Baseball Bat Making Machine for Factory

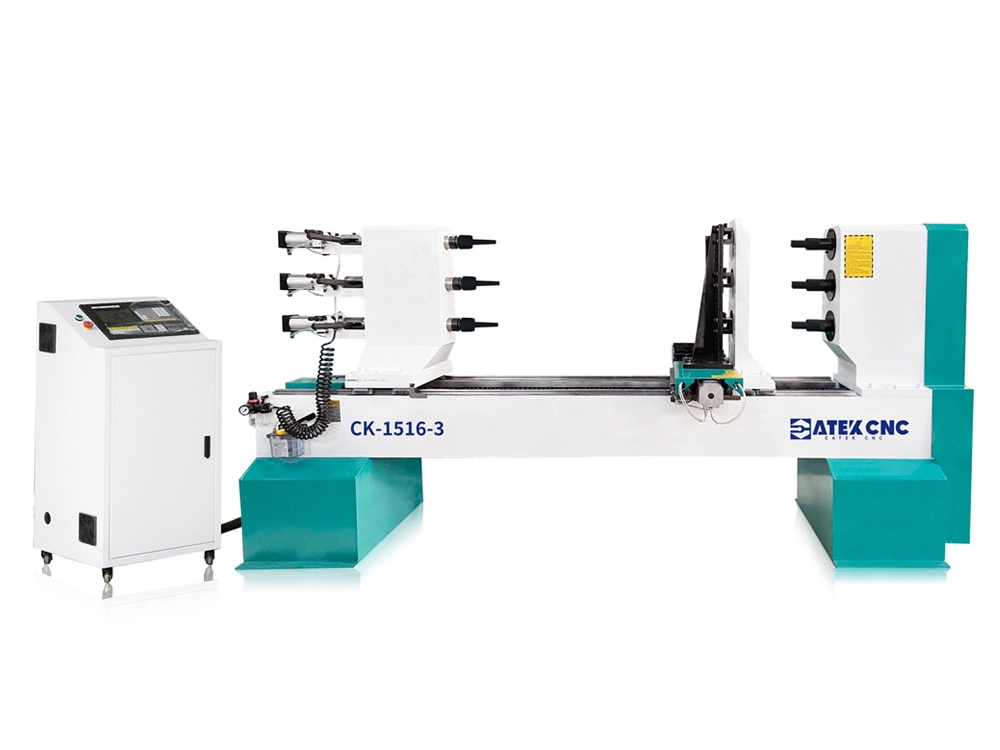

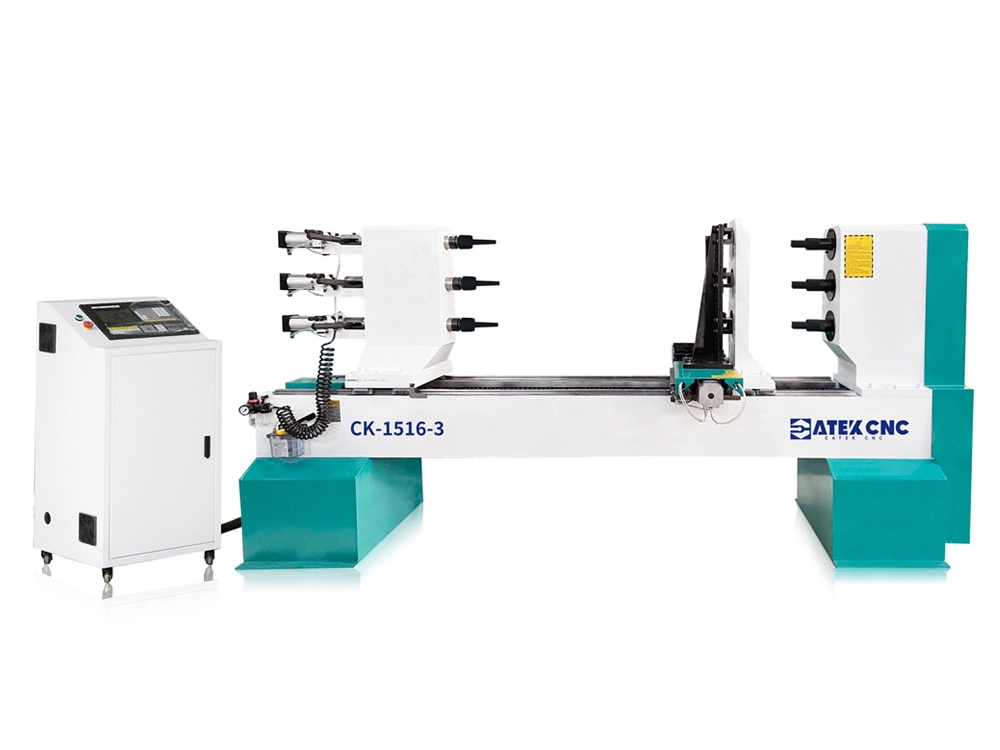

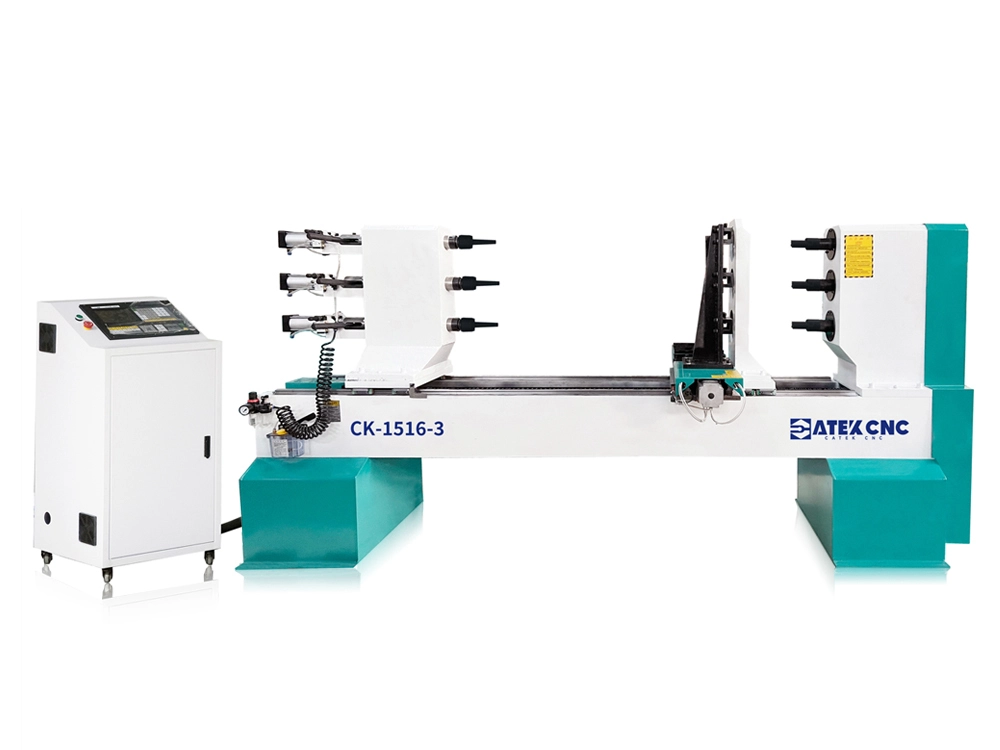

3-Station Baseball Bat CNC Making Machine for Factory Batch Production

[Function Description]

Overview of New High-efficiency 3-station CNC Wood Lathe

The new 1516-3 CNC woodworking lathe is designed for factories with mass production. This lathe is equipped with three identical processing stations, which significantly improves production efficiency. It only takes the same amount of time as before to produce three identical products, with a daily output of more than 800 pieces, which can replace 3-4 manual labors, saving more costs for the factory while greatly increasing production. Compared with the old 1512-3 CNC woodworking lathe, its processing diameter has been fully upgraded from 120mm to 160mm, which enables it to process 3 products with a diameter of 160mm and a length of 1500mm at a time, and the processed products are more standardized, with high surface finish and excellent consistency. And the lathe upgrades the 5.5KW motor to a 7.5kw three-phase asynchronous high-torque motor, which has greater torque, larger turning volume, and further improves processing efficiency. In addition, a sanding device can be optionally installed to sand and polish the product surface after the product processing is completed, reducing subsequent manual processing work.

