The Best One-Stop Platform for CNC Machines in 2026

Welcome to the CNC machinery world of CATEKCNC. As a large-scale professional CNC machinery OEM/ODM factory integrating R&D, production, sales, and after-sales service, CATEKCNC's product range includes: CNC wood lathes, CNC nesting machines, CNC wood routers, CNC stone carving machines, fiber laser cutting machines, laser marking machines, metal milling machines, CO2 laser engraving and cutting machines, plasma cutting machines, oscillating knife cutting machines, and more. Whether you are a beginner or a professional, engaged in the woodworking industry, furniture industry, advertising industry, stone processing industry, or metal cutting, mold manufacturing, and other industries, we can help you find the most suitable CNC solution for you and your budget. At CATEKCNC, we not only provide you with the most cost-effective, high-quality CNC machines, but we also offer free expert services and the best, most professional advice to help you find the most suitable CNC machining machinery for your needs.

Are you ready to start your CNC machine purchasing journey in 2026? Whether you are a CNC equipment manufacturer, distributor, school or training institution engaged in CNC education, foreign trade agent, or a wood, stone, or metal processing enterprise, you can directly contact our experts. We will assist you in selecting the most suitable CNC machinery. Of course, if you wish to learn more about our products, you can continue reading the latest buyer's guide below to choose the most suitable equipment, advance project development, and realize your creative and business plans.

-

CNC Router

CNC routers is a kind of equipment that uses CNC system control and various tools to perform cutting, drilling, boring, slotting, milling, engraving and other processing on workpieces. CNC routers machine usually adopts gantry or vertical structure. After the material to be processed is fixed to the workbench by means of fixture, chuck or vacuum table, the multifunctional spindle hanging above drives the processing tool to rotate at high speed to process the material. It is essentially a cutting or milling machine. Our CNC router series has a wide variety of products, which can process different materials such as bamboo, wood, plastic, acrylic, paper, cloth, leather, rubber, metal, stone, etc., fully covering all kinds of cutting and engraving needs in the industry, providing customers with one-stop solutions.

-

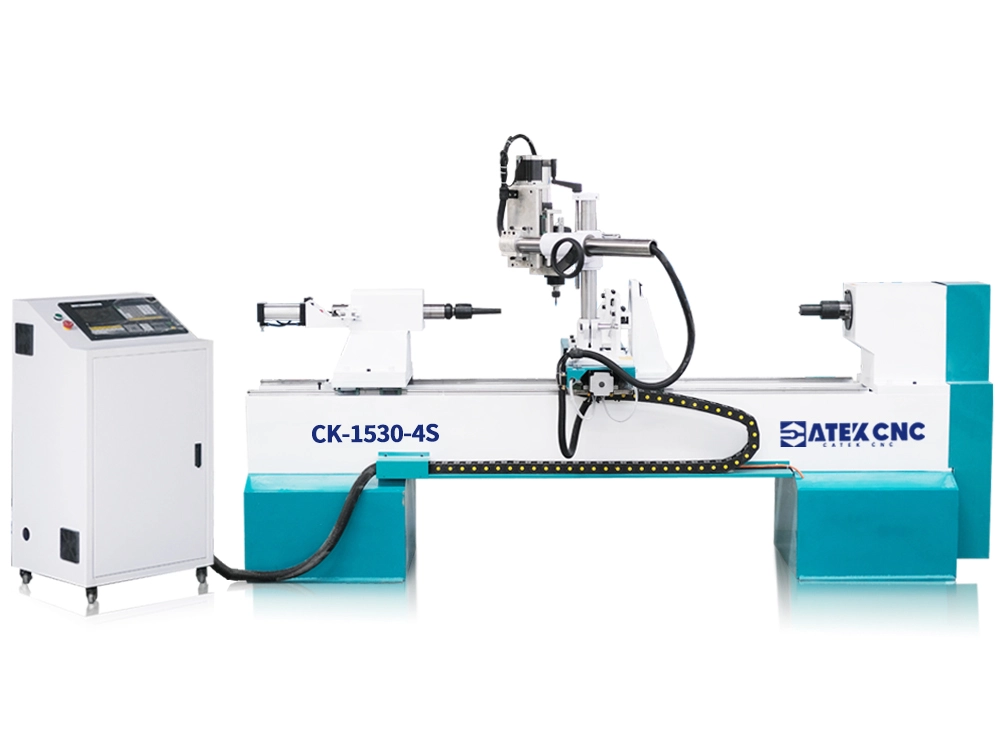

CNC Wood Lathe

CNC wood lathes is a versatile CNC turning equipment widely used for various processes such as internal and external diameter turning, drilling, sanding, engraving, milling, and grooving of non-metallic materials like natural wood, synthetic wood, and thermoplastic plastics. It is particularly suitable for the precision machining of rotating bodies such as columns, cones, and spheres, as well as complex shapes. Common processed products include baseball bats, pool cues, stair columns, vases, table and chair legs, European-style furniture, hangers, wooden bowls, barrels, and various wooden crafts.

