Small CNC Wood Lathe For Low-Budget Craftsmen

Small CNC Wood Lathe Suitable for Personal Workshops and Hobbyists

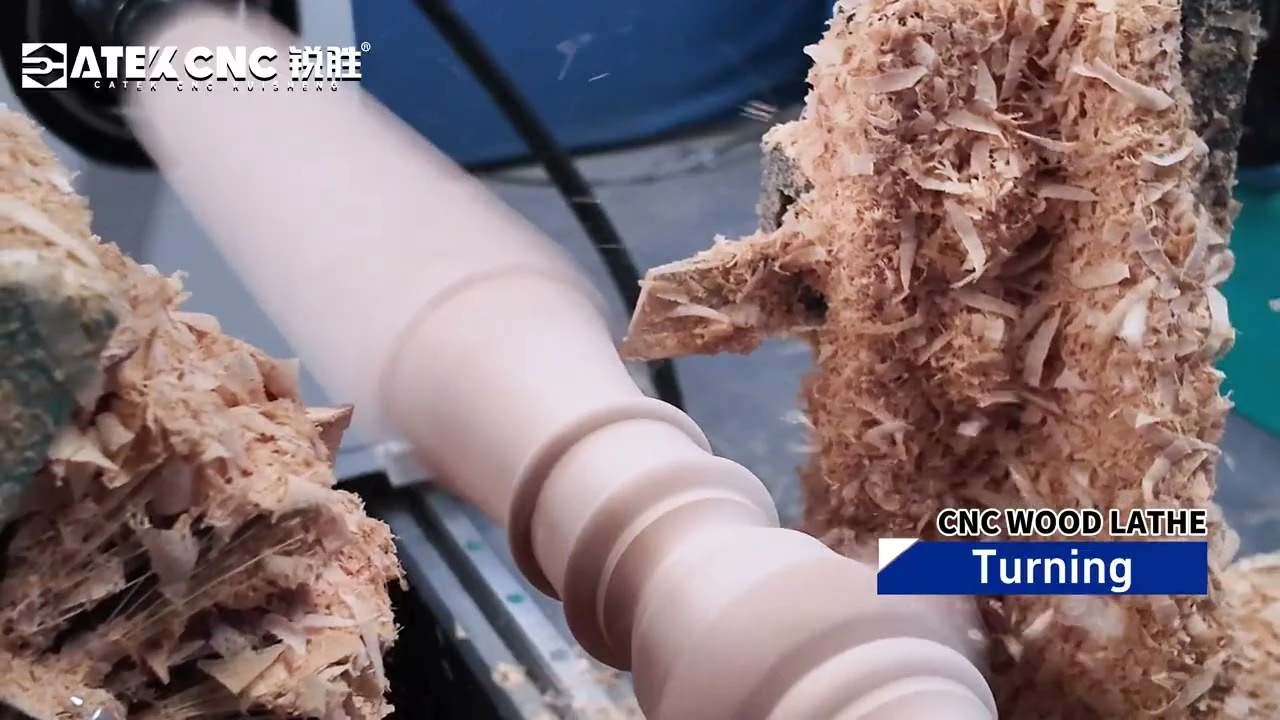

[Function Description]

