CNC Woodworking Lathe for Wood Turning Sale at Cost Price

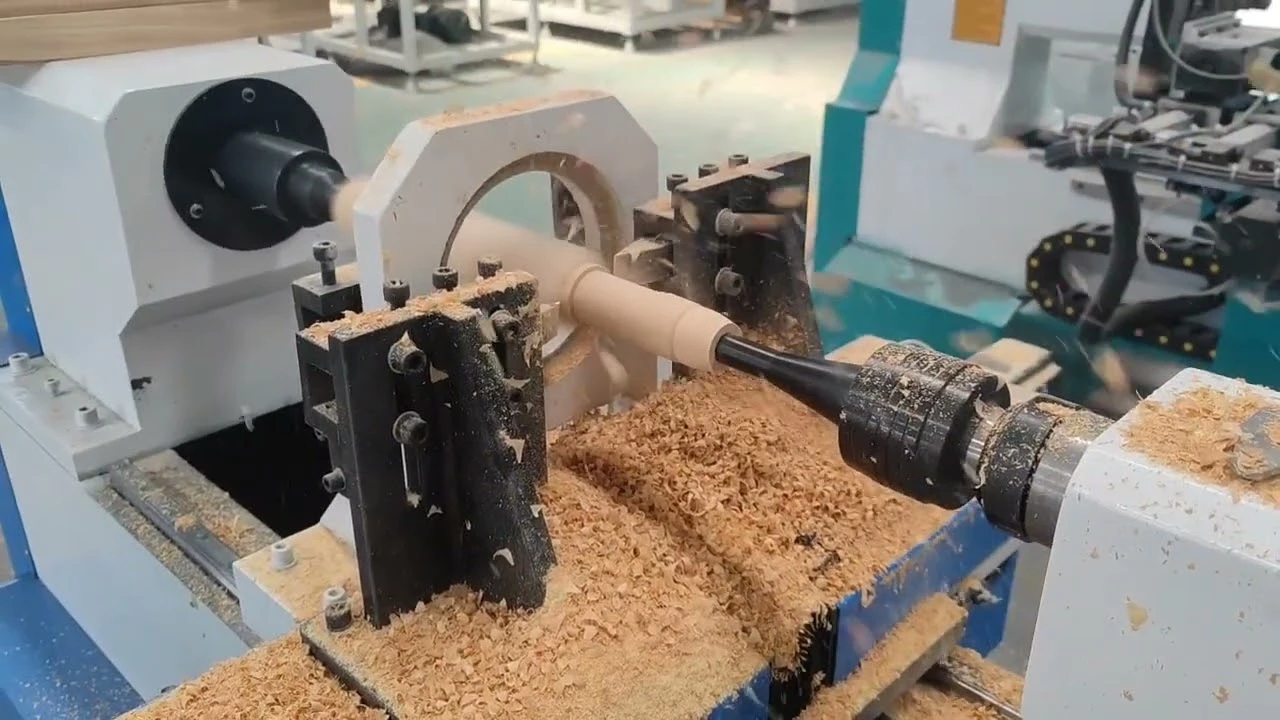

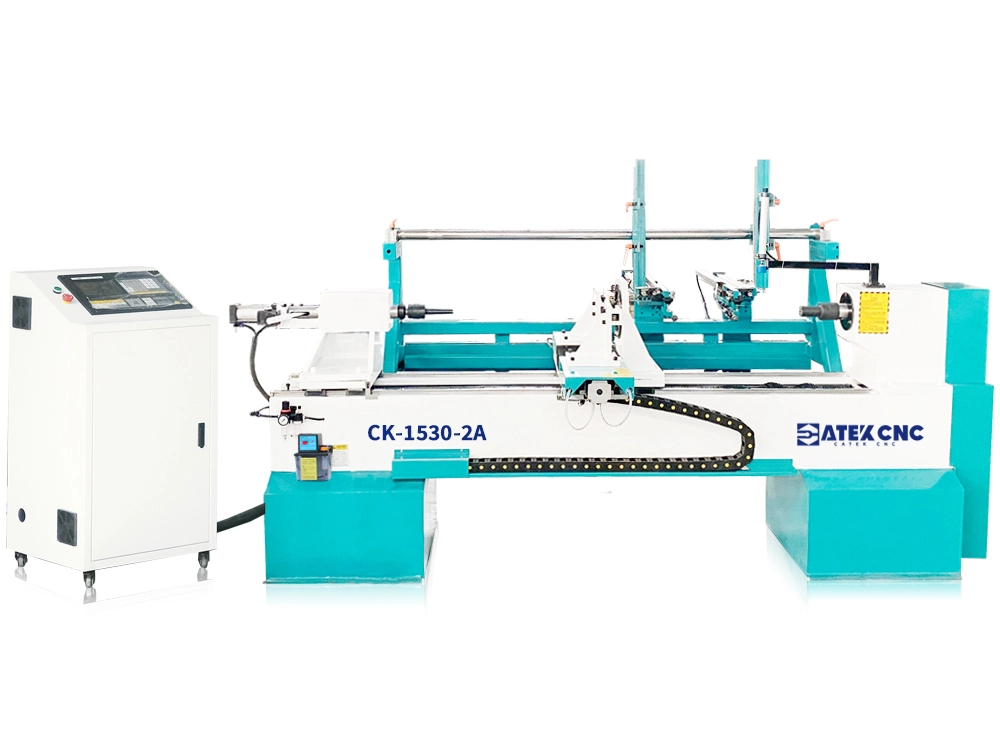

Cheap Basic Double-Knife CNC Lathe for Wood Turning

[Function Description]

What Is the Difference between CNC Wood Lathe and a Traditional Manual Wood Lathe?