-

CNC Metal Machine

CNC metal processing machines is an automated equipment that uses computer numerical control to process metal materials such as iron, stainless steel, tinplate, aluminum, copper, and alloys. It is mainly used to manufacture various metal parts and is widely applied in industrial manufacturing fields such as metal molds, automobiles, instruments, and energy equipment.

-

-

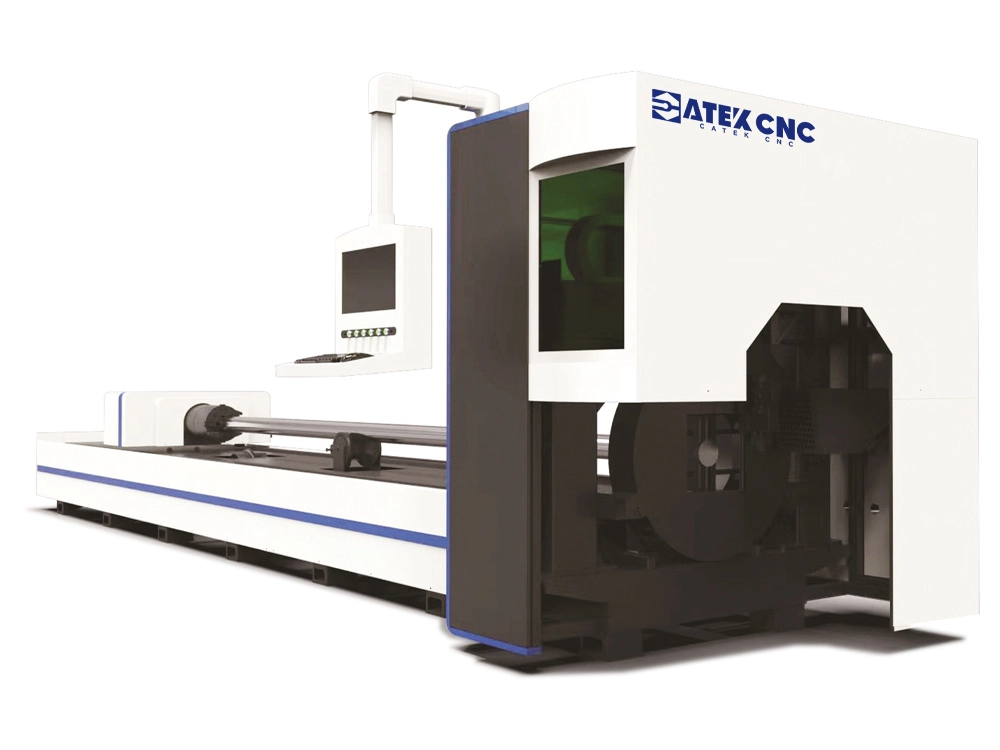

Laser Cutting Machine

Laser cutting machines is a device that uses laser to automatically cut materials, belonging to non-contact thermal processing. According to material properties, it can be categorized into fiber laser cutting machines for processing metals and CO2 laser cutting machines for processing non-metals. With extremely high processing precision, narrow kerf width, and minimal surface roughness, its market share continues to grow annually across various product cutting applications.

-

Laser Marking Machine

The function of a laser marking machines is to use a laser to mark the surface of products. Unlike using laser cutting, it only causes the surface material to evaporate or alters the material properties of the surface to achieve marking. High-power laser marking machines can also perform material cutting and engraving. This machine is suitable for marking processing such as text, patterns, barcodes, etc., on various products, covering industries including packaging, crafts, medical, electronics, clothing, hardware, and others.

