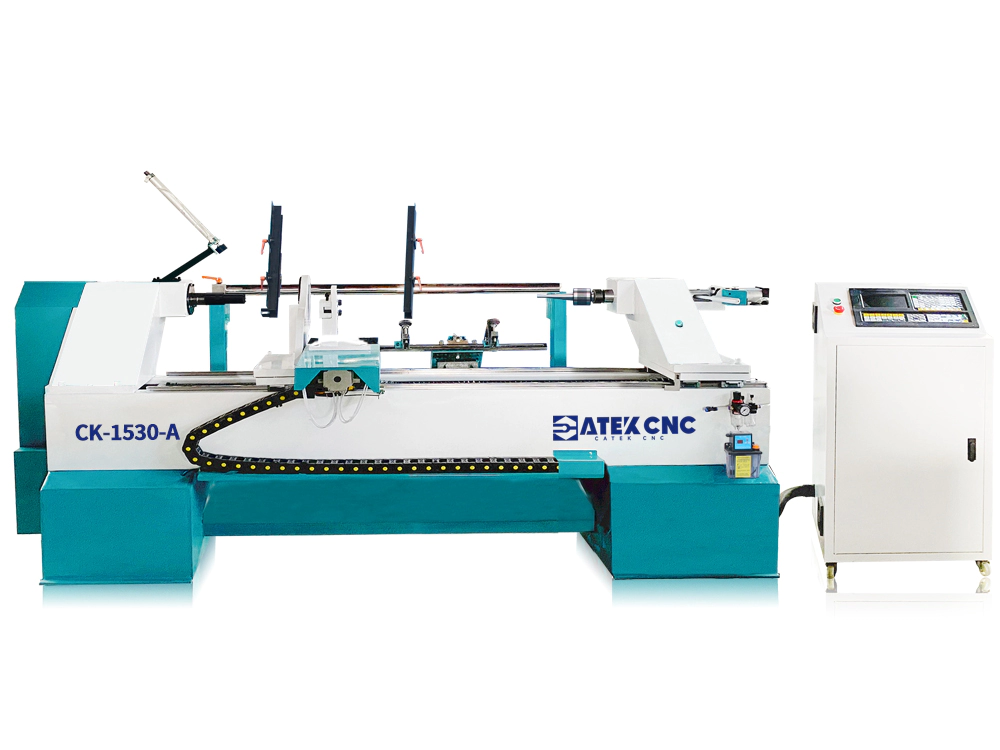

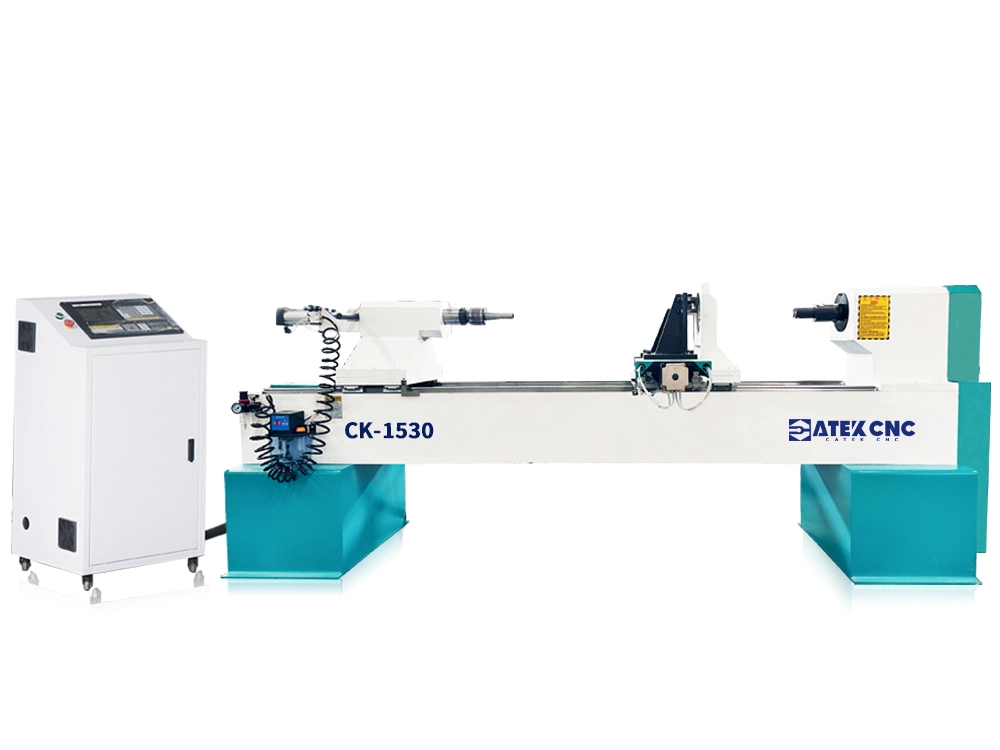

Small CNC Wood Lathe with Automatic Feeding Function for Fully Automated Machining

Compact Dual-Tool CNC Wood Lathe with Automatic Feeding

[Function Description]