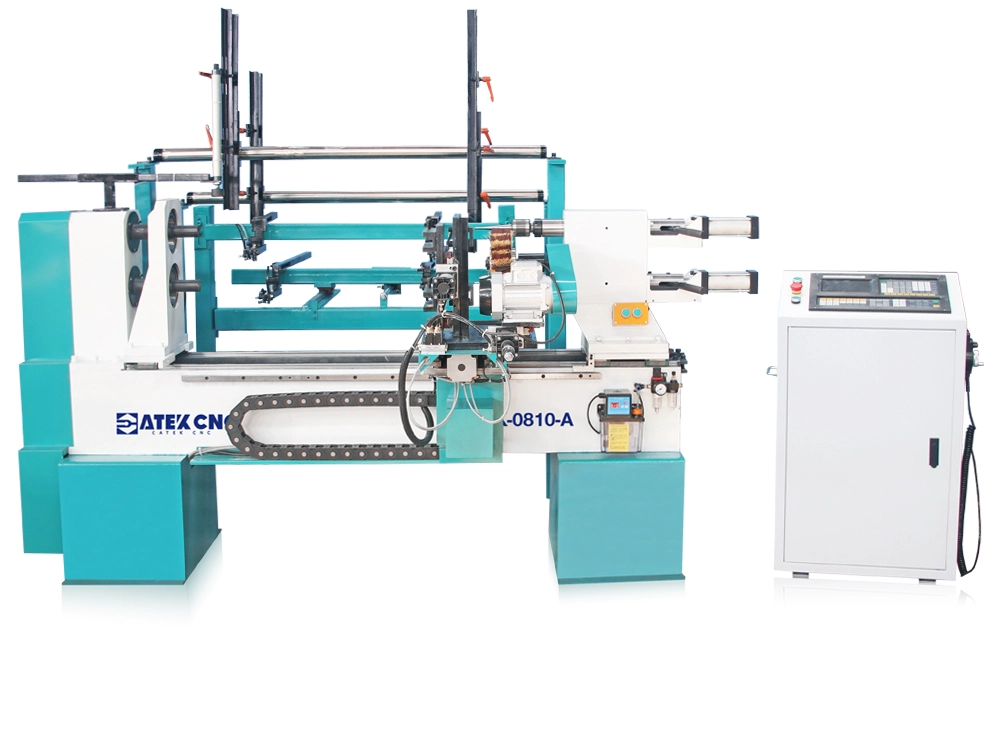

Overview of Small 0820 Double-Knife CNC Wood Lathe Suitable for Personal Workshops and Hobbyists