-

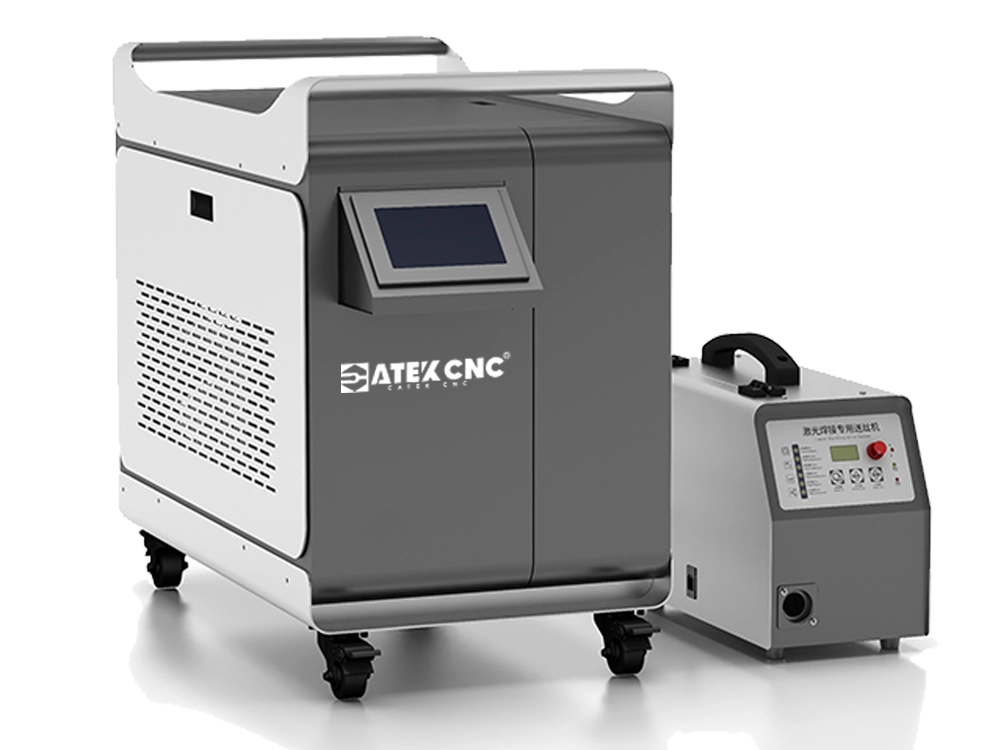

Laser Welding Machine

The laser welding machine is a device that uses lasers to weld metal materials. It belongs to a type of fusion welding, where the laser beam melts the base material or filler metal, and the molten material solidifies to join and fix the two workpieces. This equipment can be used for various welding processes such as butt joint welding, tee joint welding, corner joint welding, lap joint welding, edge joint welding of metals. It features fast welding speed, high precision, a small HAZ, and excellent welding quality, making it widely applicable in manufacturing fields such as electronics and electrical appliances, automotive manufacturing, metal component processing, and battery welding.

-

-

Hot

-

-

-

-

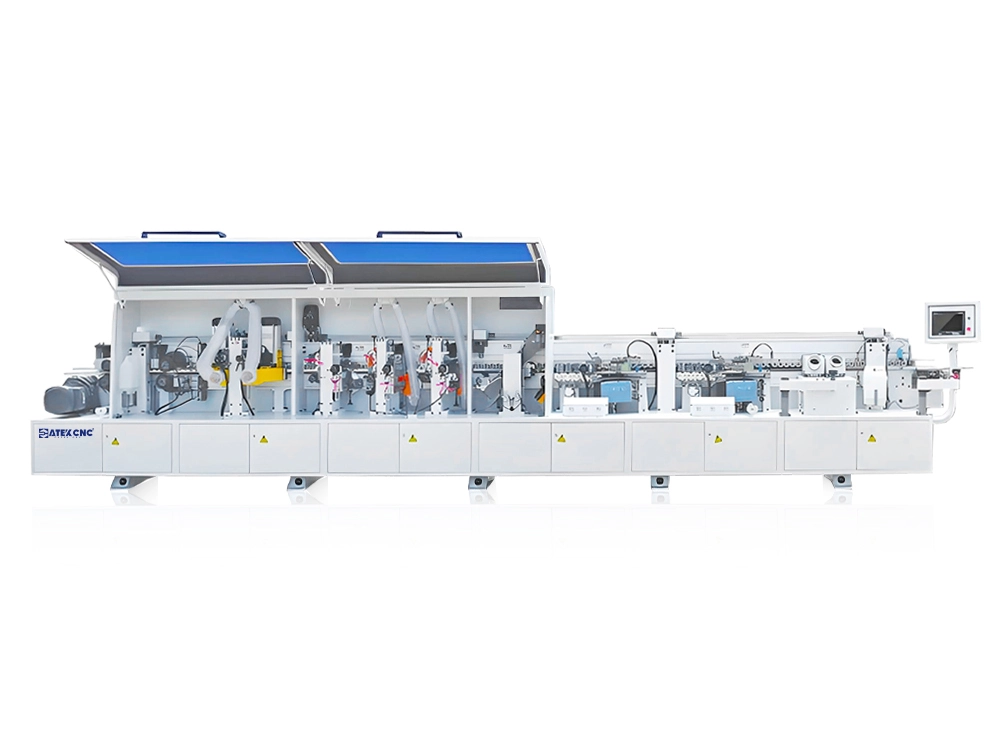

Edge Banding Machine

The fully automatic edge banding machine is the core machine in modern furniture manufacturing. Its core function is to automatically complete the edge banding of the board. They apply hot-melt adhesive to the edges of the panels, firmly affixing them to the edges. They are widely used on wardrobes, cabinets, MDF furniture, OSB furniture, and other panel furniture.