- Processing efficiency: CNC woodworking lathes are controlled by a CNC system, using computer drawing, and fully automated processing. No human intervention or tool change is required during the processing process. The processing efficiency is more than 5 times that of traditional manual woodworking lathes. Manual woodworking lathes require manual control throughout the process, which is extremely inefficient. They can only process one workpiece at a time, and tools need to be changed frequently throughout the process.

- Processing accuracy: CNC wood lathes control tool trajectories through the control system to avoid human errors. They process one-to-one according to the processing drawings, with high processing accuracy, good repeatability, and high surface finish. Traditional manual lathes are greatly affected by the operator's skill proficiency, with low processing accuracy. Each product has errors, and it is easy to make mistakes, wasting raw materials.

- Operating method: CNC wood lathes are easy to operate. Ordinary workers can start operating after simple training without professional foundation. Only the raw materials need to be placed manually, and the start button needs to be clicked, and the machine automatically completes the processing. Traditional manual lathes require operators to have a high level of skills, and they need to manually adjust the tool position and replace different tools, which is labor-intensive and prone to mistakes.

- Safety in use: CNC woodworking lathes have a high degree of automation, which reduces the chances of operators directly contacting mechanical equipment and processed parts, and are safer. Manual lathes require continuous contact with mechanical parts and processed parts during operation, which poses a great safety hazard.

- Application scope: CNC woodworking lathes are suitable for various complex parts, high-precision parts and mass production processing tasks. They are highly flexible and can quickly change processing programs to meet the processing needs of different parts. Traditional manual lathes are only suitable for processing parts with simple shapes, such as round or symmetrical workpieces, and are not suitable for mass production and high-precision parts processing.

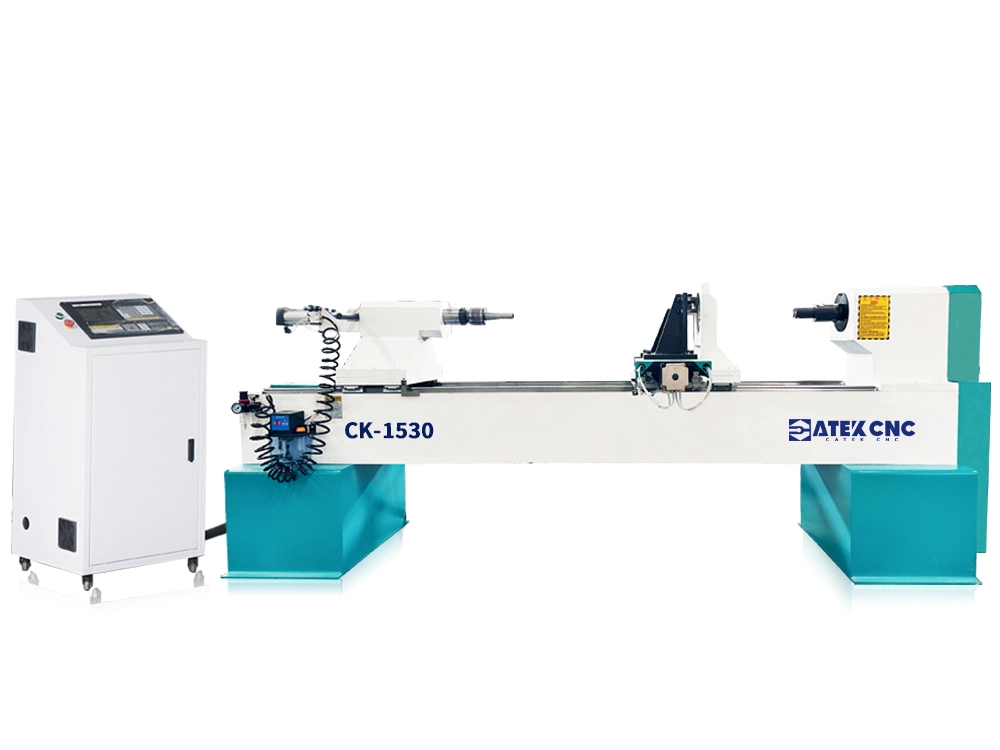

Features and Advantages of 1530 Double-Knife CNC Wood Lathe

- Double-knife wood turning leads to double efficiency and high-speed feed. The tools are all controlled by independent drive motors, and the precision can be controlled within ±0.01mm.

- The key structures of the machine, such as the bed, tailstock, and headstock, are all fabricated by gray cast iron casting. They undergo five-sided gantry milling processing. The bearing hole positions are machined using imported German boring machines, and the platforms for guide rail installation are all completed through one-time milling to ensure the bed remains distortion-free during long-term usage.