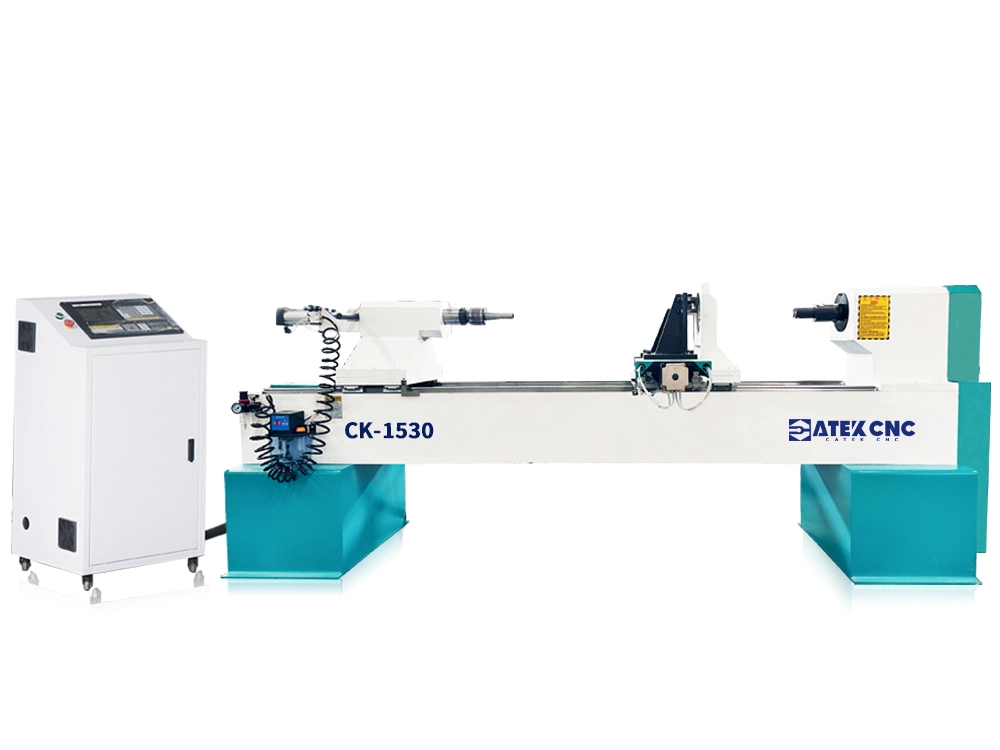

Small CNC woodworking lathe is a CNC machine designed and manufactured for small factories. It occupies a small area and is cheap. It can be bought for less than $4,000. The machine is easy to operate, with a maximum processing length of 800mm and a maximum processing diameter of 200mm. Compared with the ordinary 1530 model woodworking lathe, it only reduces the processing size, but it has the same performance as the ordinary 1530 model, using the same motor, control system and drive system, and the processing efficiency is the same as the ordinary 1530 model. We can even customize a two-spindle 0810 model mini CNC woodworking lathe for you, which can be used to process two identical products at a time, and the price is very similar to that of 0820. In addition, the small 0820 lathe can bring you a return far beyond its price. It can work continuously 24 hours a day, only one person is needed to clamp the workpiece, and it can be automatically processed by clicking the start button. It has changed the traditional woodworking handheld tool processing mode, got rid of the troubles of time-consuming and labor-intensive processing, and completed the processing in one step, improving the processing efficiency, and the processed products are completely consistent, with higher processing quality and more standard processing product size.