-

-

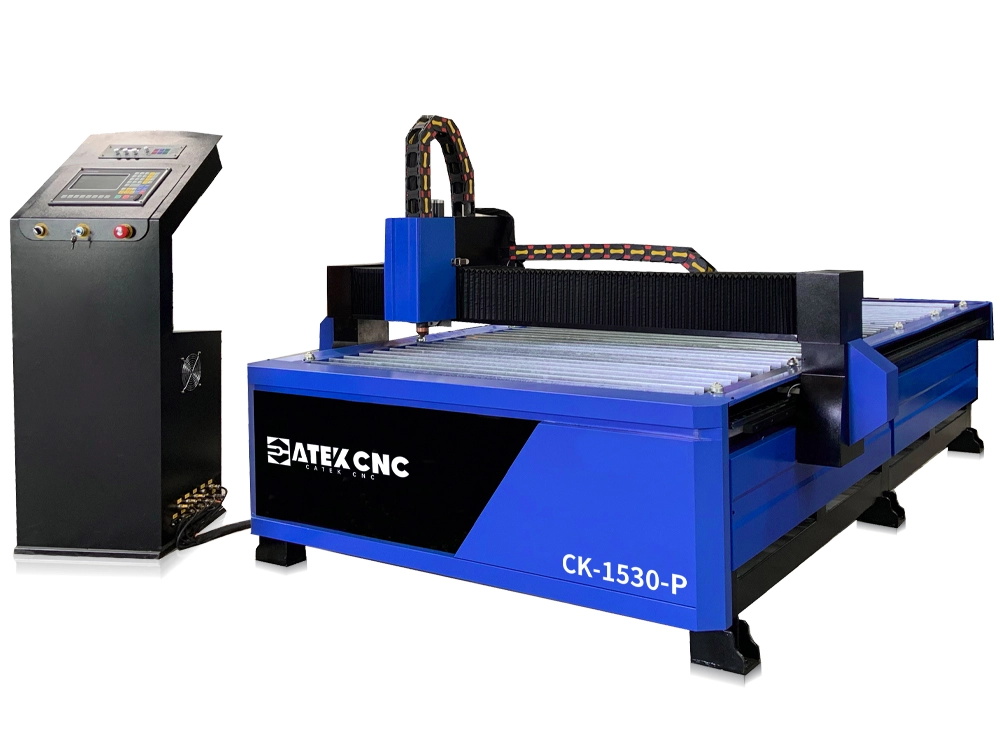

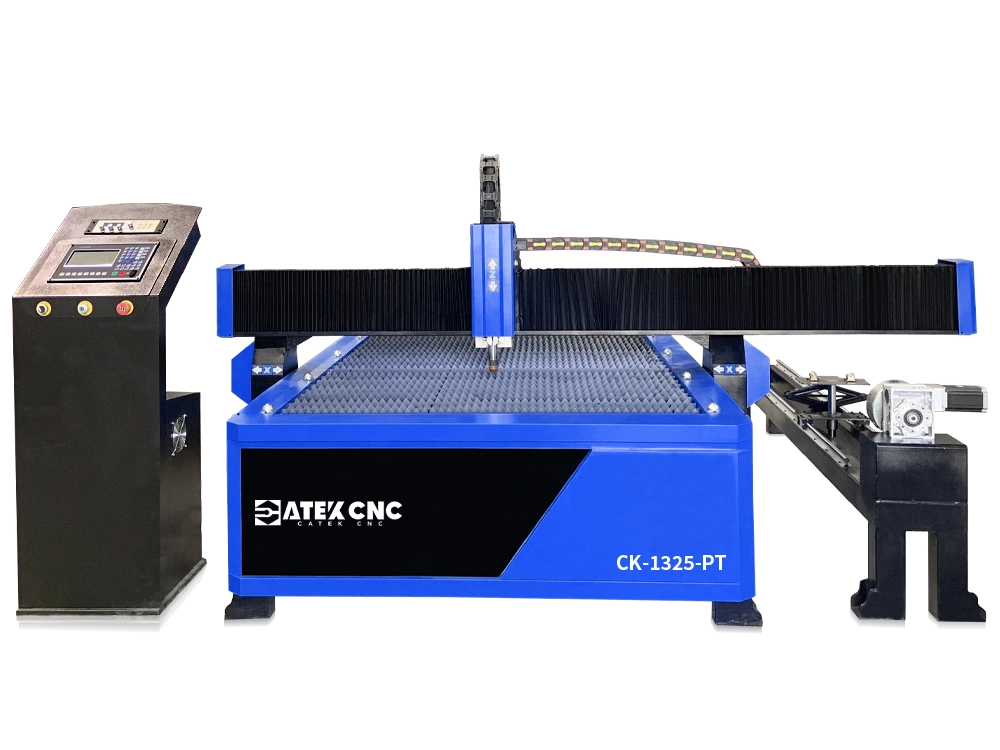

CNC Plasma Cutting Machine

CNC plasma cutting machine uses CNC technology and plasma technology to realize fully automatic cutting of metal materials. It can cut ferrous metals (iron, manganese, chromium) and various non-ferrous metals (copper, aluminum, zinc, nickel, titanium, gold, silver, platinum, etc.). When the cutting capacity is the same, the price is much cheaper than that of fiber laser cutting machine, and it can easily cut thick metal plates with non-metallic coatings and highly reflective metal plates that are difficult to cut by the latter.

-

Oscillating Knife Cutting Machine

CNC oscillating knife cutting machines mainly expand the field of flexible material machining that CNC routers have not covered. CNC oscillating knife cutting machines are equipped with various digital tools, and the typical tool is an electric oscillating knife. This type of knife will oscillate up and down at a high frequency when cutting the material, cutting the flexible material in a similar way to sawing, without heat effect, extremely fast cutting speed, and smooth cutting surface. This type of machine is widely used in cutting various flexible materials such as paper, cloth, sound-absorbing cotton, silicone, leather, KT board, stickers, etc.

-

$7,058.00~$11,800.00Hot

-

THE FOLLOWING ARTICLES MAY HELP YOU

-

CNC Router

How to Select the Milling Tools for CNC Wood Router?

A milling tool is a cutting tool with a cylindrical shape, featuring cutting edges on its circumference and bottom, which performs rotational motion to cut and machine workpieces.The milling tool family is very extensive. Together with hole-making tools (drills, reamers, taps, boring tools, etc.), they cover almost all commonly used processing tools on CNC wood router machines.Types of Milling ToolsMilling tools can be classified into various categories based on different criteria. Below are sev...

-

Other

What Is a Servo Motor?

To understand what a servo motor is, you first need to know several relevant professional terms.Open-Loop ControlA control system in which the output quantity has no impact on the system's control is called an "open-loop control system".Open-loop control is a control method that acts on the controlled object unidirectionally only through preset instructions. Its core feature is the absence of a feedback loop in the system structure. After the controller generates an operation instruction based o...

