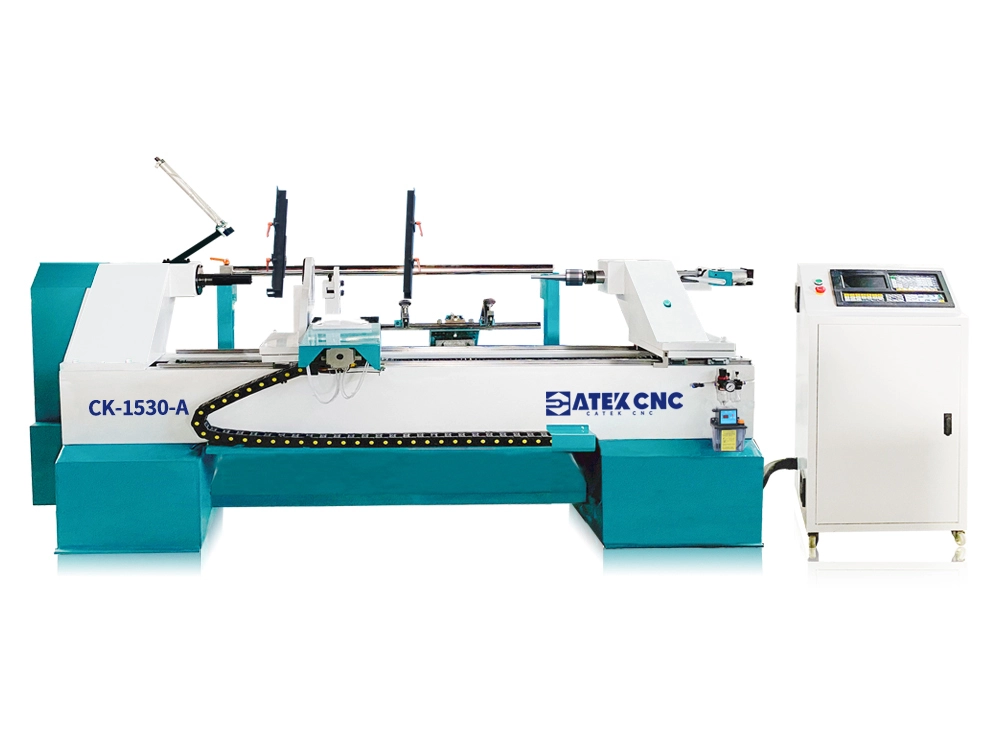

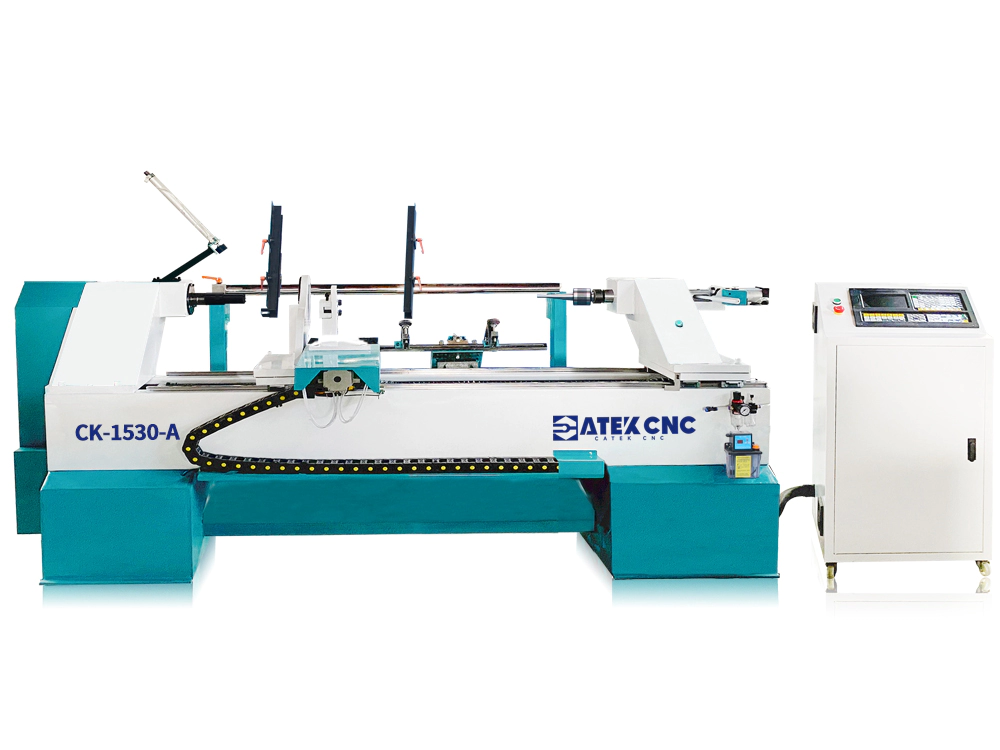

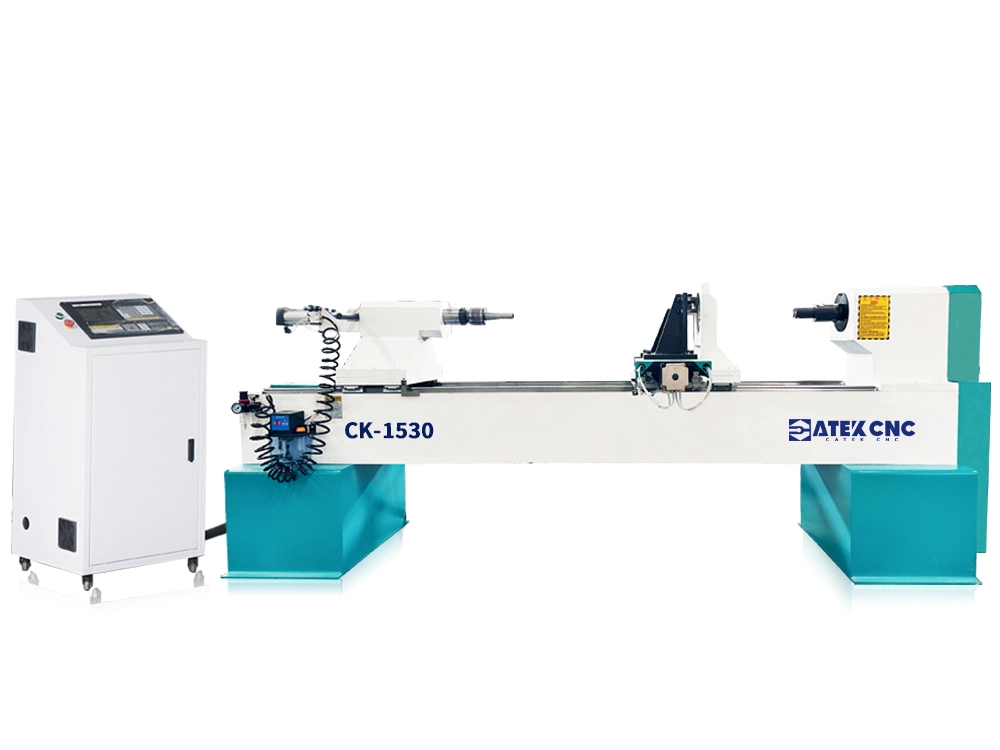

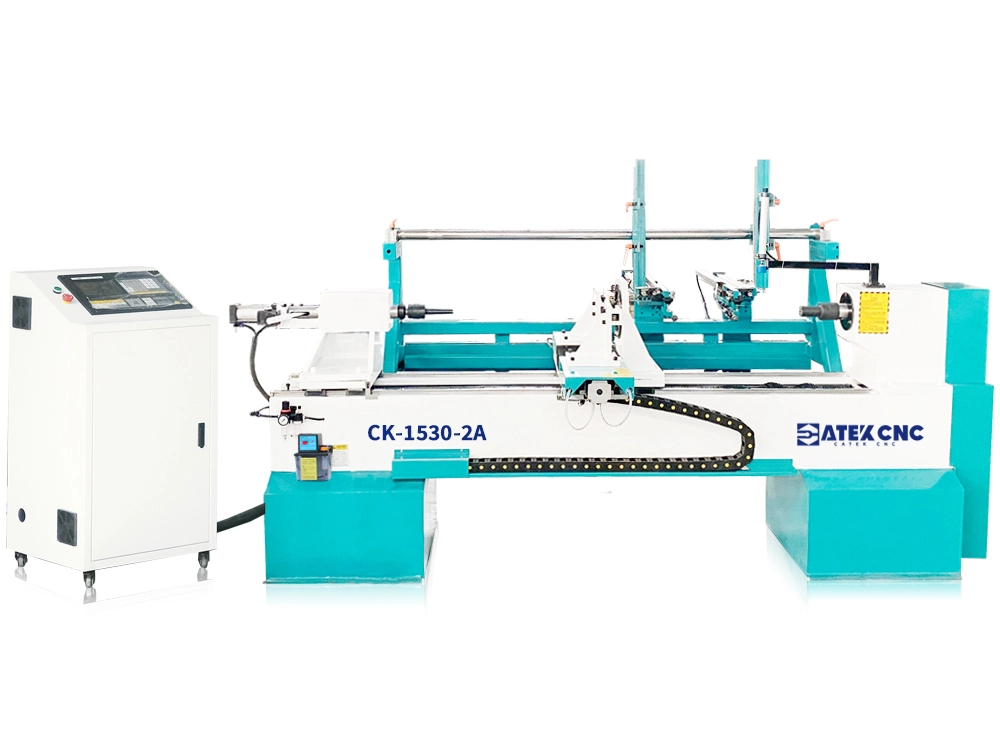

Low Price Automatic Loading And Unloading CNC Wood Lathe for Craftsman

Affordable Single-Knife CNC Wood Turning Lathe with Self-Feeding

[Function Description]

CK-1530-A automatic feeding CNC wood lathe is an advanced woodworking machine that combines CNC technology and automation technology. The use of alloy tools dedicated to CNC machine tools to turn wood can effectively improve processing efficiency compared to traditional manual lathes. For ordinary wooden products with a diameter of less than 100mm, one-cut turning can be formed. It can be flexibly equipped with a variety of CNC tools. For different products, using matching CNC tools can be more efficiently processed. The machine uses a side-inclined automatic feeding structure, and completes the automatic loading and unloading of workpieces through pneumatic devices. The adjustment