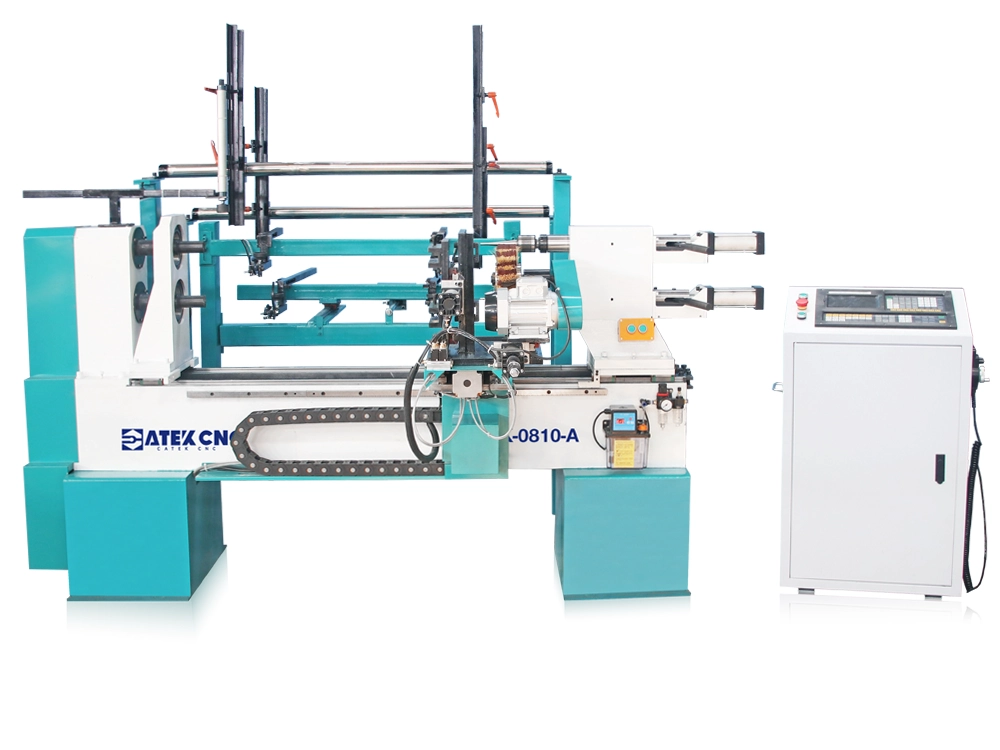

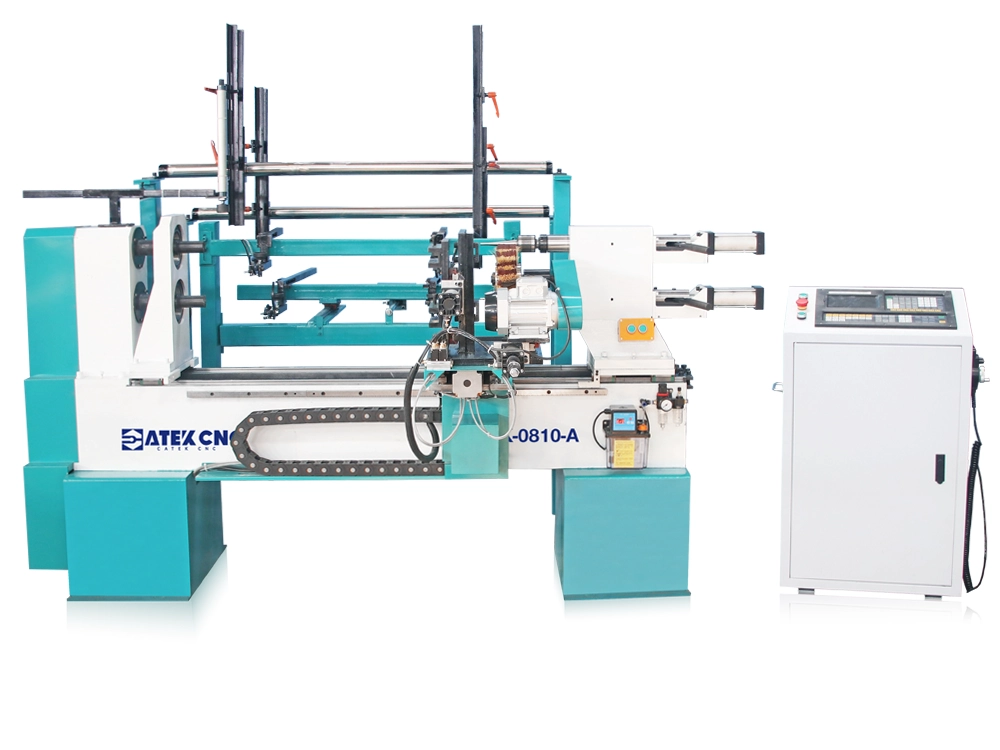

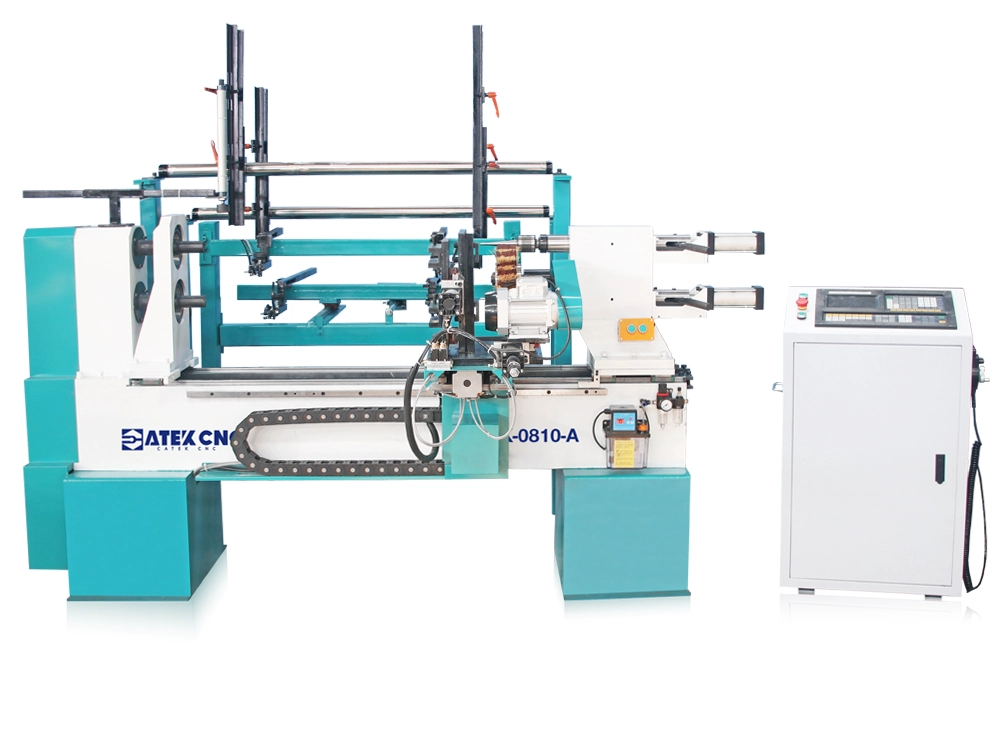

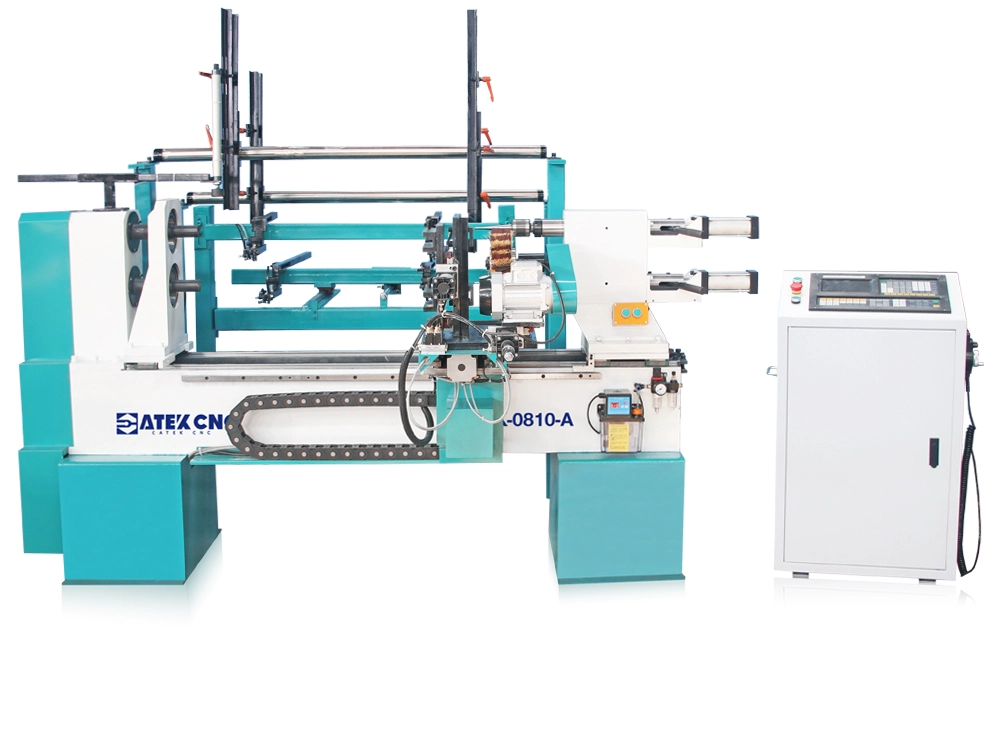

2-Station CNC Wood Lathe Suitable for Small Factories and Woodworking Workshops

Small 2-Station CNC Wood Lathe With Automatic Feeding and Sanding Device

[Function Description]

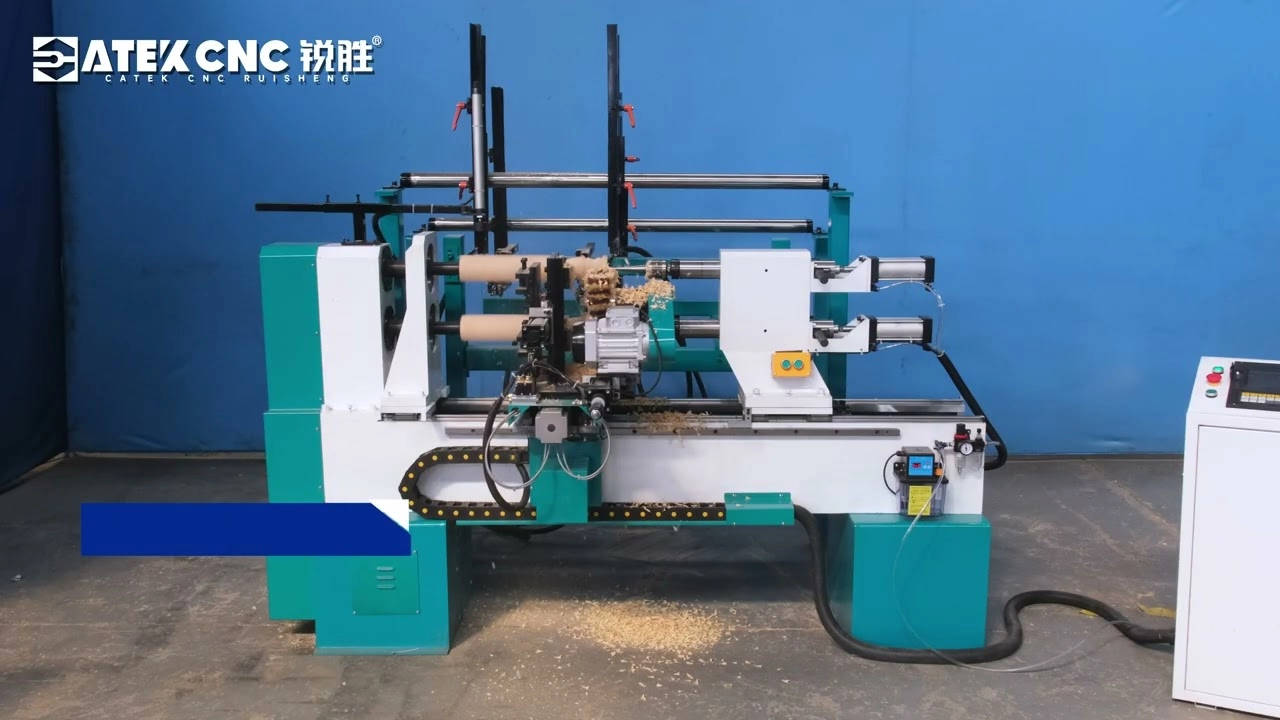

The 2-station mini CNC wood lathe with automatic feeding device and sanding device is designed for small production workshops with batch order production and factories with limited space. It is equipped with 800mm processing length and the ability to process two 100mm diameter workpieces at the same time, and on this basis, a specially customized automatic feeding device and sanding device are added. Cnc wood lathe During processing, automatic feeding is carried out through two independent silos. Each silo can hold multiple pieces of wood at a time. The wood is automatically fed into the processing area through the automatic feeding device. The machine automatically starts turning and the sanding device is started at the same time. Turning and sanding can be set to be carried out at the same time, or turning and sanding can be carried out separately. After all the wood in the silo is processed, the silo sensor senses that the wood is exhausted and the machine will automatically pause. After adding wood to the silo, press the continue button and the machine can continue to work.