-

Other

What Is the Transmission System of CNC Machine?

In CNC machines, the transmission system refers to the collective term for a series of mechanical components and devices that convert the power from the transmission system into precise and stable linear or rotary motion required by the machine's execution parts. Its primary function is to transmit power and transform the nature, direction, and speed of the motion. Specifically, in CNC router machines and CNC lathes, the transmission system mainly converts the rotational motion of various motors...

HERE ARE SOME RELATED VIDEOS OF CNC MACHINES

-

03:03

CNC RouterJul 11, 2025

CNC RouterJul 11, 20257x10ft Linear ATC CNC Wood Router

This is a large-format CNC wood router equipped with a 7'x10' vacuum worktable, featuring an HSD spindle and bus-type controller.

-

03:29

CNC Wood LatheJul 15, 2025

CNC Wood LatheJul 15, 2025Chair Leg Machining Master – The 7-in-1 CNC Wood Lathe

This video introduces the features and advantages of the 7-in-1 CNC wood lathe and demonstrates its various machining capabilities.

-

03:09

Laser Cutting MachineJul 17, 2025

Laser Cutting MachineJul 17, 2025Affordable & Compact 1390 CO2 Laser Cutter

This video will provide a detailed introduction to the advantages and workflow of the 1390 CO2 laser cutting machine.

HERE ARE SOME FUN PROJECTS FOR CNC MACHINES

-

CNC Wood Lathe

CNC Wood LatheMaking Nesting Dolls (Matryoshka) Using a CNC Wood Lathe

Matryoshka dolls also known as stacking dolls, nesting dolls, Russian tea dolls, or Russian dolls is one of the most representative traditional handicrafts in Russia. It is made of multiple wooden dolls of different sizes nested in layers, and each doll is painted with exquisite patterns.In Russian, the Matryoshka Dolls are called: матрёшка. Originally, they were based on a round-faced country girl. Gradually, the materials for nesting dolls have become more and more abundant. In additio...

-

CNC Wood Lathe

CNC Wood LatheHow to Make Chair Legs Using a CNC Wood Lathe?