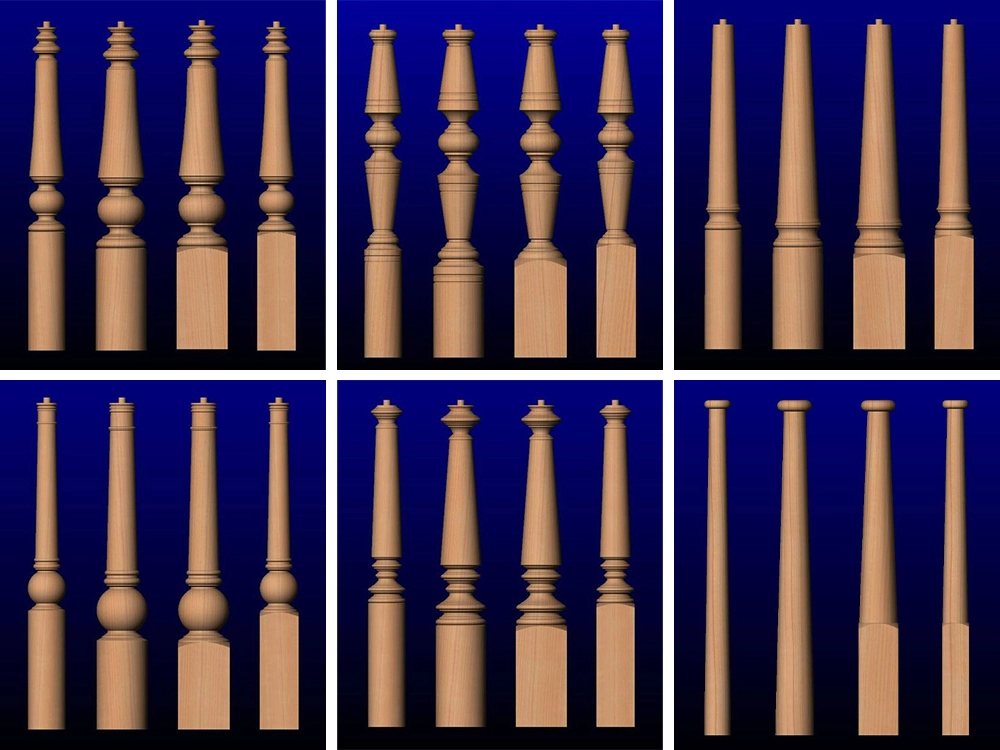

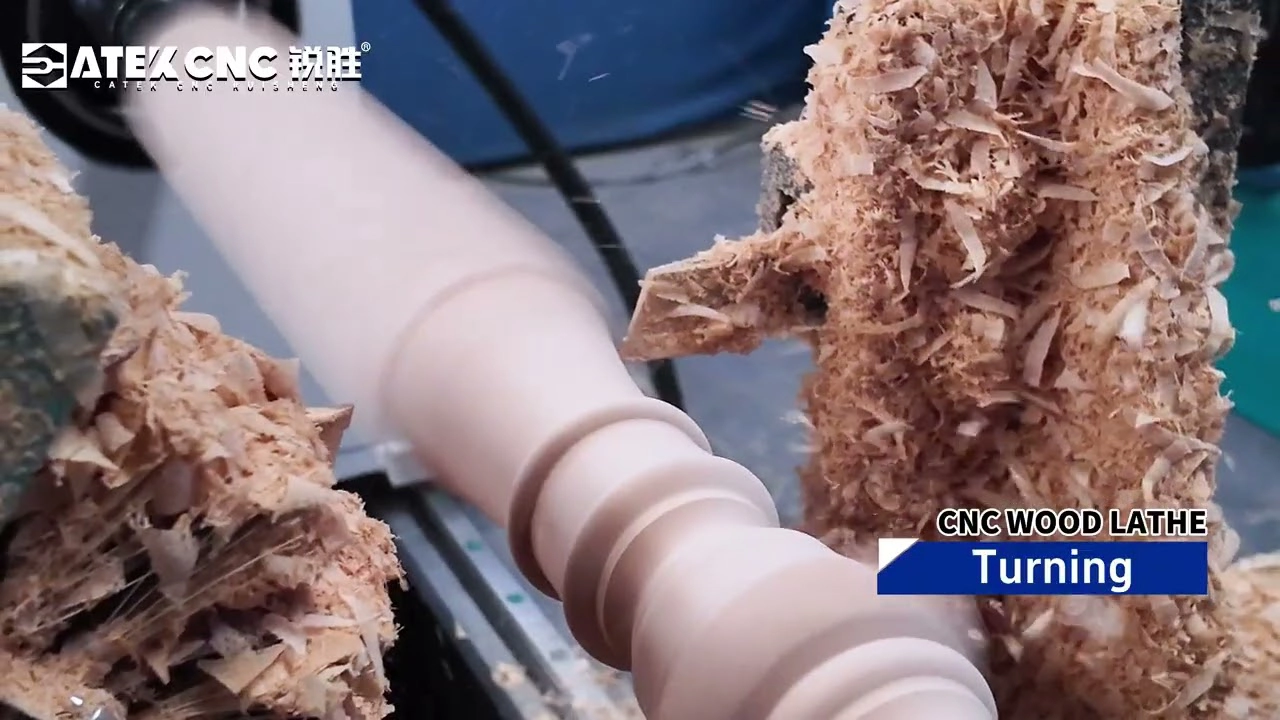

CK-0820-2A is a small CNC wood lathe specially used for processing wood products. It is equipped with a fully automatic loading and unloading device and double turning tools. It has a processing length of 800mm and a processing diameter of 200mm. It is also equipped with a fully automatic sanding device, which can be used to process various table legs, chair legs, furniture legs, wooden pillars and other products. Before processing, you only need to adjust the automatic feeding device according to the length and diameter of the raw materials, put the raw materials to be processed in the silo, and then copy the prepared drawings to the control system of the machine through a U disk. After a simple calibration of the tool through the control system, you can start fully automatic processing. The sanding device can be freely set according to the processing requirements. Sanding can be performed during the turning process, or the sanding wheel can be independently operated for sanding after the turning is completed. The entire processing process does not require manual intervention. After all the wood in the silo is processed, the sensor installed on the automatic feeding device will sense that all the wood has been processed, and the machine will automatically pause immediately, which is very safe to use.

This compact CNC wood lathe, equipped with an automatic feed system, measures a mere 2.2 meters in length, boasts a minimal footprint, and operates solely on electricity, resulting in significant energy savings. Its user-friendly design makes it accessible even to novice CNC operators, adapting seamlessly to diverse production settings and requirements.

