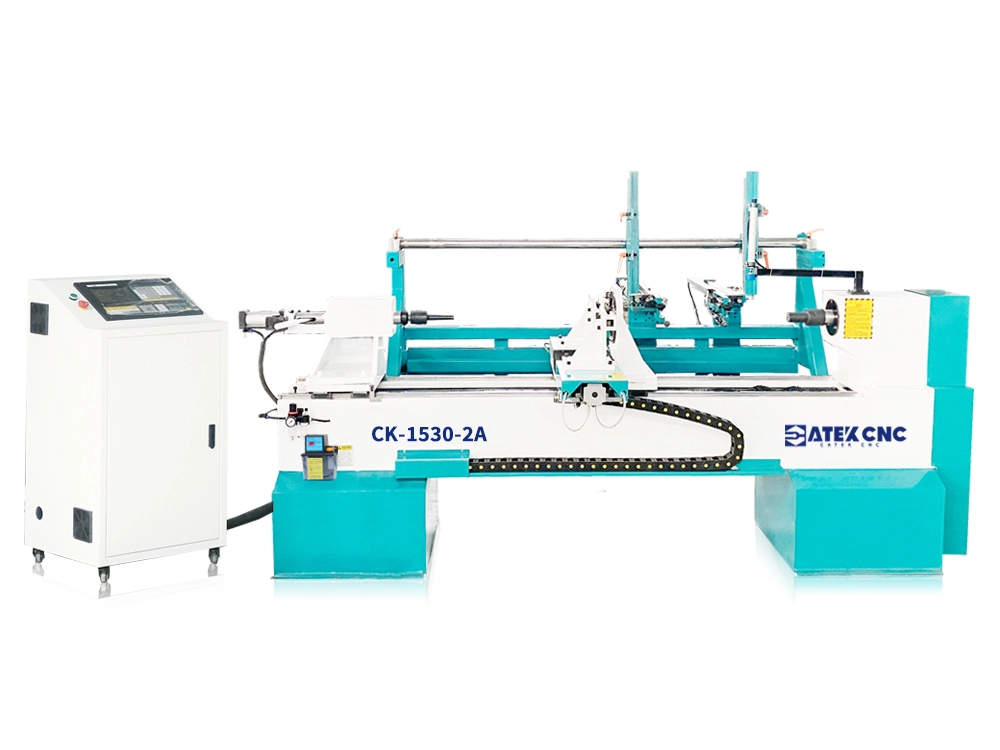

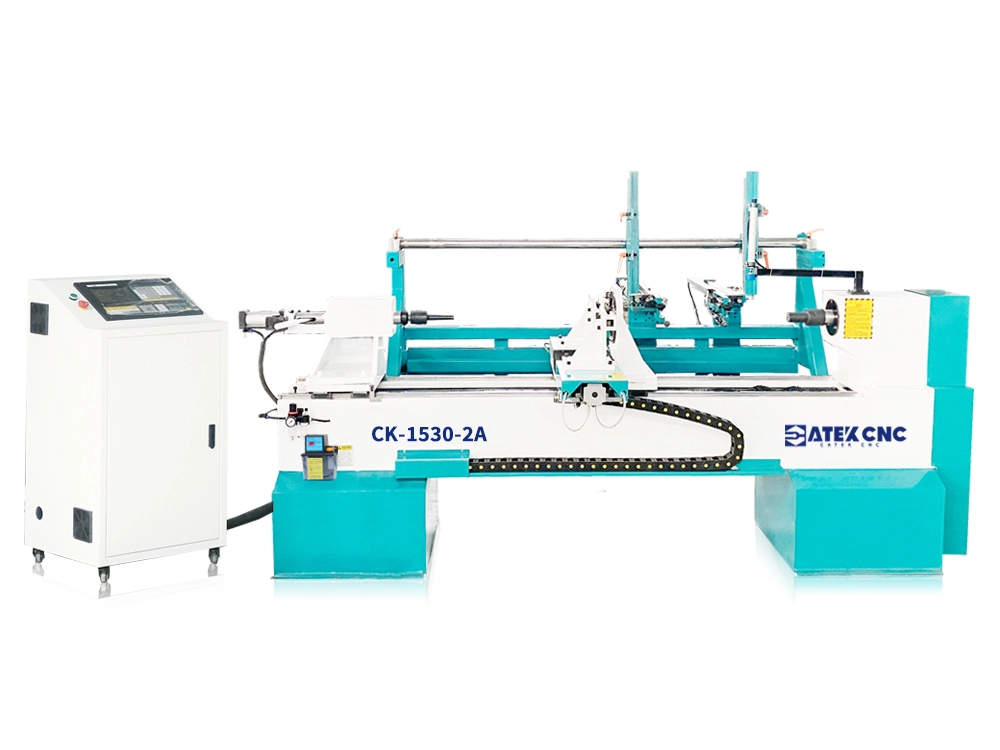

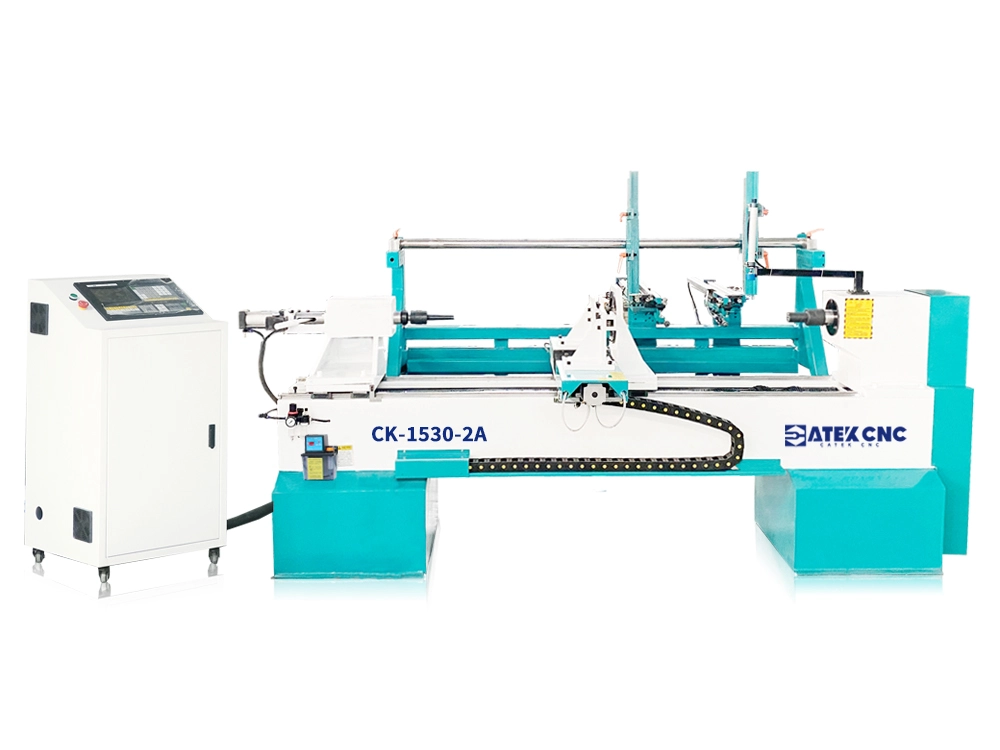