Using CNC wood lathes to make tables, chair legs or accessories is a very common application of CNC wood lathes. Some simple chair legs generally only need to be turned or slotted, while more complex special-shaped furniture legs require turning, milling, slotting, drilling and other functions to complete.

-

Laser Marking Machine

Laser Marking MachineUsing a Laser Marking Machine to Mark Lighters

In the field of high-end lighter customization, laser marking has become a mainstream choice. This article will guide you through the process of using a fiber laser marking machine for personalized marking on lighters.

POWERING YOUR PRODUCTION FORWARD WITH SUPERIOR CNC MACHINE

What Is "CNC Machine"?

"CNC" is the abbreviation of "Computer Numerical Control". As the name implies, "CNC machine tool" is a machine that uses computers to realize digital program control of machine tools. Usually, CAD/CAM software designs the machining drawings and generates the G-codes that control the machine operations.. The storage, processing, calculations, logical judgment and other control functions of these input instructions are completed by computer software, and then microinstructions generated by the processing are transmitted to the drive motor or hydraulic actuator to drive the equipment to operate.

The core of CNC machinery is the ability to achieve high-precision and high-efficiency processing through digital program control. It is widely used in cutting, turning, engraving, molding, welding, marking and other materials such as metal, stone, wood, plastic, etc. According to the differences in processing methods, materials and application scenarios, CNC machinery has many types, which can be mainly divided into physical contact processing using various processing tools and non-contact processing relying on laser or plasma melting and vaporizing the surface of the material. When selecting a machine, it is necessary to comprehensively consider material properties, processing requirements and budget and other factors.

Our Product Types

There are many types of CNC machines, and there are countless machines of various sizes and functional combinations. In our long-term operation, we have integrated various models with beautiful appearance, high integration, and reasonable functional combinations according to user needs. We can also customize various non-standard products according to your needs. As an OEM factory, we can customize the appearance, processing size, customized electrical parts, and functions.

Classification by Working Principle

| Contact Processing | Contactless Processing | ||

|---|---|---|---|

| Tool | turning tools, milling cutters, broaches,saw blades, threading tools, gear tools, hole processing tools,high frequency oscillating tools, etc. | Tool | Laser (based on the laser source, it can also be subdivided into fiber laser, CO2 laser, UV laser, etc.),high temperature plasma. |

| Rack Type | The wood lathe is a horizontal lathe, the router and vibratory knife cutter are gantry type, and the metal milling machine is vertical.Since the processing tools need to contact the material, the structure of this type of machine is generally gray cast iron casting or thick-walled square steel welding to ensure the overall rigidity of the machine. | Laser Optical System | Laser generator (including pump source, gain medium, nonlinear optical crystal medium, discharge tube, resonant cavity, etc.), beam modulation system (electro-optic modulator, galvanometer, etc.), beam transmission system (optical fiber, various reflectors, focusing lens, etc.), auxiliary optical system (beam expander, filter, anti-reflection light isolator, etc.). |

| Processing Method |

|

Processing Method |

|

Classification by Processing Materials

| Material Caterial | Typical Equipment |

|---|---|

| Metal | CNC lathes, CNC milling machines, CNC mold (carving) machines, fiber laser cutting machines, plasma cutting machines, fiber laser marking machines, laser welding machines, laser cleaning machines |

| Wood, bamboo, synthetic board and plastic | CNC wood lathe, CNC opening machine, CNC wood router, CNC cutting board saw, CO2 laser engraving machine, CO2 laser marking machine |

| Stone | CNC stone router, stone bridge cutting machine |

| Glass, Crystal and Ceramics | CNC glass engraving machine, laser engraving machine, UV laser marking machine |

| Sponge, cloth, leather, cardboard, foam | Foam mold engraving machine, CNC cutting machine, oscillating knife cutting machine |

Why Buy CNC Machinery?

- Improve Processing Accuracy and Product Consistency

-

CNC machinery uses advanced computer control systems, which can accurately control various processing tools to accurately process products. The fully automatic operation of the machine controlled by code ensures the high consistency of each product during mass production, greatly reduces human errors, and improves product quality. This is crucial for manufacturing high-precision parts and improving the overall quality of products.

- Improve Production Efficiency and Reduce Production Costs

-

CNC machine tools have functions such as automatic tool change, automatic loading and unloading, and can also process multiple workpieces at the same time, greatly improving production efficiency. It is also possible to improve utilization and reduce the waste of raw materials by optimizing the typesetting programming path. Moreover, CNC machining can realize 24-hour uninterrupted production, greatly reducing the production cycle, which not only reduces the length of time and cost spent on manual operation but also enhances the competitiveness of enterprises in the market, for the pursuit of high efficiency, mass production of enterprises, the advantages of CNC machinery is particularly obvious.

