Although the structure of Matryoshka Doll looks simple, it still has considerable requirements for craftsmanship if it is made by traditional hand-made methods. The difficulty lies mainly in the nesting of the upper and lower parts of Matryoshka Doll. If the accuracy is not properly controlled, it will cause it to be unable to be inserted or too loose. Moreover, Matryoshka Doll is reduced layer by layer from large to small. In order to fit more dolls in a limited space, the wall of each layer of dolls must be thin enough, and the gap between each doll must be moderate. The diameter gap between adjacent dolls is generally about 1-2 mm.

With the popularization of CNC machine tools, CNC machine tools have great advantages over manual labor in processing such products with high precision requirements. As long as you have the corresponding drawings and set the machine parameters, the machine can process dolls with consistent precision.

Matryoshka Dolls Production Process

- Material selection

Since the interior of Matryoshka Doll needs to be hollowed out and the wall is very thin, soft wood, light weight, and not easy to crack should be selected. Generally, logs of broad-leaved trees are used, such as basswood, birch, alder, and poplar. Basswood is now widely used. The wood must be kept dry, so it is necessary to use wood that has been naturally air-dried for at least 2-3 years. Too wet wood is prone to deformation and cracking during processing. And the wood needs to avoid knots as much as possible, otherwise it will be difficult to process or cause uneven surfaces during turning.

- Cutting and turning

When processing Matryoshka Dolls, the integrity of the doll must be considered, so the upper and lower parts are typically made from the same piece of wood. After selecting suitable wood, a saw blade is used to cut the log into appropriately sized blocks.

The shape of a Matryoshka Doll is wider at the bottom and narrower at the top, with curves that must be smooth and natural. Dimensional errors must be minimized, and the fit between the buckle joint parts must be moderate. Turning is usually the preferred method for crafting them.

When using a manual lathe to make Matryoshka Dolls, the upper and lower parts are generally processed separately. During the machining of each part, the shaping is initially roughed out with material left for finishing. The focus of the process lies in hollowing out the interior and crafting the buckle joint sections. After both parts are completed, they are assembled, and the final shaping is carefully turned to achieve the overall form.

If a CNC wood lathe is used to produce Matryoshka Dolls, the upper and lower parts are also machined separately. However, due to the high precision of CNC lathes, both parts can be turned to completion in a single operation, eliminating the need for secondary assembly and turning. The upper part is processed first, using a turning tool to shape the doll's head, followed by a boring tool to hollow out the interior. The lower part is processed similarly, with the addition of turning the ibuckle joint section.

- Polishing and painting

Use CNC lathe sanding equipment or hand to carefully polish the Matryoshka Doll to remove the knife marks and defects on the wood surface caused by the turning process. Generally, a layer of primer is also required on the Matryoshka Doll. So far, the woodworking part is over.

- Pattern drawing, glazing, and drying

The next step is the soul of Matryoshka Doll: pattern drawing.

This requires the painter to have superb skills, accurate painting skills, and most importantly, to understand the traditional Russian patterns, patterns, characters, etc. Each Matryoshka Doll is unique.

After waiting for the pattern to be drawn and the ink to be completely dry, it is necessary to apply more varnish to the doll. Each layer will be air-dried for 4-5 hours or even a day to make the surface of the Matryoshka Doll smoother. In order to make it more beautiful, gold powder is sometimes used for decoration according to the style.

After all the production is completed, it can be taken to dry. In order not to damage the surface painting and paint, it is best to use natural air drying.

At this point, a beautiful and cute Matryoshka Doll is completed!