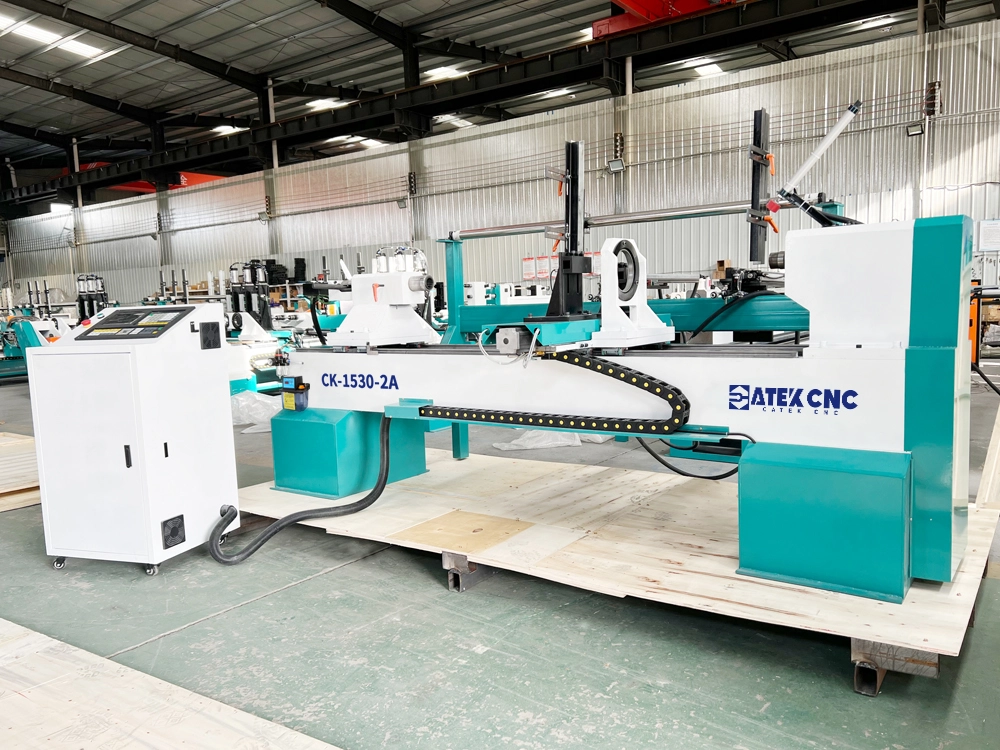

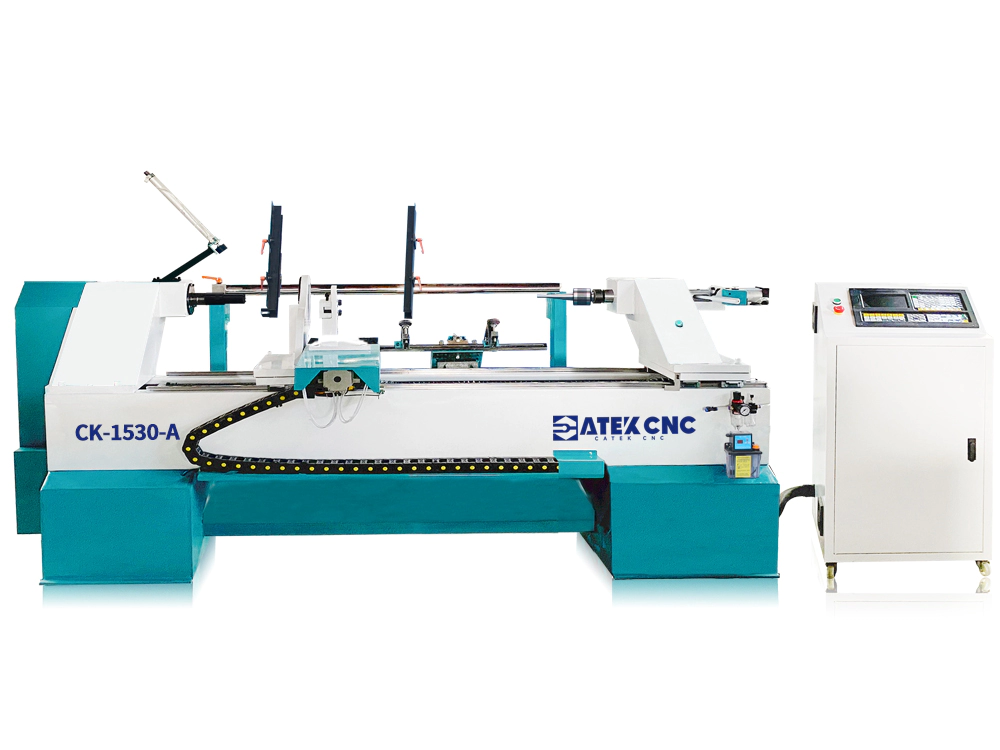

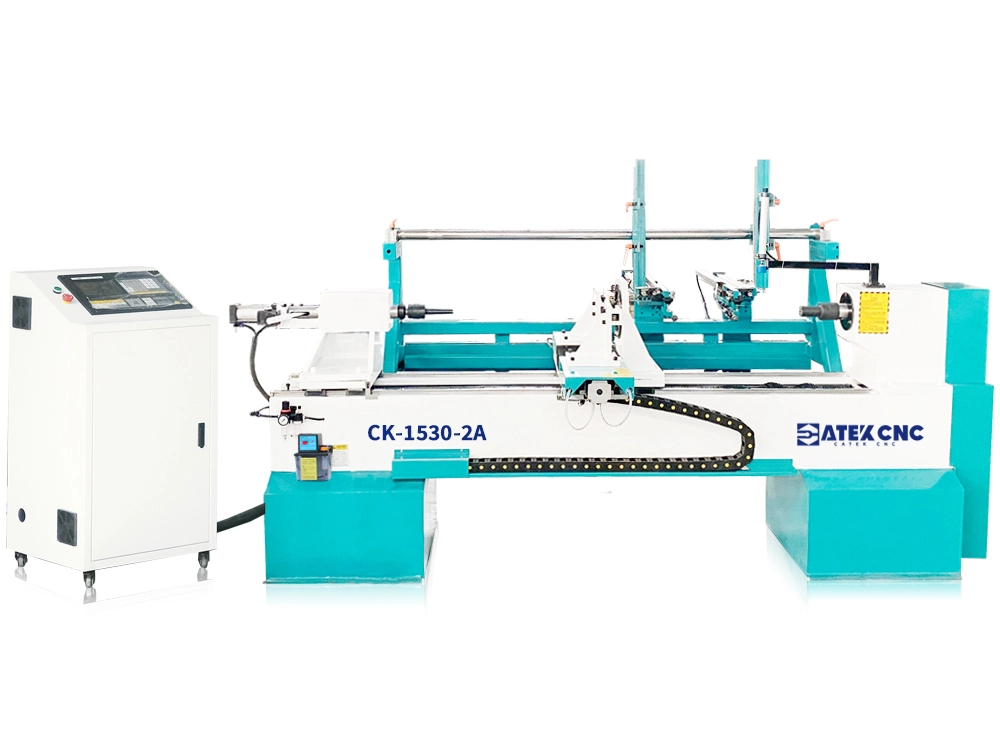

Efficient Dual Tool Automatic Loading and Unloading CNC Wood Turning Machine

Double-Knife CNC Wood Lathe with Automatic Feeding for Roman Column

[Function Description]