The automatic feeding device greatly saves manual labor and improves processing efficiency. Traditional ordinary CNC woodworking lathes require manual work to find the center points of both ends of the wood, and then manually align and fix the wood. The time for fixing the wood alone takes up one-third of the working time. The use of an automatic feeding device can save the time for fixing the wood. It is only necessary to put the wood into the hopper at regular intervals. One person can operate 3-5 machines. At the same time, the machine is equipped with a sanding device, which can sand the workpiece while turning, saving subsequent sanding time. It only takes 1 minute to complete the manufacture of two 750mm*60mm conical table legs. The average daily output can reach more than 1,000 legs, which far exceeds the efficiency of manual processing. It not only saves manual labor and improves processing efficiency, but also effectively reduces production costs.

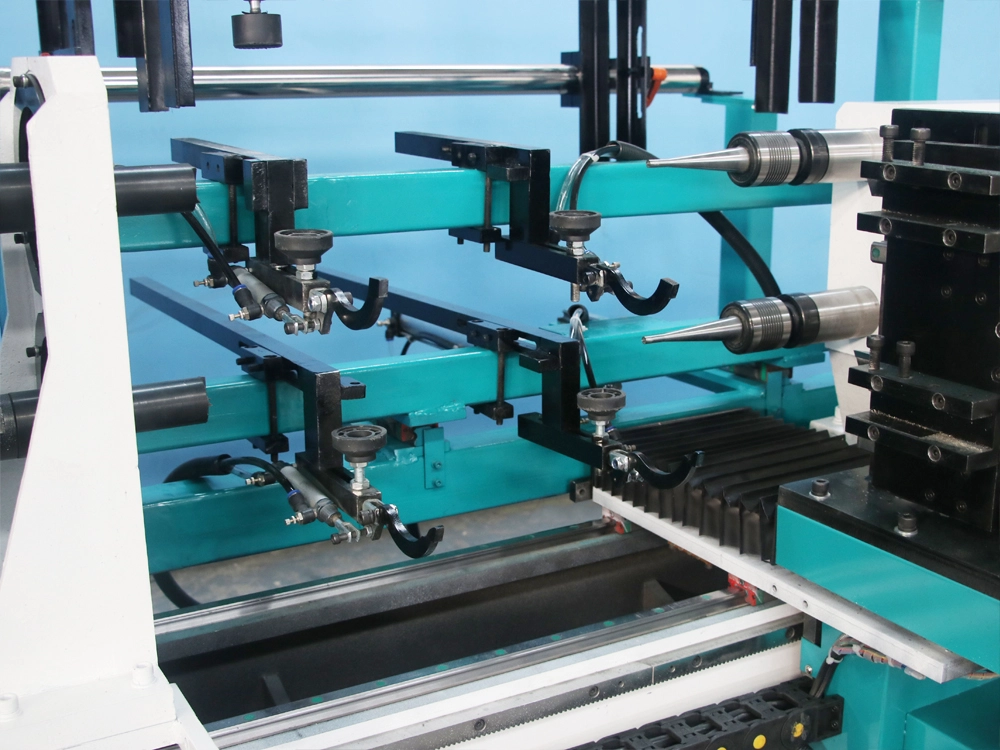

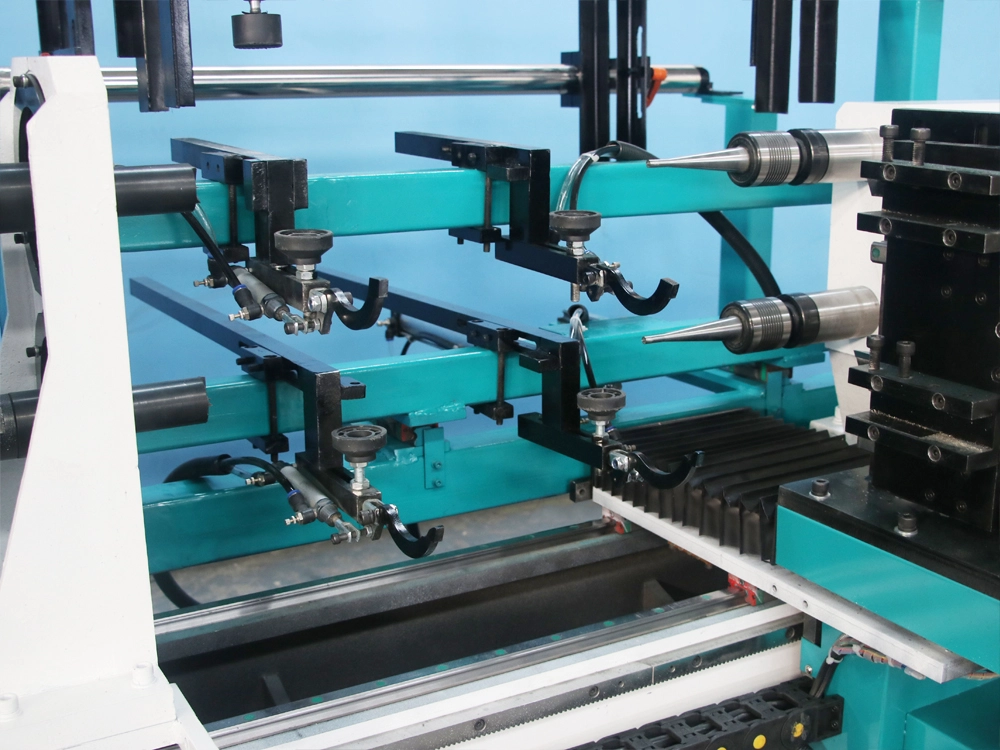

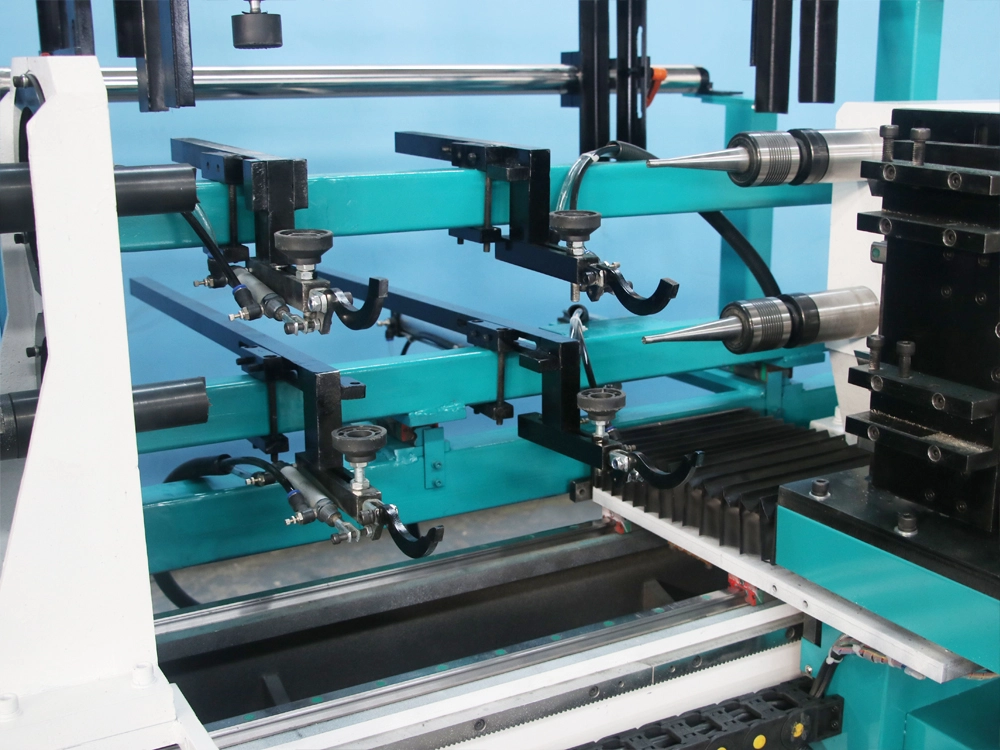

How Does the Automatic Feeding Device of the 2-Station Automatic Feeding CNC Wood Lathe Work