is simple. You only need to put the wood to be processed into the silo, and then simply adjust the center point. Click the start button to start automatic processing. Each moving axis of the machine is equipped with a safety induction limit system. When it senses illegal operation during processing, it can automatically alarm and stop. It is more suitable for small factories or production workshops that lack manual labor. One person can take care of multiple machines, and the entire processing process only requires continuous feeding of the machine. The sanding wheel device can be optionally installed, which can automatically sand and polish the product after processing, eliminating the trouble of secondary sanding. You can also add a high-speed air-cooled spindle to drill and slot the product, which is more convenient for manufacturing furniture legs and furniture accessories, saving time for secondary processing. Whether you are a small processing plant or a large-scale factory with batch production, you can use this 1530 automatic feeding CNC wood lathe to help your production..

Advantages and Features of 1530 CNC Woodworking Lathe with Automatic Feeding Device

Single-knife turning processing, equipped with large-size steady rest, single processing volume of more than 50mm, higher processing efficiency.

The pneumatic device is used for linkage operation, which realizes fully automatic feeding, simple adjustment, one-button start, and one person can manage multiple machines.

The main motor uses a 5.5KW high-torque high-speed motor, equipped with a high-torque inverter, and the speed can be adjusted arbitrarily from 0 to 6000 rpm.

Optional functional configurations such as sanding wheels and air-cooled spindles save the trouble of secondary sanding, drilling, and grooving.

Using the industrial display CNC system, the system's built-in macro program can automatically convert dxf files into G code, eliminating the trouble of using software to generate G code, and is more convenient to use.

