6-Station Wood Engraving Machine Suitable for Batch Machining

Multi-Head CNC Router for Engraving of Multiple Wood Panels

[Function Description]

Multi-head CNC wood router is very versatile and can be used to process all kinds of furniture, furniture fittings, handicrafts, decoration materials and so on. You can customize the machine in multiple angles according to the actual production requirements. Whether the length is 3 m, 4 m, or the width is 1.5 m, 2 m, the processing size can be tailored according to your requirements. The number of spindles of the machine also supports customization, from one spindle, two spindles, to six, eight, and up to 20 spindles at the same time. By installing multiple spindle motors, the Multihead CNC Woodworking Engraving Machine is able to engrave and process multiple identical workpieces at the same time, significantly improving processing efficiency. Multiple spindles can be operated simultaneously to process the same workpiece, or only one or two spindles can be activated to produce a small amount of work, which makes it very flexible to use.

Advantages of Multi-Spindle CNC Router Machine

- Equipped with multiple high-power high-speed water-cooled spindles with a maximum speed of 24000r/min, it can quickly process raw materials. (We can also use air-cooled spindles for you according to your needs)

- It can process multiple identical products at the same time, and can adjust the processing according to the product size. It is very suitable for mass production, greatly improving processing efficiency and ensuring product consistency.

- Aviation-grade T-slot aluminum alloy workbench, with the clamp, the product can be quickly fixed, easy to use, and vacuum adsorption table or double-rod pneumatic roller can be added according to requirements.

- Taiwan Hiwin guide rails/linear bearings, XY axis uses high-precision helical racks, Z axis uses high-precision TBI ball screws, and processing is fast positioning.

- Use heavy-duty thickened square steel welded bed, integrated high-temperature tempering square steel gantry, thickened aluminum alloy spindle hanging plate, processing and use are more stable.

- DSP control system, no need to connect to a computer, simple to use, support advanced functions such as power-off processing, compatible with jdpaint/type3/artcam and other types of software, and run using G code.

- All spindles can be used simultaneously or individually, with intelligent control, flexible and convenient to use.

Details of CNC Router with Multiple Spindle

- Water-cooled spindle

-

The standard model uses a high-speed water-cooled spindle and water circulation cooling, which has good heat dissipation performance and is more suitable for long-term continuous work.

- Workbench

-

The T-slot workbench is easy to use and can fix any workpiece regardless of its size.

- Lubrication system

-

The automatic lubrication system automatically and regularly lubricates all transmission parts of the machine to prevent inadequate lubrication due to manual lubrication.

- DSP control handle

-

DSP control handle is simple to use and easy to operate, and novices can easily start and run the machine.