Advantages of Small Double-Knife Wood Lathe

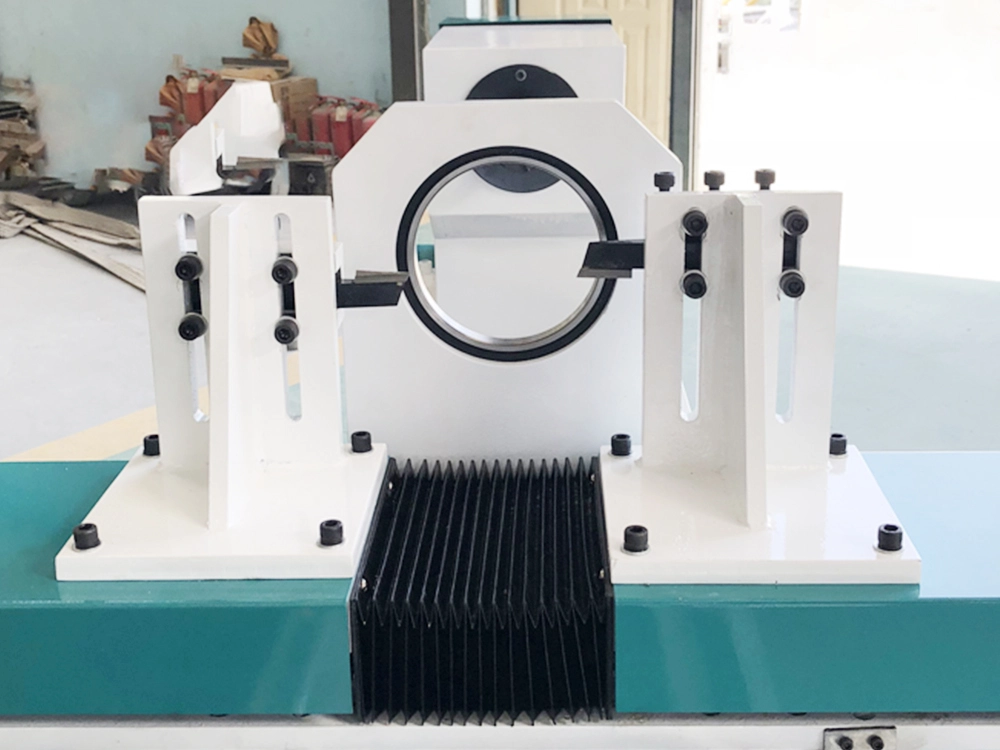

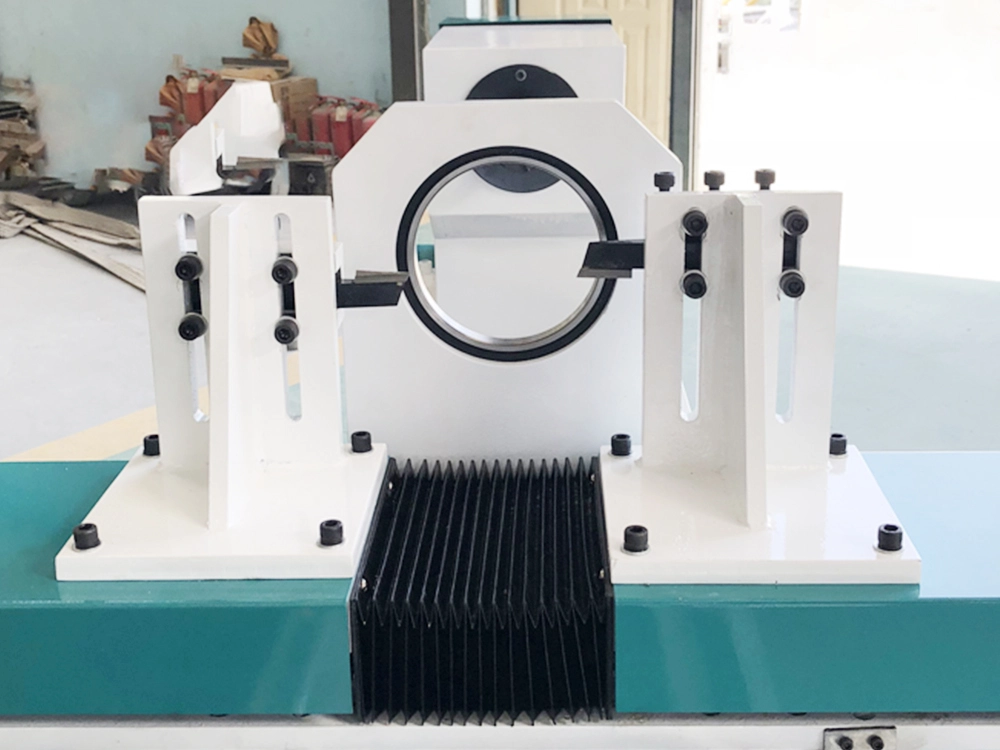

The single spindle and double knife design is more suitable for processing small products. It is also equipped with a follow-type steady rest, which is also easy to process slender products (optional double-station four-knife or sanding device).

The mini CNC wood lathe uses a gray cast iron bed. After five-sided gantry milling, the guide groove is processed in one go, effectively ensuring the processing accuracy of the machine.

The main motor uses a 4KW high-torque three-phase asynchronous motor, equipped with an independent frequency converter, and the speed can be adjusted at will within 6000 rpm, which is more convenient to use.

Use a dedicated CK1000TC control system to control the machine operation and processing, identify standard G codes, and be compatible with various CAD and CAM software.

Use Morse centers and four-claw chucks to fix the material for processing, stable processing and high efficiency.

The replaceable chuck, with the inner hole tool, can process wooden bowls, vases, plates, flower pots and other products.

HIWIN linear guides/linear bearings, TBI ball screws, stable operation and precise positioning.

Details of Mini CNC Wood Lathe

- Symmetrical double turning tools

The double-tool symmetrical design makes the turn more stable. The same tool can be equipped to achieve double cutting depth, or different tools can be equipped to achieve roughing and finishing.

