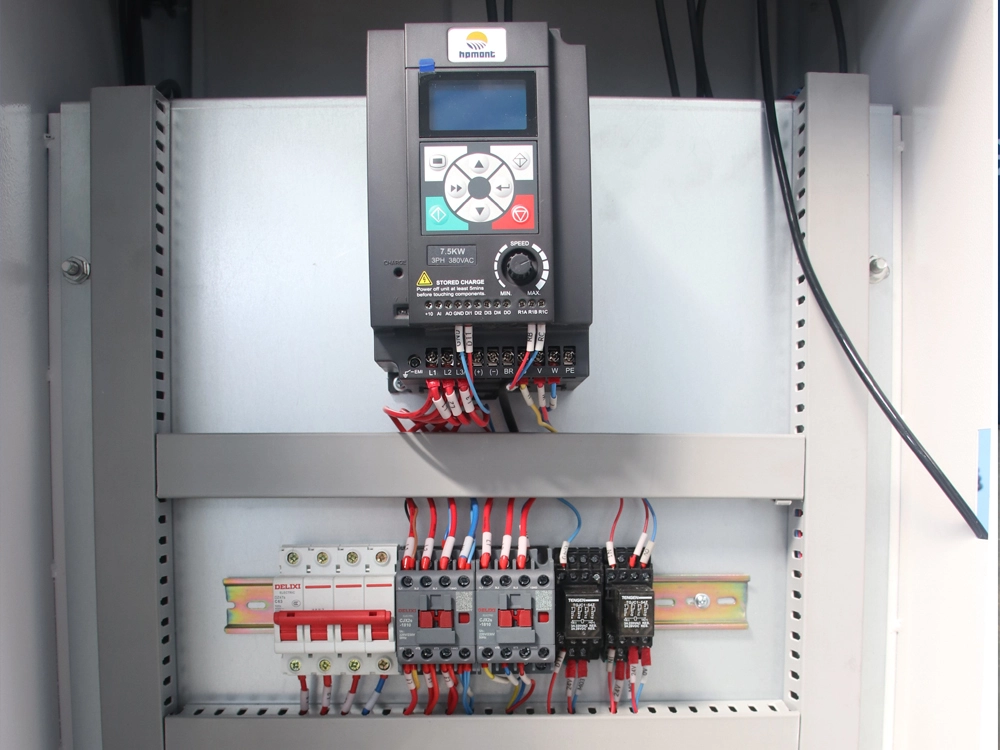

- It is controlled by an independent control box, equipped with dual cooling fans, and built-in main electrical parts, which can effectively isolate electromagnetic interference.

- It uses a 5.5KW three-phase asynchronous large motor with greater torque and is equipped with a high-power inverter to accurately control the speed.

- It uses Morse centers, which are easy to replace. The drive spindle can be replaced with a chuck, which is easier to clamp parts.

- The heavy-duty integral cast iron bed, the headstock and the tailstock are cast in gray cast iron, which is more stable and does not deform.

- It is equipped with a steady rest which can stabilize the raw materials when processing slender wooden sticks and other products, and solve the shaking problem during wood processing.

- HIWIN linear guides and flange linear bearings, TBI ball screws are used in the transmission parts, with high running accuracy, precise positioning, and good consistency of processed parts.

- The CNC woodworking lathe can be equipped with an automatic cylinder centering frame, which can automatically align the center when installing the material, solving the problem of manually finding the center point of the wood, and is easy to use.

Details of 2-Station CNC Wood Lathe

- Two-station design

Two drive spindle, four turning tools, equipped with steady rest.

- CATEKCNC dedicated numerical control system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

- External pulse control handwheel

Wired or wireless control, providing a range of intuitive and simple operations for CNC lathes.

- Inverter

High power and high torque Hpmont inverter.