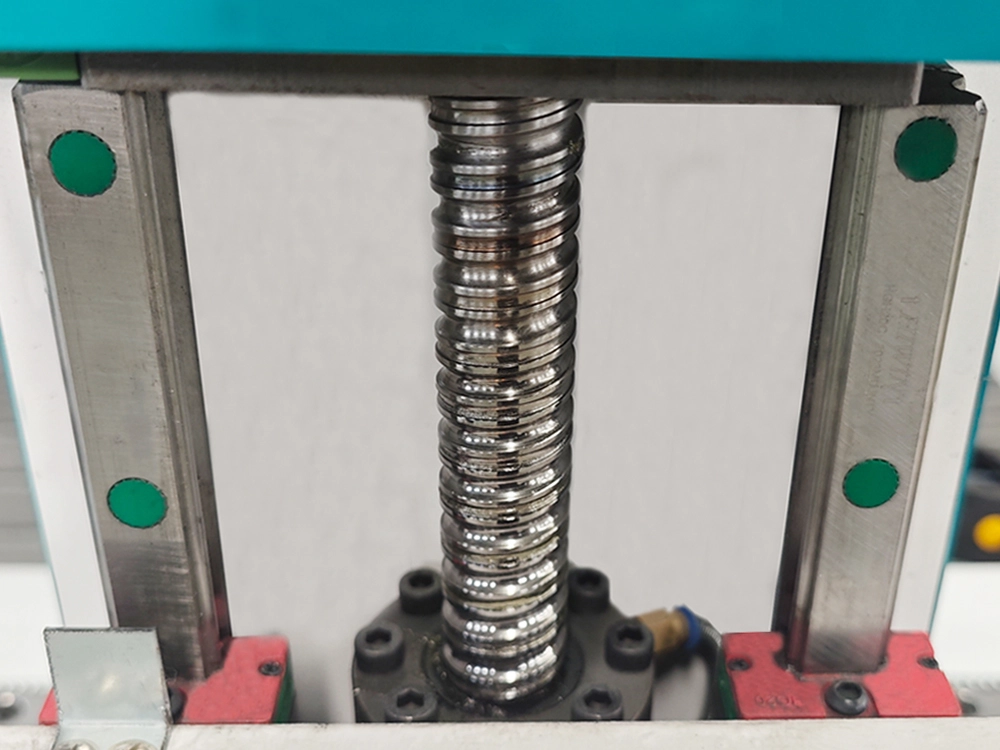

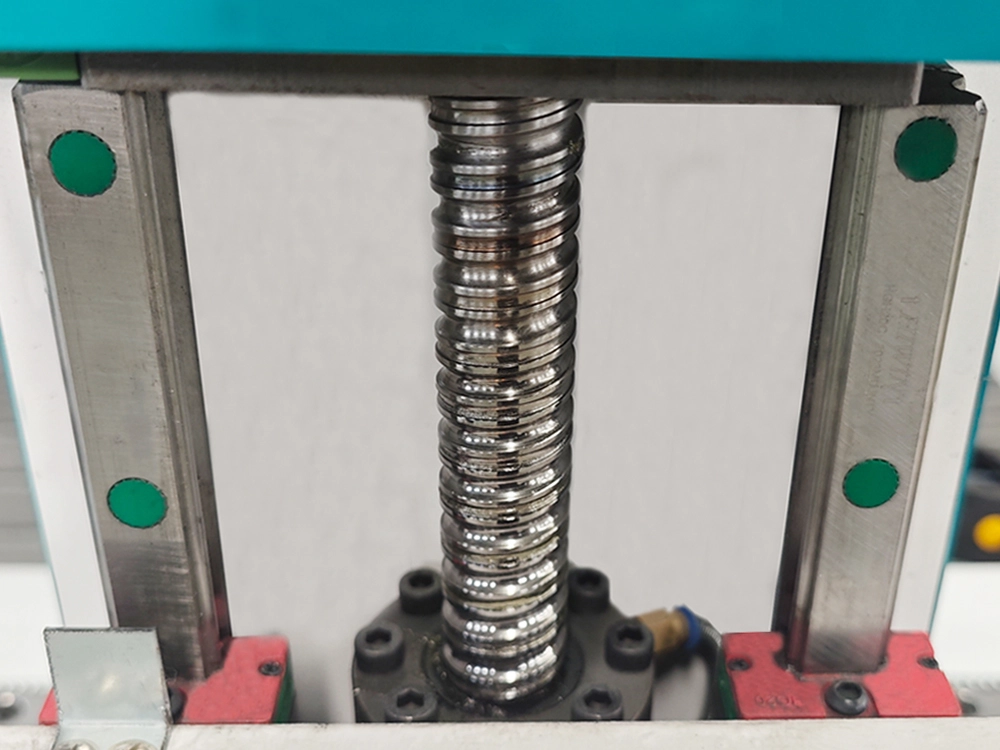

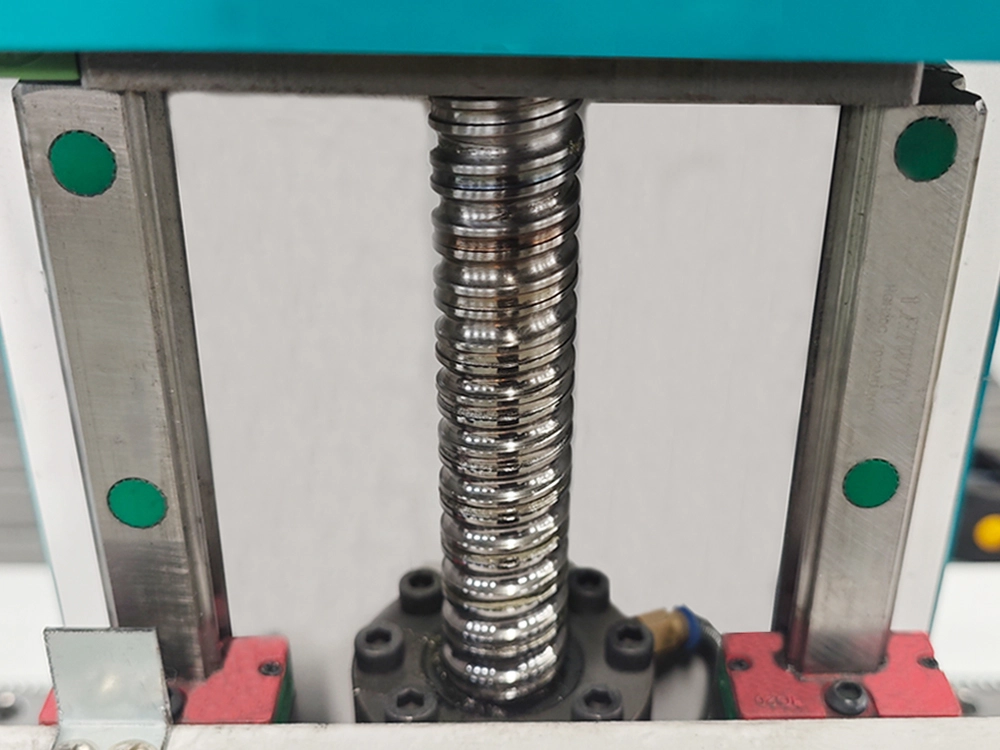

- TBI high-precision screw

-

TBI high-precision screw, accurate positioning.

- Transmission system

-

Taiwan Hiwin guide rails, sliders, high-precision helical racks, fast running speed and high precision.

- Multi-head CNC router with optional vacuum adsorption workbench

-

Optional vacuum adsorption workbench to quickly adsorb and fix the plate.

- Customized four-spindle router

-

A custom-made machine with four spindles that can process four products at a time.

Technical Parameters of CNC Routers That Can Process Multiple Parts at a Time

| Model | CK-2030-6 |

|---|---|

| Machining Capacity | 2000*3000*200mm (processing size and quantity can be customized) |

| Bed | The bed by machining center processed (heavy duty bed), independent control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | CATEKCNC dedicated 3.5KW high-speed water-cooled spindle * 6 (spindle quantity / power can be customized) |

| Spindle Speed | 6000-24000r/min |

| Table | Aluminum alloy T-slot table |

| Transmission Mechanism | XY axis high-precision ground helical rack + Z axis high-precision TBI ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc. |

| Control System | NCStudio v5.4.49 (support resuming carving after power outage) / Mach3 |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks, UG, powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Rapid Traverse Speed | 25000mm/min |

| Max. Working Speed | 18000mm/min |

| Weight | 2400kg |

| Dimensions | 3600*2500*1650mm |

Multi-Head CNC Router Optional Configuration

| Control System | Richauto DSP controller/mach3/NCStudio etc. |

|---|---|

| Spindle | 1.5/2.2/3.5/4.5/6/7.5 etc. air-cooled, water-cooled variable frequency spindle. |