Advantages of Small CNC Wood Lathe With Automatic Feeding Device

- Processing length 800mm, diameter 200mm, can process various types of table and chair legs, bed legs, columns, etc.

- Use a high-torque 4KW three-phase asynchronous motor and a Hpmont inverter. The speed can be adjusted from 0 to 3000 rpm. The speed can be adjusted according to different processing sizes, which is easy to use.

- The machine's base, including the headstock and tailstock, is made of heavy-duty, thick cast gray iron. This ensures stable operation even at high speeds.

- Equipped with a central bearing support frame, it will not shake even when processing slender workpieces, effectively ensuring the processing quality.

- The processing accuracy can be controlled within ±0.05mm, which can effectively ensure the quality of the workpiece, make the workpiece more standardized, and facilitate subsequent assembly processes.

- Use CATEKCNC self-developed CNC system, equipped with simple programming software, easy to use, and also compatible with various cad/cam type software, very easy to get started.

- Four-link pneumatic automatic feeding device, multiple cylinder combination, fully automatic operation, automatic loading and unloading of materials, no manual intervention required.

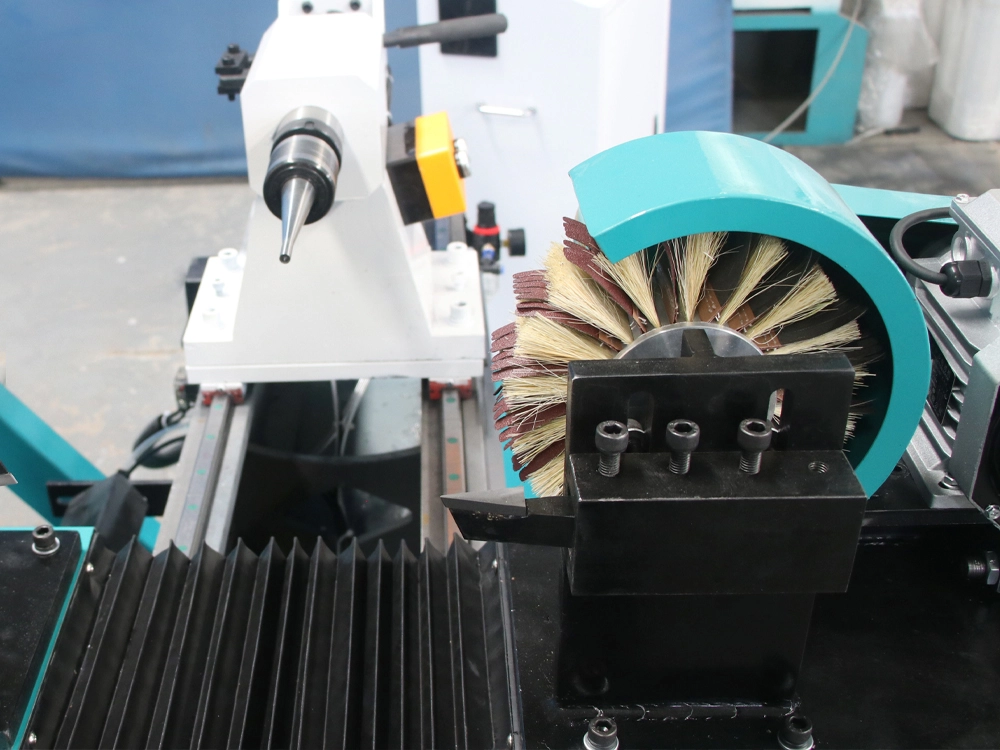

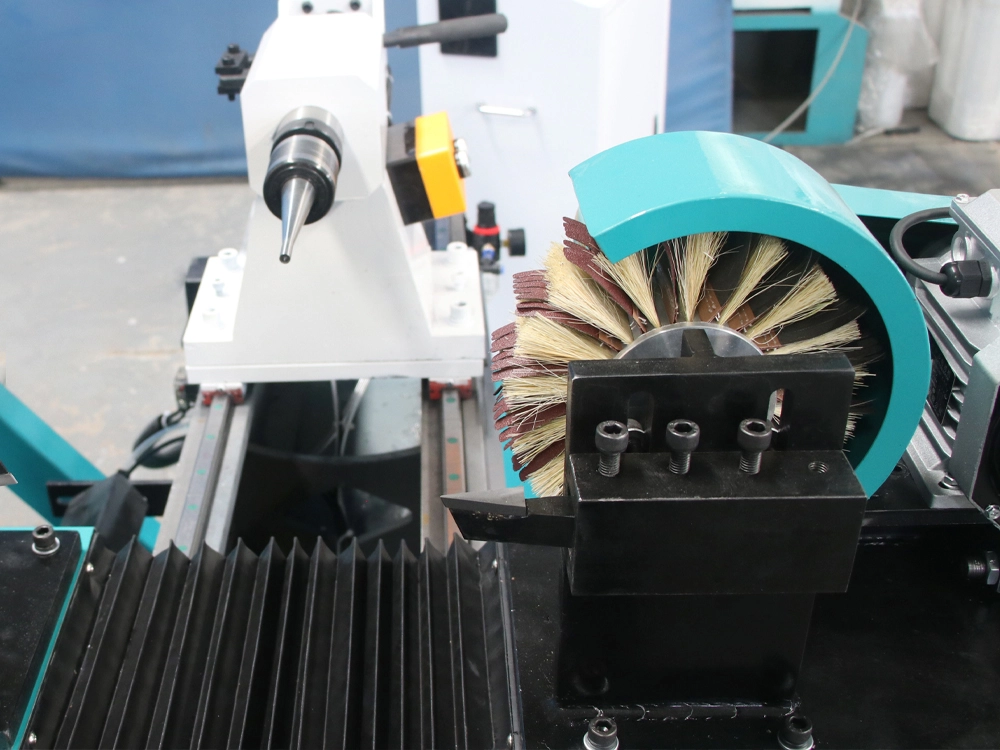

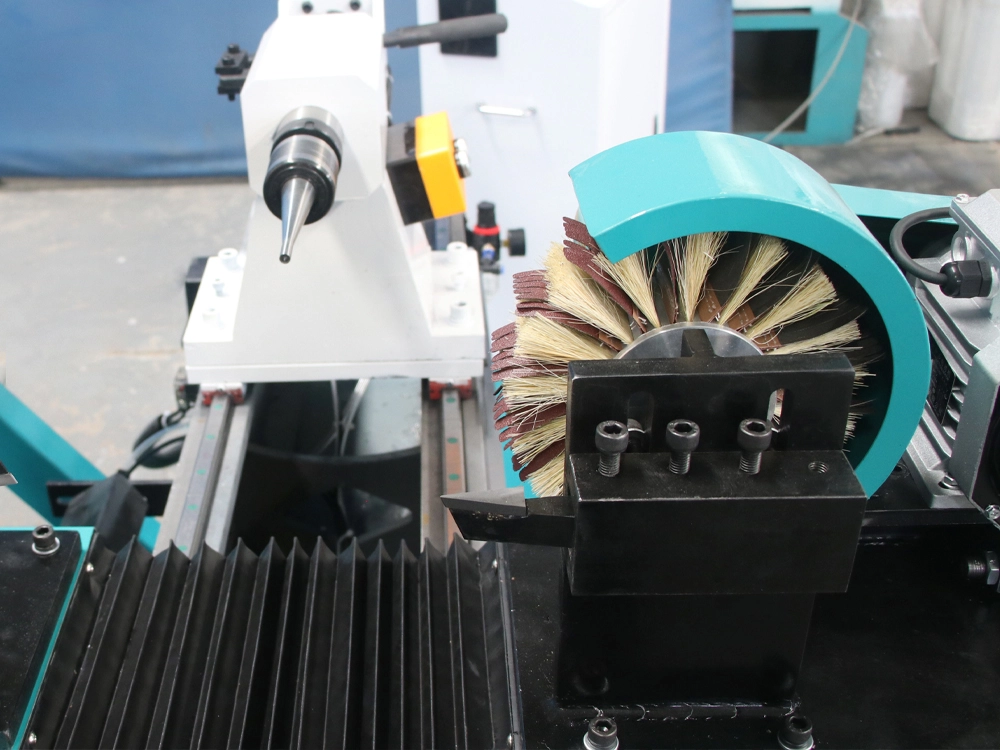

- Independent sanding device, the sandpaper mesh can be selected arbitrarily, and polishing brushes are installed interspersed, which can automatically sand the processed products and save sanding time.