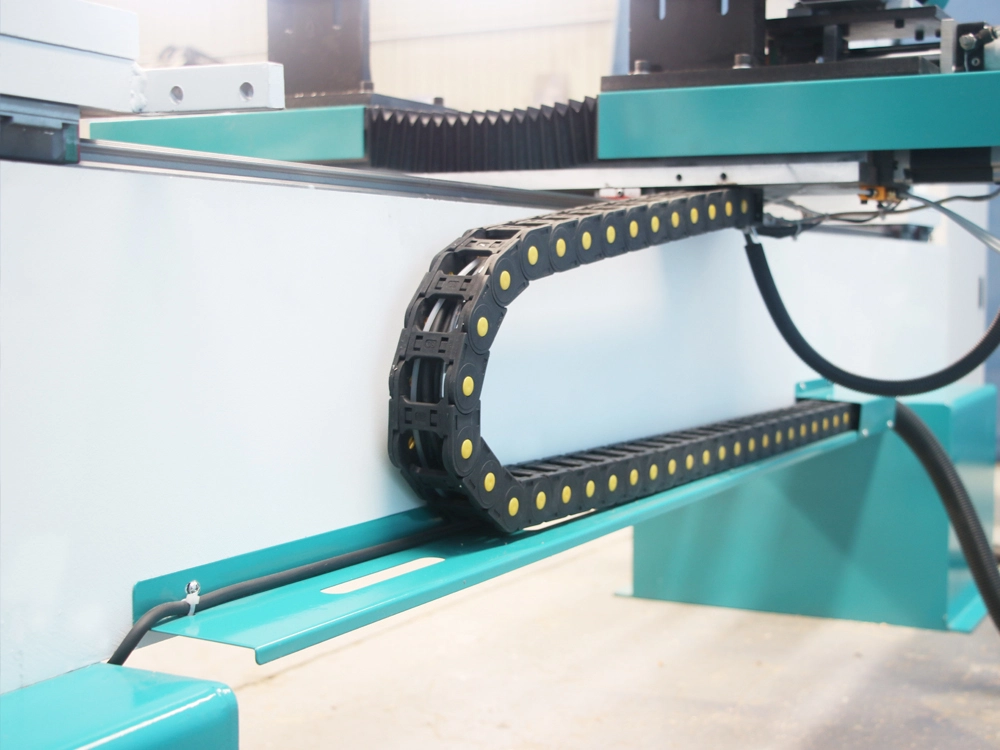

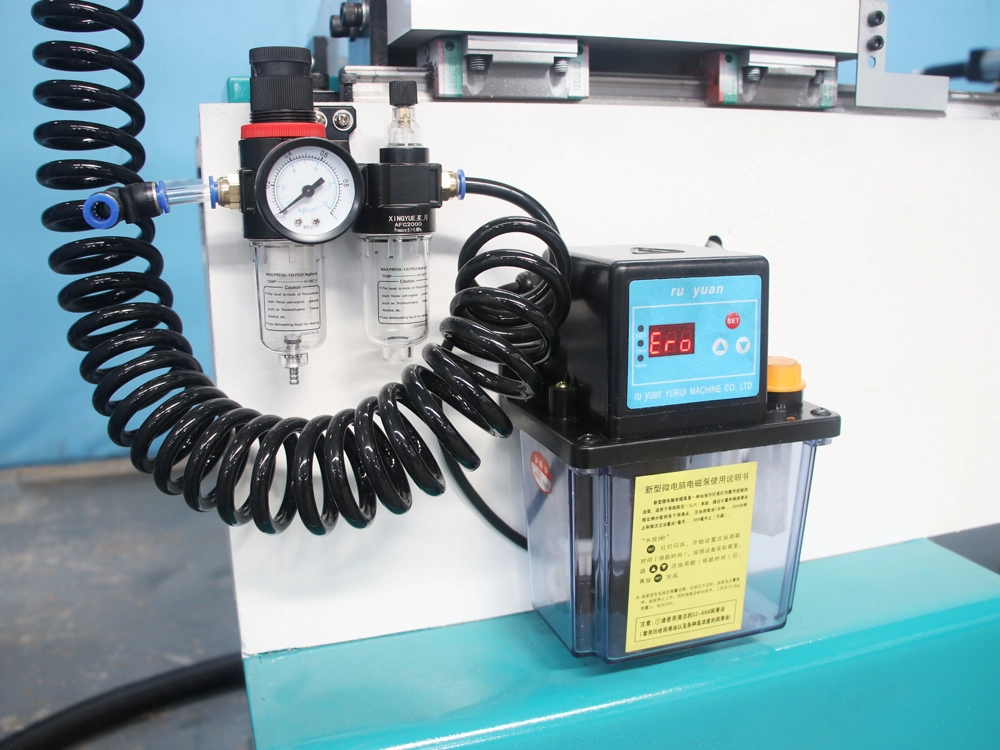

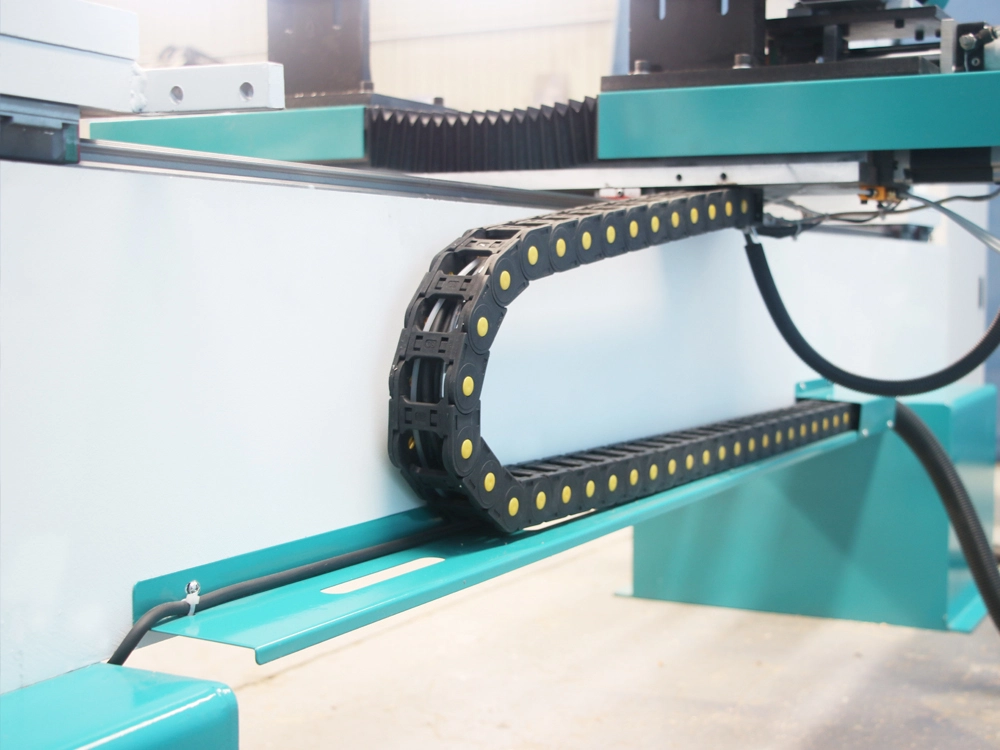

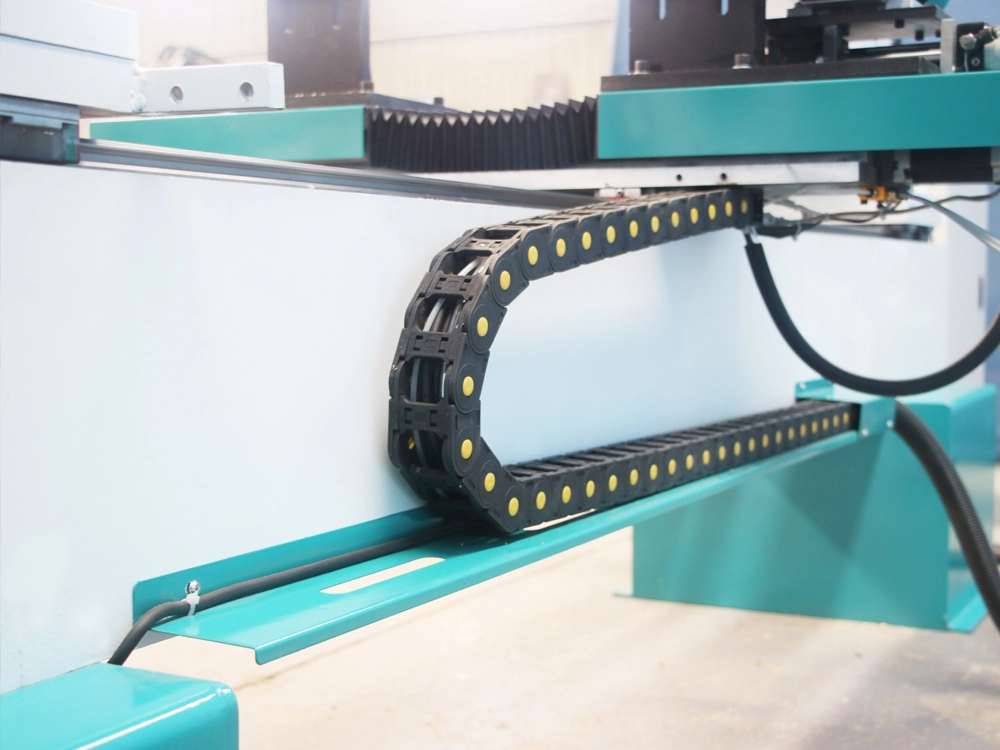

- Tank drag chains

Tank drag chains are used to protect and properly store cables, oil pipes, etc., so that they can move safely and orderly when the lathe moves.