| Table | Vacuum adsorption platform/double rod pneumatic pressure roller |

| Drive motor | Yaskawa/Delta and other servo motors |

Application Scope of CNC Routers for Woodworking Suitable for Batch Production

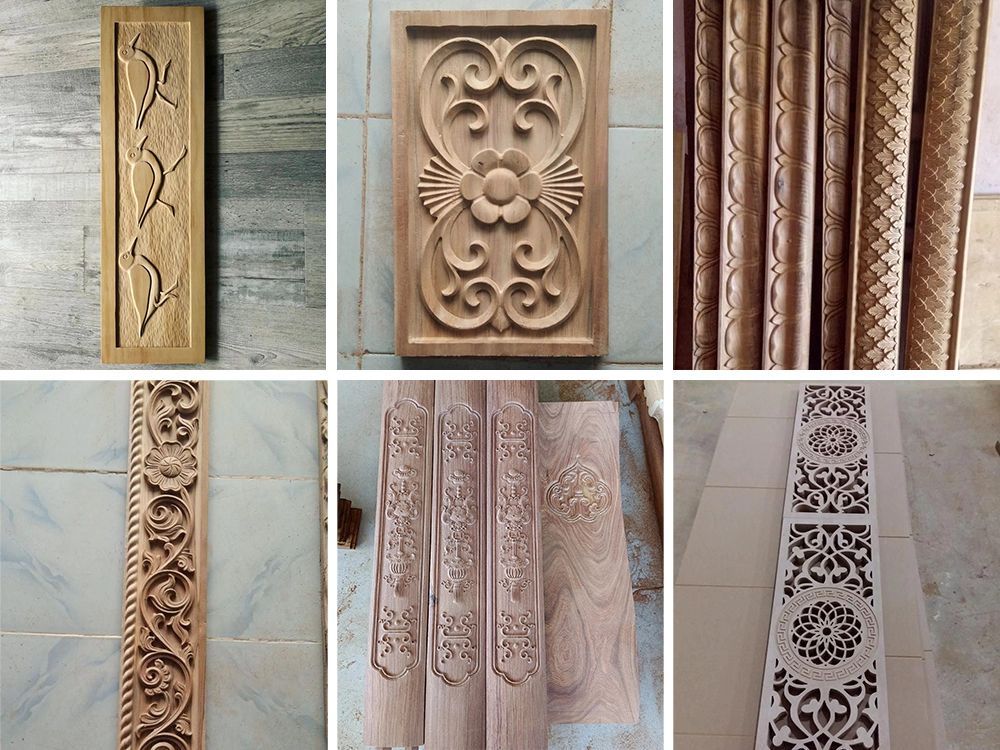

- Furniture: wooden furniture carving, board cutting, board punching, grooving, decorative board carving, classical furniture, bookshelves, antique furniture, European furniture, cabinet doors, screens, tables and chairs, sofas, mahogany furniture, carved furniture, tea trays, plaques, screens and other product processing.

- Crafts: wooden signs, portraits, decorations, wooden door decorations, three-dimensional reliefs, hollow carvings, advertising light boxes, density board reliefs, parts cutting, drilling and other products.

The Following Are the Processable Products of Multi-Head CNC Router

| Model | CK-2030-6 |

|---|---|

| Machining Capacity | 2000*3000*200mm (processing size and quantity can be customized) |

| Bed | The bed by machining center processed (heavy duty bed), independent control cabinet |

| Gantry | Thickened cast iron gantry, thickened cast iron bracket |

| Spindle | CATEKCNC dedicated 3.5KW high-speed water-cooled spindle * 6 (spindle quantity / power can be customized) |

| Spindle Speed | 6000-24000r/min |

| Table | Aluminum alloy T-slot table |

| Transmission Mechanism | XY axis high-precision ground helical rack + Z axis high-precision TBI ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc. |

| Control System | NCStudio v5.4.49 (support resuming carving after power outage) / Mach3 |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks, UG, powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Rapid Traverse Speed | 25000mm/min |

| Max. Working Speed | 18000mm/min |

| Weight | 2400kg |

| Dimensions | 3600*2500*1650mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.