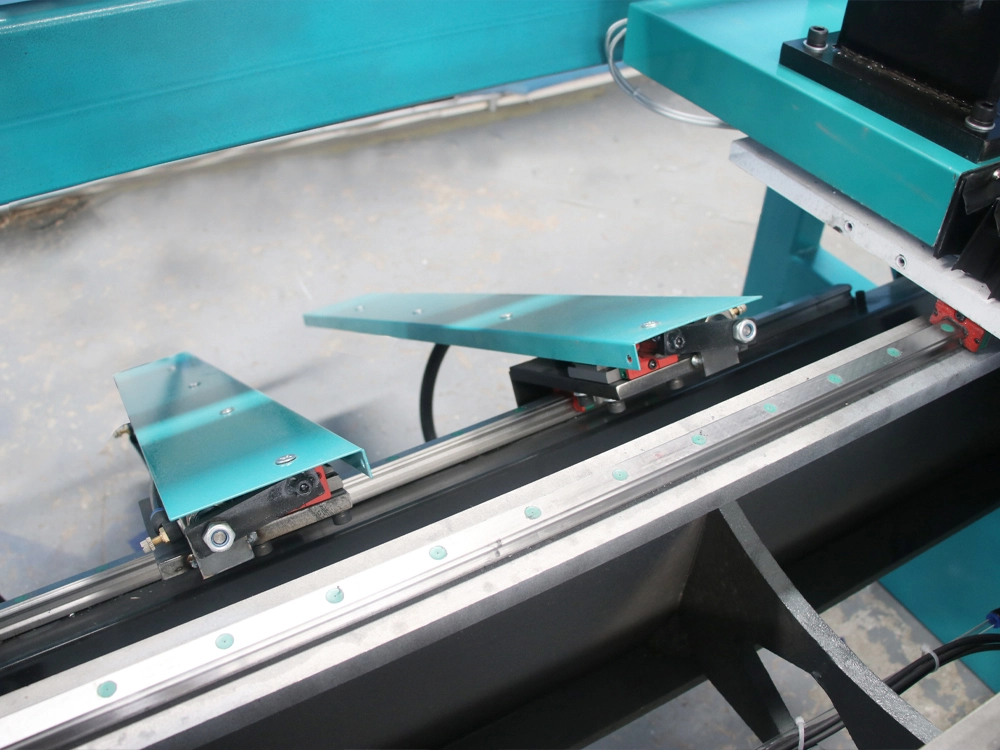

- Using Taiwan Hiwin guide rails, flange type linear bearings, XY axis using TBI rolled ball screw, high running accuracy and low noise.

- The XYZ three-axis is driven by a servo motor, which has high positioning accuracy and can provide continuous and accurate torque input, resulting in better product processing effects.

- Equipped with two turning tools, during processing, one tool is used for rough processing and the other tool is used for fine turning to ensure the processing effect of the workpiece.

- When processing large-sized workpieces, layered turning can be set, and the control system can freely set the number of layers to ensure stable processing of large-sized workpieces.