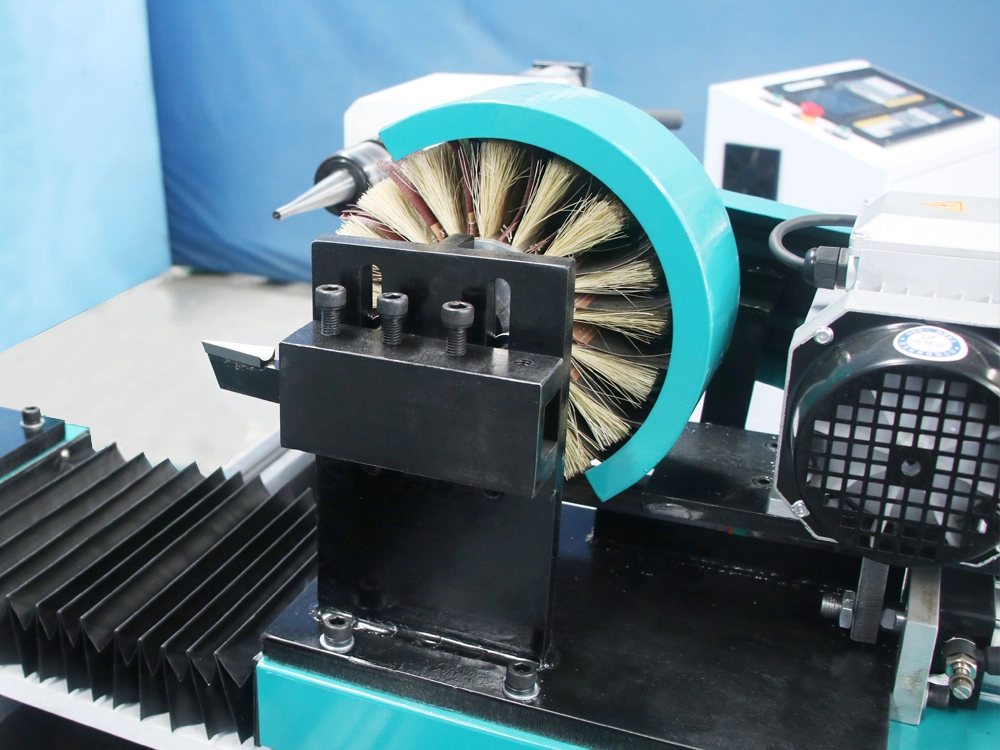

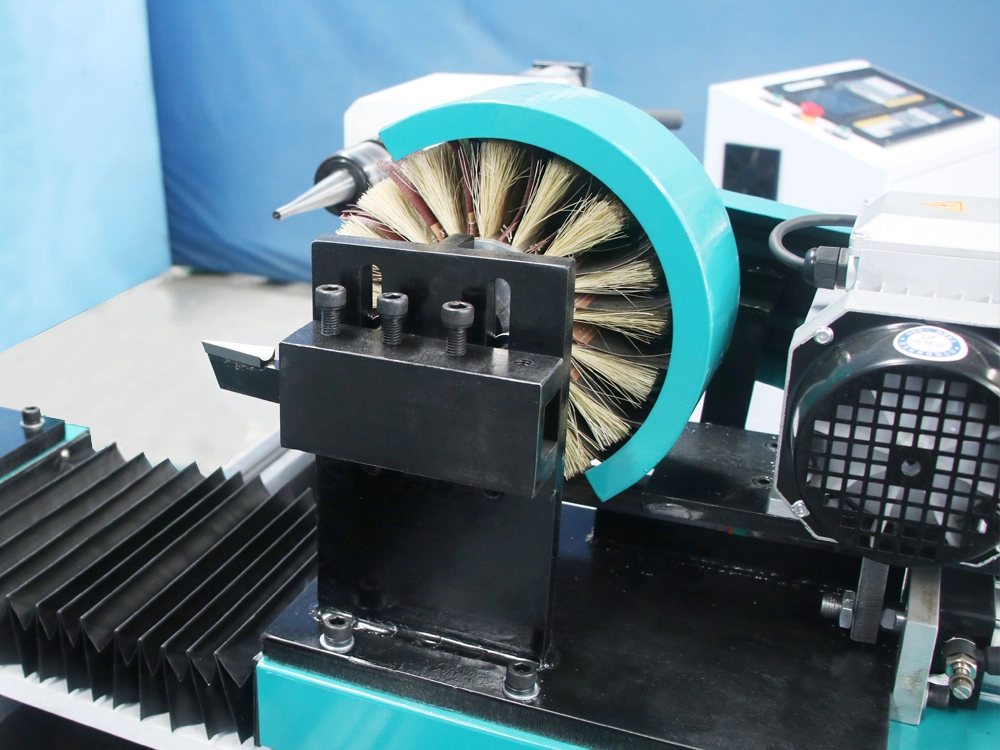

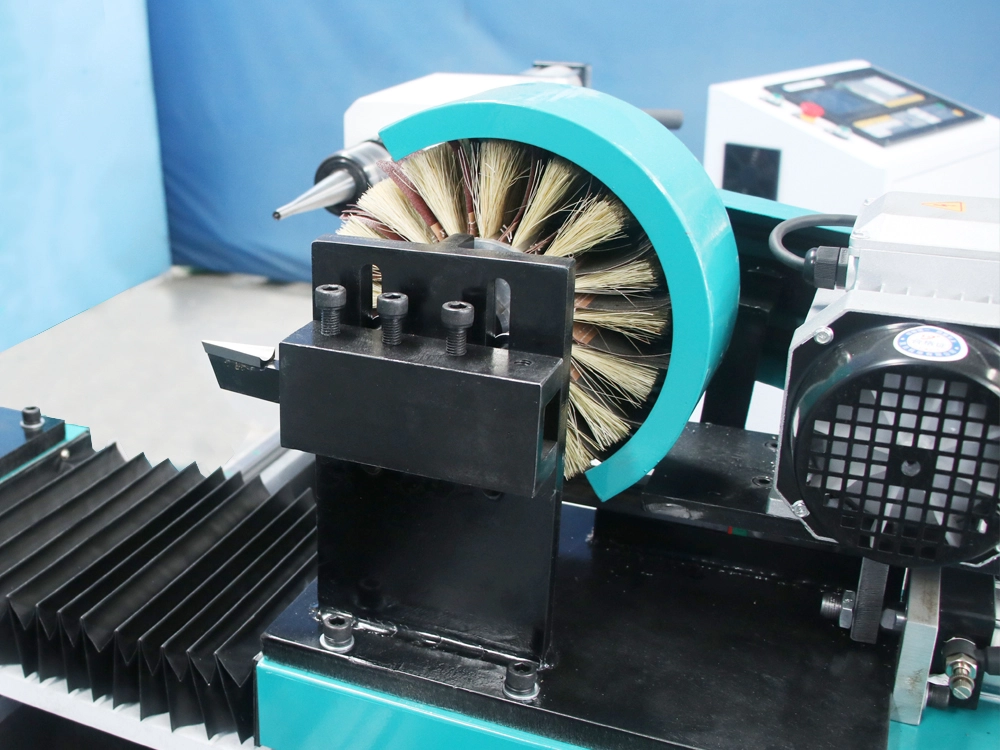

- Mini 0820 CNC wood wood lathe with sanding wheel

Sanding wheels are optional, and automatic sanding is performed after processing.

- Mini 0820 CNC wood lathe with electric tool holder