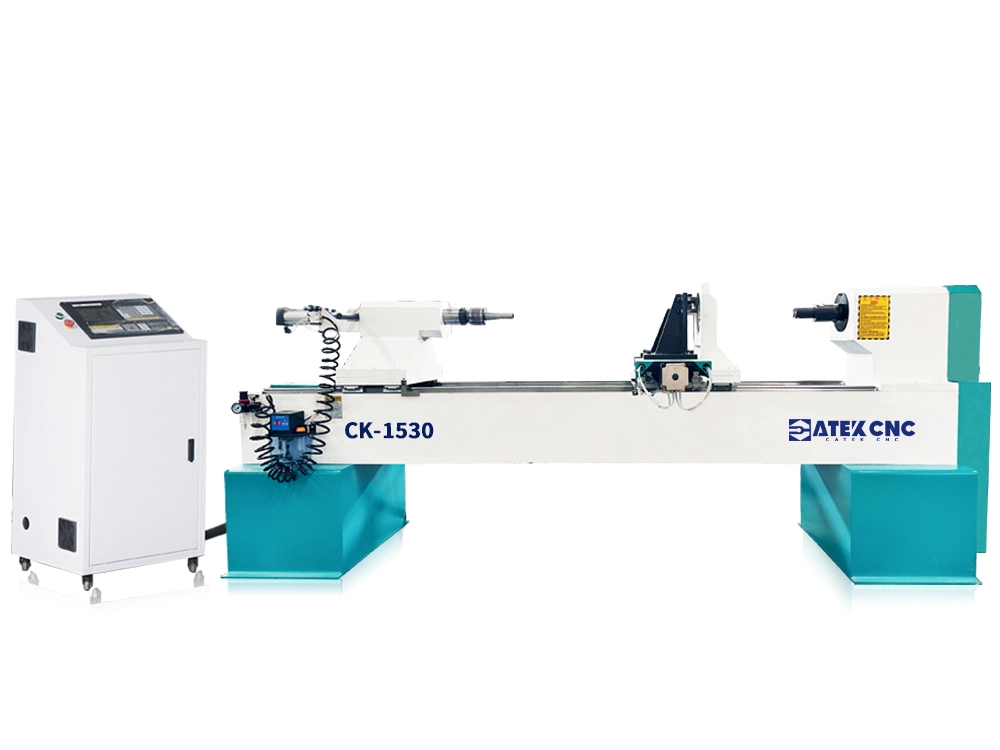

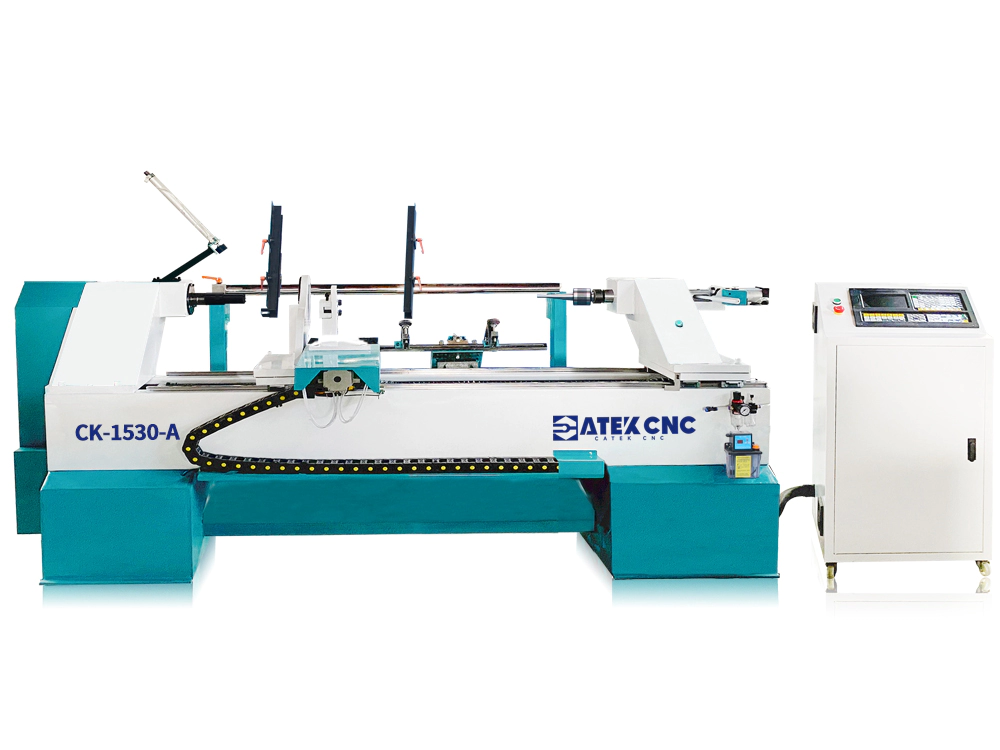

Recommended CNC Wood Lathes for Matryoshka Dolls

Since the production of Russian Matryoshka dolls requires internal hollowing (end-face machining), it is essential to use equipment capable of single-end clamping. Single-end clamping refers to securing the workpiece using a pneumatic chuck or collet.

Most of our lathes support replacing the lathe center with a chuck. Alternatively, you can choose a model that comes standard with a pneumatic chuck, such as the 0615-A small CNC wood lathe.

In addition to the clamping method, you should also consider the diameter of the dolls. Our standard lathe model is the 1530, which can handle workpieces up to 1500×3000 mm (length × diameter), covering almost all Matryoshka Doll sizes. If your dolls are smaller in diameter, the 0615-A CNC wood lathe is the most suitable choice. Not only is it cost-effective, but its unique pneumatic chuck clamping system enables single-end clamping and automatic feeding, making it ideal for batch-processing multiple workpieces from a single long wooden blank.