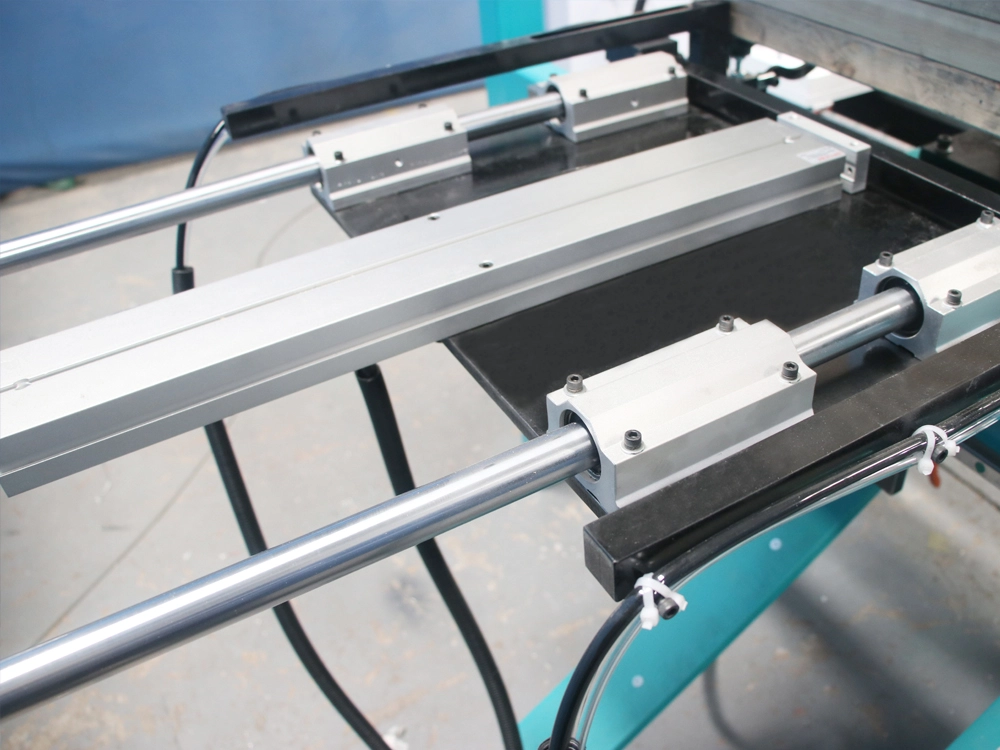

Taiwan HIWIN's guide rails, flange sliders, and TBI high-precision ball screws are used together to achieve higher precision and accurate positioning.

Large diameter steady rest, specially used for processing various slender products, such as drum sticks, crutches, canes, etc., effectively preventing wood from shaking.

High-power drive motor, large torque, fast feed speed, higher efficiency of processing products, better surface finish.

Single-Knife CNC Wood Lathe With Automatic Loading & Unloading Technical Parameters