Advantages of 3-Spindle 6-Knife CNC Wood Lathe Machine Suitable for Factory

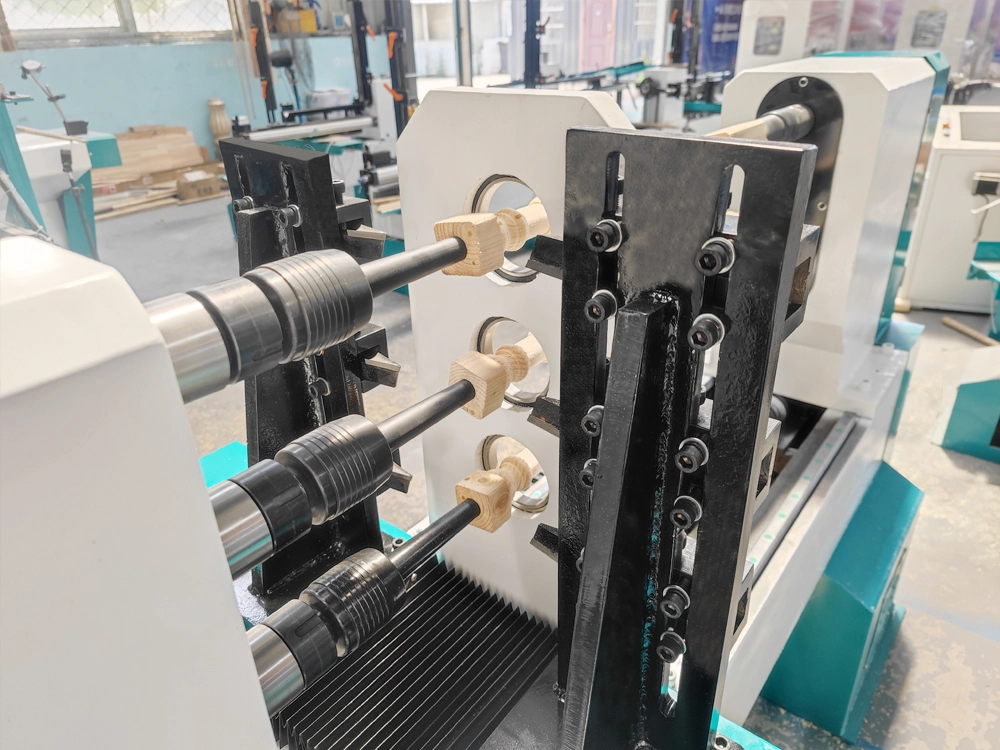

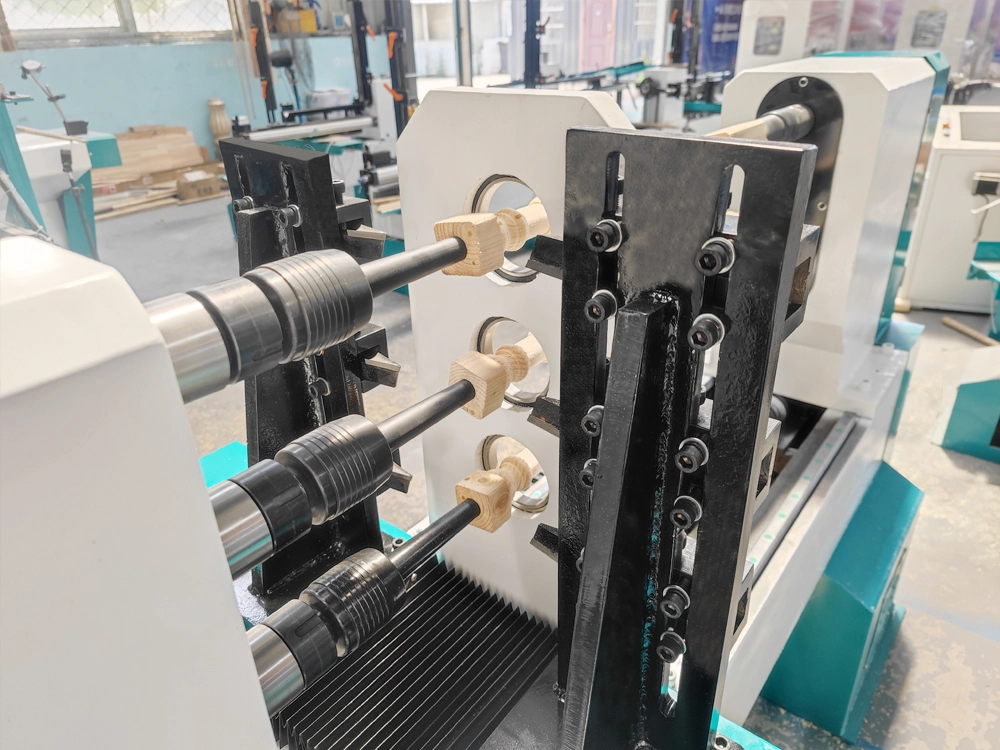

- Three axes and six knives, processing three raw materials at the same time, with higher efficiency, saving labor and electricity.

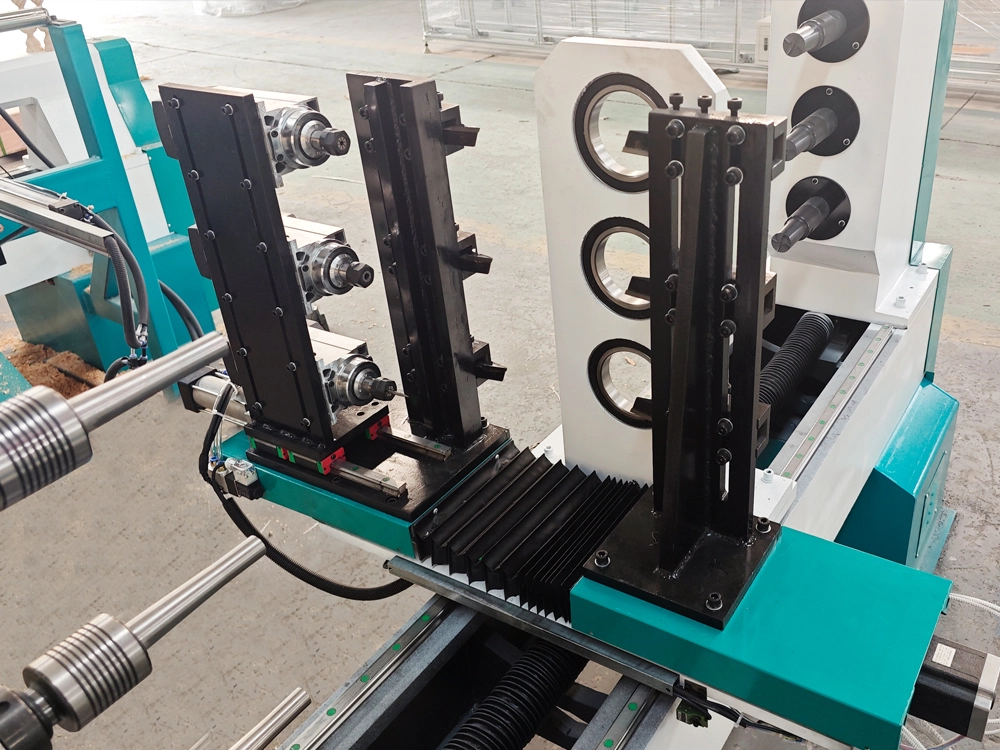

- Three independent large-diameter center sheaths and tool holders, equipped with three bearings, can be used for processing slender products to prevent wood from shaking during processing.

- The main motor uses a 7.5KW high-torque high-speed motor with a maximum speed of 6000r/m. The inverter can adjust the matching speed for different products to make the product smoother.

- The whole machine uses a heavy gray cast iron casting bed, thickened spindle box/rear tailstock, and stress relief treatment, which is more stable and non-deformed.