- 2-station CNC wood lathe with sanding

Technical Parameters of 2-Station 4-Tool Woodworking CNC Lathe

| Model | CK-1516-2 |

| Processing Dimensions | 1500mm length * 160mm diameter * 2 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont high torque inverter |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

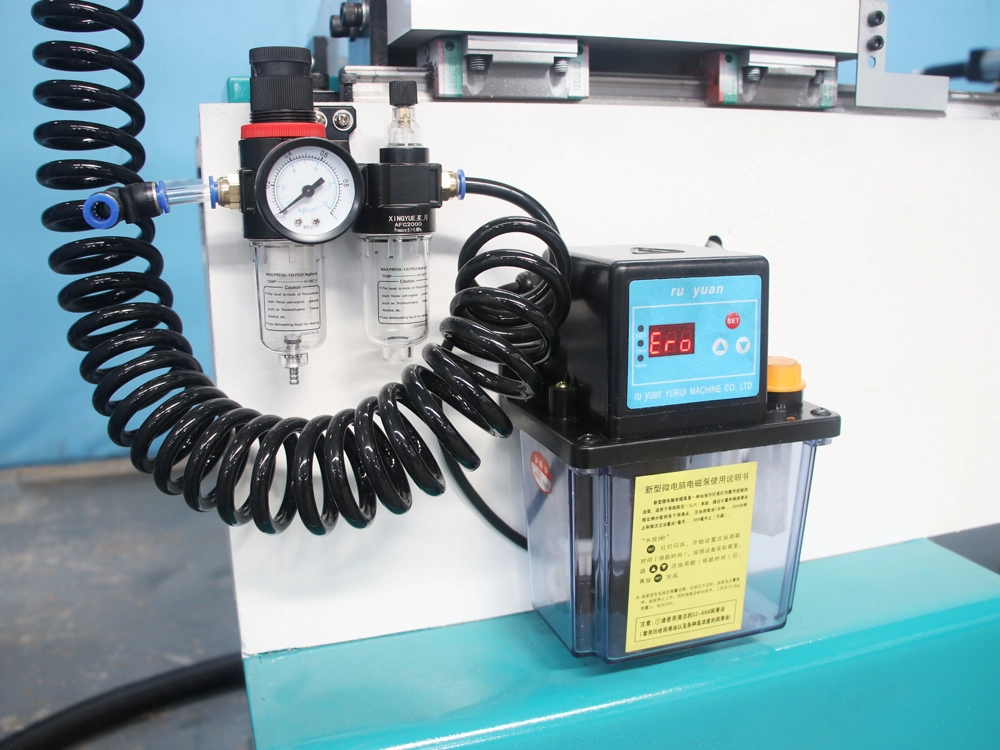

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1500mm |

Application Scope of 2-Station CNC Wood Lathe

Widely used in various industries, such as:

Daily necessities: wooden furniture accessories, such as stair railings, Roman columns, bed legs, table legs, chair legs; various wooden furniture, such as wooden stools, outdoor wooden pavilions, fences, bay window fences, etc.; and various wooden ornaments, such as wooden bowls, vases, wooden cups, etc.

Sports and music supplies: baseball bats in sports supplies; in terms of musical instruments, common drumsticks, flutes, bassoons and other wind instruments, as well as piano tables, piano stools, billiard tables, etc.

The Following are The Processable Products of 2-Station 1516 CNC Wood Lathe

Which Tool Should Be Used When Using CNC Wood Turning Machines for Different Processing Needs?

Which tool should be used when using CNC wood turning machines for different processing needs:- When turning ordinary parts, we only need to use V-shaped alloy turning tools to start processing. There are standard integrated V-shaped alloy turning tools and other discarded V-shaped alloy tools.

- Some products will have some right-angle end faces. At this time, we need to replace the 90° right-angle turning tools to turn the right-angle end faces of the products.

- When processing round rod-shaped, conical, and rod-shaped products, we can replace the U-shaped tools to obtain more processing volume, more wood turning can be performed at one time, and processing efficiency can be improved.

- When processing vases, wooden bowls, pen holders and other types of products, a chuck needs to be used, and a right-angle inner hole knife is used for processing. After processing the outer shape, the inner hole knife is used for inner hole processing.

- When the workpiece needs to be cut, the cutting knife needs to be replaced to cut the product.

- CNC woodworking lathes can also choose to use profiling tools for product turning. The blade shape of the profiling tool is exactly the same as the shape of the part to be processed, which can turn wood efficiently. However, this type of tool wears quickly and is difficult to sharpen.

| Model | CK-1516-2 |

|---|---|

| Processing Dimensions | 1500mm length * 160mm diameter * 2 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont high torque inverter |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1500mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.