| Model | CK-1530-A |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

| Transmission Mode | X axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

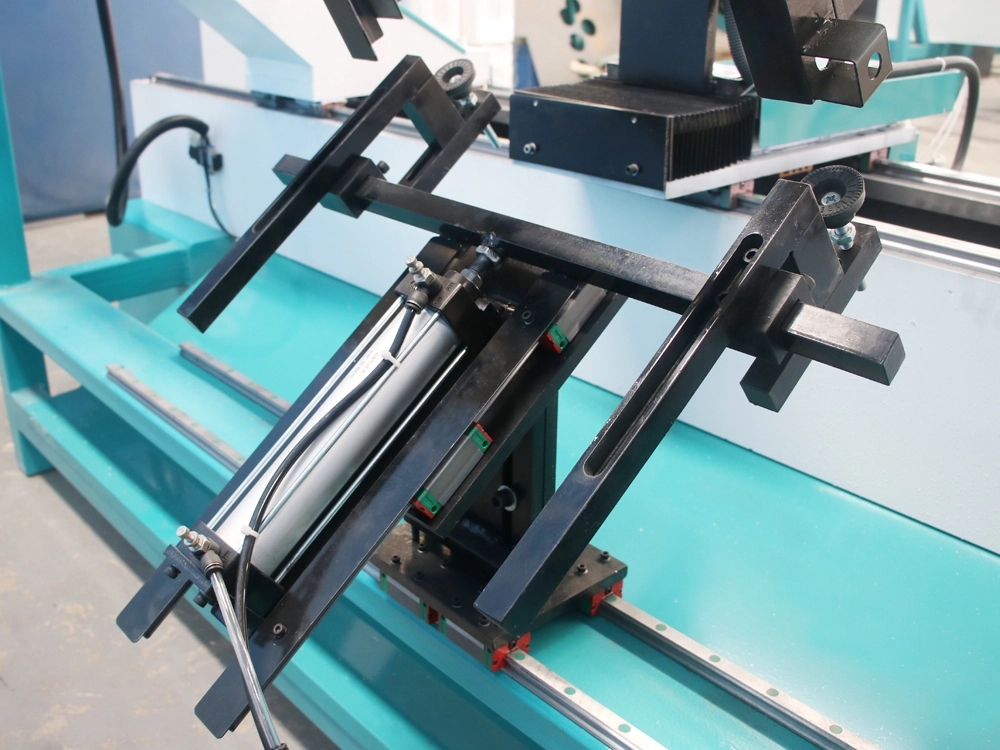

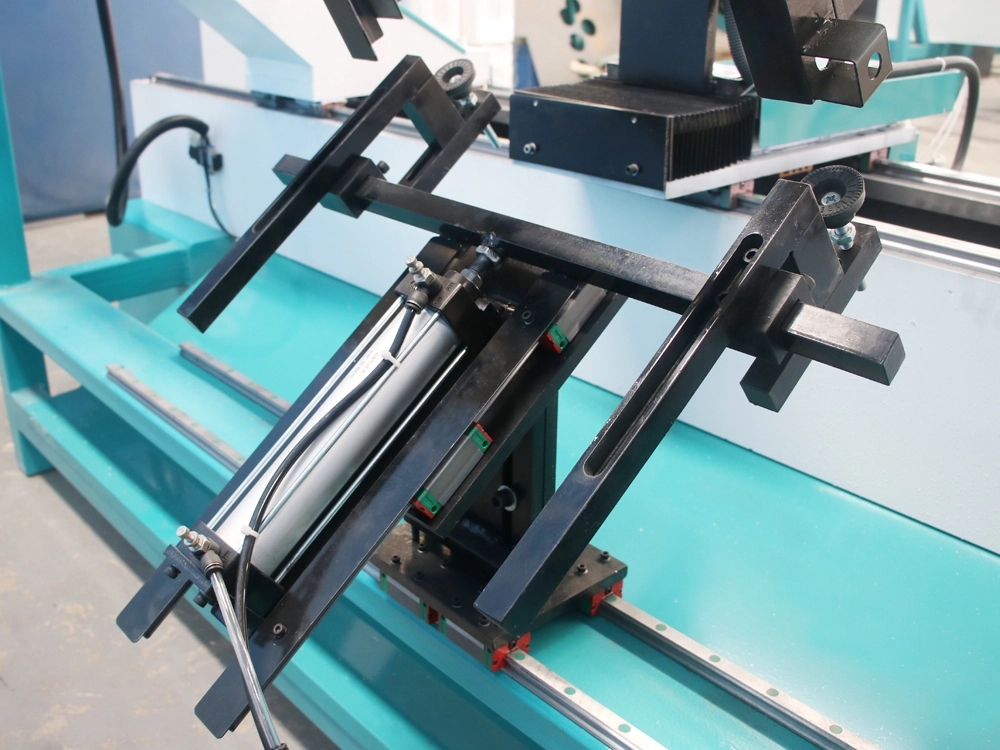

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instructions | Standard G code, u00,mmg,plt |

| Security System | XZ two-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1450*1650mm |