- Meet Diversified Processing Needs and Expand Business Scope

-

CNC machine tools can not only perform conventional milling, drilling, cutting, turning and other operations, but also complex curve processing, engraving and thread processing. This versatility allows CNC machine tools to adapt to the processing needs of different industries and products and can handle complex geometric shapes (such as curved surfaces and special-shaped parts) that are difficult for traditional machinery to complete, meeting the needs of modern product design. Enterprises can also flexibly adjust design drawings and programming paths according to process requirements to meet customer customization needs.

- Reduce Labor Costs and Improve Production Safety

-

CNC machinery realizes automatic operation through computer control systems, reducing human intervention and operation. This reduces the skill requirements for operators and reduces dependence on skilled workers to cope with the problem of rising labor costs. Moreover, the high degree of automation of CNC machinery has enhanced the safety and controllability of the production process, reduces the risk of safety accidents caused by human operating errors, and can also avoid quality problems caused by worker fatigue or negligence.

- Perfect After-Sales Service and Technical Support

-

When purchasing a brand new CNC machine, you can usually get perfect after-sales service and technical support. The professional after-sales service team can provide users with the most professional and convenient services, solve various problems encountered by users in the production process, and reduce the entry threshold.

Purchasing Cost of CNC Machinery

If you are planning to select and buy a CNC machine in 2026, the price must be a factor that you focus on. If you choose a used machine, the price will be relatively cheap, but it's after-sales service quality is difficult to compare with that of a new machine, and the failure rate is also high. Especially for users who use this type of machine for the first time, choosing a high quality supplier to purchase a new machine can not only obtain complete machine teaching materials, but also enjoy good after-sales maintenance services, which is more helpful for learning and operating the machine.

Some equipment with relatively simple functions and low precision requirements may cost between 1000USD and 2570USD. This type of equipment is suitable for amateur beginners or small processing companies. Although the functions and performance are relatively basic, they can meet basic processing needs.

CNC machinery with relatively complex functions ranges from 3285USD to 11500USD. This type of equipment has certain processing capabilities and precision and can produce products in batches for a long time. It is suitable for small and medium-sized processing companies and can meet relatively complex and efficient processing needs.

High-end CNC machinery is more expensive, and the budget may require tens of thousands or even hundreds of thousands of dollars. This type of equipment usually has advanced functions and high performance, suitable for large factories and enterprises, and can meet complex and precise processing needs. For example, some five-axis CNC machine tools, high-power fiber cutting machines, etc., often cost hundreds of thousands or even millions of dollars.

The actual price may vary depending on factors such as model, configuration, country and region. When purchasing CNC machinery, it is recommended that you choose according to your actual needs and budget, and contact our professional sales staff for a more accurate quote.

Why Choose Us?

-

We have a real factory that has been engaged in domestic trade and OEM for a long time. You must have browsed many websites before, no matter how exaggerated these websites are, you should know that the cost of publicity is very low and you should always trust your own judgment. So now ask yourself, do these platforms really have their own factories? We believe that you must want to buy from the source factory rather than the agent, because the former is very reliable in terms of price, technical support and after-sales.

We can provide you with the relevant factory qualification certificate. If it is convenient for you, you can also come to the factory to have a look. We will have someone to pick you up at the airport and accompany you to visit the factory. If you like, you can also play in various attractions in Jinan. Jinan is an ancient city, known as the "City of Springs". I believe you will not be disappointed:).

-

We support multiple payment methods and issue professional invoices to maximize the security of your funds and after-sales service.

-

We have perfect after-sales support. The warranty period of CNC machines can reach three years, and all machines purchased from us can enjoy lifetime free upgrades and technical support.

How to Buy Our Machines?

-

Due to the particularity of CNC machines, please be sure to clarify your processing needs first, including the size and material of the product you need to process, and the processing technology (such as cutting, turning or engraving).

-

Although our mall supports direct orders, the best practice is to contact our sales first (click on the website "Get a Quote", make a phone call, send an email, chat on WhatsApp). First, tell the salesperson your processing needs and budget. Our salesperson will give you professional purchase suggestions after comprehensive evaluation, including the recommended machine model, machine configuration customization, transportation plan, comprehensive quotation sheet, etc. These require long-term professional accumulation to ensure that you can buy CNC machines that meet your requirements and are reliable and inexpensive, and save you the maximum amount of unnecessary expenses in the transportation and import process. This is why it is not recommended that you place an order directly.

-

During the communication with pre-sales staff, if you are worried about whether the machine can perfectly process your product, we recommend that you send the sample photos to our salesperson, and we will test process the sample for you (the number of trial samples should not be too large for cost considerations), and then we will send you the processed samples and processing videos, so as to eliminate your concerns.