- The main motor employs a 5.5KW high-power three-phase asynchronous motor. It is controlled by a frequency converter for protecting high-torque motors. The rotational speed can be adjusted freely and can be adjusted to match the processing requirements of different raw materials.

- The CATEKCNC dedicated control system is equipped with an industrial liquid crystal display and a pulse handwheel. It features simple operation and more convenient tool setting.

- All the XYZ axes utilize TBI ball screw drives, which offer high transmission accuracy and a long service life.

- Taiwan HIWIN guide rails and flange-type sliders provide high running accuracy, durability, and a repeat positioning accuracy of up to 0.01mm.

- The use of an external pulse handwheel to connect the control system makes it more convenient to control the movement of the XYZ axes and more intuitive to calibrate the tools.

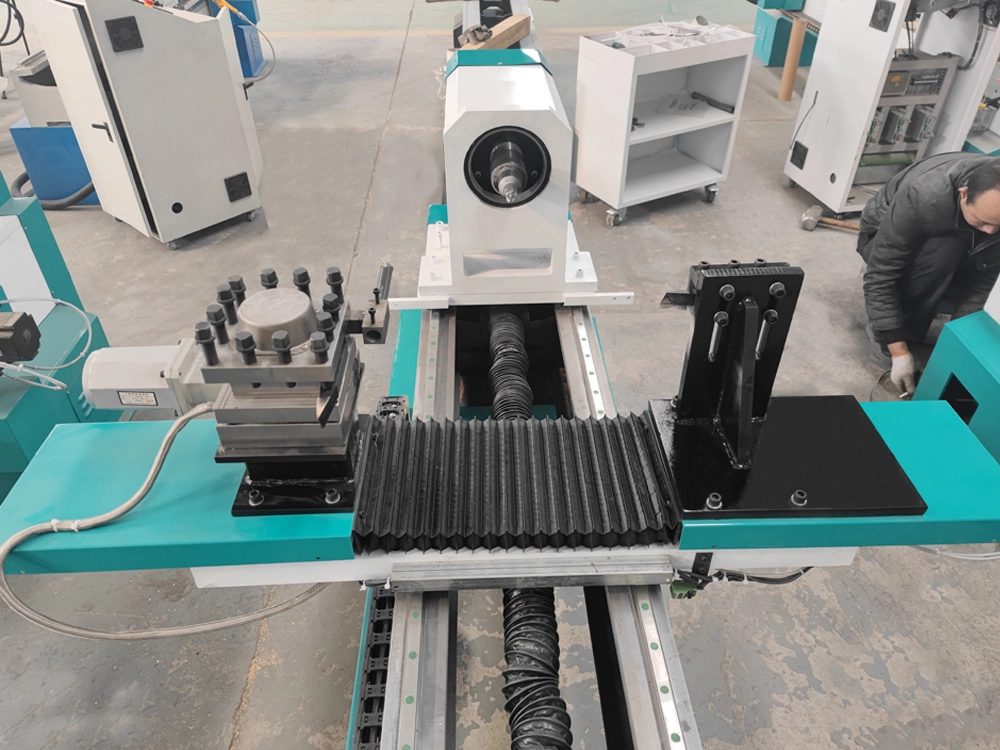

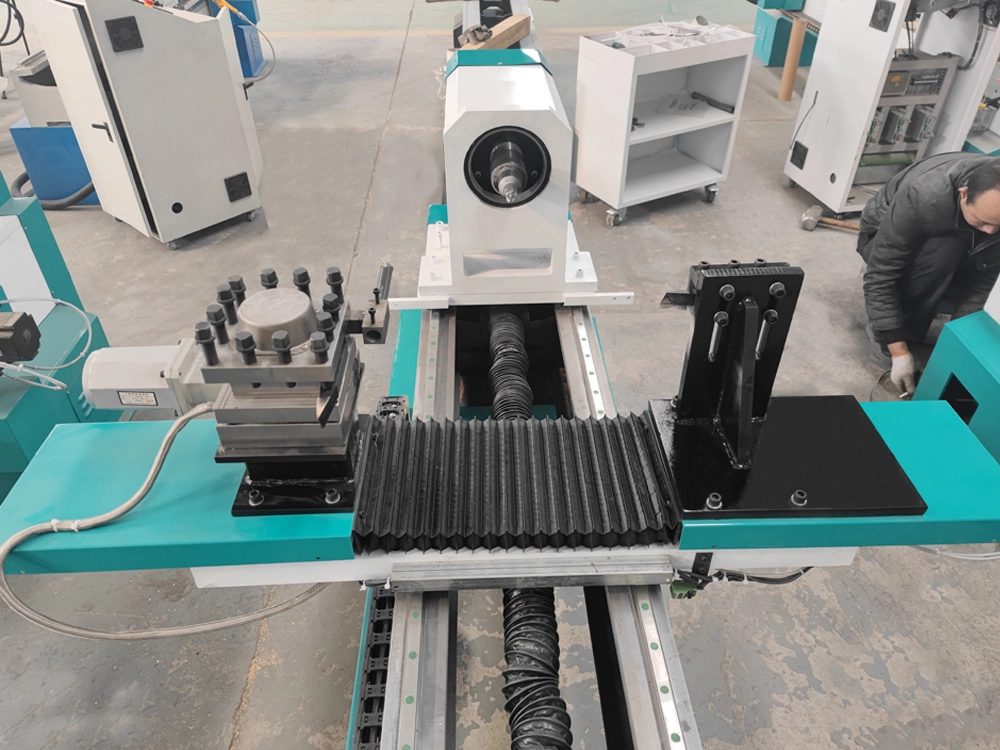

Details of 1530 CNC Wood Lathe

- Two V-shaped alloy turning tools for X and Y axes

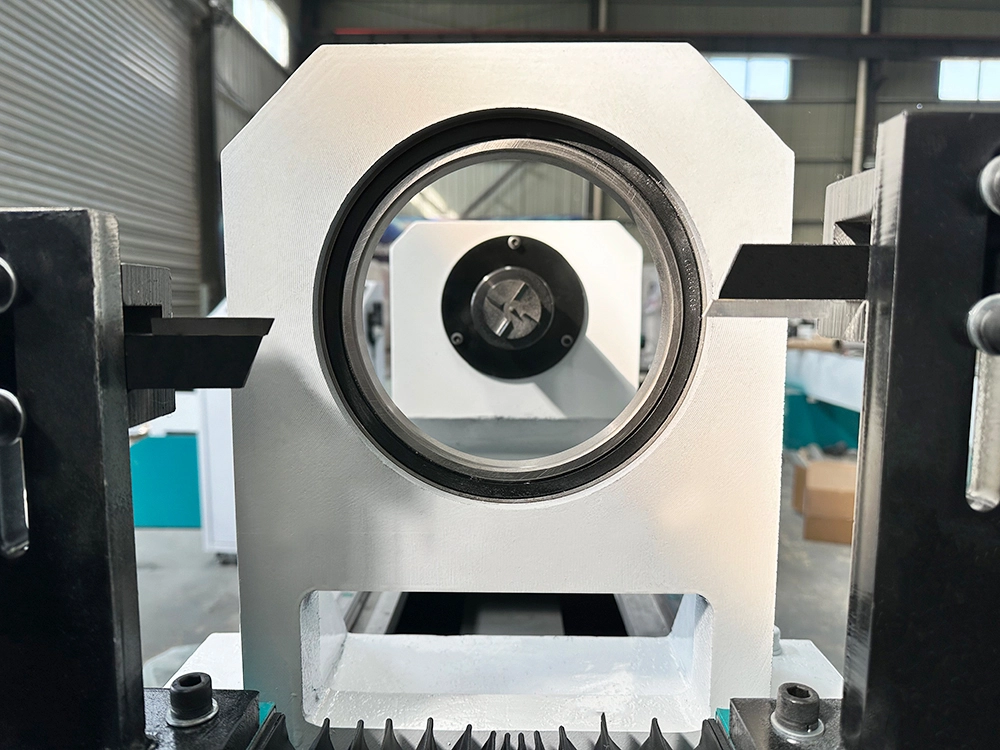

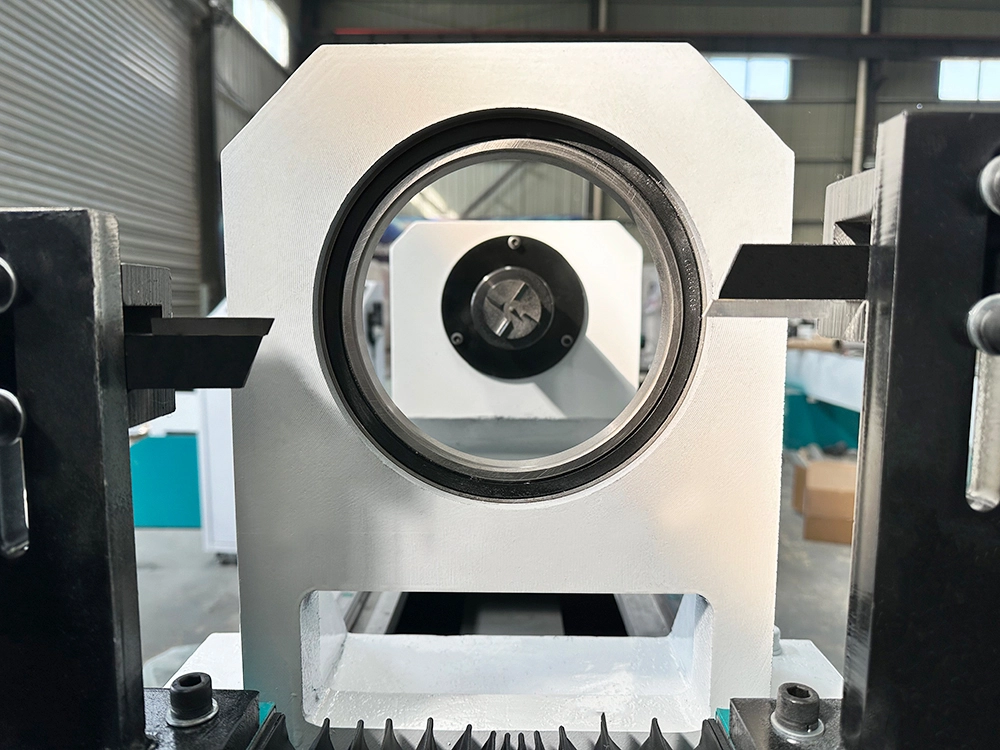