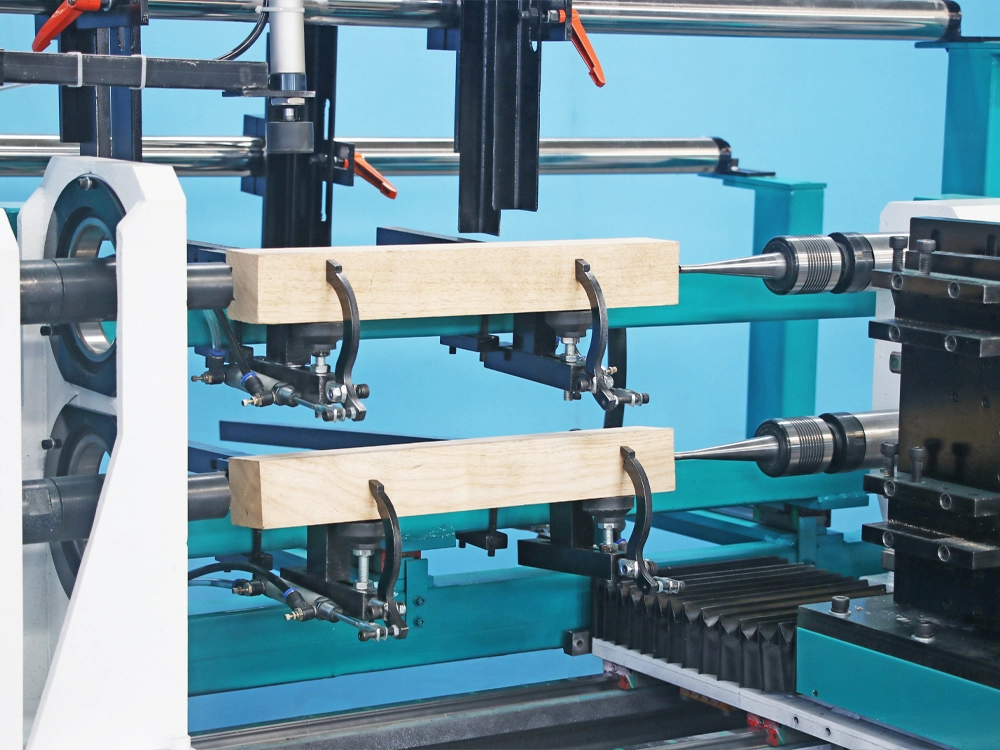

The 2-station automatic feeding device is equipped with two independent silos, two independently adjustable feeding devices and a unified material unloading device. Before processing, the silo and feeding device are adjusted according to the required wood size. After the adjustment is completed, the raw materials to be processed are placed in the silo, and the machine's tools are calibrated before it can start running. During operation, the two feeding devices simultaneously push the wood in the silo through the cylinder and automatically send it to the processing position. After the wood arrives at the processing position, the fixing device automatically fixes the material to the processing position to start processing. After processing is completed, the material unloading device automatically unloads the processed workpiece, automatic loading → automatic processing → automatic unloading. The entire processing process is fully automatic and cycled without human intervention, which can greatly improve processing efficiency and reduce costs.

Advantages of 2-Station Small CNC Woodworking Lathe With Automatic Feeding and Sanding

- The whole machine uses a thickened cast iron bed, the spindle box has three built-in ball bearings, the rear tailstock uses a Morse rotary center top, and the weight of the whole machine is more than 1200kg.

- Two independent silos and independent feeding devices can be freely adjusted, flexible and convenient to use.

- 800mm processing length, two stations can process 100mm diameter at the same time, a single station can process 200mm diameter, and can process workpieces of various sizes.

- CATEKCNC self-developed CNC system, supports various nc/txt/tap/dxf/dbf files, and can automatically convert plane curve files into G code when using dxf/dbf files, simplifying the operation steps and making it easier to get started.

- Automatic lubrication device, which can automatically lubricate and maintain the transmission parts of the machine at regular intervals without manual maintenance.