Detailed Introduction of CK-1530-A Model CNC Wood Lathe

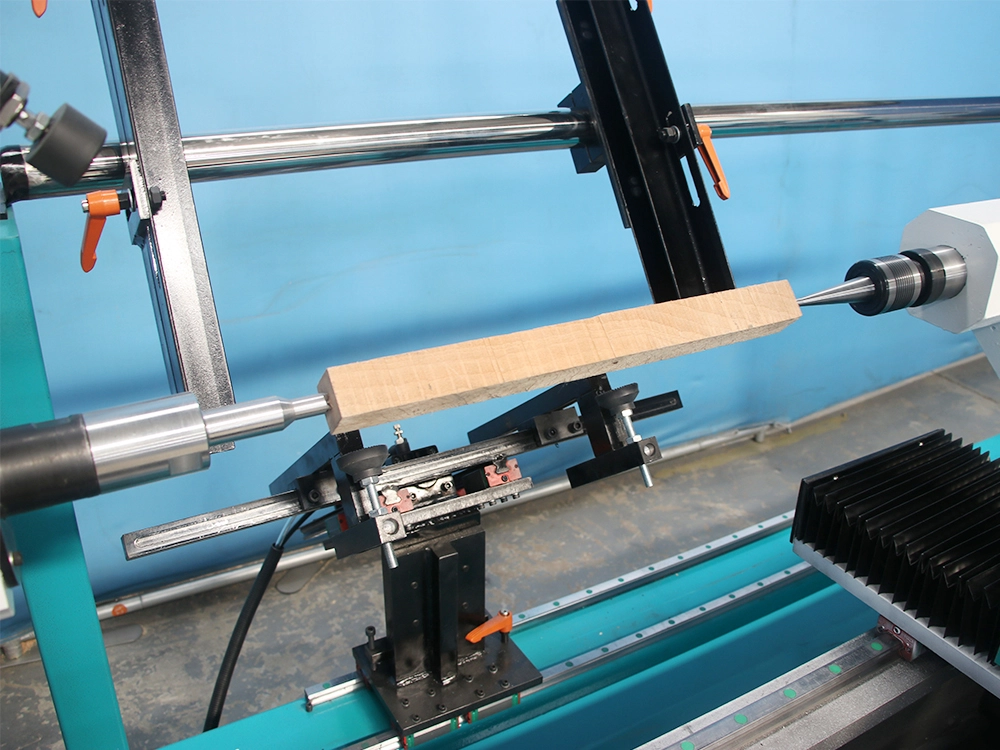

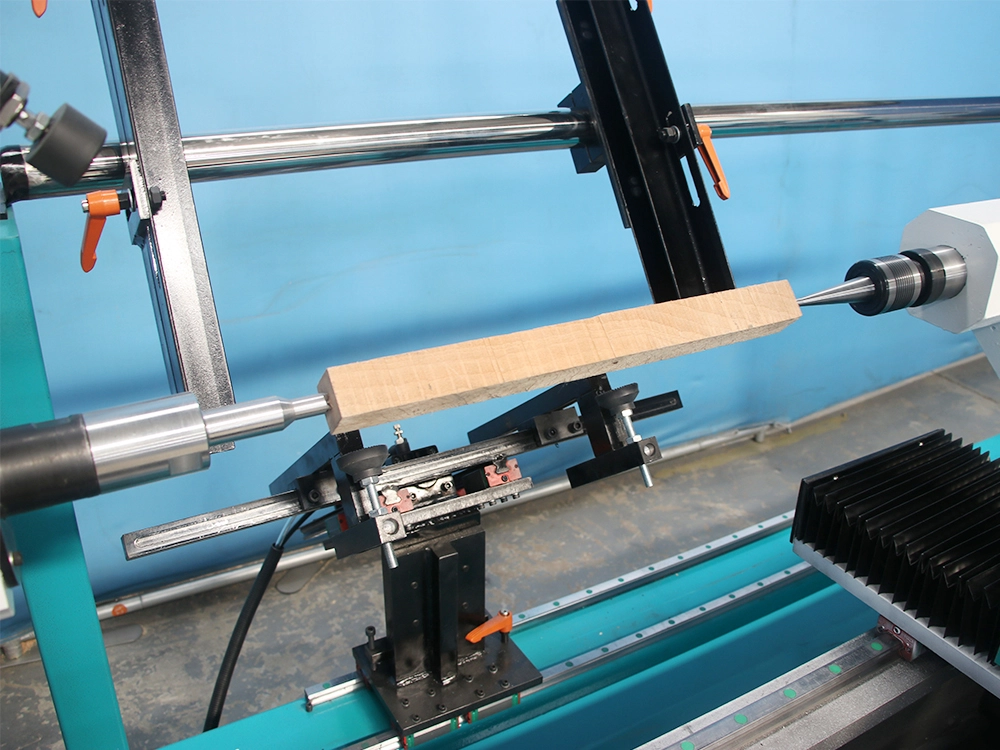

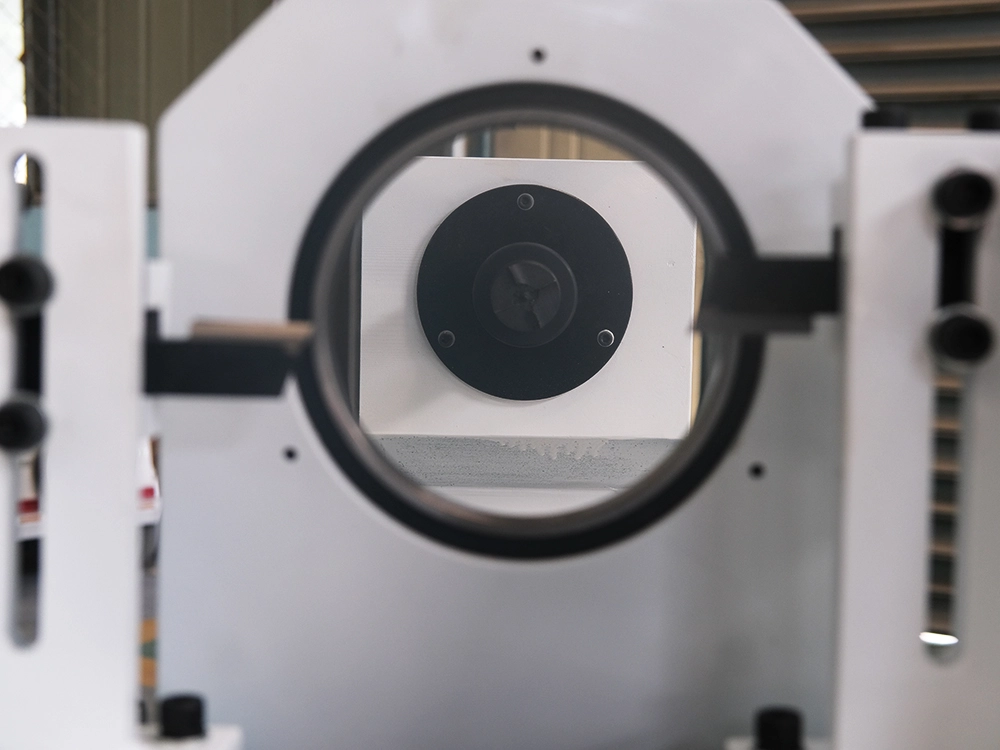

- Steady rest

The steady rest the wood from shaking due to high-speed rotation.

- Automatic feeding device

Pneumatic automatic feeding device, easy to use and adjust.