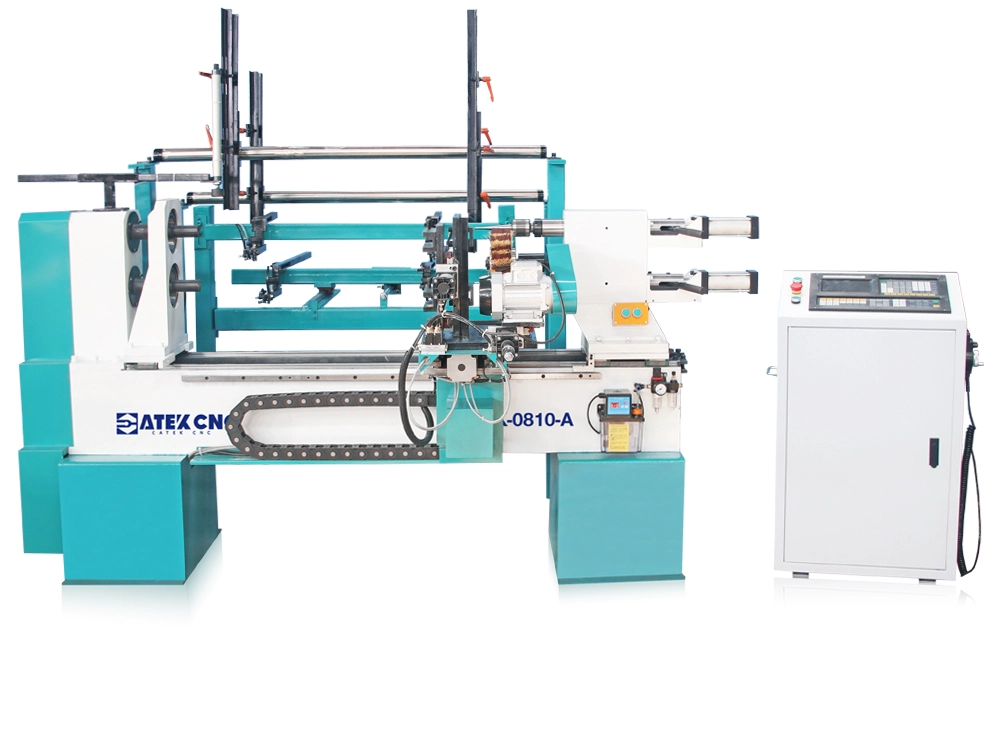

Overview of Professional Automatic Feeding Double-Knife CNC Woodworking Lathe

The automatic feeding CNC wood lathe is specially designed for factory workshops. It uses a heavy-duty gray cast iron bed and is stable in processing. During processing, you only need to put the wood into the pre-adjusted silo to realize the automatic loading and unloading of the material to be processed. When in use, you only need to adjust the machine to start processing, multiple cylinders are linked to automatically feed, accurately locate the center point of the material, and automatically unload the material after processing. This eliminates the step of manually placing the material, reduces the dependence on skilled workers, and greatly saves human resources. The operator only needs to put the material in on time and then focus on other work. The addition of the automatic loading and unloading system makes unmanned production possible, which can achieve continuous and uninterrupted production, reduce manual operation time, and improve production efficiency.

The machine has strong versatility, with a maximum processing length of 1500mm and a maximum processing diameter of 300mm, it can be adjusted and processed arbitrarily within this size.The machine can be equipped with an optional sanding function. The product can be sanded and polished synchronously during processing, or it can be done separately after processing. The standard fllow with tool steady rest is customized according to the material diameter. It has a built-in large central bearing and can rotate at high speed. This ensures that there is no shaking of the workpiece when processing extra-long products, thus ensuring the processing quality.

Advantages of Double-Knife Automatic Feeding CNC Wood Lathe

- Single-spindle double knives, both knives can be driven independently, the processing depth can be set at will, and layered and multi-stage processing can be performed according to different processing requirements.

- Use multiple combined cylinder structures to realize automatic loading and unloading. Just a simple set it up and start the processing with one button. It is easy to operate.

- The control system uses international standard G code, supports multiple software outputs, has good compatibility, and comes standard with an external pulse handwheel, which makes tool setting more convenient.

- Each cylinder of the automatic loading and unloading function is controlled by an independent button and can be adjusted and used separately.

- Use a 5.5KW high-power three-phase asynchronous motor with fast speed, large torque, and faster processing.

- The CNC control system has an integrated macro program, which is compatible with various CAD and CAM software, and can directly recognize DXF, DBF, TXT, and NC format drawings.

- It supports fixed material processing through the lathe center, and can also use a chuck for single-end clamping, which is flexible to use.