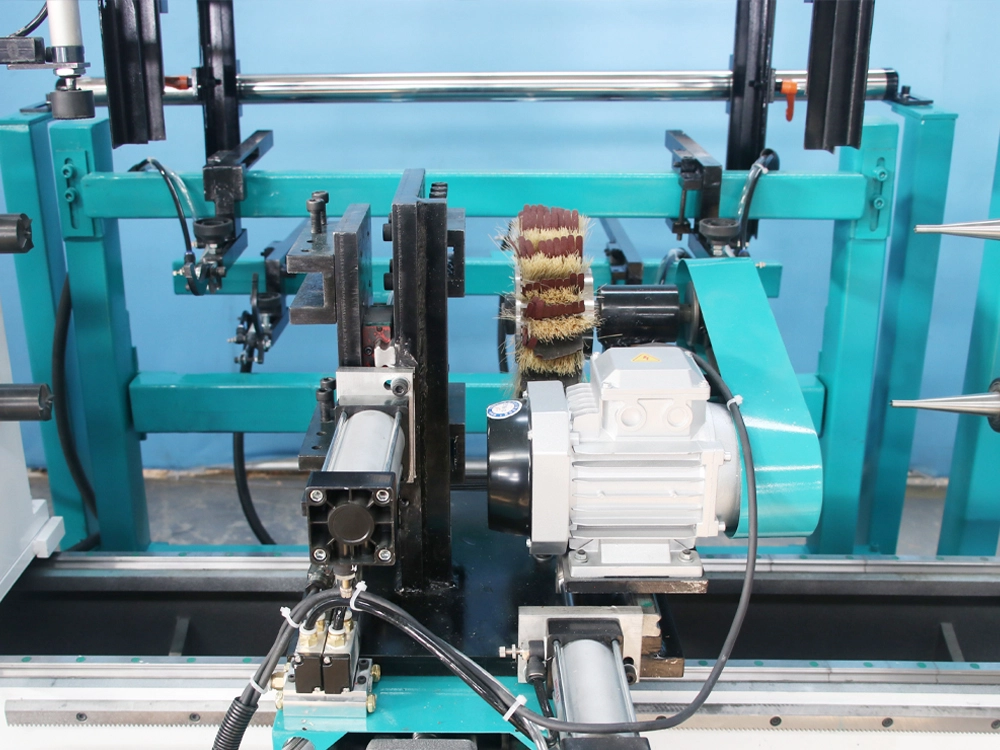

- Independent sanding device, driven by a 370w high-speed motor, the sanding wheel sandpaper can be freely changed, the number of sanding times, and the sanding depth can be freely set.

- Equipped with a central support frame, it can be used to process slender products to prevent the slender products from shaking during processing, resulting in material waste.

Photos of a 2-Station Small CNC Wood Lathe With Automatic Feeding and Sanding

- 2-station automatic feeding device

The specially designed 2-station automatic feeding device can be freely adjusted according to the size of raw materials and is easy to use.

- Independently controllable sanding device

The sanding wheel can be driven and operated independently, the sanding work can be set separately, the sanding times and sanding depth can be set, and it is easy to use.

- Automatic lubrication system

Fully automatic lubrication of the transmission parts of the machine, no manual lubrication required.

- Transmission system

Taiwan Hiwin guide rails/sliders, high-precision helical racks/gears, high positioning accuracy and fast moving speed.

- CK-1000TC CNC system

Built-in macro program, supports various CAD/CAM software, full English interface, simple operation, easy to use.

Technical Parameters of 2-Station Mini CNC Wood Lathe With Automatic Feeding and Sanding

| Model | CK-0810-A2 |

|---|---|

| Working Size | 800mm length * 100mm diameter * 2 (processing size can be customized) |

| Bed Base | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Drive Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

| Sanding | 370W high speed motor, 230mm*50mm sanding wheel |

| Transmission Mode | X axis 25 TBI ball screw transmission, Z axis uses high-precision helical rack |

| Guideway | Taiwan Hiwin high precision linear guide rail / flange type linear bearing |

| Equipment Cable | Highly flexible pure copper anti-bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Loading and Unloading Device | 2-station multi-link cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, solidworks, UG, powermill, etc. |

| Security System | XZ two-axis photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Dimensions | 2300*2250*1750mm |

| Weight | 1200kg |

What Products Can the 2-Station Automatic Feeding CNC Wood Lathe Be Used to Process

Wooden table legs, chair legs, bed legs, sofa legs, tapered table legs, round bars, wooden sticks, wooden sticks, wooden pillars, support pillars, baseball bats, coat racks, wooden handles, handles, furniture accessories, stair columns, Roman columns, rolling pins, wooden accessories, wooden crafts, wooden vases, pen holders, wooden bowls, wooden cups and other wooden products as well as other non-wood products such as plastic, pvc, acrylic, resin, plaster, asbestos, etc.

| Model | CK-0810-A2 |

|---|---|

| Working Size | 800mm length * 100mm diameter * 2 (processing size can be customized) |

| Bed Base | Heavy-duty integral casting bed, independent anti-interference control cabinet |

| Motor | 4KW three-phase asynchronous motor |

| Motor Speed | 0-6000rpm |

| Drive Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST/Hpmont inverter |

| Sanding | 370W high speed motor, 230mm*50mm sanding wheel |

| Transmission Mode | X axis 25 TBI ball screw transmission, Z axis uses high-precision helical rack |

| Guideway | Taiwan Hiwin high precision linear guide rail / flange type linear bearing |

| Equipment Cable | Highly flexible pure copper anti-bending cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Loading and Unloading Device | 2-station multi-link cylinder loading system (simple and easy to use) |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, solidworks, UG, powermill, etc. |

| Security System | XZ two-axis photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Dimensions | 2300*2250*1750mm |