- Use high-flexibility and anti-bending pure copper cable, which can be used for a long time. Frequent bending will not damage the wire skin and cause leakage, and it is more assured to use.

- The TBI ball screw with a diameter of 32MM has stable transmission, repeated positioning accuracy of up to 0.01mm, and high processing accuracy.

- The three axes of XYZ are driven by CATEKCNC dedicated high-torque motors, with strong turning force and high efficiency.

- The three processing stations are equipped with independent cylinders, which can be used at the same time or only one of them can be used for processing, which is highly flexible.

Details of a Wood CNC Lathe That Can Process Three Blanks At a Time

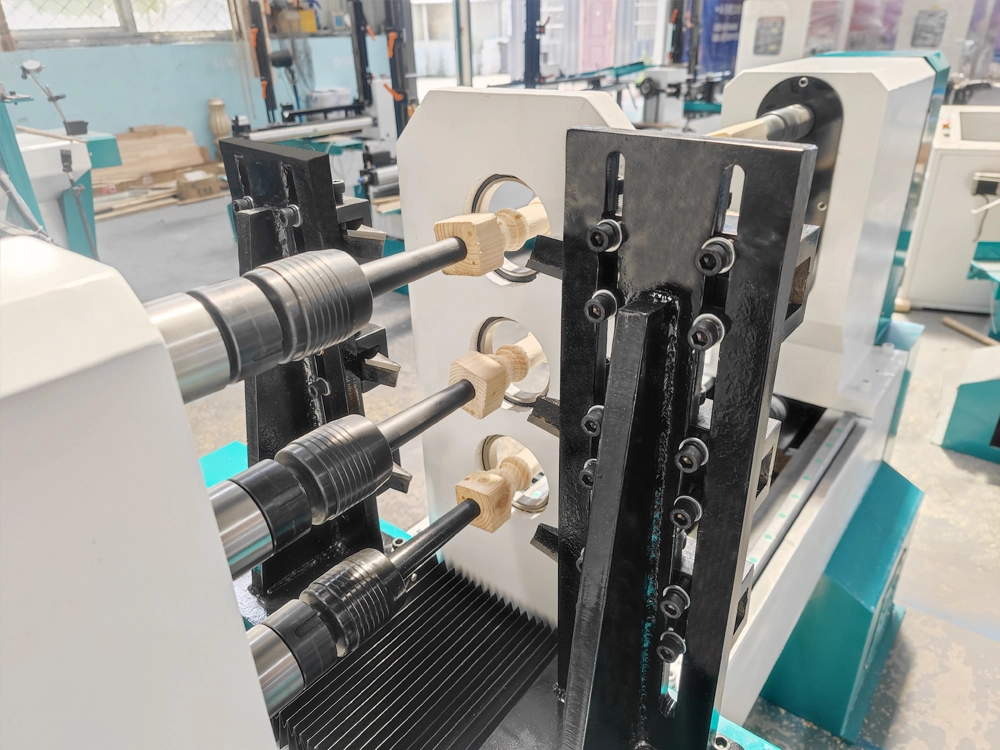

- Three stations and six tools

Equipped with six V-shaped tools for turning, three blanks can be processed at one time.

- Increased diameter steady rest

Specially designed for processing slender workpieces, it moves with the turning tool during processing to prevent tool marks caused by wood shaking.

- BEST inverter

7.5KW pure copper three-phase asynchronous motor, combined with BEST high-torque inverter, has high output torque and strong force.

- Three-station CNC woodworking lathe with spindle

By adding three multi-function spindles to the machine, the machine becomes a CK-1516-3S model, which can perform tasks such as engraving and slot milling.

Technical Parameters of The New 3-Station 6-Tool CNC Wood Lathe

| Model | CK-1516-3 |

| Processing Dimensions | 1500mm length * 160mm diameter * 3 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 7.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont high torque inverter |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*1400*1650mm |

What Products Can Be Processed by the 3-station Wood CNC Lathe Suitable for Factory?