This part is optional. It can be installed with up to four tools and can be rotated for tool switching.

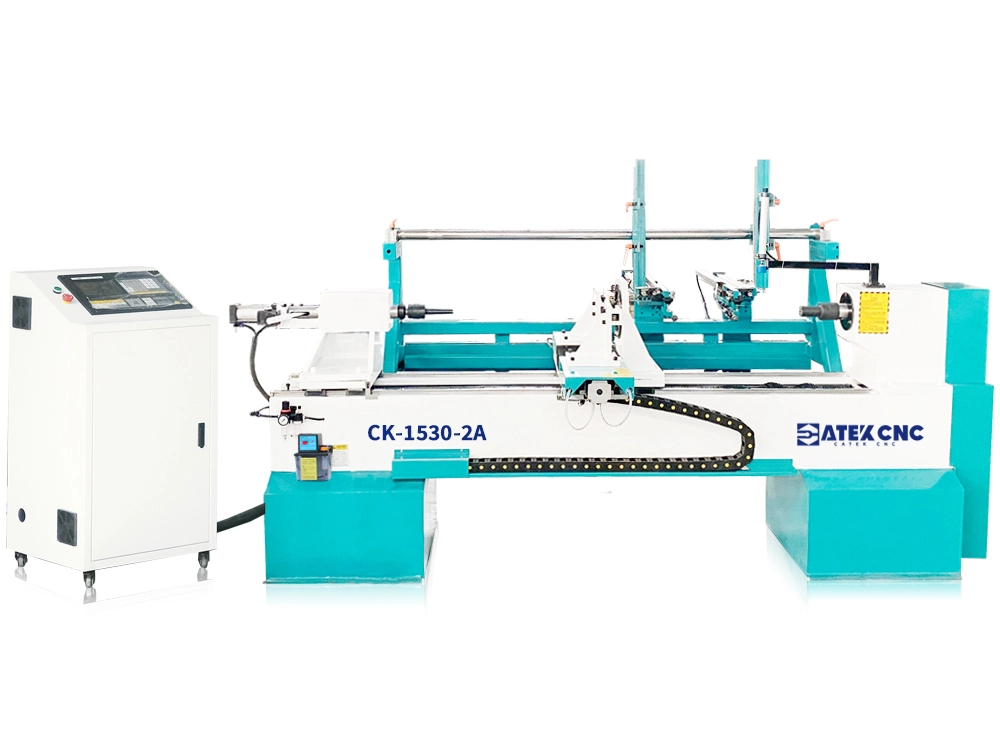

- Mini 0820 CNC wood lathe with two spindle and four tool

Equipped with two identical machining stations, each equipped with a set of one center and two turning tools, it is possible to machine two identical products simultaneously.

