Using CNC wood lathes to make tables, chair legs or accessories is a very common application of CNC wood lathes. Some simple chair legs generally only need to be turned or slotted, while more complex special-shaped furniture legs require turning, milling, slotting, drilling and other functions to complete.

In modern furniture design, chairs are beginning to be designed more and more simple, and the process is relatively more and more complicated, which requires the machine functions of furniture making to be more perfect and meet more processing needs.

CNC wood lathes are not only capable of processing completely symmetrical wooden stick parts, they can also produce special-shaped parts with high processing difficulty, such as European chair legs, curved chair legs, etc.

If a European curved chair leg is processed by traditional manual processing, it takes about 50 minutes, while using a multi-functional CNC wood lathe such as CK-1530-7T, it only takes 2-3 minutes to complete, and it also includes subsequent processes such as sanding, which can greatly improve processing efficiency.

Chair legs requiring only turning

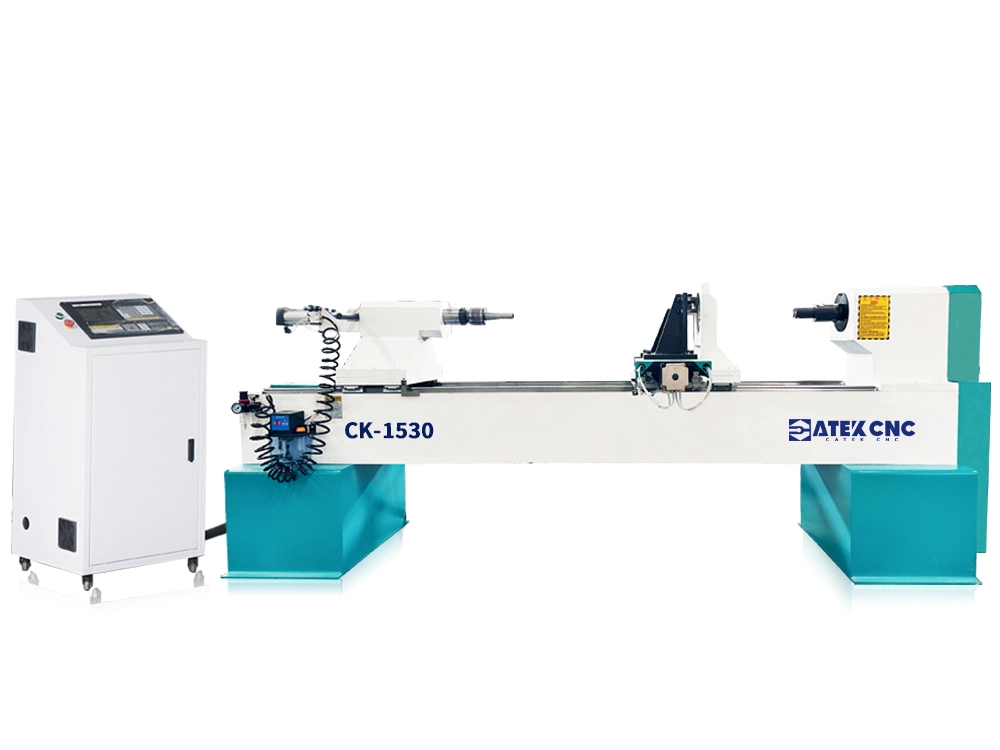

This type of table leg can be processed using any CNC wood lathe equipped with turning tools, including the compact CK-0820 model. Simply import a basic DXF/DBF file, and the CK-1000TC control system will automatically execute the turning operation. The entire machining process typically takes just 30 seconds to 1 minute to complete.

Chair legs requiring multifunctional spindle

Grooved table legs:

This type of table leg requires the coordinated use of turning tools and the spindle. First, the turning tool is used to shape the external profile. Then, the spindle clamps a grooving tool to create grooves on the pre-shaped profile. This combined machining process enhances the aesthetic appeal of the table leg.

To machine such legs, you need a Combined CNC wood lathe. This allows the material to be completed in a single setup—both the external turning and grooving processes are finished in one operation. Similar to turning the profile, grooving only requires simple 2D drawings (such as DXF or DBF files). Using the CK-1000TC control system, you can set the angle, length, and quantity of the grooves, making the grooving operation straightforward. The entire machining process typically takes just 1–2 minutes to complete.