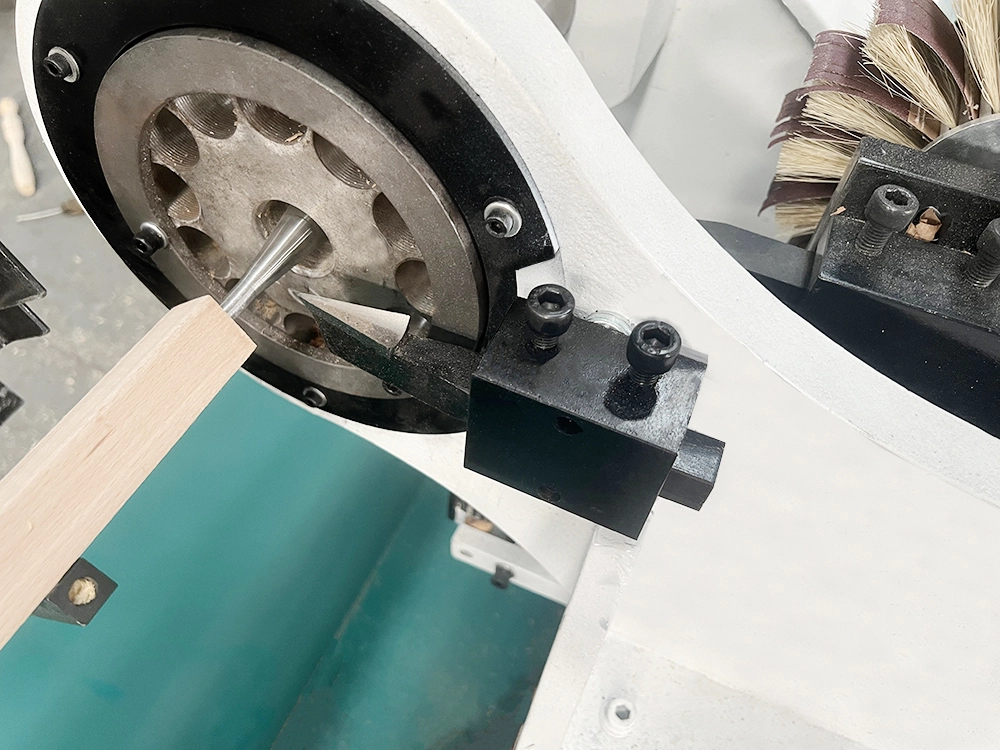

- Pre-turning tool

By adding a pre-turning tool to the outside of the center rest, non-standard sized blanks can be rough-machined to match the workpiece diameter with the center rest.

- CNC control system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

- Optional sanding device

Optional sanding device can complete turning and sanding in one step, saving time for subsequent processes.

What Can Be Processed by Industrial Automatic Feeding CNC Wood Lathe?

CK-1530-A model automatic feeding CNC wood lathe is widely used in various industries. The maximum processing length of the standard model machine is 1500mm, and the maximum processing diameter is 300mm (the processing size can be customized according to your needs). Products within this size can be processed arbitrarily. When processing larger products, the CNC system can be used for layered processing. Only by simply modifying the parameters and then reading the DXF drawings, the control system can automatically average the layers. By adjusting the parameters reasonably, the processing depth of each layer can be flexibly controlled to ensure that the machine is more stable and the processing effect is better. In addition, when processing products of different diameters, the speed and air pressure need to be matched and adjusted. Products with smaller diameters can use higher speeds and lower air pressures when processing, and products with larger diameters are suitable for lower speeds and higher air pressures. For different types of products, matching parameter adjustments are the key to ensuring the processing effect.

- Decoration industry: stair railings, Roman columns, stair columns, support columns, Roman column heads, etc.

- Furniture industry: table legs, chair legs, stool legs, bed legs, coat racks, sofa legs and other furniture accessories.

- Decorative crafts: vases, pen holders, wooden bowls, wooden basins, plates, jars, candlesticks, wooden boxes, etc.

- Other products: drumsticks, baseball bats, crutches, canes, billiard table legs, musical instrument parts, chess, building parts, etc.

- Before processing, it is necessary to confirm the speed and air pressure of the machine to prevent problems caused by mismatch of speed or air pressure.

- When processing products without reserved ends of wood, it is necessary to confirm that the diameter of the ejector pins at both ends is smaller than the diameter of the product to be processed to prevent tool collision during processing.

- When processing products, it is necessary to use a suitable feed speed to ensure the processing effect.

- Before processing, it is necessary to modify the parameters of the machine and set the appropriate number of layers and processing speed.

- After the machine processing is completed, the machine needs to be cleaned and lubricated in time.

- When using an automatic feeding device, the feeding device needs to be adjusted according to raw materials of different sizes.

The Following Are the Processable Products of Single-Knife Wood Lathe With Automatic Loading & Unloading

Precautions When Using Automatic Feeding CNC Woodworking Lathe?

| Model | CK-1530-A |

|---|---|

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

| Transmission Mode | X axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XZ two-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1450*1650mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.