| Weight | 1200kg |

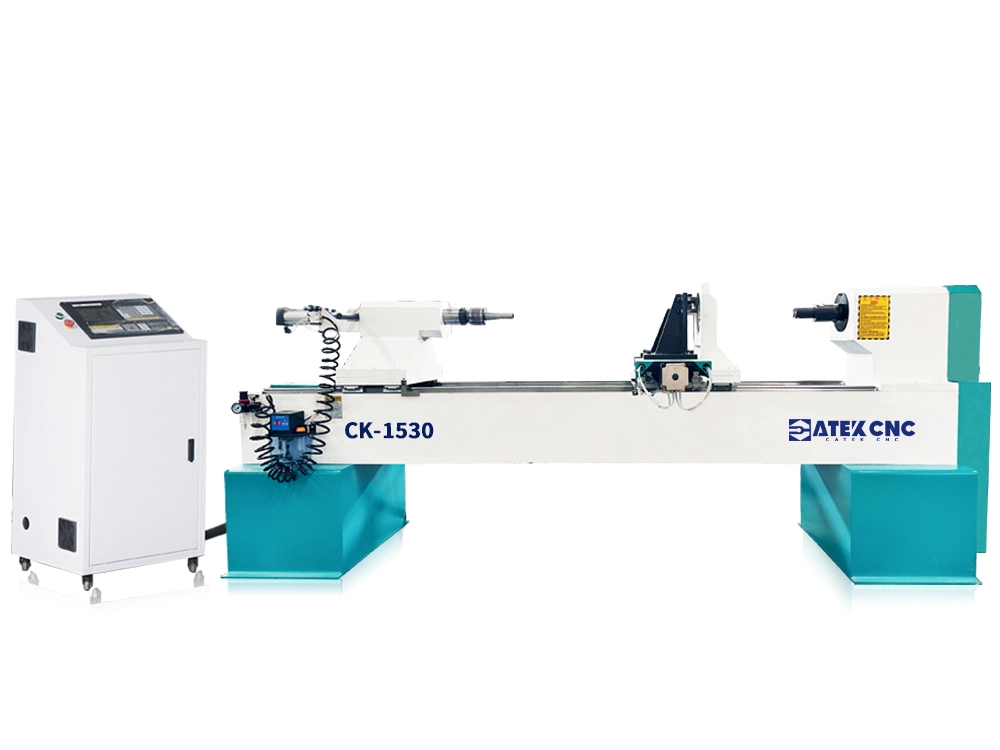

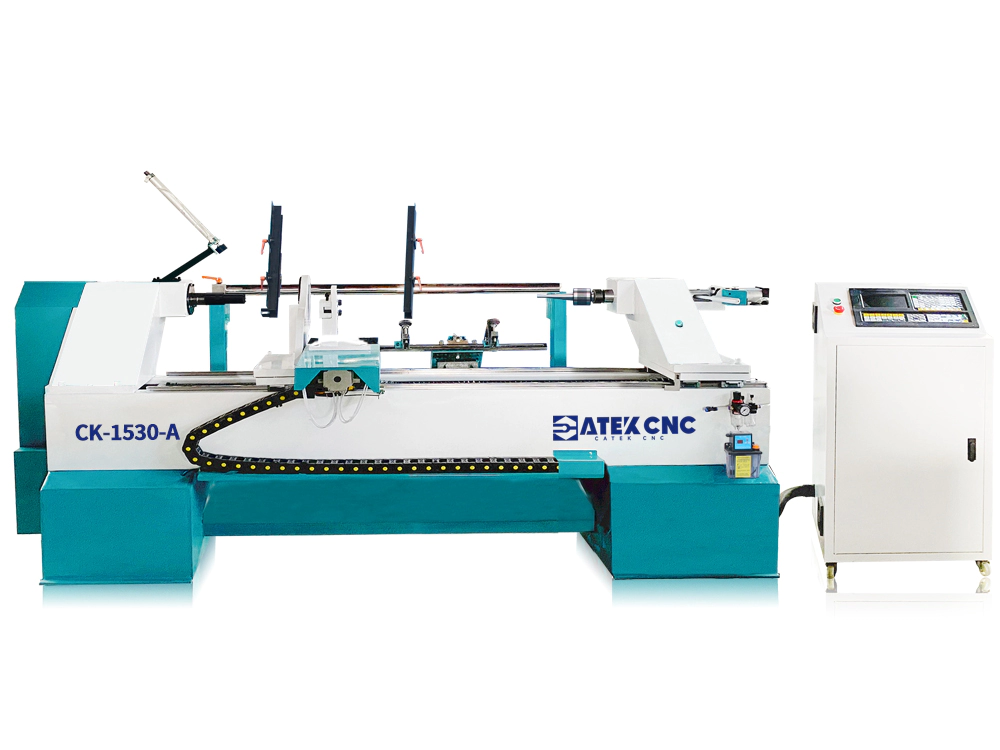

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.