Basic Introduction of Pool Table Legs

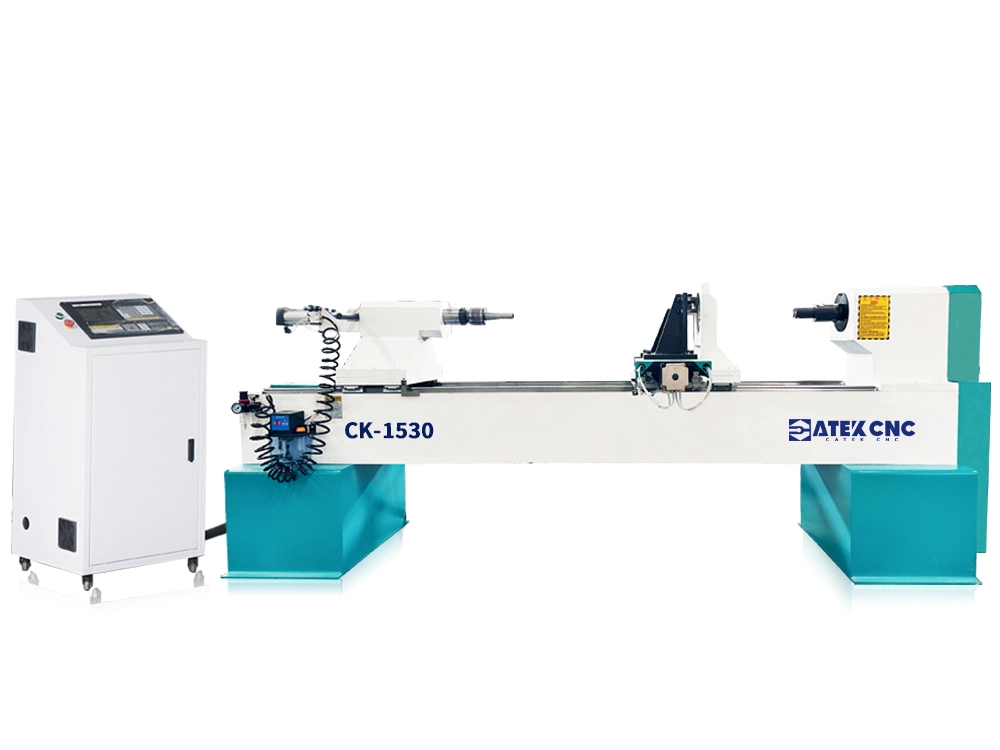

The diameter of a pool table leg is generally about 170mm and the length is about 760mm. The processing size of the standard 1530 series CNC wood lathe is 1500mm in length and 300mm in diameter, so this series can be used to perform all-round processing and machining of pool table legs.

The materials used to make pool table legs are generally solid wood materials such as rubber wood, but there are also some special materials, such as MDF, or some pool table legs made of metal.

The cutting tools used for billiard table legs vary depending on the processing technology and shape. The cutting tools must be specially customized according to the shape of the table leg surface to meet different processing requirements.

There are many types of lathes that can be used to make pool table legs. You need to choose the appropriate model according to the process of the product to be processed.

The shape of the legs of this type of pool table is relatively simple, and the recommended model is: CK-1530 and other CNC wood lathes with basic turning functions.

The shape of this type of table legs is relatively complex, and multiple processes are required for processing, including turning, milling, planing and other functions. Recommended models: CK-1530-3T, CK-1530-4T, etc.

Pool Table Leg processing

The following will take this type of billiard table legs as an example:

Fix the wood on the CNC wood lathe, and fix the two ends with a four-jaw chuck and a Morse pin respectively.

Note: When processing billiard table legs, the wood speed should be controlled below 2000r/m, and the air pressure should be adjusted to above 0.6mpa, because this type of product is heavy, and excessive speed or low air pressure can easily lead to dangerous situations.

Import the turning shape drawing into the machine, and perform shape cutting on the wood. The machine can automatically process the wood in layers according to the drawing, and the wood is processed to the corresponding size and shape.

Use a planer tool (Our multi-functional CNC wood lathes are standardly equipped with large independent planer cutters for enhanced machining capabilities) to process, move the planer to the wood processing position, plan the raw material, and automatically rotate the angle according to the drawing to process the wood into six faces or other types of polyhedrons.

Grooving is performed using a high-speed air-cooled multifunctional -spindle. A multi-function spindle is equipped with tooling matching the profile of the required groove, then through pre-programmed instructions, the machine precisely cuts the groove into the wood according to the technical drawings.

These three machining steps can be programmed on the CNC lathe to enable complete automatic process switching, allowing turning, milling, and grooving operations to be completed in a single clamping.

Pool Table Leg processing notes

During the processing, the processing speed can be adjusted in real time according to the processing effect, and the processing amount can be adjusted appropriately according to the processing depth.

TThe desired processing shape can be designed into corresponding technical drawings as needed, and the machine can interpret standard G-code to execute precision machining according to the programmed instructions.

CNC wood lathes can use a variety of software to draw drawings for processing, such as: Powermill, JDpaint, Artcam, Mastercam, UGNX, SolidWorks and other types of CNC software.

CATEKCNC can provide you with a full range of CNC solutions, including billiard table legs, billiard table tops, and other types of solid wood accessories for billiard tables.

Whether you're a CNC expert or a beginner, we provide 24/7 support services. Should you have any technical inquiries, our team is readily available for consultation.