Details of Double-Knife Wood Lathe With Automatic Loading & Unloading

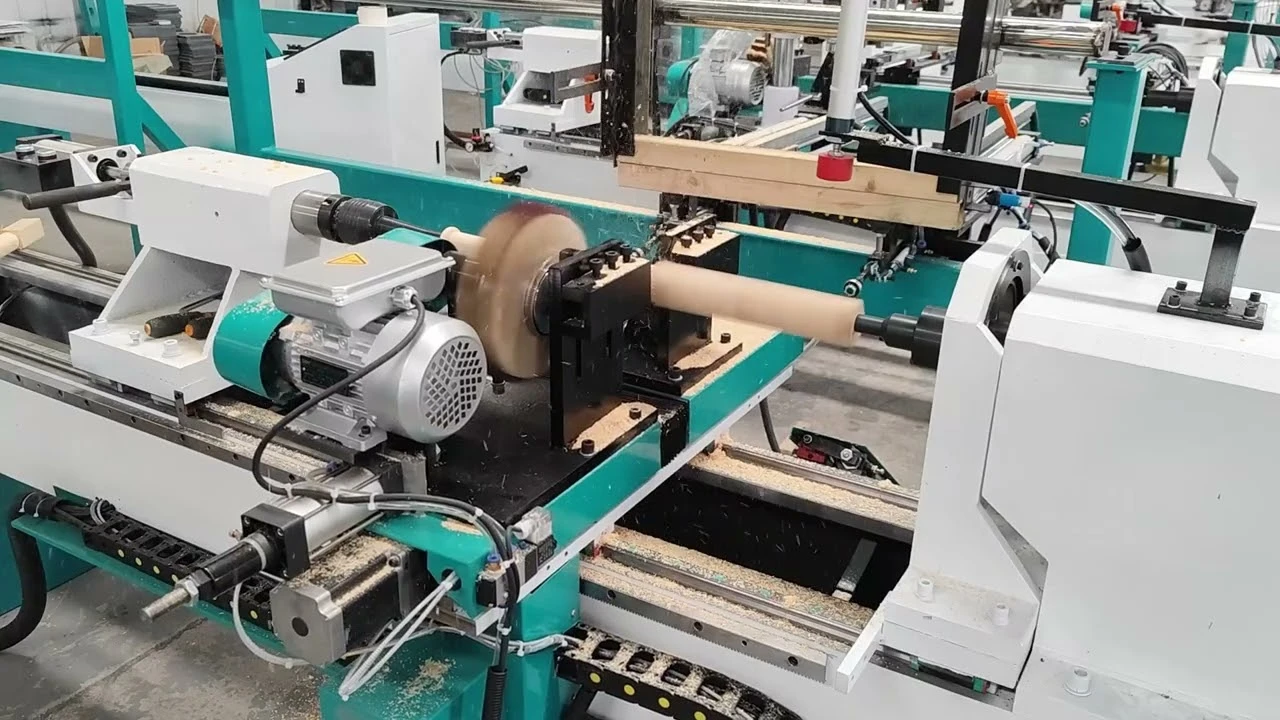

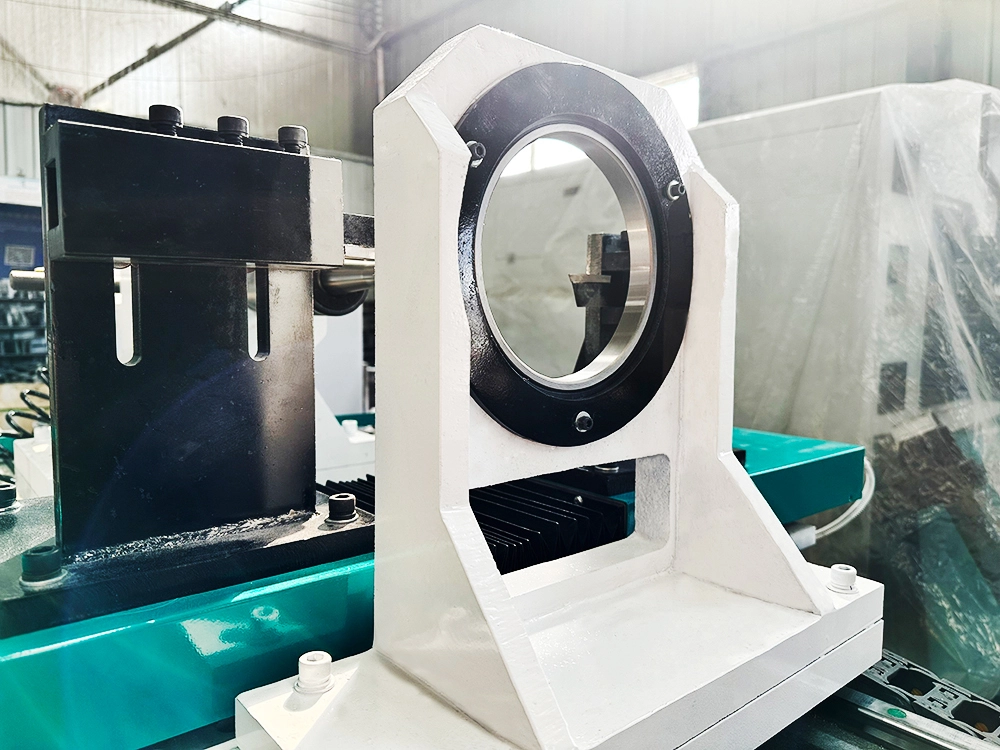

- Turning device

Two tools are equipped in a single station, with a large diameter steady rest in the middle, which is safe to use.