- Mini CNC wood wood lathe with loading and unloading

Equipped with automatic loading and unloading device, workers only need to add wood to the hopper, and the machine can automatically complete the loading, positioning, processing and unloading of the blanks.

Technical Parameters of Small Automatic CNC Wood Lathe

| Model | CK-0820 | CK-0810-2 |

| Processing Dimensions | 800 * 200mm (customizable according to processing requirements) | 800 * 100mm * 2 (customizable according to processing requirements) |

| Bed | Heavy-duty integral casting bed, independent control cabinet | |

| Motor | 4KW three-phase asynchronous motor | |

| Motor Speed | 0-6000rpm | |

| Driving Mode | CATEKCNC dedicated high-torque servo motor | |

| Frequency Converter | BEST/Hpmont inverter | |

| Transmission Mode | XY axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw | |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider | |

| Equipment Cable | Pure copper high-flexible bending-resistant cable | |

| Control System | CATEKCNC dedicated control system panel, CK1000TC | |

| Lubrication System | Electric oil injection maintenance system | |

| Operating Voltage | AC380V/220V 50/60Hz | |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. | |

| Engraving Instruction | Standard G code, u00,mmg,plt | |

| Security System | XYZ three-axis all photoelectric limit | |

| Repeat Positioning Accuracy | ±0.02mm | |

| Weight | 1100kg | 1200kg |

| Dimensions | 2300*1200*1300mm | 2300*1300*1400mm |

Application Scope of Small Wood Lathe

Applicable Materials:

Wood, plastic, acrylic, nylon, PVC, carbon fiber, artificial wood substitutes, etc.

Applicable Industries:

Furniture: table legs, chair legs, sofa legs, bed legs, pool table legs, stair railings, Roman columns, etc.

Musical instruments: piano legs, flutes, suona, bassoons, drumsticks, etc.

Sports: baseball bats, wooden balls, chess, etc.

Other products: wooden handles, wooden bowls, vases, plates, cups, etc.

The Following Are the Processable Products of Small Wood Lathe

Things to Note When Using CNC Wood Turning Machines

The small CNC wood lathe is very easy to use. After receiving the machine, you only need to connect the machine to the power supply according to the instructions. After the power supply is completed, you need to test the function of each axis separately. After all the preparations are completed, use the drawing software to draw the processing drawings, copy them to the machine through the USB flash drive, and then use the machine to calibrate the tool. After the tool adjustment is completed, the machine can start normal processing. After the daily processing is completed, the machine needs to be cleaned and maintained.

If you encounter problems during use or encounter difficulties in operation, you can contact CATEKCNC's after-sales engineers at any time. The engineers will provide you with services through online chat, video calls, emails, etc.

About Us

CATEKCNC is a professional CNC machinery manufacturing source factory with 18 years of experience. We focus on the production of CNC woodworking lathes, CNC engraving machines, fiber cutting machines, CO2 laser engraving machines and other types of CNC machinery. We have a professional sales and after-sales team to provide you with machine-related services 24 hours a day. No matter what problems you encounter, you can contact us at any time. You can leave your contact information by clicking here.

| Model | CK-0820 | CK-0810-2 |

|---|---|---|

| Processing Dimensions | 800 * 200mm (customizable according to processing requirements) | 800 * 100mm * 2 (customizable according to processing requirements) |

| Bed | Heavy-duty integral casting bed, independent control cabinet | |

| Motor | 4KW three-phase asynchronous motor | |

| Motor Speed | 0-6000rpm | |

| Driving Mode | CATEKCNC dedicated high-torque servo motor | |

| Frequency Converter | BEST/Hpmont inverter | |

| Transmission Mode | XY axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw | |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider | |

| Equipment Cable | Pure copper high-flexible bending-resistant cable | |

| Control System | CATEKCNC dedicated control system panel, CK1000TC | |

| Lubrication System | Electric oil injection maintenance system | |

| Operating Voltage | AC380V/220V 50/60Hz | |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. | |

| Engraving Instruction | Standard G code, u00, mmg, plt | |

| Security System | XYZ three-axis all photoelectric limit | |

| Repeat Positioning Accuracy | ±0.02mm | |

| Weight | 1100kg | 1200kg |

| Dimensions | 2300*1200*1300mm | 2300*1300*1400mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.