Basic introduction of Pool Cues

- Common pool cues can be roughly divided into English and American styles. English-style cues feature narrower tips (common 3/4 cue), primarily designed for snooker. American-style cues have wider tips (commonly 1/2), optimized for pool games like 9-ball, 10-ball, and carom billiards.

The raw materials used for English cues are generally maple, and there are also some special materials, such as carbon fiber, carbon, glass fiber, etc.; the raw materials used for American cues are generally ash wood for the front branches (ash wood is lighter and more elastic), and the back branches are made of wood with higher density, such as sandalwood.

Usually, the shaft length of 3/4 cue is 1080 ~ 1180mm, the butt length is 430 ~ 530mm, and a thinner head with a diameter between 9-10.5mm. The total length of 1/2 cue is 1500 ~ 1550mm, and a thicker head with a diameter between 12-13.5mm.

Pool Cue processing

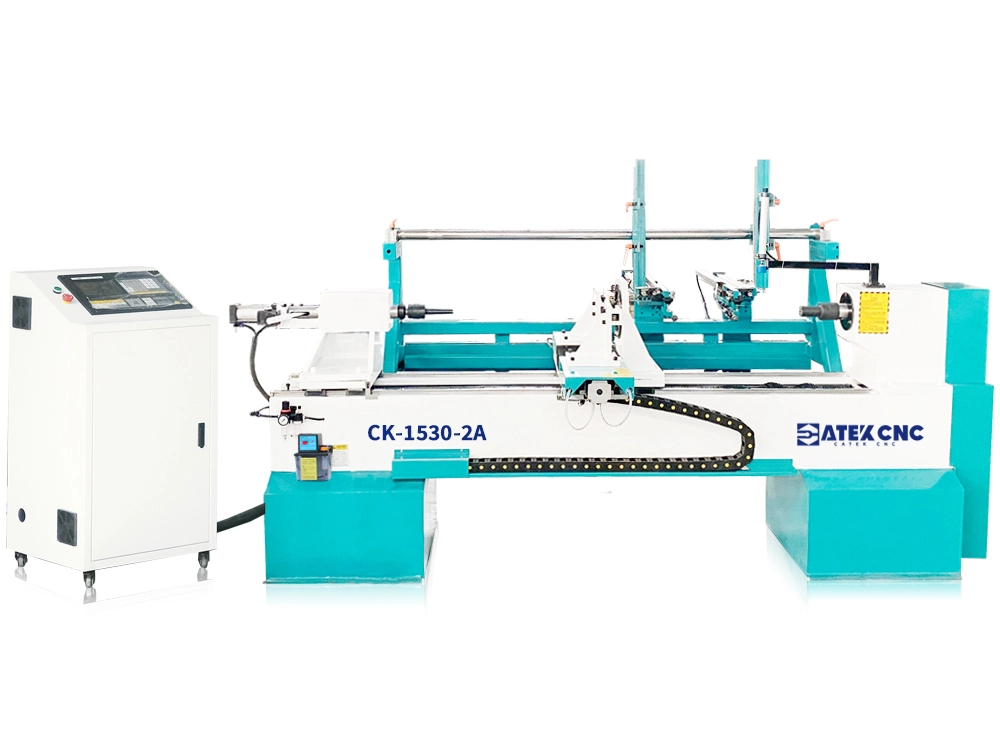

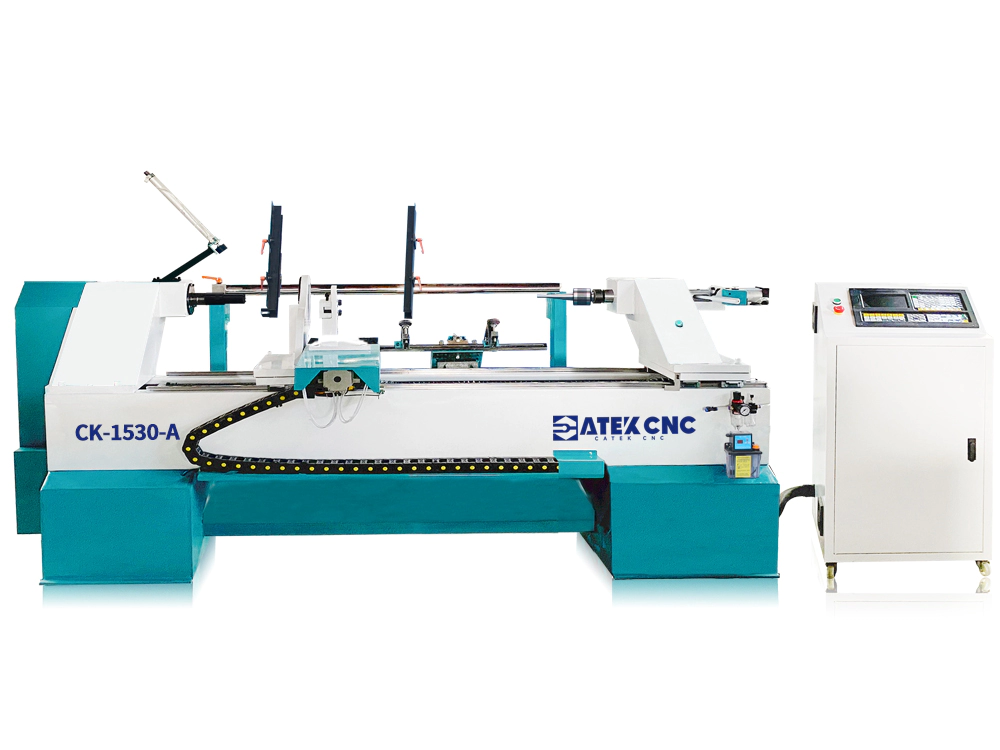

The CNC cue lathe (cue tapering machine) is used to process the taper. First, set the machining dimensions on the machine, then proceed with the machining process.

The semi-finished pool cue undergoes additional steps such as splitting, cutting, and engraving to ensure its aesthetic appeal.

Drill holes and fill with weight-balancing material to achieve optimal weight distribution., copper joints are inlaid, insert screws to fill the hole.

After joining the shaft and butt, the entire cue undergoes sanding and polishing.

The tip is glued and trimmed, the entire cue is final adjusted, and painting/lacquer finishing is applied.

Pool Cue processing notes

The processing technology of different types of cues will be different. Generally, the most processed ones are English cues and American cues.