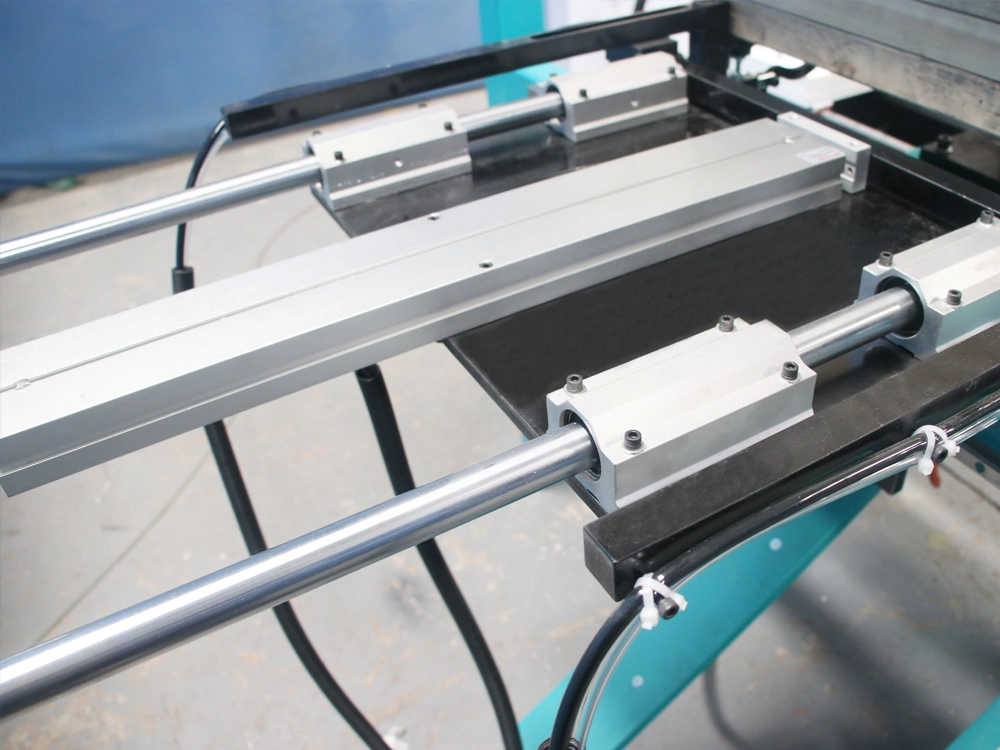

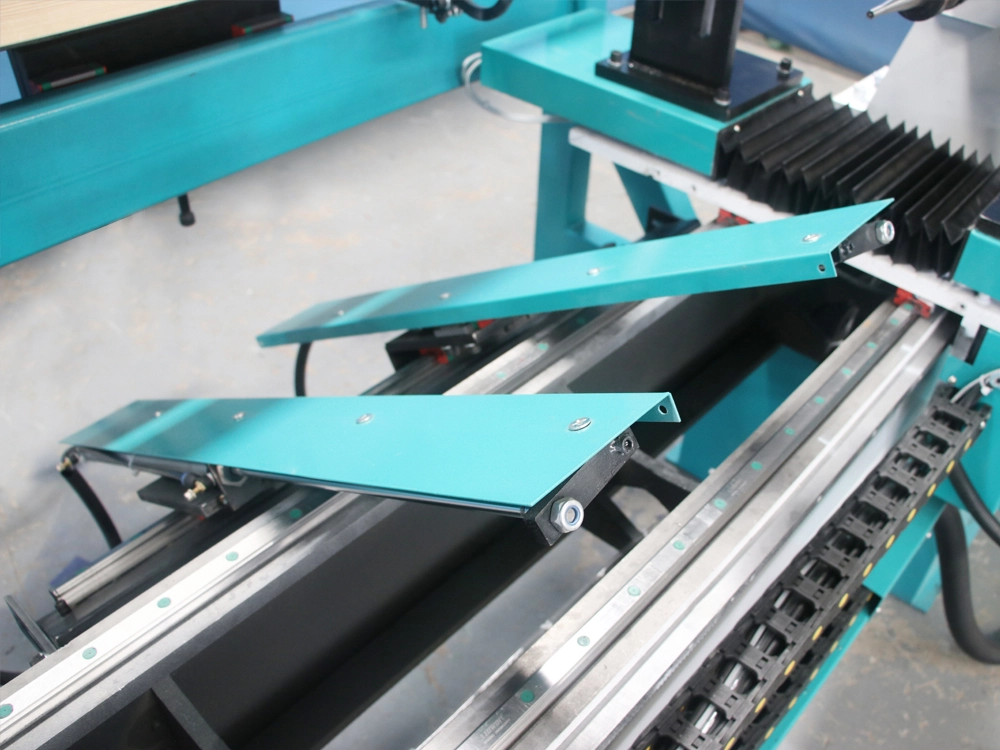

- Automatic loading device

Using multiple pneumatic devices to link, easy to use.