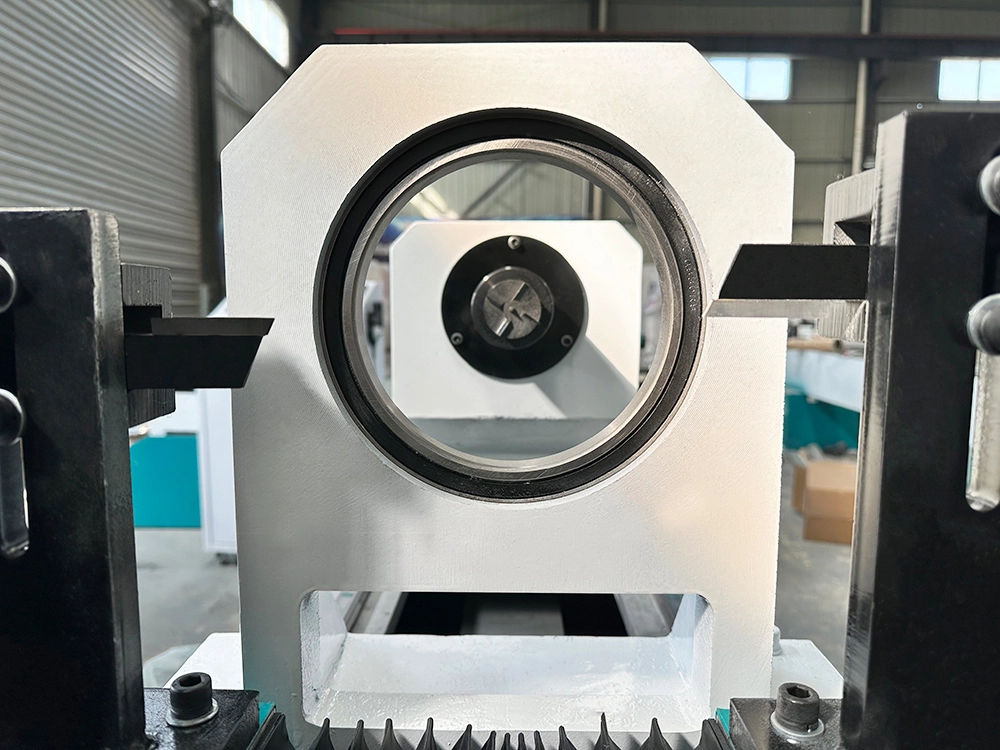

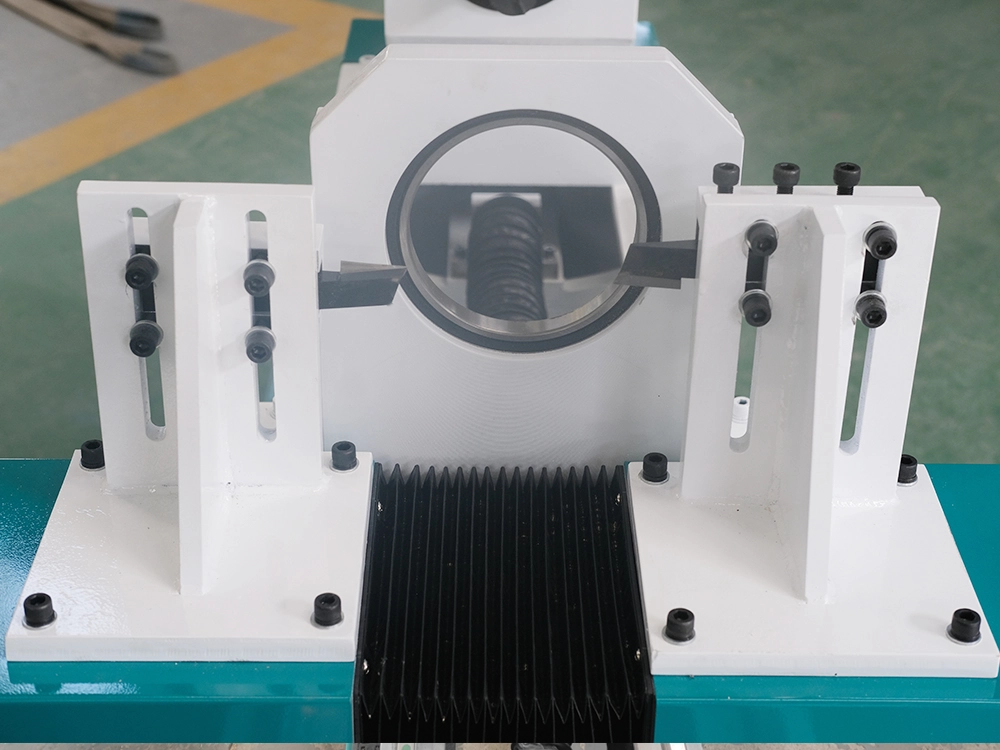

- Large diameter follow-type steady rest

- CATEKCNC dedicated numerical control system

The CK-1000TC is a lathe-specific CNC system independently developed by CATEKCNC. It is comprehensive and powerful in functionality, featuring built-in macro programs. It can also be used with CATEKCNC's auxiliary design software to automatically convert design files into G code without manual programming. Even beginners with no prior experience in CNC can easily get started.

