How to Choose the Right Desktop CNC Router Machine for Your Applications?

How to Choose the Right Desktop CNC Router Machine for Your Applications?

- Jan 09, 2026

In production workshops, the demand for flexibility is growing ever higher. Whether you're manufacturing wooden components, cutting acrylic signs, processing plastics, or producing lightweight aluminum parts, desktop CNC router machines deliver efficient production solutions.

Compared to large industrial CNC router, desktop CNC router offers more portable installation, more affordable pricing, and greater adaptability. Desktop CNC router machine is better suited for hobbyists, small workshops, and startups. With numerous options available on the market, selecting the right small CNC router isn't as straightforward—especially for those new to CNC technology.

In this guide, I will help you understand what a desktop CNC router machine is, its uses, and how to choose the best mini CNC router for your specific application.

I. What is a desktop CNC router machine?

Desktop CNC router machines are compact computer-controlled cutting and engraving machines suitable for placement on desks or in small spaces. They convert CAD/CAM digital design files into precise toolpaths, automatically performing high-precision engraving, milling, carving, and drilling on materials. Despite their small footprint, they deliver high precision, stable motion control, and repeatable machining results.

Compared to traditional hand tools, CNC desktop router offers the following advantages:

- Higher precision and consistency

- Automated operation

- Reduced material waste

- Greater design flexibility

Most CNC router desktop employs three-axis (X, Y, Z) motion, making them suitable for tasks such as woodworking, acrylic cutting, and fine engraving.

II. Why Choose a Desktop CNC Engraving Machine?

1. Compact structure, space-saving

One of the greatest advantages of desktop CNC router machines is their compact size and space-saving design. Compared to traditional CNC router machines, these devices do not require large factory floor space. They can be installed and operated on a single workbench or in a small area.

Portable cnc router is ideal for customers with limited workspace, such as home studios or small production workshops. Featuring an integrated design, they require no complex electrical modifications or additional supporting infrastructure, significantly lowering the barrier to entry and initial investment.

2. Cost-effective

For small businesses and hobbyists, mini CNC router machines represent a cost-effective investment. They deliver professional-grade precision and consistency at lower purchase and operating costs.

3. Easy for beginners to operate

The compact CNC router machine was designed as an entry-level CNC engraving solution, featuring intuitive software and a simplified control system that makes it ideal for users with no prior CNC experience.

III. Key Factors to Consider When Selecting a Desktop CNC router Machine

When selecting a suitable desktop CNC router machine, price is only one factor. What truly impacts long-term usability and processing results is whether the machine's configuration aligns closely with your application scenarios, material types, and operational skill level. The following seven key points will help you make a more informed decision.

1. Workbench Dimensions

The workbench size determines the maximum material dimensions you can process and directly impacts production flexibility. Note that the effective cutting area is smaller than the machine's overall dimensions. While desktop CNC routers have a compact footprint, sufficient space must still be allocated for operation, loading, and maintenance.

- Small work areas are suitable for engraving, sign making, models, and crafts.

- Larger workbenches are better suited for processing wood panels, furniture components, and decorative panels.

2. Spindle Power and Speed

The spindle is the core cutting component of any CNC router machine system, directly impacting cutting capability and machining efficiency.

- Low-power spindles are suitable for wood, medium-density fiberboard, acrylic, PVC, and lightweight materials.

- Higher-power spindles deliver superior performance when machining hardwoods, plastics, and aluminum.

Spindle speed is also critical:

- High speeds facilitate intricate engraving and smooth surface finishes.

- For harder materials, stability at lower speeds is paramount.

For beginners or hobbyists, the reliability and stability of a CNC router machine typically outweigh maximum power requirements.

3. Machine Structure

The machine structure determines the rigidity, service life, and cutting precision of a CNC desktop router machine.

Common structural types include:

- Aluminum profile structure: Practical and cost-effective, suitable for beginners and light machining.

- Reinforced aluminum or steel structure: Enhanced rigidity, ideal for high-precision and high-stability machining.