Carved table legs:

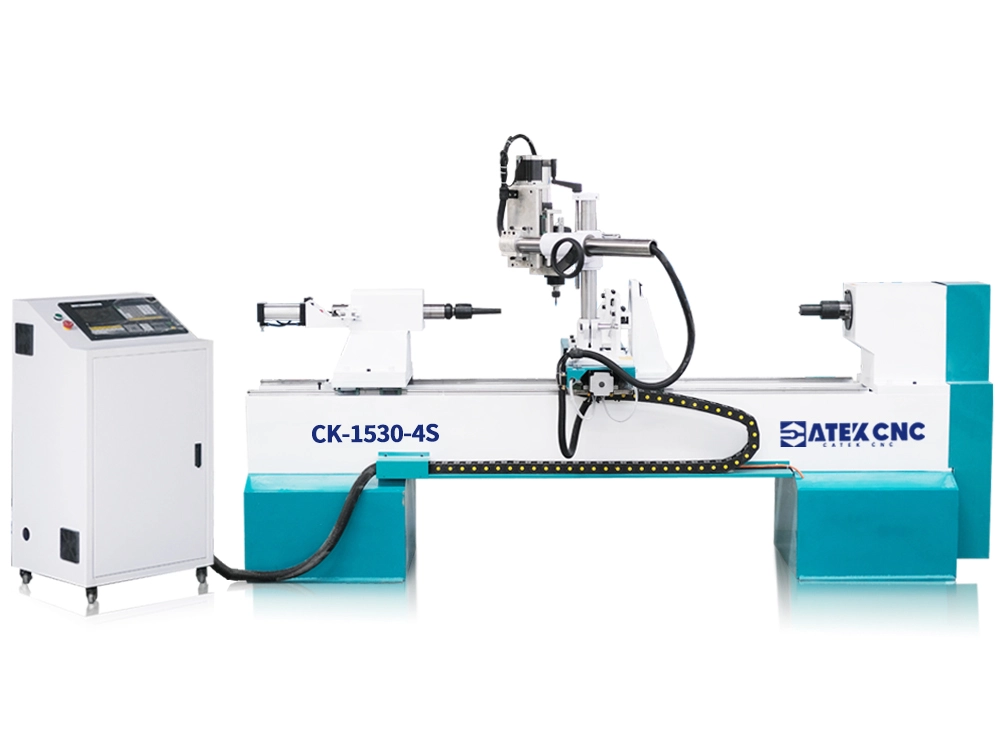

This type of table leg requires machining with a multifunctional spindle engraving function. The process generally begins with roughing using a large-diameter milling cutter to remove excess material, followed by switching to a fine engraving tool for detailed carving.

Processing such legs necessitates the use of STL-format 3D model files. Software like ArtCam or PowerMill can convert the model into NC or TAP format programs based on the wood material dimensions for machining. The entire process typically takes 30 minutes or more to complete.

Milled table and chair legs:

This type of table leg requires the use of milling or planing tools for processing. Through the high-speed rotation of the spindle or motor, the wood is milled into the desired shape according to the design path.

Similar to other type legs, machining these legs also requires STL-format 3D model files. CAD/CAM software is used to convert the model into NC programs, which are then executed by the control system to operate the machine. The entire process typically takes approximately 5 minutes to complete.

Planed table and chair legs:

This type of table and chair legs requires the use of planing tools to perform surface planing on wood. During the planing process, the control system precisely regulates the depth and angle of the cut, enabling the completion of various planing tasks and enhancing the aesthetic appeal of the legs. This machining operation typically takes approximately 3-5 minutes to complete.

Composite type table legs:

This type of table and chair legs usually requires a combination of multiple functions such as shape turning, milling, drilling, grooving, etc., which are controlled by the control system. Each function is automatically switched according to the program to complete various complex table and chair legs required in furniture.

By combining the functions of CNC woodworking lathes, such as turning, milling, drilling, and slotting, the shape, mortise, and tenon grooves of table and chair legs can be processed. For example, when using the CK-1530-7T CNC wood lathe, the machine is equipped with an automatic feeding function for automatic loading. After loading, the turning tool is automatically used for shape turning, and then the spindle is used for slotting and drilling. At the same time, the product is polished with a sanding wheel after processing. All processes of the product can be processed at one time, effectively improving processing efficiency.

If you are not sure whether your product can be processed with a CNC woodworking lathe, you are welcome to consult CATEKCNC. We will handle it for you as soon as we receive your message and recommend the most suitable machine for you according to your needs.