Use a high-speed air-cooled spindle of 18,000 rpm to clamp a multi-blade milling cutter to quickly process and cut the material surface. During the processing, the wood rotates at a speed of less than 250 rpm. The lower speed prevents the shaking of too fine materials during the processing, making the surface of the processed wood smoother.

During processing, the material can be processed in layers, and the larger material can be processed in layers and cycles to avoid damage to the tool and material caused by excessive processing in a single operation.

During the machining process, feed rate, material rotation speed, and tool rotation speed can be adjusted as needed.

During processing, adjust the appropriate air pressure according to the material's length/diameter to avoid insufficient pressure that fails to secure the material, or excessive pressure that compresses and deforms the wood.

All CNC woodworking lathes can be equipped with fully automatic vacuum cleaners to ensure that the sawdust in the processing process is completely recycled, which is more environmentally friendly and realizes the secondary use of wood.

The dedicated CNC wood lathe for pool cues is exceptionally well-suited for taper machining of billiard cues, with precision controllable within 0.05mm tolerance.

CATEKCNC provides you with comprehensive pool cue processing solutions, including:

- Pool cue tapering

- Pool cue drilling

- Pool cue splitting

- Pool cue engraving

- Pool cue threading

- Pool cue tenon fabrication

- Pool cue polishing

CATEKCNC provides solutions for dozens of well-known pool cue factories, has a lot of practical processing experience and theoretical experience, and we have professional engineers to provide you with service 24 hours a day.