- Various revolving wooden products: can process revolving wooden products with complex shapes such as cylindrical, conical, arc, spherical, etc., such as stair columns, table legs, chair legs, vases, wooden bowls, Buddhist beads, handles, rolling pins, etc.

- Crafts and decorations: vases, candlesticks, pen holders, wooden bowls, wooden plates, cups, canes, etc.

- Musical instrument parts: drumsticks, woodwind instruments, flute parts, piano legs, piano stool legs, etc.

- Other products: crutches, wooden handles, handles, grips, billiard table legs, baseball bats, axe handles, chess, small wooden products, etc.

The Following Are the Processable Products of Three-Axis Six-Knife CNC Wood Lathe

| Model | CK-1516-3 |

|---|---|

| Processing Dimensions | 1500mm length * 160mm diameter * 3 (the maximum diameter of a single piece is 300mm, the processing size can be customized) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 7.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont high torque inverter |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*1400*1500mm |

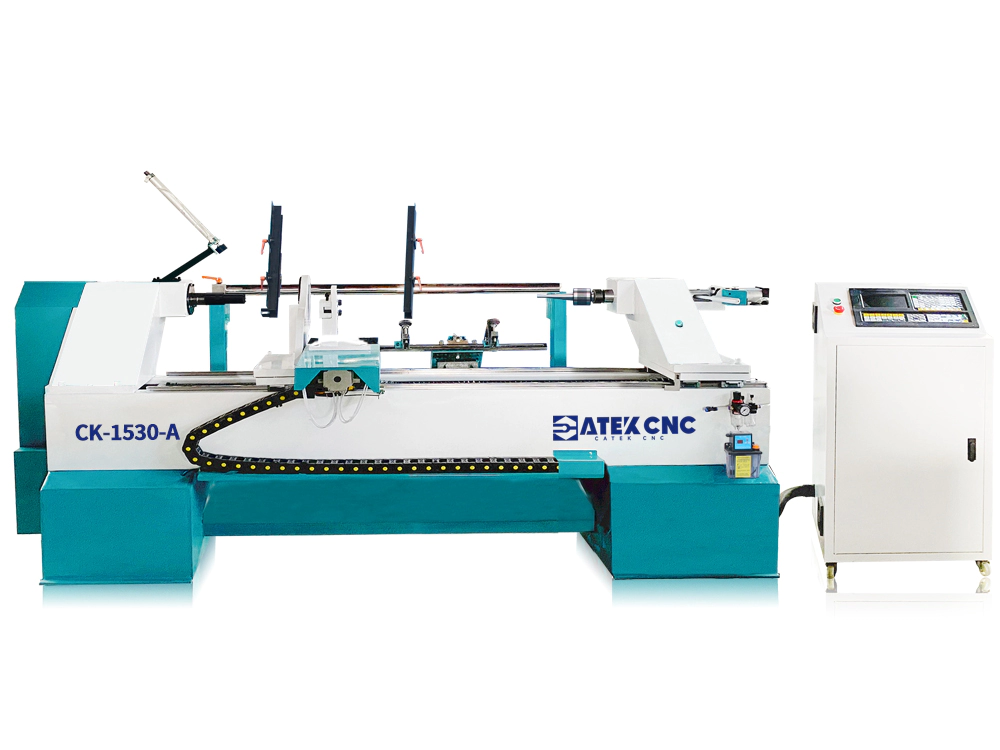

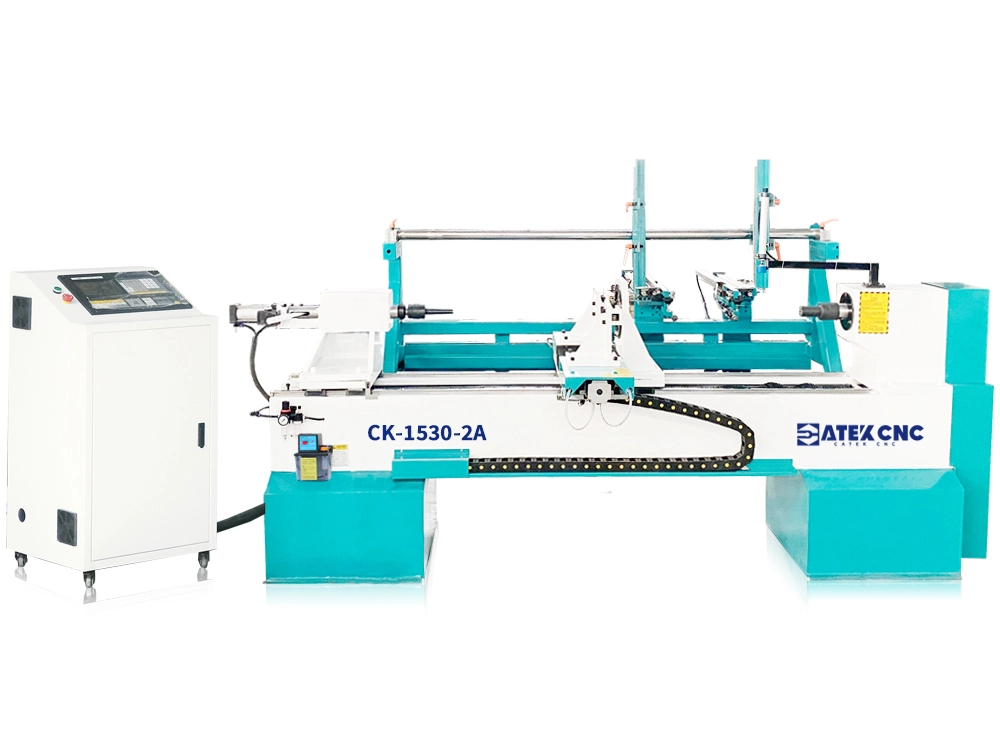

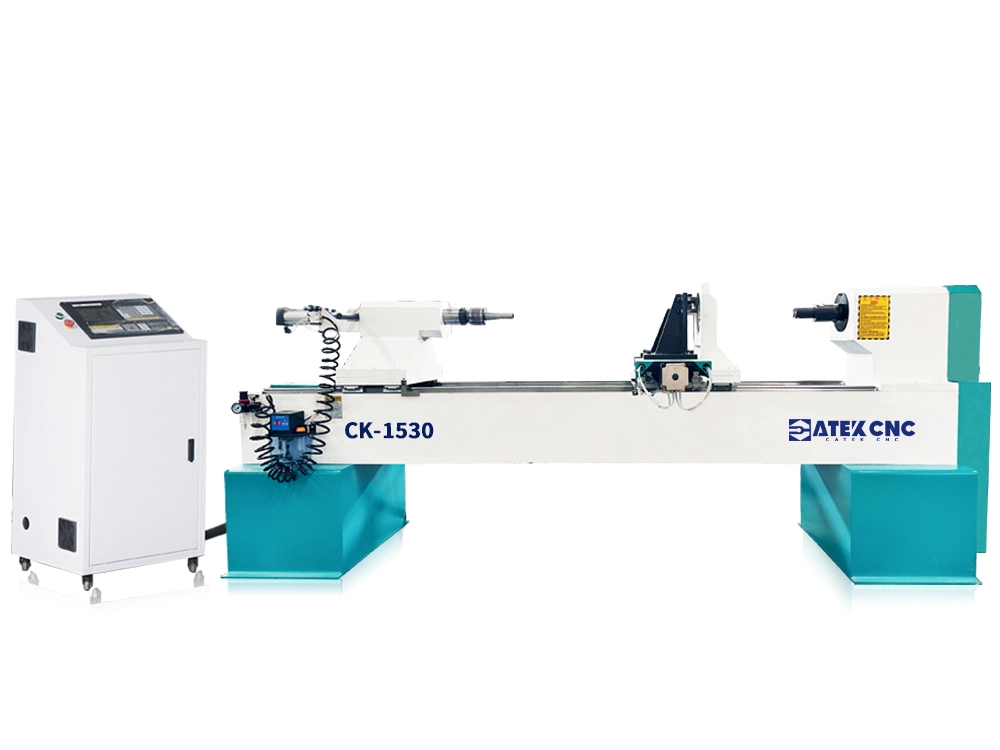

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.