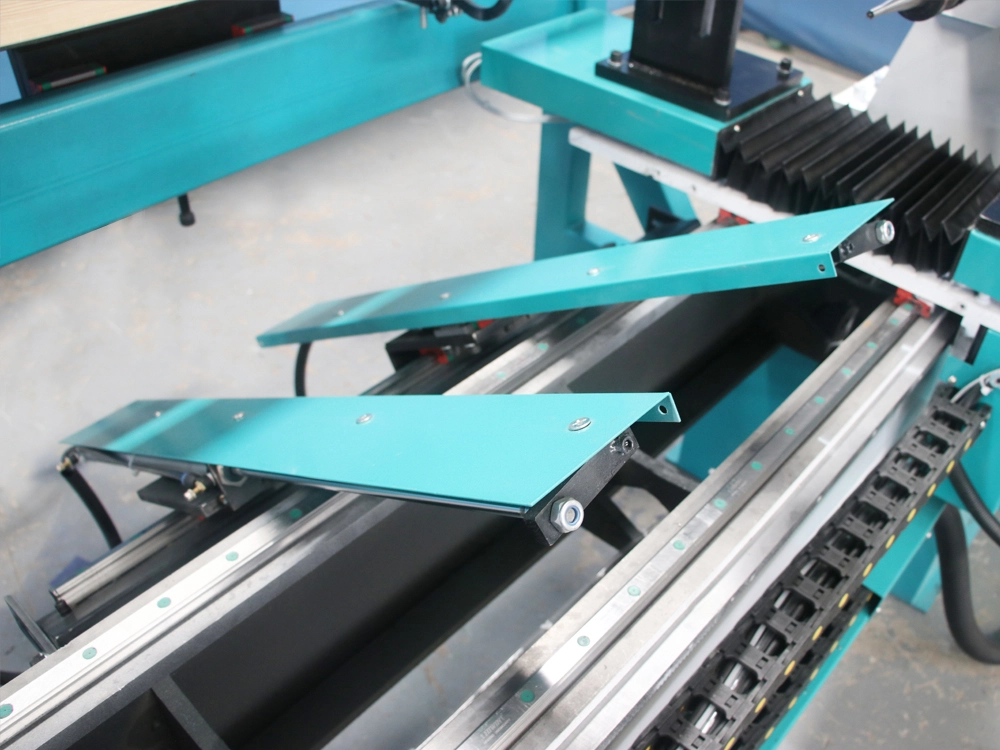

- Automatic unloading device

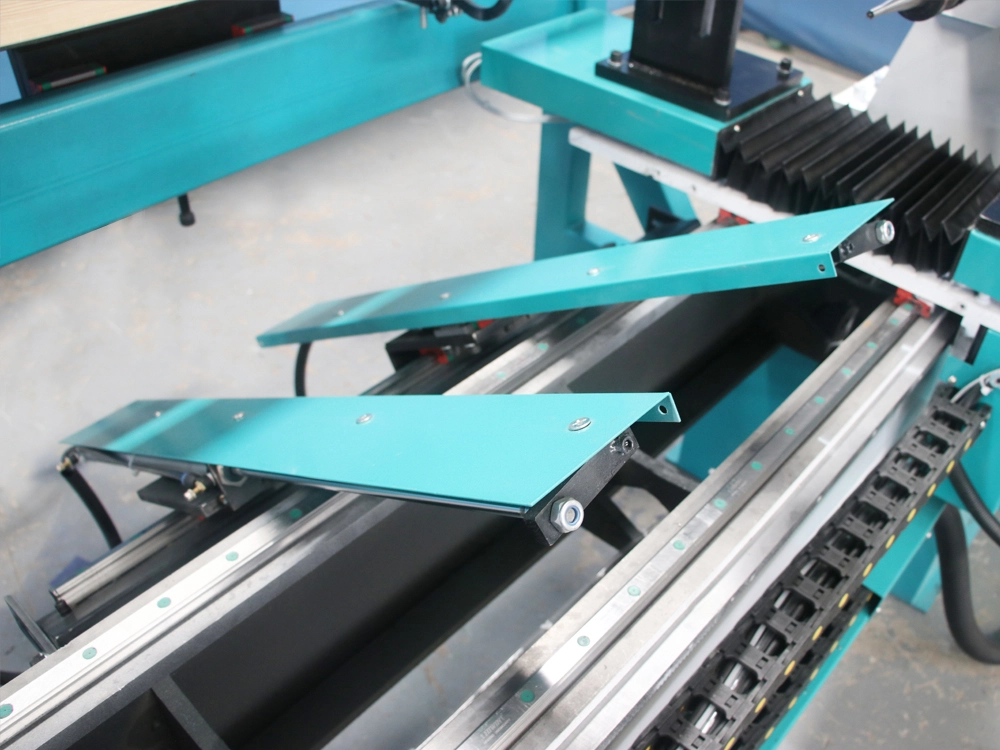

The wood is pushed out by the ejector cylinder and slides down through the receiving slide.

- Industrial inverter

High-torque industrial inverter and high-quality electrical accessories.

- Optional sanding wheel

After the turning work is completed, the sanding device can be automatically switched to polish the parts.

- Optional half-enclosed protective

An cheap and simple half-enclosed protective cover to prevent wood chips from splashing.

- Automatic feeding CNC wood lathe with milling and engraving device

Using the spindle to hold the tool, you can engraving, drill, milling, etc., without having to clamp the semi-finished product again to another machine for drilling, etc., and to improve efficiency.

The Technical Parameters of CK-1530 Double-Knife CNC Wood Lathe With Automatic Feeding