- DSP handle

It is compact and available in wired and wireless versions.

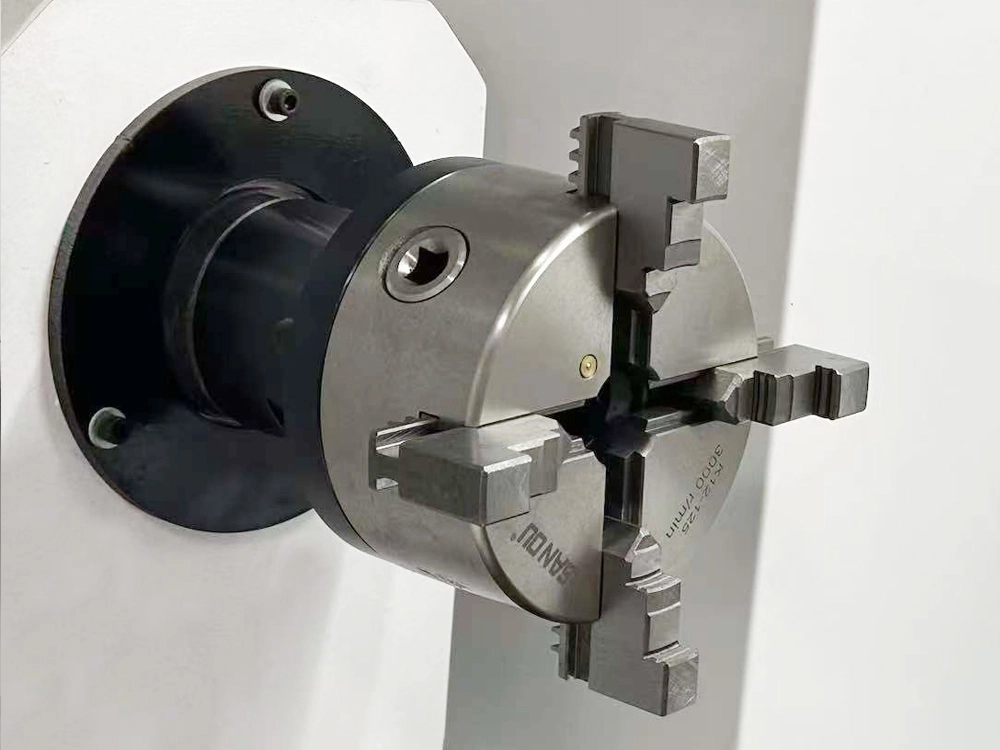

- Four-jaw chuck

Optional self-centering chuck is used for processing wooden crafts, such as wooden bowls, vases, cups and other products.It is more stable for processing large products.