-

Then you can decide whether to make the purchase. Before this step, all the communication and sample trial processing with our pre-sales staff are completely free. If you decide to buy, please contact our pre-sales staff first, and they will arrange contract-related matters for you. It should be noted that to avoid factory losses caused by malicious order requests, we will charge you a deposit of 50% of the machine price (this is a common practice in the industry, please understand our difficulties). Regarding the collection and refund of this deposit, please click "Return and Refund Policy".

-

After the purchase contract is signed, we will transfer the order to the factory, and the factory will schedule the production of the machine for you. This process is affected by many factors such as statutory holidays, factory order density, machine complexity (we can customize various non-standard machines according to your needs), and may deviate from the production time previously estimated by the pre-sales staff, but we promise to try our best to produce quickly while ensuring the quality of the machine.

-

After the machine is produced, your salesperson will contact you, and then we will arrange packaging and shipping. During this process, we will reduce your participation as much as possible to reduce the troubles caused by the complicated shipping process. From packaging, contacting freight, customs declaration to shipping, you don’t need to worry about the whole process. After shipping, we will give you a bill of lading, and you can use this document to get your goods or track the shipping process.

After the machine arrives at the port, you can pick up the goods yourself with the bill of lading. If you don’t know how to operate it, you can still contact our sales, and they will contact your local freight to directly deliver the machine to your door. For details, please see our "Shipping Policy".

-

After getting the machine, you need to install and debug the machine. Our machines generally come with relevant technical information and tutorials. If you can’t operate it, please contact your sales. They will arrange technicians to provide you with remote guidance. If necessary, they can also arrange on-site training. Our long-term operation has allowed us to contact customers of all levels and summarize a complete set of training methods for different customers. You don’t have to worry about not being able to use the machine.

-

If you have any questions with the machine during use, we can provide lifelong technical support, from video remote (free) to on-site assistance (you need to pay for it), so you don't have to worry about having no one to service your machine after you've purchased it. We also have a warranty policy that is at the forefront of the industry. You don't need to pay any fees for any quality problems of the machine during the warranty period.

CUSTOMER REVIEWS

-

Cada vez que he tenido una pregunta, han respondido rápido, son claros y me han ayudado a resolverlo en el momento. ¡Eso para mí vale mucho!

CardenasDec 07, 2025 -

I was surprised that this CNC small wood lathe could perform so well! It completely exceeded my expectations. This wood lathe is optimized for small crafts processing. The clamping device is very stable to ensure that the material will not shift during processing. Before purchasing, the salesperson Cici determined the appropriate chuck for me according to my processing size, and provided me with the machine drawings for free, and also gave me some extra turning tools. I highly recommend this machine.

DavidFeb 15, 2025 -

This CNC wood lathe is a perfect fit for my products! It’s super fast for batch processing, and I’ve been using it for three months now, zero issues so far.

RijalJan 01, 2026 -

A very efficient small CNC wood lathe, which is very efficient in processing wooden handles, helped me solve the problem of the order. This machine is very easy to operate. I followed the engineer's teaching video and learned how to use it in just 3 hours. It is much simpler than I thought. I will keep in touch with CATEKCNC.

FloresMar 03, 2025 -

Máquina og̃uahẽma, aipeguã hína. Pe fábrica omba’apo porãite, opa mba’e oho porãite.

MeaurioMay 07, 2025 -

This fiber laser marking machine works perfectly for engraving on pens. But I recently learned that they offer a specialized rotary attachment designed specifically for holding pens. I'm currently in touch with them to purchase this accessory to improve our efficiency.

DabornJul 05, 2025 -

Delivery: CATEKCNC team delivered the machine within the agreed time and provided us with a confirmation video and photos of the machine. Quality: The machine is of very good quality and the salesperson told me that they would provide a three-year free warranty. The machine is very powerful and I use it to make molds and it has been running well so far. Service: The salesperson Angie was very helpful and provided me with quotes for various configurations of the machine and offered me discounts and extra tools.

SanchezcastroFeb 14, 2025 -

My end-client is extremely happy with the UV laser marker. I truly appreciate our collaboration, which made this successful transaction possible. With the competitive pricing, I was able to secure a very handsome profit margin.

MirzauevnaSep 27, 2025 -

I'm Rakesh from Ahmedabad running a pipe fabrication unit. After much research, purchased this 3000W fiber laser tube cutting machine from China 2 months back. Must say - it's working like a champion!

RakeshMay 01, 2025 -

I ordered this custom 4-station CNC cue tapering machine, and it’s brilliant! Just clamp the wood blank in place, and the machine does the rest. The finished cues come out with perfect roundness. I’m so chuffed with the results, I’m even thinking of buying their drilling and splicing machines next.

MurphyApr 22, 2025