A well-constructed desktop CNC router machine should feature:

- High-strength gantry frame structure

- Robust crossbeam support

- High-quality linear guides

Poor structural rigidity can cause vibration, reduced precision, and inconsistent results.

4. Accuracy and Stability

Precision and stability are key indicators for evaluating an excellent desktop CNC router machine, suitable for repetitive or precision-oriented tasks.

Critical factors affecting precision include:

- Rigid workbench

- Linear guide quality

- Ball screw design

- Fully enclosed dust covers for X and Y axes

A stable desktop CNC router machine ensures smooth engraved edges and surfaces, maintaining consistency in batch production with minimal deviation even during prolonged cyclic processing.

5. The material you plan to cut

Different materials impose varying demands on CNC desktop machines.

- Wood, MDF, plywood: Suitable for most hobby CNC wood routers.

- Acrylic and plastics: Requires stable spindle speed and smooth machining motion.

- Aluminum and soft metals: Demands a robust frame structure, precise motion system, and adequate cooling system.

When selecting a machine, always base your choice on the hardest material you plan to process, not just your most commonly used materials.

6. Control System and Software Compatibility

Usability largely depends on the control system and software support.

A good desktop CNC router machine should feature the following:

- Support for common CAD/CAM software

- Acceptance of standard file formats (G-code, DXF, etc.)

- Provision of an intuitive parameter settings interface

For beginners, mastering the software is as crucial as hardware quality. A comprehensive desktop CNC router system can significantly reduce setup time and minimize operational errors.

7. Ease of Operation and Maintenance

Long-term availability is often overlooked, yet equally important. Choosing machines that are easy to maintain offers better long-term value for business CNC engraving machine users.

CATEK desktop CNC router machines are designed with user convenience in mind. Equipped with intuitive control systems and clear operating logic, these machines enable operators to quickly get up to speed with minimal training. Routine maintenance tasks such as lubrication, tool replacement, and basic calibration are straightforward and require no specialized technical skills.

IV. The Most Suitable Desktop CNC router Machine for Beginners and Advanced Users

Choosing the best desktop CNC router machine means finding a product that matches your skill level, material requirements, and long-term goals. Whether you're a beginner just starting with CNC machining or an experienced professional seeking higher productivity and automation, CATEKCNC offers a range of desktop CNC router machines that combine quality, performance, and value.

Below are four outstanding products from CATEKCNC, each suited for specific applications and user levels.

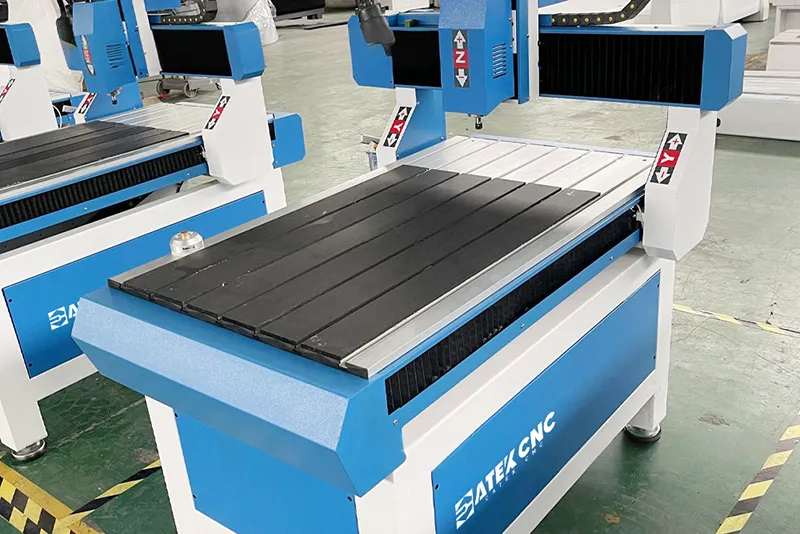

1. Mini 6090 CNC Router - The Best Choice for Beginners and Hobbyists

The CATEK Mini 6090 CNC router Machine is highly favored by beginners, DIY enthusiasts, makers, and small woodworking shops. Its 600×900mm working area balances ample workspace with compact dimensions, making it an ideal entry-level machine for limited spaces.