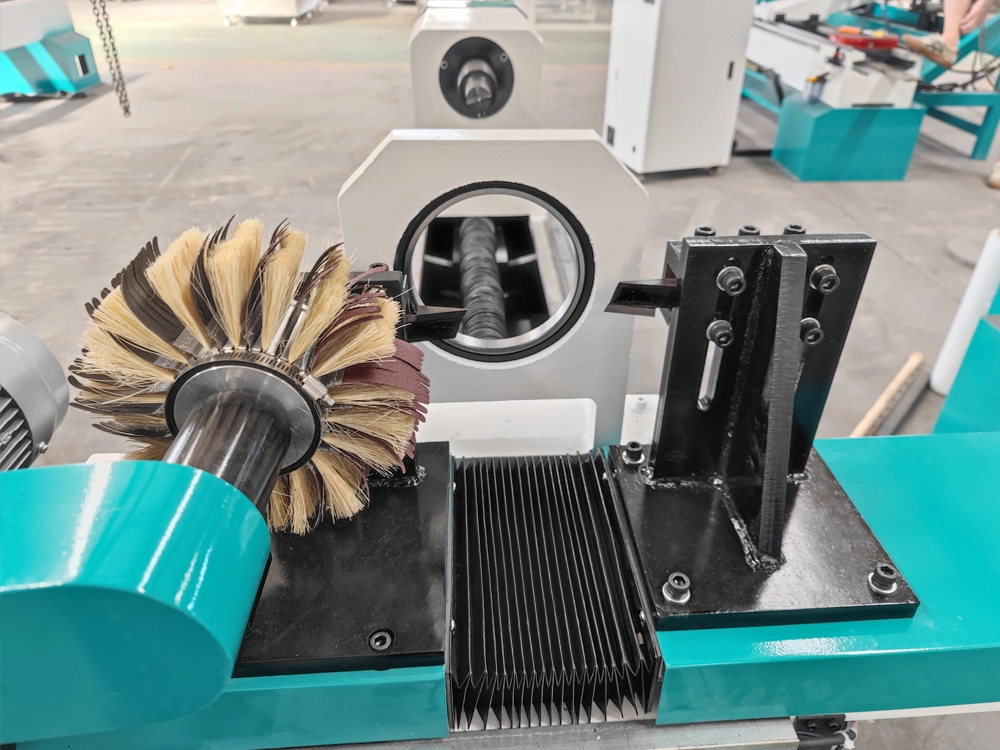

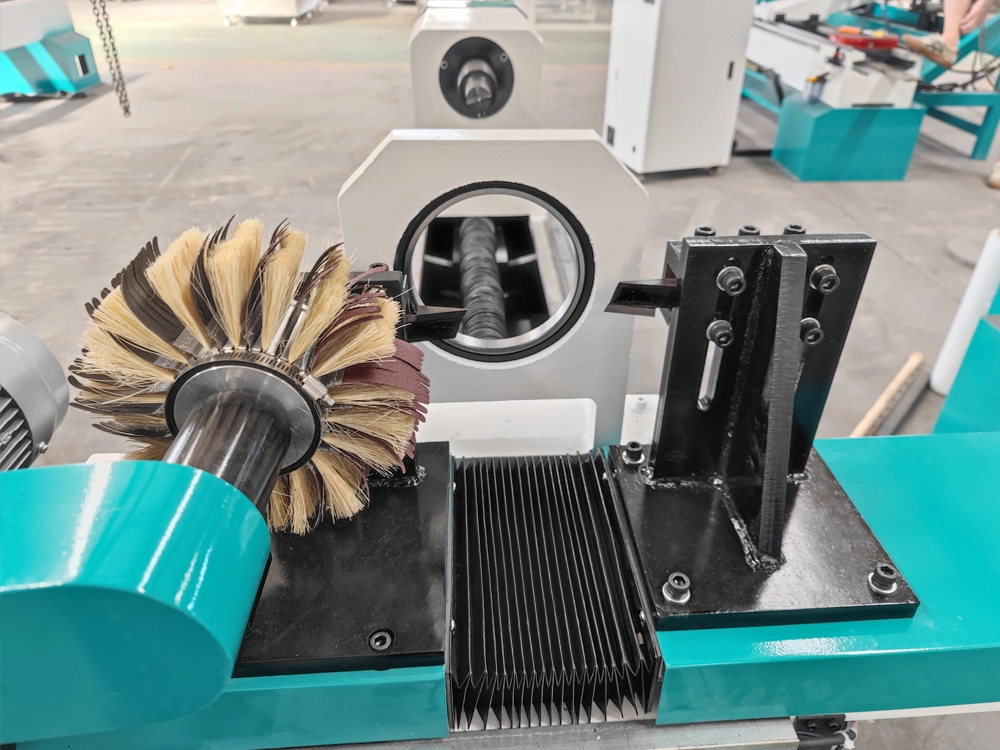

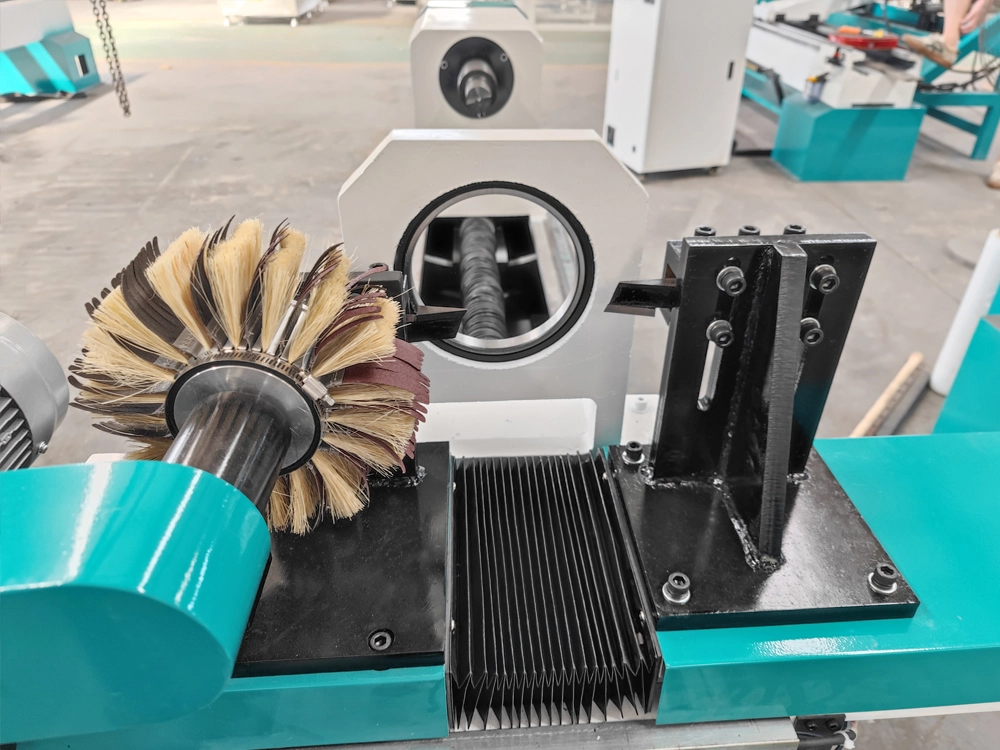

- Double-knife cnc wood lathe with sanding wheel

Optional sanding wheel, driven by an independent motor, can be used to sand various workpieces.

- Double-knife cnc wood lathe with sanding wheel and electric tool holder

Symmetrical double-knife design makes processing more stable. Two knives can turn the workpiece at the same time, thereby increasing the turning volume. Different knives can also be equipped for roughing and finishing respectively.