| Model | CK-1530-2A |

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

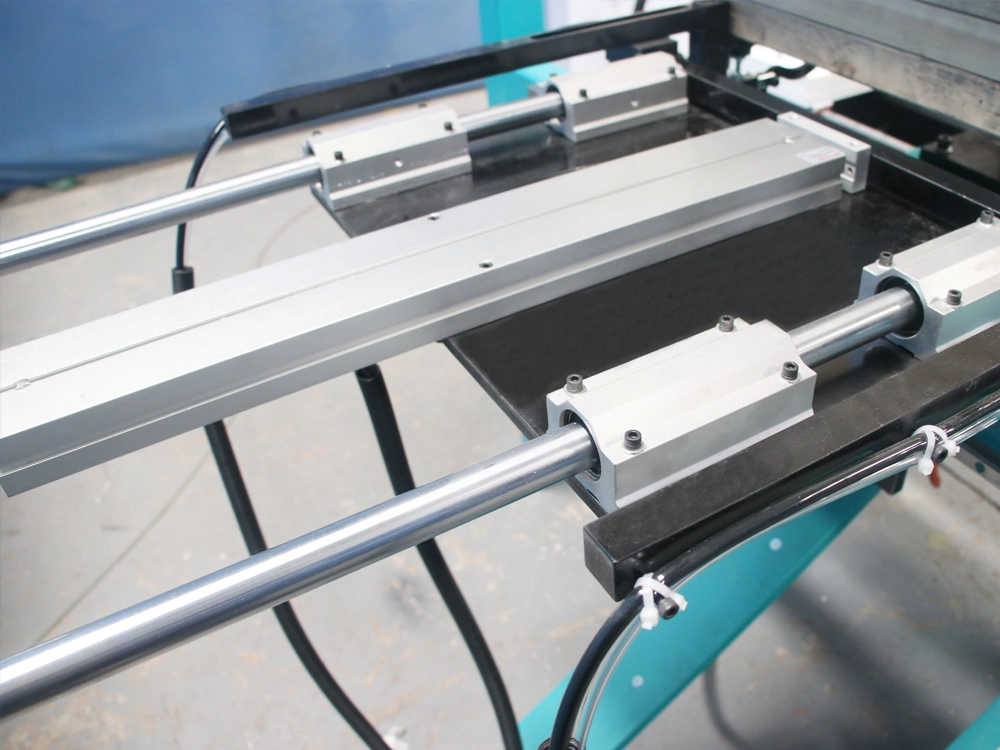

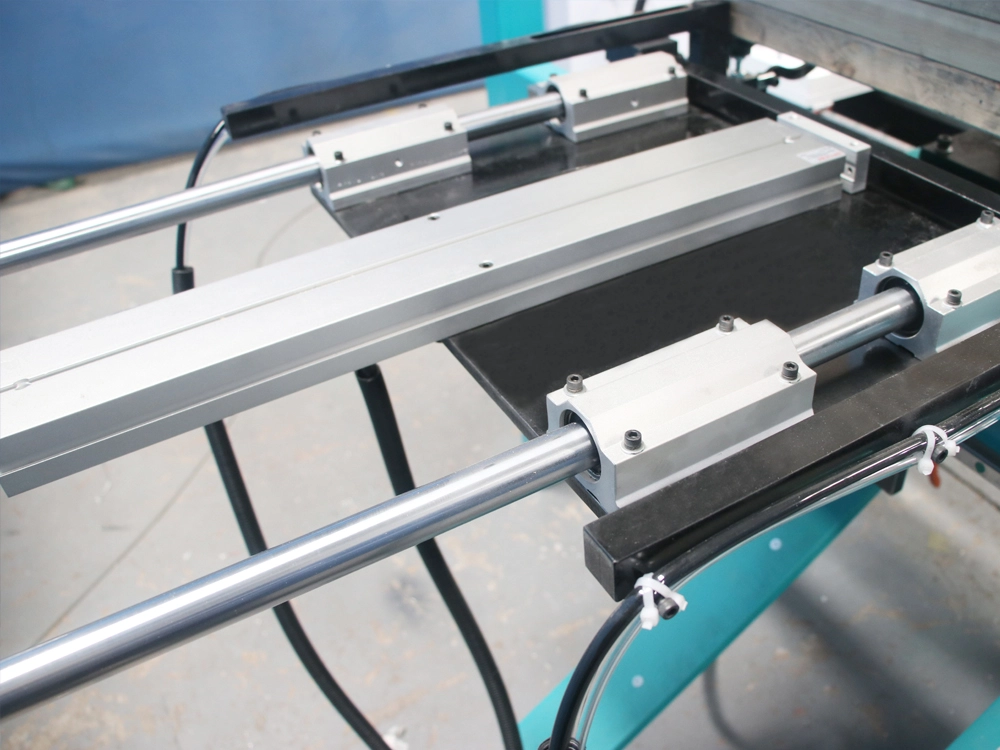

| Transmission Mode | XY axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*2150*1650mm |

Application Scope of Double-Knife Automatic Feeding Wood CNC Turning Machine

- Various furniture parts: Wstair railings, table and chair legs, children's bed posts, sofa legs, etc.

- Various decorative wooden products: Wwooden vases, wooden table lamps, candlesticks, vases, etc.;

- Other industries: Wbaseball bats, wooden handles, drumsticks, pillars, rolling pins, etc.;

If you are not sure whether your product can be processed on this lathe, you are welcome to fill in your contact information in the "Request for Quote" form and our sales specialist will provide you with professional advice.

The Following Are the Processable Products of Double-Knife Wood Lathe With Automatic Loading & Unloading

The Operation Sequence of Automatic Feeding CNC Woodworking Lathe Processing

- Feeding device adjustment: When preparing for processing, first adjust the feeding device of the machine to the state that matches the size of the wood to be processed, and adjust the corresponding cylinder position and center position respectively.

- Parameter setting: According to the size of the processed product, set the appropriate number of layers, match the appropriate speed and air pressure, and then copy the finished drawings to the control system through the USB flash drive.

- Tool calibration: Perform tool calibration on the machine, select the handwheel, use the handwheel to move the tool to the position to be processed, and then set the zero point on the control system.

- Start processing: Click Start, the machine can start fully automatic processing, the infrared sensor switch of the machine will automatically detect the amount of raw materials in the silo, if the remaining wood is not enough to continue processing, the machine will automatically pause. After continuing to put materials into the silo, the machine will automatically continue processing.Infrared sensor switches are installed on the XYZ axis and silo of the machine. During processing, if the processing range of the machine exceeds the safe range, the CNC woodworking lathe will automatically pause processing and alarm. At this time, you only need to cancel the alarm to resume normal processing, effectively preventing the risk of collision of the machine and ensuring safe use.

| Model | CK-1530-2A |

|---|---|

| Processing Dimensions | 1500 * 300mm (customizable according to processing requirements) |

| Bed | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 5.5KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

| Transmission Mode | XY axis 25 TBI high-precision ball screw, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high-precision 25 straight square rail / 25 flange slider |

| Equipment Cable | Pure copper anti bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Loading & Unloading Device | Multi-linked cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00,mmg,plt |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1900kg |

| Dimensions | 3100*2150*1650mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.