It is perfectly suited for beginners and hobbyists:

- User-friendly controls and simple operation are perfect for CNC machining novices.

- Equipped with a 2.2KW high-speed water-cooled spindle, it delivers smooth cutting on wood, acrylic, and lightweight materials during 24-hour continuous operation.

- Compatible with popular CAD/CAM software like ArtCAM, Type3, and JDpaint, enabling beginners to transition quickly from design to fabrication.

- Compact size and low noise make it perfect for studios and small workshops without compromising engraving precision.

Overall, the Mini 6090 CNC router stands as one of the best desktop CNC routers for beginners, offering reliable performance without unnecessary complexity.

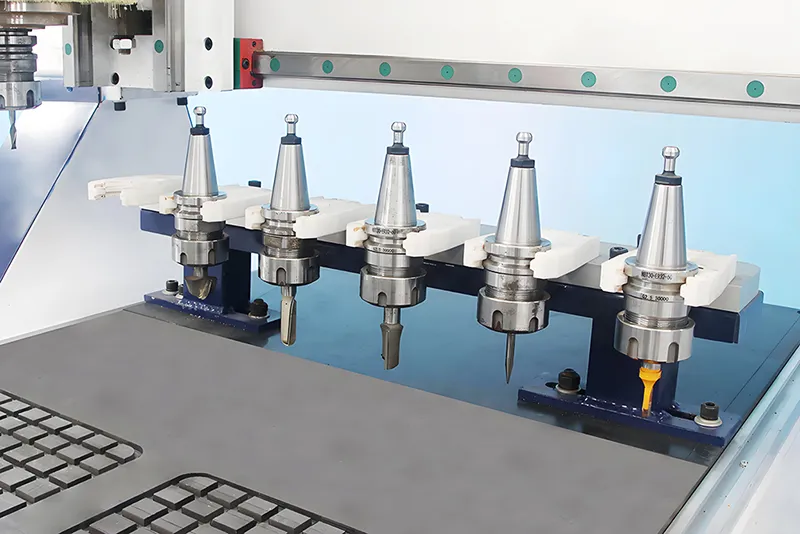

2. CATEK Mini 6090 Linear Automatic Tool Changer CNC Router Machine - Efficient Project Upgrade

For small business owners seeking to enhance speed and flexibility, the CATEKCNC Mini 6090 Linear Automatic Tool Changer CNC router Machine incorporates an Automatic Tool Changer (ATC) and vacuum-assisted work table. This model upgrades standard desktop CNC machines into more automated, efficient systems.

- The automatic tool change system with a 6-tool linear magazine reduces manual intervention and boosts efficiency.

- Vacuum clamping and T-slot work surface enable flexible, secure workpiece holding.

- Increased spindle power (5.5 kW water-cooled ATC spindle) delivers precise engraving, cutting, drilling, and routing across diverse materials.

This configuration is ideal if you're transitioning from hobby-level CNC woodworking router to small-scale production while minimizing setup time.

3. Mini 2-in-1 CNC Router Machine—Dual Spindle Flexibility

The CATEKCNC Mini 2-in-1 CNC router machine elevates versatility to new heights by offering two interchangeable spindles, effectively supporting diverse applications without requiring machine replacement.

- The dual spindle configuration enables rapid switching between different machining tasks without physical hardware changes.

- Equipped with a 3.5 kW high-speed air-cooled spindle, it delivers greater cutting force for harder materials compared to typical hobby CNC routers.

- Features a reinforced square steel welded bed and heavy-duty gantry frame for exceptional stability.

The Mini 2-in-1 CNC router machine is the ideal choice for users seeking enhanced functionality and flexibility without investing in large industrial CNC machinery.