Details of Dual-Tool Small CNC Wood Lathe Equipped With Automatic Feeding

- Dual-tool turning

Two turning tools, one for roughing and one for fine turning. The two tools work together to perform turning, doubling the processing efficiency.

- Automatic feeding device

Multi-cylinder combination automatic feeding, can be freely adjusted according to different raw material sizes, easy to use.

- Silo

Multiple raw materials can be placed at one time. The machine can automatically feed, process and unload without manual operation, saving labor.

- Automatic unloading device

After processing is completed, the cylinder of the automatic unloading device will automatically rise, and the workpiece will automatically roll down along the unloading slide, without the need for manual unloading of materials.

- Sanding device

370w high-speed motor drives sanding, sanding wheel size 230mm diameter * 50mm width, can be used for sanding various types of products, saving subsequent sanding time.

- Headstock

The headstock has a four-tooth Morse taper, which can effectively grip the wood and prevent the raw material from slipping during turning.

- Tailstock

The tailstock has Morse taper No. 5, built-in 3 bearings, stable operation.

- Wood: beech, oak, Chinese toon, birch, teak, sapele, merlot, sandalwood, rosewood, cherry, walnut, pine, mahogany, ash, maple and other woods.

- Plastics and synthetic materials: PVC, polyethylene (PE), polycarbonate (PC), acrylic, resin, PTFE, asbestos, gypsum, etc.

- First layer

Before packaging, we will apply anti-rust oil to the transmission parts and rust-prone parts of the machine to avoid rust and corrosion caused by long-term transportation, and then use stretched wrapping film to completely wrap the machine.

- Second layer

Use anti-collision foam to protect the raised and vulnerable parts of the machine to prevent damage caused by collision during transportation.

- Third layer

Secure the machine to the wooden crate base, constructed from metal square tubing and multi-layered plywood. Completely seal the crate with steel nails and reinforce the exterior using metal banding.

Technical Parameters of Double-Tool Small CNC Wood Lathe Equipped With Automatic Feeding

| Model | CK-0820-2A |

|---|---|

| Working Size | 800mm length * 200mm diameter (processing size can be customized) |

| Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Drive Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

| Sanding | 370W high speed motor, 230mm*50mm sanding wheel |

| Transmission Mode | XY axis 25 TBI ball screw transmission, Z axis uses high-precision helical rack |

| Guideway | Taiwan Hiwin high precision linear guide rail / flange type linear bearing |

| Equipment Cable | Highly flexible pure copper anti-bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Loading and Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, solidworks, UG, powermill, etc. |

| Security System | All XYZ three-axis photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Dimensions | 2300*1950*1650mm |

| Weight | 1100kg |

What Can a Small CNC Woodworking Lathe With Automatic Feeding Function Be Used to Process

Materials:

Products:

Wooden stair columns, sofa legs, table legs, chair legs, bed legs, Roman columns, coat racks, wooden handles, wooden handles, wooden cups, wooden bowls, vases, hammer handles, axe handles, agricultural tool handles, walking sticks, trekking poles, baseball bats, wooden crafts, furniture accessories, support columns, rolling pins and other products.

How Is the Small CNC Woodworking Lathe Packaged and Shipped

Whether it is a small machine or a large machine, catekcnc uses the same delivery process. We use three layers of packaging for all machines to ensure that the machine can be transported to you intact:

| Model | CK-0820-2A |

|---|---|

| Working Size | 800mm length * 200mm diameter (processing size can be customized) |

| Bed Base | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Drive Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

| Sanding | 370W high speed motor, 230mm*50mm sanding wheel |

| Transmission Mode | XY axis 25 TBI ball screw transmission, Z axis uses high-precision helical rack |

| Guideway | Taiwan Hiwin high precision linear guide rail / flange type linear bearing |

| Equipment Cable | Highly flexible pure copper anti-bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Loading and Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, solidworks, UG, powermill, etc. |

| Security System | All XYZ three-axis photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Dimensions | 2300*1950*1650mm |

| Weight | 1100kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.