The steady rest is standard and can move with the tool holder. It is used to support slender workpieces to prevent them from being deformed by force.

An electric tool holder is optional. Each of the four sides of the device can hold a tool and the tools can be switched by rotating.

The CK-1530 Double-Knife CNC Wood Lathe Technical Parameters

| Model | CK-1530 |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integral high-temperature tempered gray cast iron full-cast bed, integral cast iron spindle box, integral cast iron tailstock, independent control cabinet (better anti-interference performance) |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont high torque inverter |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm (Continuously variable speed) |

| Transmission Mode | XY axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | Customized dedicated control system panel, CK1000TC, high-definition LCD display screen, industrial-grade dedicated |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, UCancam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Processing Accuracy | ±0.05mm |

| Center/Chuck | M55*2/Mohs No. 5 |

| Air Pressure | 0.6mpa↑ |

| Weight | 1840kg |

| Dimensions | 3100mm*1300mm*1450mm |

The Double-knife 1530 CNC Wood Lathe Machine Is More Suitable for Traditional Woodworking and Start-up Workers and Personal Studios.

Double-knife 1530 lathe is stable in structure, simple in operation and cheap in price, it is a very welcome basic CNC woodworking lathe, which is compatible with recognizing various versions of drawings in DXF format, traditional NC drawings, or G-code drawings in DBF, TXT and other formats, and drawing 2D plane drawings of the products to be processed by CAD, CAM and other software on the computer, and after importing into the machine by using a USB flash drive, it only needs a After importing the drawing into the machine using a USB flash drive, it is only necessary to set up the machine and move the tool to the starting point of wood processing, and then the machine can start processing automatically. Simple operation, learning 1-2 hours to start operating, whether you are a CNC novice or CNC experts can easily master the CNC woodworking lathe. Wide versatility, whether you are processing wooden handles, stair railings, sofa legs, table legs, chair legs, bed legs, drumsticks, baseball bats, wooden bowls, vases or other wood products, you can use it.

The double-knife 1530 CNC woodworking lathe is more suitable for beginner entrepreneurs, hobbyists and personal workshops, as well as some small factories. The optional auto-feed function or sanding function for the machine can realize auto-feed and auto-sanding and polishing, no matter what combination of configurations you need, CATEKCNC can provide you with a full range of customization.

Application Scope of Double-Knife CNC Wood Lathe

CK-1530 double-tool CNC wood lathe is very widely used, if you are not sure whether your product can be processed with CNC machine tools, you can contact us for free technical support, after confirming that it can be processed, we can provide free sample processing services.

Applicable Materials:

Wood, solid wood, oak, walnut, cherry, beech, mahogany, mdf, synthetic wood, glue wood, rubber wood, pine, antiseptic wood, toon, plastic, acrylic, nylon, PVC, carbon fiber, artificial wood substitutes and other materials.

Applicable Industries:

Furniture: table legs, chair legs, sofa legs, bed legs, pool table legs, stair railings, Roman columns, furniture accessories, etc.

Musical instruments: piano legs, flutes, suona, bassoons, drumsticks, etc.

Sports: baseball bats, wooden balls, chess sets, etc.

Other products: wooden handles, wooden bowls, vases, plates, cups, crafts, etc.

The Following Are the Processable Products of Double-Knife CNC Wood Lathe for your reference

Issues to Note When Purchasing 1530 CNC Woodworking Lathe

There are a lot of issues to pay attention to when you buy CNC woodworking lathe, first you need to confirm your processing size (the processing length and diameter of the product) as well as the processing technology (punching, slotting, sanding, milling).

You need to confirm your voltage, CNC woodworking lathe support 380V 3PH/220V 3PH/220V 1PH, in addition we can provide you with voltage customization, if you have special voltage requirements (such as 440V, 550V, etc.), you can contact our sales specialists to customize the transformer for you to ensure that the machine can be used normally.

If you have crafts (such as vases, wooden bowls) production needs, you can choose the combination of four-jaw chuck and bore tool, the products to be processed will be turned to the product shape you need, and then use the four-jaw chuck to clamp the product on the machine tool, the use of the bore tool on the end face of the product for the bore processing. We also provide optional automatic tool changer, which can save the time of manual tool change.

If your product has the demand of engraving, milling groove and other functions, you can add the spindle on the basis of ordinary CNC machine tools, which can engrave, milling line, drilling and other processing of various parts.

| Model | CK-1530 |

|---|---|

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integral high-temperature tempered gray cast iron full-cast bed, integral cast iron spindle box, integral cast iron tailstock, independent control cabinet (better anti-interference performance) |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont high torque inverter |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm (Continuously variable speed) |

| Transmission Mode | XY axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail/25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | Customized dedicated control system panel, CK1000TC, high-definition LCD display screen, industrial-grade dedicated |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/3PH/50/60Hz OR AC220V/3PH/50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, carving, powermill, UCancam, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Processing Accuracy | ±0.05mm |

| Center/Chuck | M55*2/Mohs No. 5 |

| Air Pressure | 0.6mpa↑ |

| Weight | 1840kg |

| Dimensions | 3100mm*1300mm*1450mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.