4. Mini CNC Router Machine with Full Cooling System—Expanded Workspace and Water-Cooling Capability

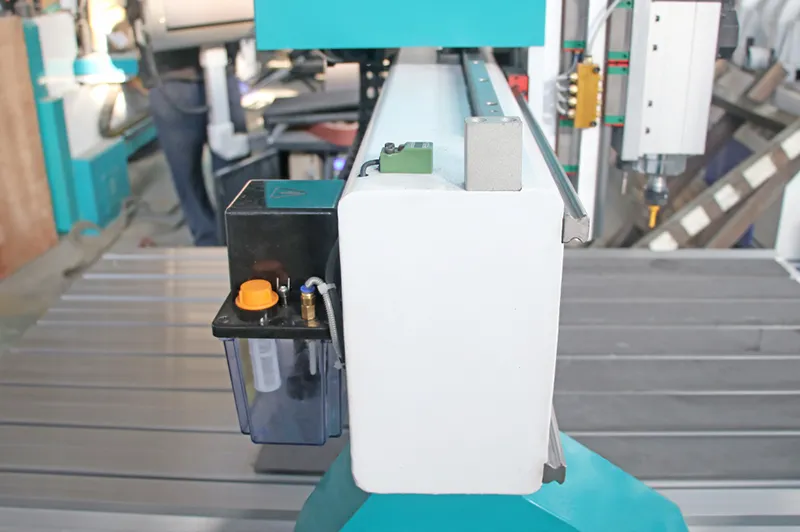

For projects involving larger panels or requiring continuous cooling during extended machining, the CATEK Mini CNC Router with full cooling system delivers expanded workspace and enhanced cooling support. Featuring a 900×1500mm working area and a 3.2kW water-cooled spindle, this model perfectly meets the needs of hobbyists and semi-professional production users.

The water-cooled sink workbench not only cools the cutting tool but also helps clear debris from the cutting area during wet machining. This machine can process hard materials such as stone and soft metals, making it suitable for creating large signage, cabinet components, and oversized decorative items.

V. Comparison of Desktop CNC Router Machines with Other CNC Routers

CNC router machines used by hobbyists emphasize flexibility, affordability, and personal applications, while industrial CNC machines prioritize speed, automation, and heavy-duty workloads.

| Feature | Desktop / Hobby CNC Router | Industrial CNC Router |

|---|---|---|

| Size | Compact | Large |

| Cost | Affordable | High investment |

| Skill Level | Beginner to intermediate | Professional |

| Power | Moderate | High |

| Applications | DIY, crafts, small business | Mass production |

VI. Common Mistakes When Purchasing Desktop CNC Router Machines

Many buyers make costly mistakes when purchasing desktop CNC router machines, often due to insufficient understanding of the machine's design, construction, and after-sales support. As a CNC router machine manufacturer with 20 years of production experience, CATEKCNC frequently encounters customers who previously purchased low-cost desktop CNC router machines with weak structures, unstable spindles, and inconsistent precision. This results in poor cutting quality and short machine lifespans.

Another common issue is selecting a desktop CNC machine that doesn't match actual application needs. Insufficient spindle power, limited working areas, or lack of automation options quickly constrain productivity as project complexity increases. Furthermore, machines sourced through intermediaries often lack proper technical support, spare parts availability, and application guidance, leading to downtime and hidden costs.

Selecting desktop CNC engravers directly from reliable manufacturers like CATEKCNC ensures consistent quality control, application-specific configurations, and long-term technical support. This approach helps users avoid costly mistakes and achieve superior results from the outset.

VII. Conclusion

Desktop CNC router machines offer powerful and versatile capabilities, making them ideal for woodworking, sign making, and DIY projects. Whether you're seeking a hobby CNC router, a CNC router for beginners, or the best desktop CNC router for small-scale production, understanding machine specifications and application requirements is crucial.

By carefully evaluating your needs and selecting the appropriate desktop CNC router machine model, you can achieve professional results while controlling costs and space requirements.

RELATED MODELS

We recommend some related models for you...